Ultra-high-performance concrete reinforced concrete column with fiber reinforced polymers wound around steel pipe

A technology of concrete reinforcement and reinforced concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems that the confinement effect of steel sleeves is not as good as that of steel pipe confinement ultra-high performance concrete, the concrete strength is not high, and the structural integrity is not strong, etc., to achieve Improved corrosion resistance, high strength, and enhanced seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

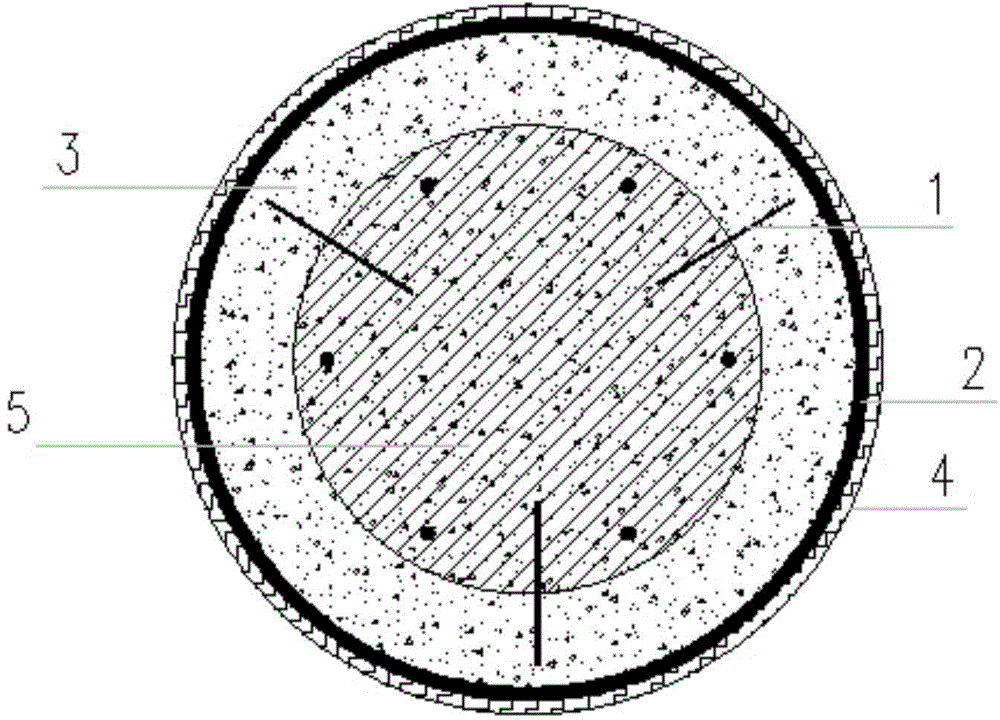

[0038] Such as figure 1 As shown, when the original reinforced concrete column is a circular structure, first plant bars on the existing concrete surface 1; make a half-section steel pipe, hoist it in place and fix it, and weld the two semi-circular sections to form a closed steel pipe 2; Pour ultra-high performance concrete 3 into the steel pipe 2; wrap FRP cloth 4 outside the steel pipe 2, and perform fire protection treatment on the FRP.

[0039] In this embodiment, the original reinforced concrete column 5 adopts a circular section column with a diameter of 800mm.

[0040] Rebar planting 1 adopts HRB335 steel bars with a diameter of 12mm, and the spacing along the longitudinal direction of the column is 100mm, and the depth of planting bars is 88mm.

[0041] The type of steel used in the steel pipe 2 is Q345, the thickness is 30 mm, and the length of the steel pipe is 3.5 m. The axis of the steel pipe is concentric with the original reinforced concrete column 5 .

[004...

Embodiment 2

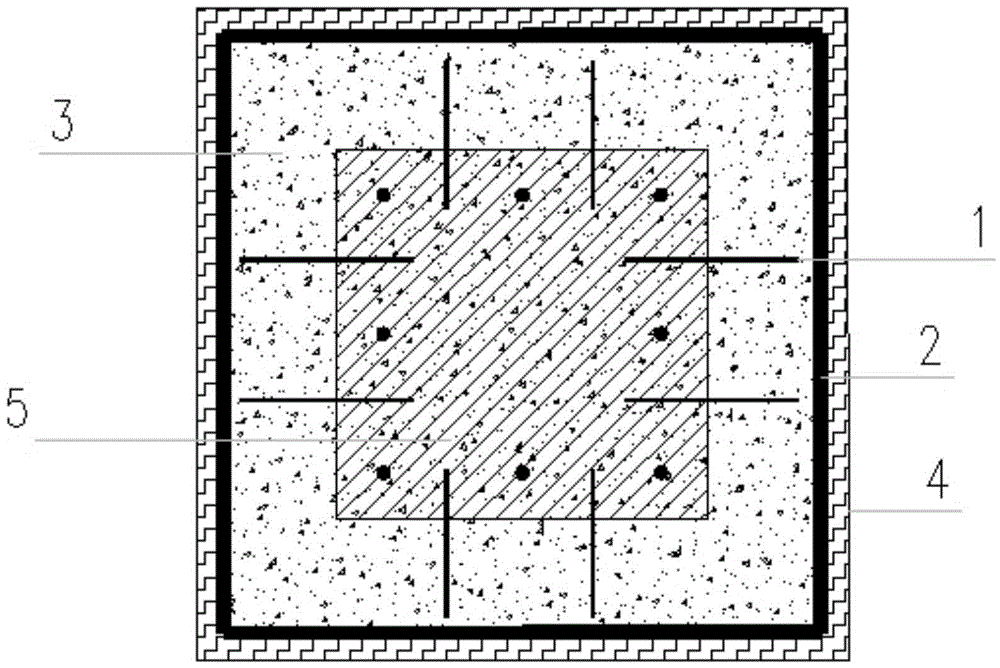

[0045] Such as figure 2As shown, when the original reinforced concrete column is a square structure, first plant bars on the existing concrete surface; make half a steel pipe, hoist it in place and fix it, and weld two L-shaped cross-section steel members to form a closed square steel pipe 2. Pouring ultra-high performance concrete 3 in the steel pipe 2, and wrapping FRP cloth 4 outside the steel pipe 2, and performing fire prevention treatment on the FRP.

[0046] In this embodiment, the original reinforced concrete column 5 adopts a square column with a side length of 600 mm.

[0047] Rebar planting 1 adopts HRB335 steel bars with a diameter of 12mm, and the spacing along the longitudinal direction of the column is 100mm, and the depth of planting bars is 95mm.

[0048] The type of steel used in the steel pipe 2 is Q345, the thickness is 20mm, and the length of the steel pipe is 3m. The axis of the steel pipe is concentric with the original concrete square column.

[004...

Embodiment 3

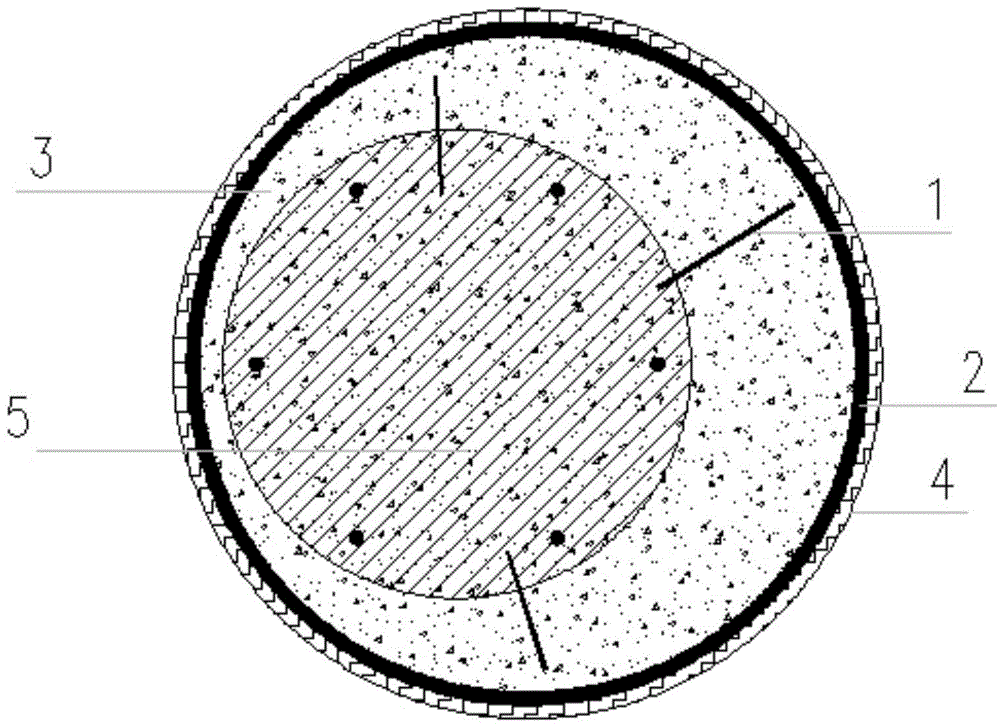

[0052] Such as image 3 As shown, when the original reinforced concrete column is a circular structure, the steel pipe 2 is placed eccentrically. Circular cross-section steel plates are welded to form closed steel pipes 2; ultra-high performance concrete 3 is poured into the steel pipes 2, and FRP cloth 4 is wrapped around the steel pipes 2 to perform fireproofing treatment on the FRP.

[0053] In this embodiment, the original reinforced concrete column 5 adopts a circular section column with a diameter of 600 mm.

[0054] Rebar planting 1 adopts HRB335 steel bars with a diameter of 12mm, and the spacing along the longitudinal direction of the column is 80mm, and the depth of planting bars is 105mm.

[0055] The type of steel used in the steel pipe 2 is Q345, the thickness is 25mm, and the length of the steel pipe is 3m. The axis of the steel pipe is not concentric with the existing concrete circular column.

[0056] The axial compressive strength of ultra-high performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com