Method for processing ultra-soft soil through combining shallow-surface-layer intermittent strong water-pumping/draining with short-term air-curing

A treatment method and technology for ultra-soft soil, which is applied in the field of foundation treatment and super-soft soil reinforcement treatment of superficial silt or dredging silt before soft foundation treatment, which can solve the problem of low construction efficiency, uneven reinforcement effect, and hard shell layer Problems such as limited thickness to achieve the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

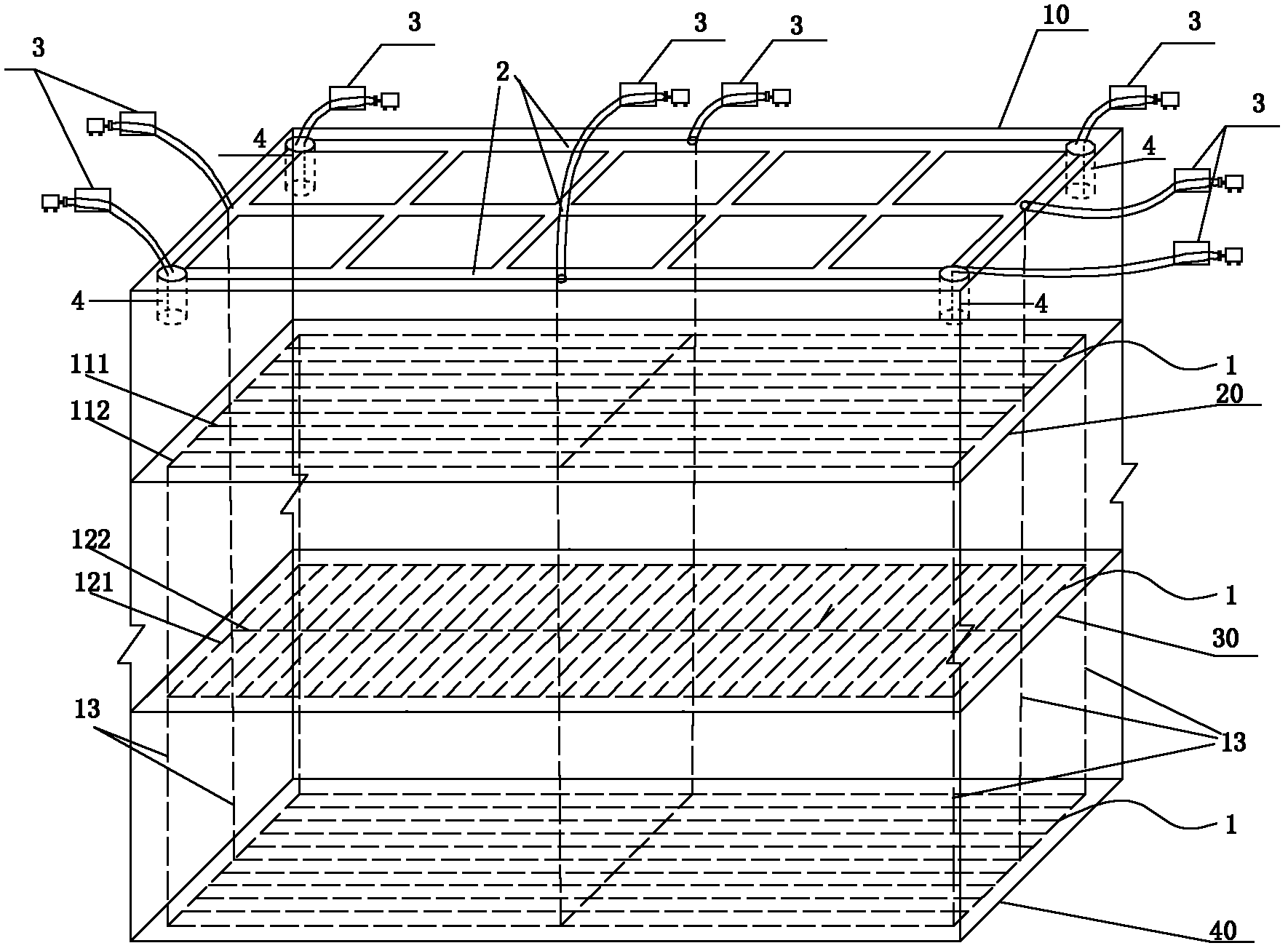

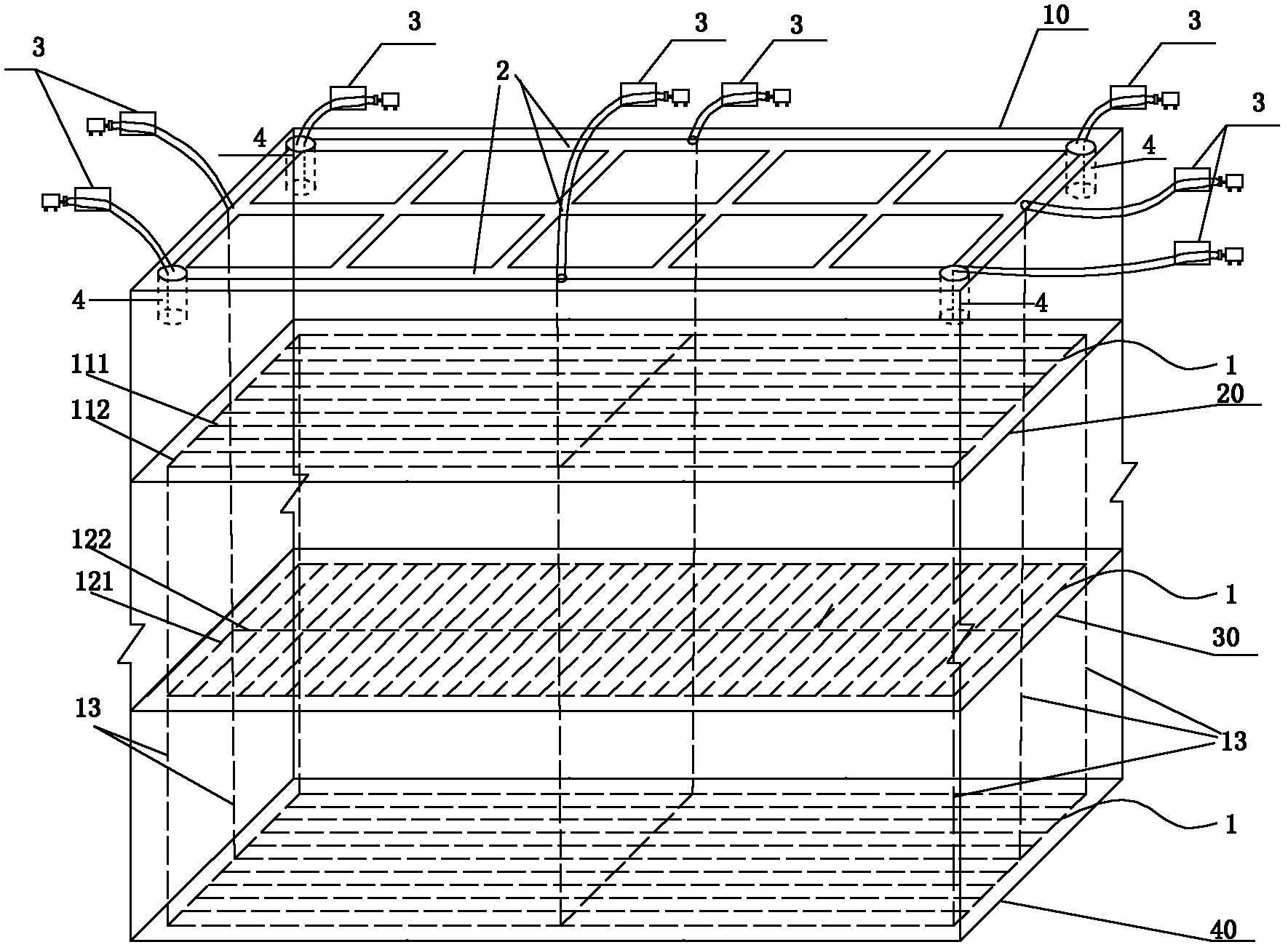

[0020] Such as figure 1 As shown, several layers of pumping and drainage pipe networks 1 are laid horizontally on the supersoft soil surface 10 of the shallow surface layer of silt or dredging silt, and are artificially pressed down layer by layer to different depths (20, 30, 40) of the shallow surface layer. The pumping and draining pipe network 1 can be composed of several horizontally arranged pumping and draining pipes 111, and a longitudinal collecting pipe 112 is arranged at a certain distance to communicate with the horizontal pumping and draining pipes 111; or it can be composed of several longitudinally arranged pumping and draining pipes 121. A horizontal collecting pipe 122 is arranged at a certain distance, and communicated with the longitudinal pumping and draining pipe 121 . The longitudinal collecting pipe 112 or the horizontal direction 122 is connected to the pumping and drainage equipment 3 through the pipeline 13 to form a three-dimensional pumping and drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com