Pipe periphery backfilling material suitable for flexible pipeline and preparation method and backfilling method of pipe periphery backfilling material

A technology of flexible pipes and admixtures, which is applied in sewer pipe systems, waterway systems, buildings, etc., and can solve the problems of non-compact backfilling at the axillary corners of flexible pipes, failure to meet the required compactness, and supercritical instability of flexible pipes. Achieve the effect of reducing the risk of soil loss around the pipe, improving the efficiency of backfilling operations, and reducing road surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

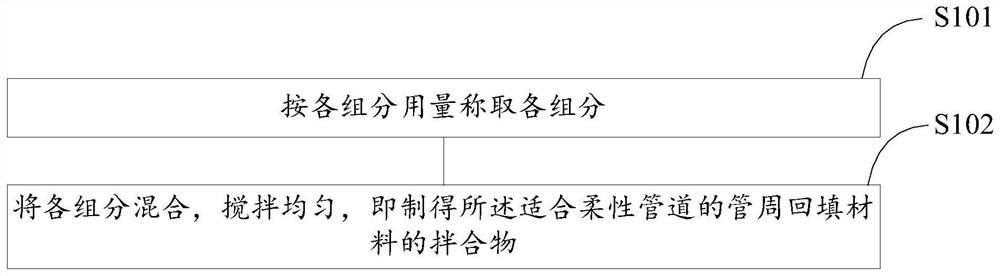

[0050] figure 1 For the process flow chart of the preparation method of the pipe circumference backfill material suitable for flexible pipelines in the embodiment of the present invention, please refer to figure 1 , the embodiment of the present invention also provides a method for preparing the above-mentioned pipe circumference backfill material suitable for flexible pipelines, including:

[0051] S101, weighing each component according to the amount of each component;

[0052] S102. Mix and stir the components evenly to prepare the mixture of the surrounding backfill material suitable for flexible pipelines.

[0053] In some embodiments, the stirring time is 3 to 15 minutes.

[0054] In some embodiments, the initial expansion of the mixture of circumferential backfill materials suitable for flexible pipelines is greater than 550 mm.

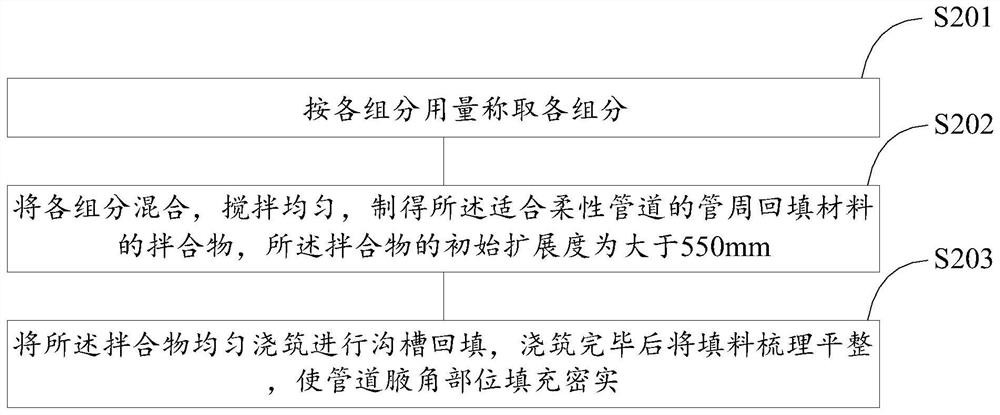

[0055] figure 2 For the process flow diagram of the backfill method for the pipe circumference backfill material suitable for flexible p...

example 1

[0062] The flexible pipe used in this example is: a commercially available flexible pipe made of FRP sand pipe or HDPE (high density polyethylene) with a diameter of DN1000-2000.

[0063] The formula of the surrounding backfill material suitable for flexible pipelines used in this example is:

[0064] 310Kg of water, 30Kg of cement, 370Kg of fly ash, 1100Kg of fine sand, 127Kg of stone powder, 7Kg of accelerator, 3.5Kg of water reducer, and 0.775 water-binder ratio (water-binder ratio refers to the water consumption per cubic meter of concrete and all cementitious materials Dosage ratio).

[0065] Wherein, the accelerator used in this example consists of 20% CaO, 38% SO 3 and 31% Al 2 o 3 Composition, the water reducer is a polycarboxylate water reducer. Preparation method and backfilling method:

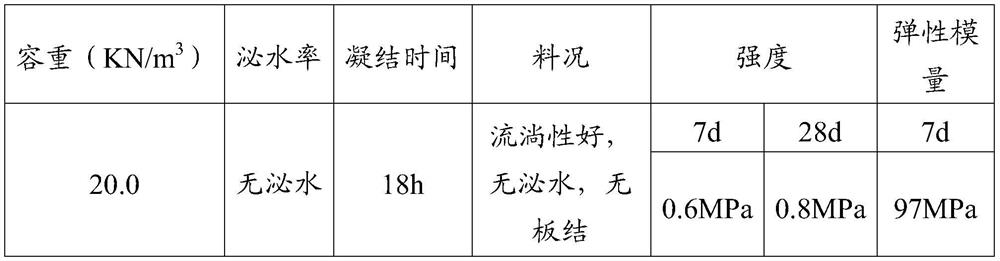

[0066] (1) Filler mixing: Weigh each component according to the amount of each component, mix each component, and stir for 3 to 10 minutes, so that each component is fully mixe...

example 2

[0074] The flexible pipe used in this example is: a commercially available flexible pipe made of FRP sand pipe or HDPE with a diameter of DN1000-2000.

[0075] The formula of the surrounding backfill material suitable for flexible pipelines used in this example is:

[0076] Water 326Kg, cement 30Kg, fly ash 370Kg, fine sand 1100Kg, stone powder 150Kg, accelerator 7Kg, water reducer 3.7Kg, water-cement ratio 0.82 (water-cement ratio refers to the water consumption per cubic meter of concrete and all cementitious materials Dosage ratio).

[0077] Wherein, the quick-setting agent used in this example is made of 20.9% CaO, 38.1% SO 3 and 30.5% Al 2 o 3 Composition, the water reducer is a polycarboxylate water reducer.

[0078] Preparation method and backfilling method:

[0079] (1) Filler mixing: Weigh each component according to the amount of each component, mix each component, and stir for 3 to 15 minutes, so that each component is fully mixed and stirred evenly, and the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com