Backfill protective structure and protection method for high voltage electric power pipeline at top of deep foundation pit

A high-voltage power and protection structure technology is applied in the field of backfill protection structures for high-voltage power pipelines at the top of deep foundation pits, and can solve problems such as lack of reliable protection of pipelines, affecting the use safety and safe service life of original pipelines, and damage to original pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

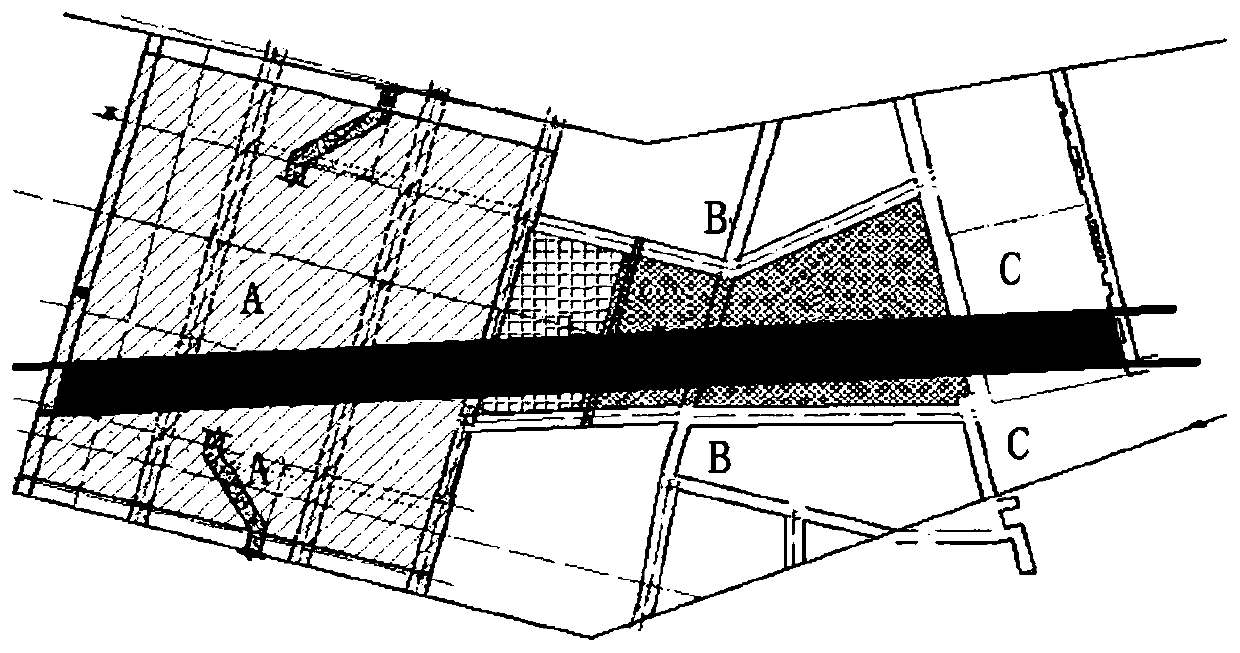

[0027] In one or more embodiments, a backfill protection structure for high-voltage power pipelines on the top of a deep foundation pit is disclosed. During earthwork backfilling, the high-voltage power pipelines of the upper-span foundation pit structure are protected. Spatial relations, adopt different protection schemes.

[0028] Among them, earthwork backfilling means that the pipelines located within the scope of the excavation of the foundation pit are protected in situ after foundation pit excavation, structural construction, and waterproof construction are completed, followed by earthwork backfilling to restore the original landform and ecology.

[0029] During the earthwork backfilling process, according to the different spatial states of the bottom, side and top of the high-voltage power pipeline, the distance from the completed structure, the use function of the ground after backfilling, etc., different protection schemes are adopted to ensure the operation of the high-vo...

Embodiment 2

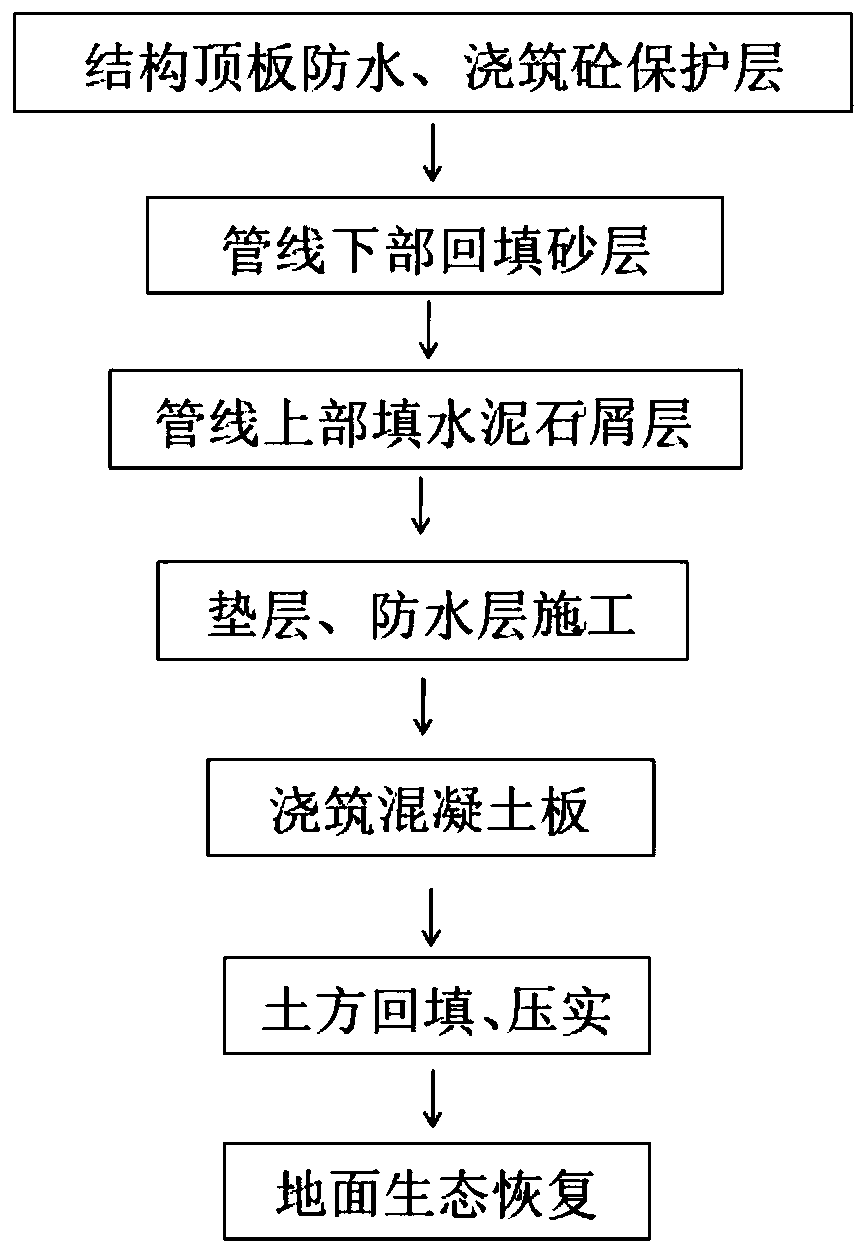

[0046] In one or more embodiments, the backfill construction process of the high-voltage power pipeline on the top of the deep foundation pit is disclosed, such as figure 1 As shown, including the following steps:

[0047] The roof of the structure is waterproof and concrete protective layer is poured. After the main construction of the underground structure is completed, the waterproof construction of the roof and the waterproof concrete protective layer are carried out;

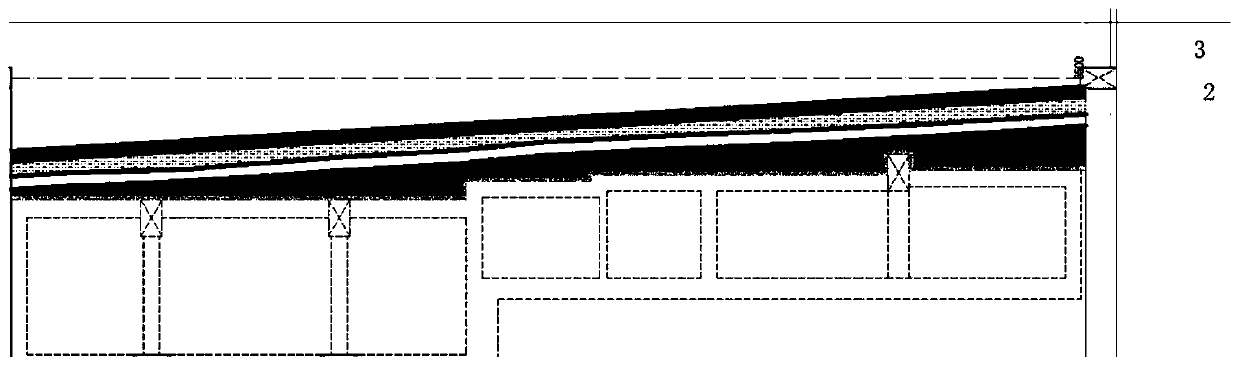

[0048] Backfill sand cushion 1 in the lower part of the pipeline, and backfill sand cushion 1 in the lower part of the pipeline according to the design requirements to complete the first layer of protection for the pipeline;

[0049] Fill cement chip layer 2 on the upper part of the pipeline, and backfill cement chip layer 2 on the upper part of the pipeline according to the design requirements to complete the second layer of protection for the pipeline;

[0050] Cushion and waterproof layer construction, pour a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com