A lightweight foam soil used for backfilling foundation pits of subway stations

A lightweight foam and subway station technology, applied in the field of lightweight foam soil, can solve the problems that people and machines cannot work in the working space, affect the safety and service life of the subway, and cannot be backfilled compactly, so as to speed up the hydration speed, The pore size is uniform and independent, and the effect of enhancing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

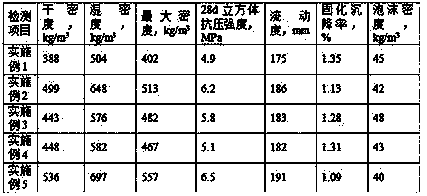

Embodiment 1

[0057] The lightweight foam soil applied to the backfilling of subway station foundation pits provided by the invention is made of the following raw materials in parts by weight: 250 parts of cement, 20 parts of diatomite, 35 parts of granulated blast furnace slag, 50 parts of fly ash, 120 parts of water, 0.5 parts of water reducer, 3 parts of inorganic omega fiber, 20 parts of plant fiber, 4 parts of foaming agent, and 1 part of microfoaming agent.

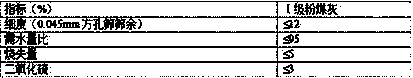

[0058] Wherein, the cement described in this embodiment adopts PO42.5 ordinary Portland cement; the fly ash is Class I fly ash, and the technical indicators of Class I fly ash meet those shown in Table 1, and will not be repeated here; The water reducer is a polycarboxylate water reducer; the foaming agent is a composite foaming agent, its components include animal protein and vegetable protein, and one or more of rosin soap, hydrogen peroxide and aluminum powder; The above-mentioned microfoam is prepared by diluting the foaming ...

Embodiment 2

[0060] The lightweight foamed soil applied to the backfilling of subway station foundation pits provided by the invention is made of the following raw materials in parts by weight: 400 parts of cement, 10 parts of diatomite, 5 parts of granulated blast furnace slag, 10 parts of fly ash, 200 parts of water, 1.25 parts of water reducer, 6 parts of inorganic omega fiber, 5 parts of plant fiber, 6 parts of foaming agent, and 5 parts of microfoaming agent.

[0061] Among them, the cement described in this example is PO42.5R ordinary Portland cement; the fly ash is Class I fly ash, and its technical indicators meet those shown in Table 1; the water reducer is polycarboxylate Water reducer; the foaming agent is a composite foaming agent, its composition includes animal protein and vegetable protein, and one or more of rosin soap, hydrogen peroxide and aluminum powder; the foaming agent is the foaming agent Diluted with water at 1:1500, and micro-foamed by plunger pump.

Embodiment 3

[0063] The lightweight foamed soil applied to the backfilling of subway station foundation pits provided by the invention is made of the following components by weight: 350 parts of cement, 12 parts of diatomaceous earth, 25 parts of granulated blast furnace slag, 5 parts of fly ash, 150 parts of water, 2 parts of water reducing agent, 8.5 parts of inorganic omega fiber, 15 parts of plant fiber, 5.5 parts of foaming agent, and 3 parts of microfoaming agent.

[0064] Among them, the cement described in this example is PO42.5R ordinary Portland cement; the fly ash is Class I fly ash, and its technical indicators meet those shown in Table 1; the water reducer is polycarboxylate Water reducer; the foaming agent is a composite foaming agent, its composition includes animal protein and vegetable protein, and one or more of rosin soap, hydrogen peroxide and aluminum powder; the foaming agent is the foaming agent Diluted with water at 1:1500, and micro-foamed by plunger pump.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com