A method for efficient excavation of earth pressure shield machine in water-rich round gravel stratum

A technology of shield machine and round gravel, which is used in earthwork drilling, underground chamber, wellbore lining, etc., can solve the problems of large land subsidence, slurry loss, tool wear, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

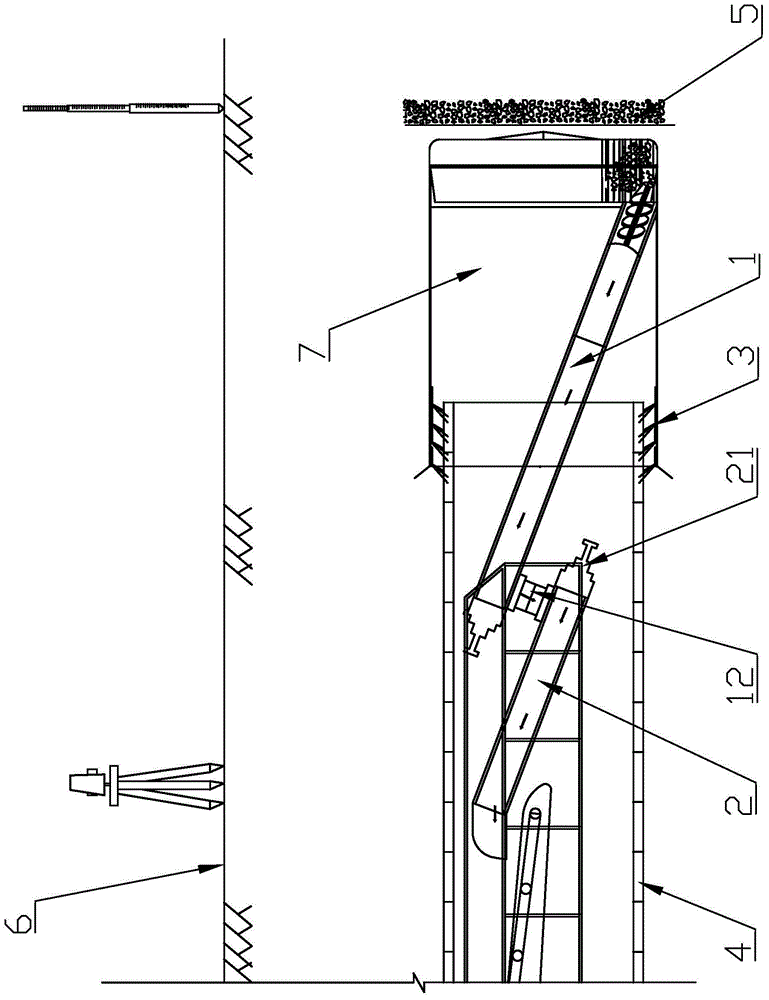

[0024] refer to figure 1 , the present invention is a kind of earth pressure shield machine the method for efficient excavation in water-rich boulder stratum, comprises the following steps:

[0025] 1) The main drive of the cutter head of the earth pressure balance shield machine 7 is hydraulic drive, the maximum torque of the shield machine 7 is not less than 6228 kNm to adapt to the excavation in the water-rich boulder formation 5, and the escape torque of the shield machine 7 is not Less than 7447kNm, the opening rate of the cutter head of the shield machine 7 is 20% to 30%;

[0026] 2), the shield machine 7 adopts wear-resistant protection methods including surfacing, wear-resistant protection, burning wear-resistant welding, welding wear-resistant protection blocks, and welding carbide strips to protect the cutter head, cutter, knife box, cutter head nozzle and Screw machine to increase service life;

[0027] 3) The shield machine 7 adopts three different improvement te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com