Socket-and-spigot double-flat-wall composite pipe and manufacturing method thereof

A double-flat wall and socket-type technology, applied in the direction of hoses, pipes, rigid pipes, etc., can solve the problems of difficult backfill compaction, inconvenient dragging and rolling of double-wall corrugated pipes, etc., to achieve high production efficiency, light weight, Easy to drag and scroll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

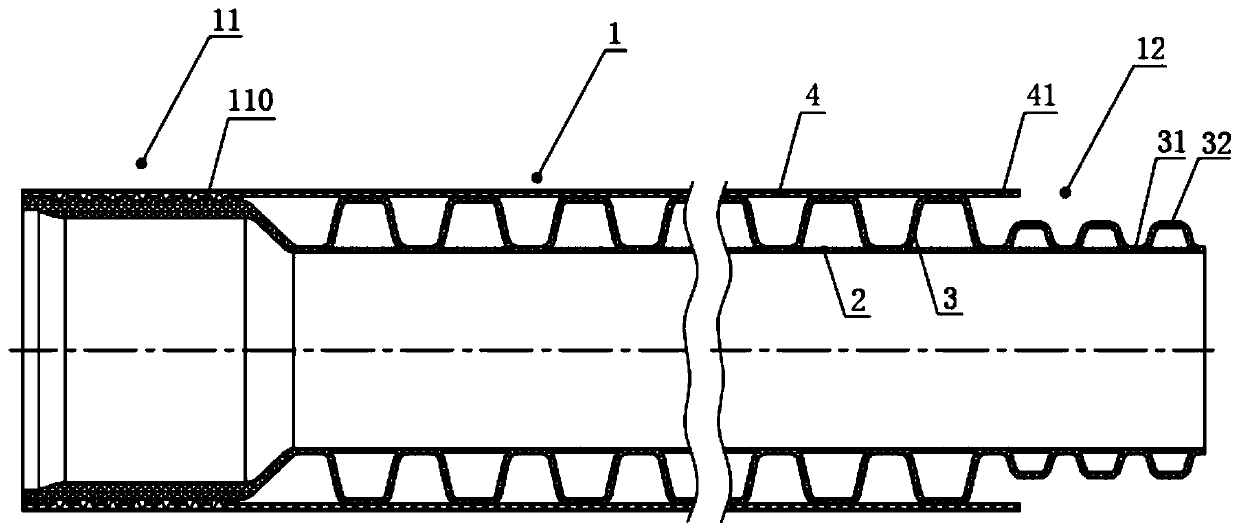

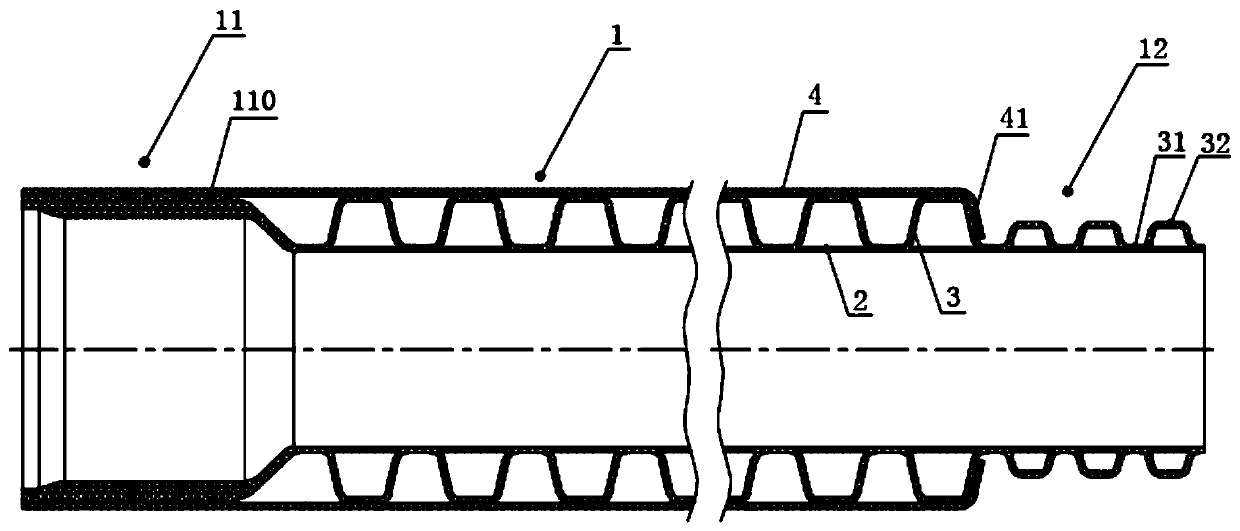

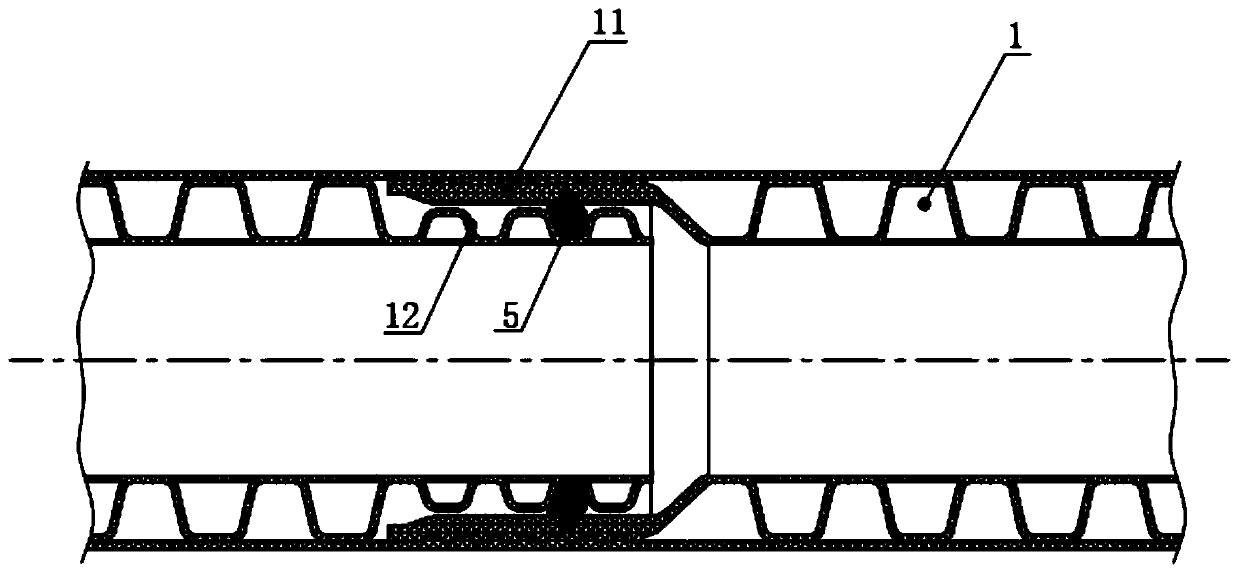

[0027] Figure 5 The structural diagram of the socket of the double-wall corrugated pipe in the prior art is shown, and the socket has a rib structure. The existing double-wall corrugated pipe includes a double-wall corrugated pipe main body 1 and a socket 11 integrally provided at one end of the double-wall corrugated pipe main body 1. The end of the double-wall corrugated pipe main body 1 away from the socket 11 is provided with a socket connection section 12. The main body of the wall corrugated pipe includes an inner flat wall layer 2 and a corrugated reinforced layer 3. The outer wall of the corrugated reinforced layer 3 is provided with wave crests 32 and wave troughs 31, and a plurality of annular reinforcement ribs 110 are arranged on the outer circumferential surface of the socket 11 at intervals along the axial direction. .

[0028] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com