Damming method through seepage draining prism bodies realizing bidirectional permeation and reverse laying

A prism and reverse technology, which is applied in the field of two-way permeation and reverse laying of drainage prism dams, can solve the problems of tailings pond overall stability imbalance, weak dry beach strength, and inability to form dry beaches, so as to reduce the cost of dam construction Low cost, good stability, and the effect of improving anti-sliding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A method for building a dam with two-way permeable reverse laying drainage prisms, comprising the following steps:

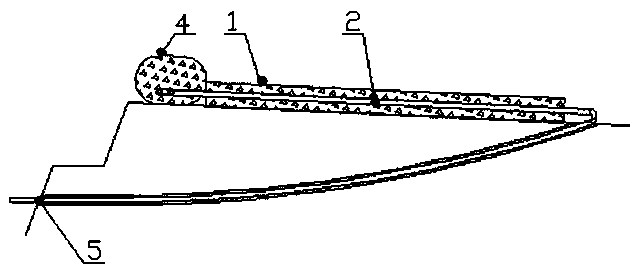

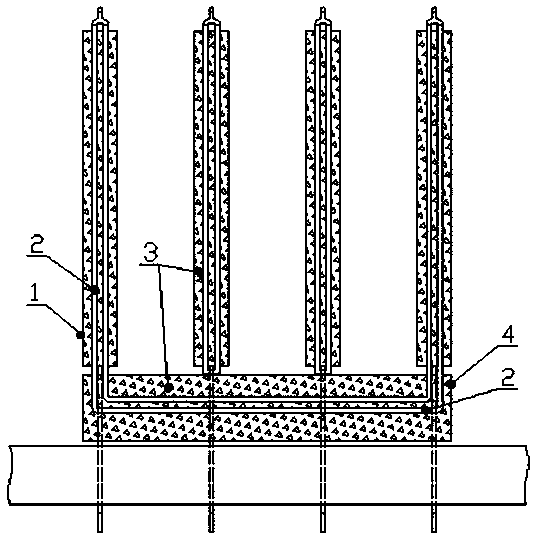

[0026] Step 1, laying the longitudinal flexible permeable tube 1 inwards along the natural slope of the dry beach;

[0027] Step 2, laying water guide pipes and joints along the bottom of the longitudinal flexible water permeable tube 1 from the outside of the dam to the inside of the reservoir according to a specified angle and slope to form a water guide system 5;

[0028] Step 3, penetrating the drainage pipe 2 in the longitudinal flexible permeable cylinder 1, and connecting with the water guiding system 5;

[0029] Step 4: Inject the tailings sand 3 into the vertical flexible water permeable cylinder 1, the fine tailings and water in the tailings sand 3 enter the water guide system 5 through the internal drainage pipe 2 and discharge, and the vertical flexible water permeable cylinder 1 forms a vertical drainage prism ;

[0030] Step 5, laying the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com