Integrated tailing damming machine

An integrated, tailings technology, applied in construction, solid waste removal, sea area engineering, etc., can solve problems such as difficulty in movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

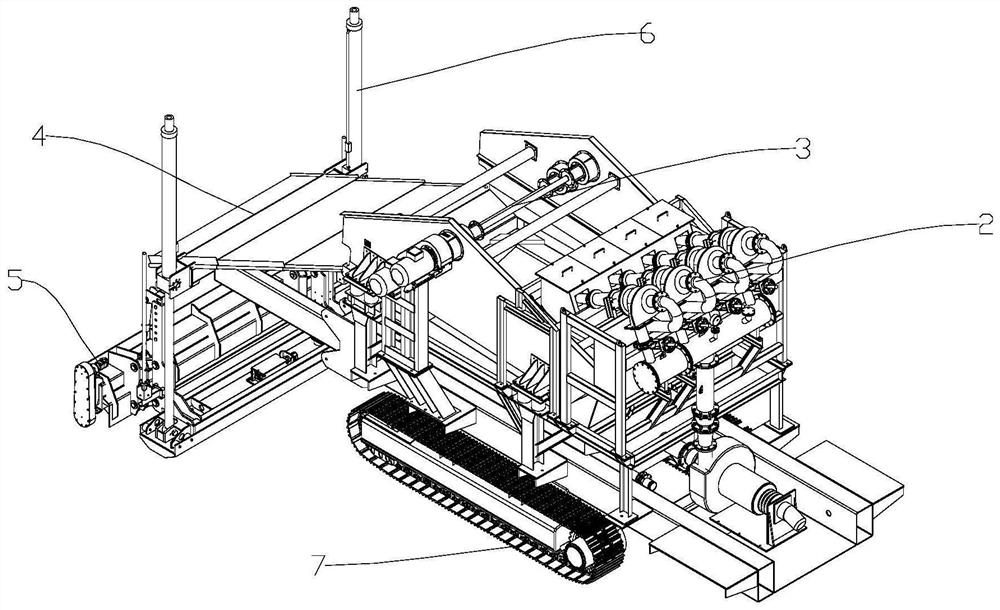

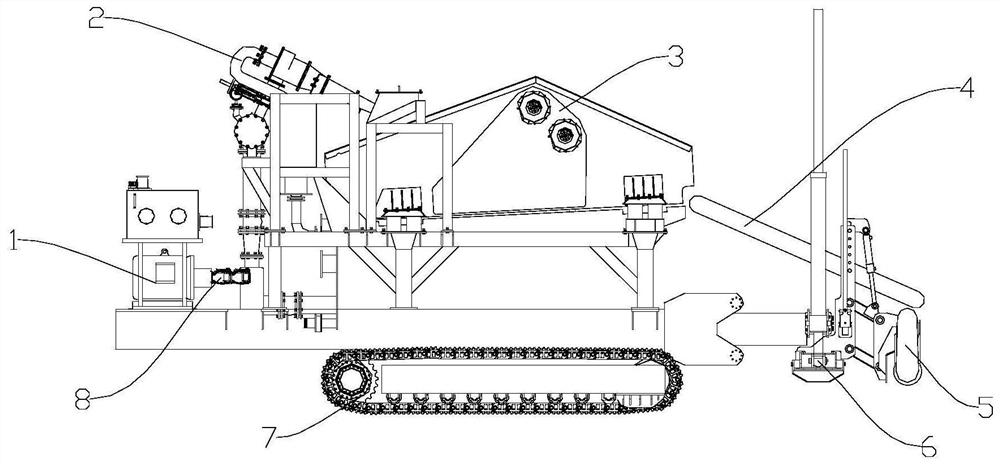

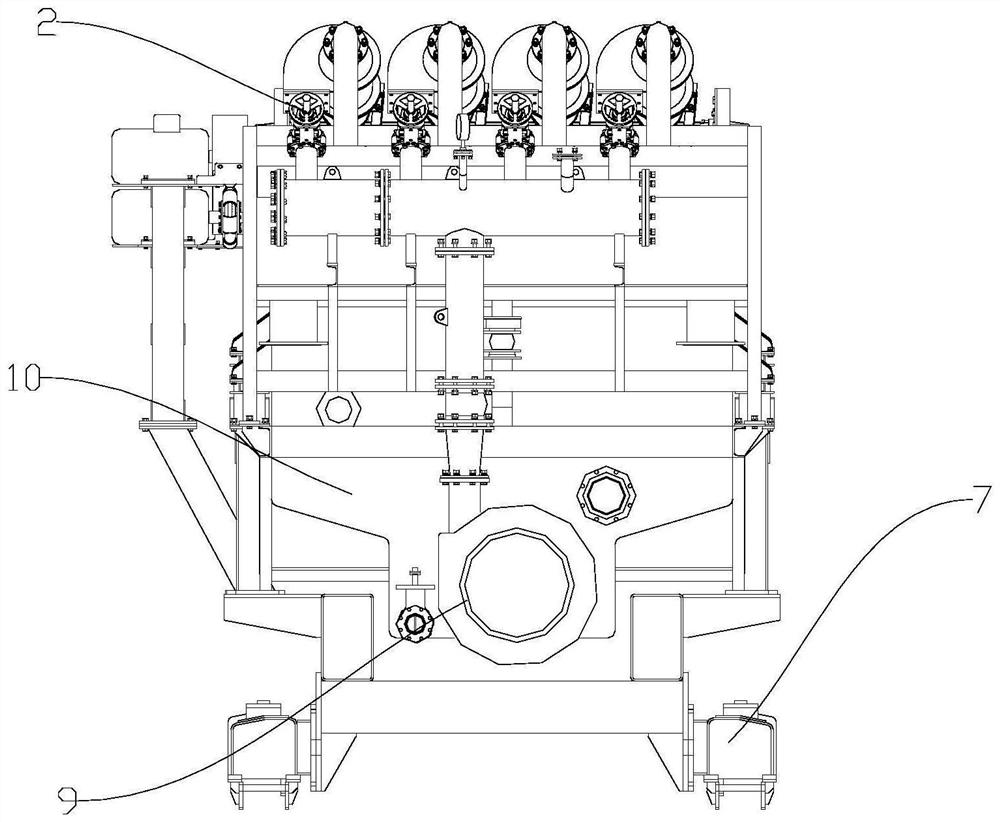

[0047] Please refer to Figure 1-Figure 5 , this embodiment provides an integrated tailings damming machine, including:

[0048] Cyclone 2, the above-mentioned cyclone 2 is used for the separation of large particle materials in tailings;

[0049] A vibrating dewatering screen 3, the inlet of the above-mentioned vibrating dewatering screen 3 is connected to the discharge port of the large particle material of the above-mentioned cyclone 2;

[0050] Paver 5, the above-mentioned paver 5 is arranged at the solid material outlet of the above-mentioned vibrating dewatering screen 3, and the above-mentioned paver 5 is used to spread the material of the above-mentioned vibrating dewatering screen 3 inside;

[0051] A vibratory compactor 6, the above-mentioned vibratory compactor 6 is set in cooperation with the above-mentioned paver 5, and the above-mentioned vibratory compactor 6 is used for compacting the material layer after the material of the above-mentioned paver 5 is tiled;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com