A method of filling a deep cyclone pool with air lift to drain seepage and build a dam

A swirling pond and air lift technology, applied in filling, building, dam and other directions, can solve the problems of overall stability and imbalance of tailings pond, slow consolidation of dry beach of heap body, and large waste of resources, etc., and achieve good drainage effect, The effect of low construction cost and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

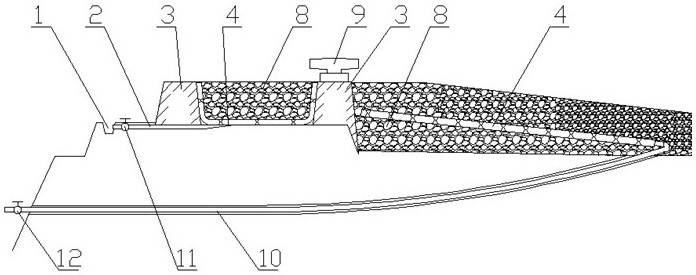

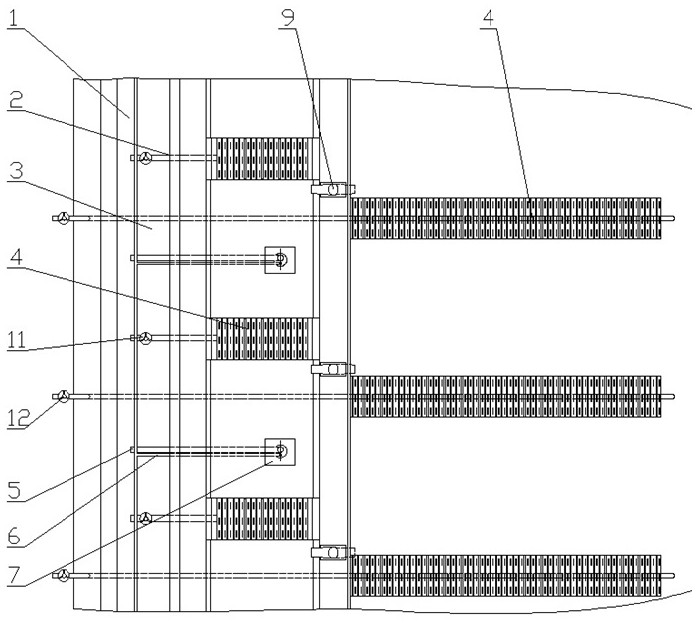

[0029] A method for building a dam with deep filling of swirling pools with gas lift and seepage drainage comprises the following steps:

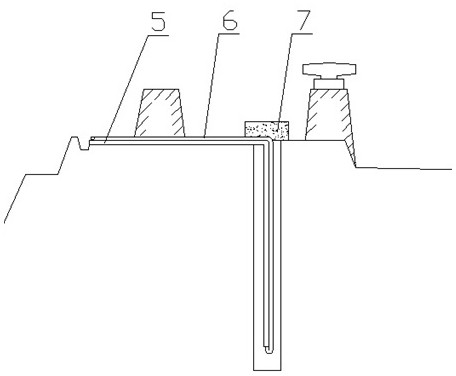

[0030] Step 1: Dig a longitudinal drainage ditch 1 on the original dam body, embed horizontal drainage pipes 2, air intake pipes 6, and air lift drainage pipes 5 according to the designed spacing. The drainage pipe 5 is laid in the middle of the two drainage pipes 2, and the horizontal drainage pipe 2 is provided with a drainage valve 11 to control the water flow switch.

[0031] Step 2, leave a certain passage distance on the outer edge of the original dam crest and build two small dams 3 respectively on the dry beach in the dam.

[0032] Step 3, in the two small dams 3, the vertical dam body is drilled to the depth of the dam body and the seepage pipe is installed, the air intake pipe and the air lift drain pipe are put into the water seepage pipe, the bottom of the air intake pipe 6 is inserted into the air lift drain pipe 5, and the see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com