Given force variable stiffness discrete material pile ramming and expanding machine and application thereof

A technology of granular materials and tamping pile machine, which is applied in sheet pile walls, soil protection, construction, etc., can solve problems such as limited bearing capacity of composite foundations, and achieve the effect of enhancing the quality of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

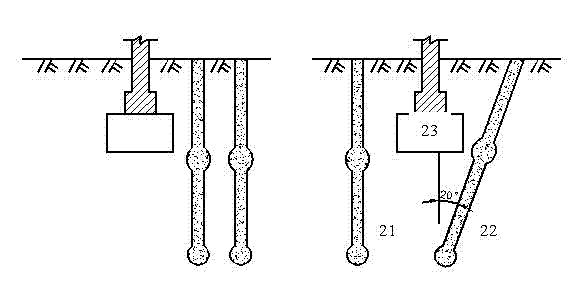

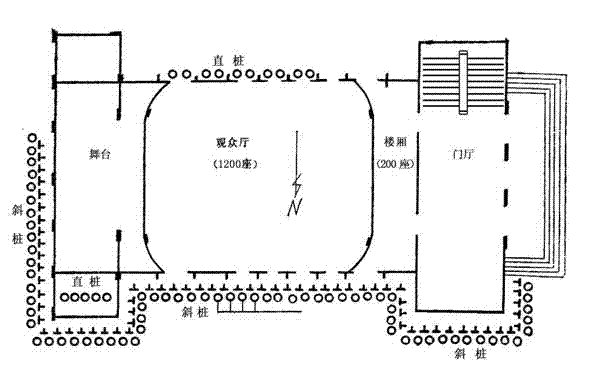

Method used

Image

Examples

Embodiment Construction

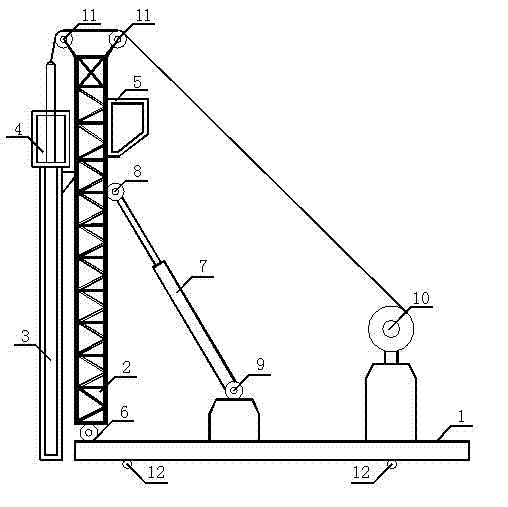

[0048] (1) The tamping and expansion pile machine for granular material with variable stiffness to meet the operational performance requirements of the multi-section expanding head granular material pile composite foundation prestressed construction method. The pile driver consists of the following six parts:

[0049] a) Chassis: Chassis 1 (including four stabilizing feet and counterweight) is welded by vertical and horizontal I-beams. The hoist system and control system are arranged on the top, and there are symmetrical stable feet and walking steps on both sides. In addition, anti-eccentric counterweight iron blocks are also stored.

[0050] b) Walking parts: The walking parts (including moving walking steps, rubber wheel axles and tires) are divided into moving walking parts and rubber wheel rolling walking parts. The step-by-step walk is the shifting movement during piling construction operations; the rolling walking part is temporarily installed with rubber wheels and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com