Vacuum preloading foundation treatment construction method

A foundation treatment and construction method technology, which is applied in the fields of basic structure engineering, soil protection, construction, etc., can solve the problems that the reinforcement effect cannot meet the requirements, the content of soil organic matter increases, and soil pollution, etc., so as to improve the stiffness and Rigidity, fast reinforcement rate, and the effect of increasing construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

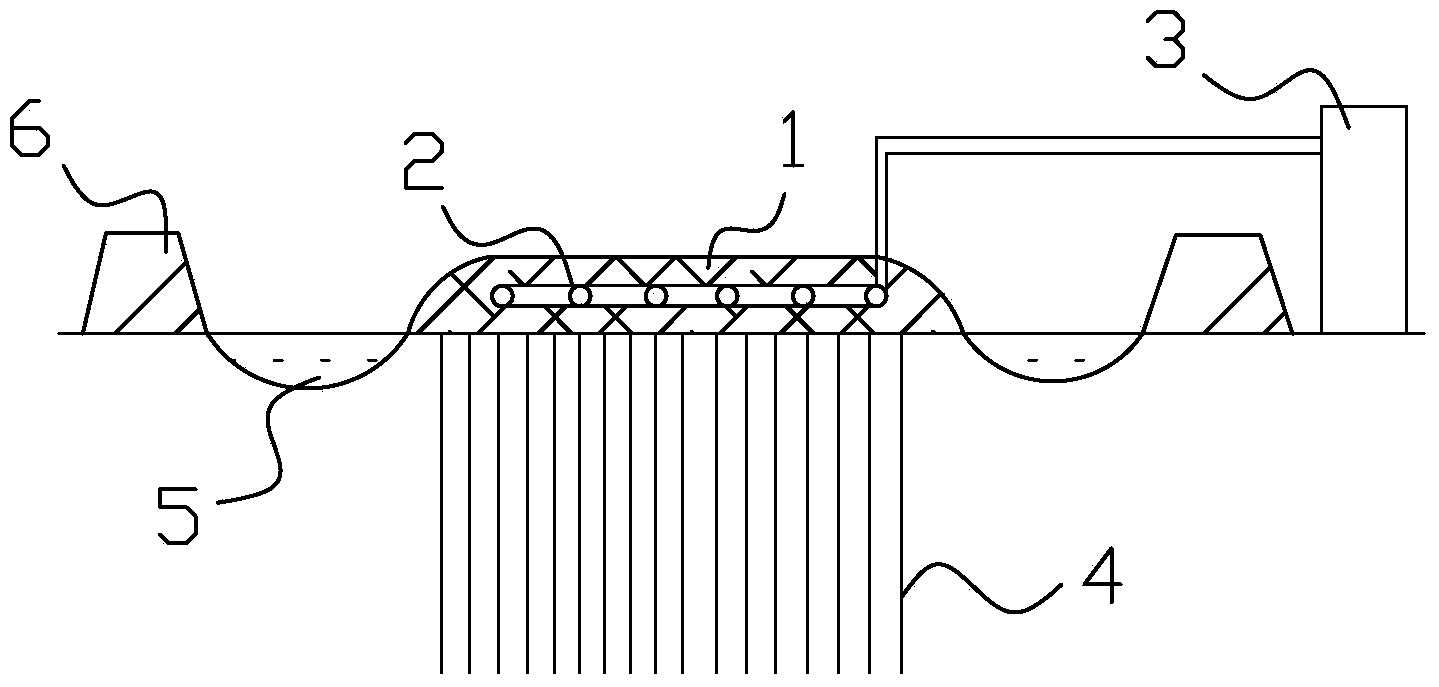

[0043] The invention is a vacuum preloading foundation treatment construction method, the working principle of which is to make the water in the soft foundation pass through the filter membrane of the plastic drainage plate to reach the sand cushion from the drainage channel through the pressure difference generated by the vacuum, and then pass through the horizontal drainage channel The sand cushion enters the filter pipe buried in the sand cushion, and is discharged in the jet box which enters the outside through the film outlet connected with the vacuum pump.

[0044] This construction method requires the following materials:

[0045] 1. Jingba, weathered sand, drainage sand, plastic drainage board, sealing film, filter tube, vacuum jet pump, vacuum gauge.

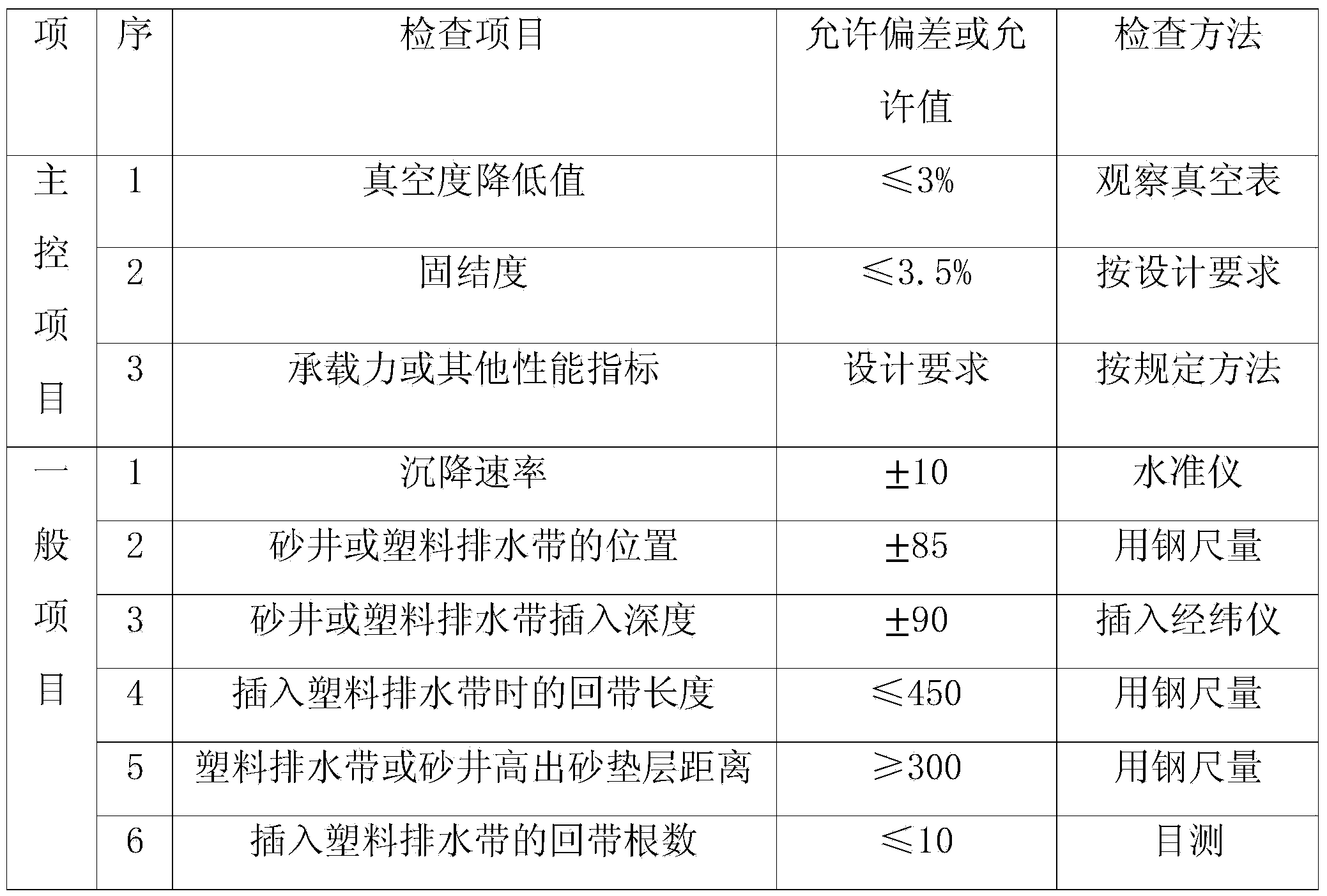

[0046] 2. The data parameters of this construction method are shown in Table 1:

[0047]

[0048] Table 1 Quality inspection standard of preloaded foundation

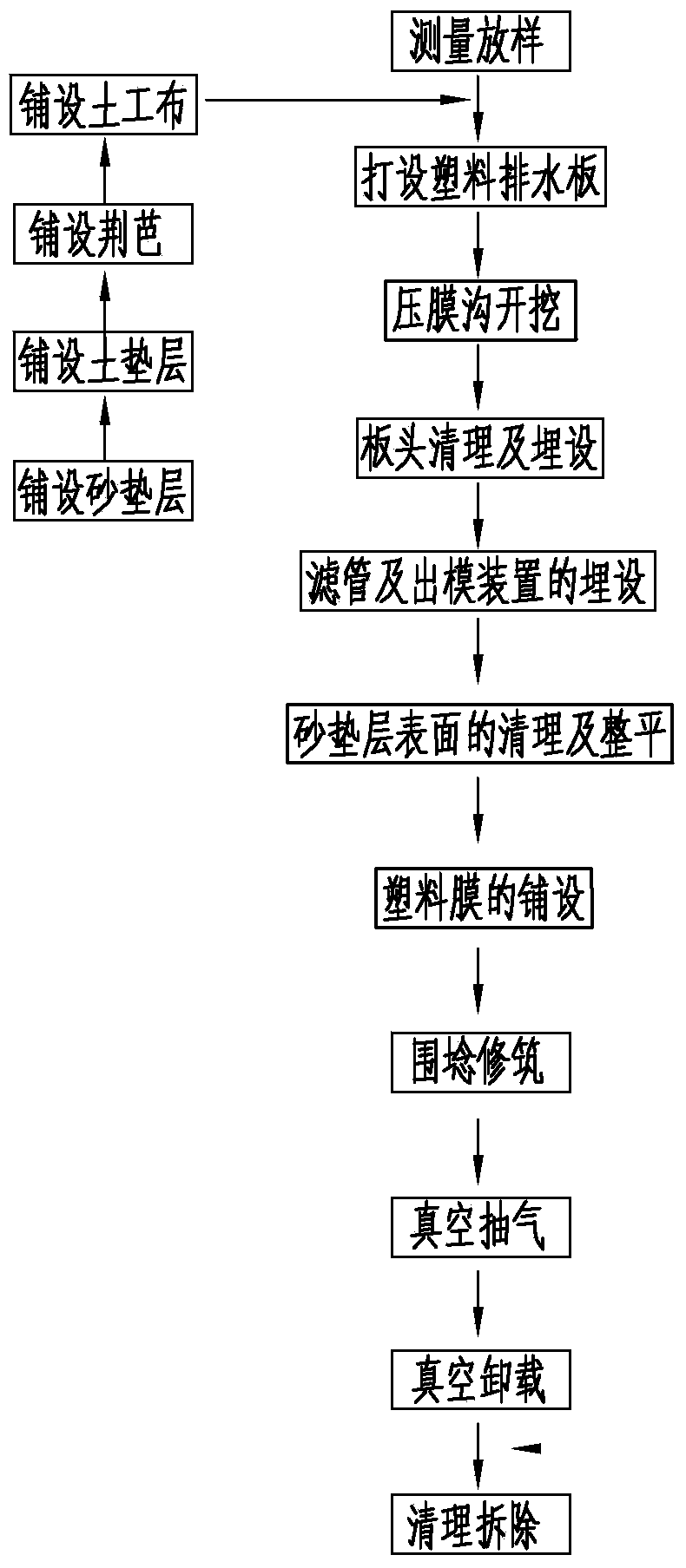

[0049] This construction method comprises the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com