Fast mud dehydrating device

A rapid dehydration and slurry technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc., can solve the problem of blocked vacuum transmission, inconspicuous treatment effect, and reduced treatment efficiency, etc. problem, to achieve the effect of uniform vacuum pressure distribution, guaranteed reinforcement effect, and fast reinforcement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

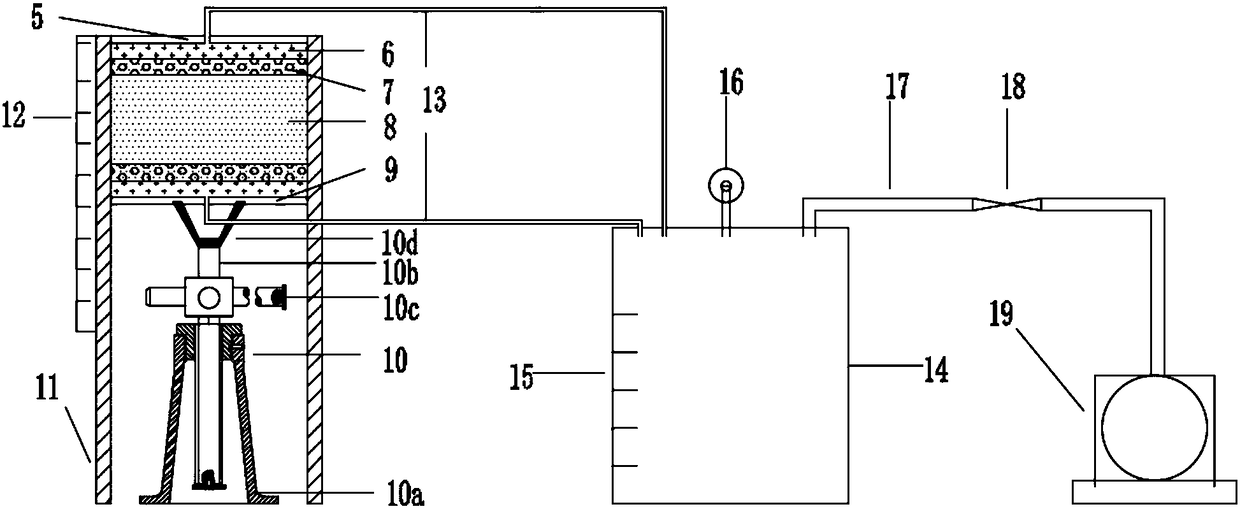

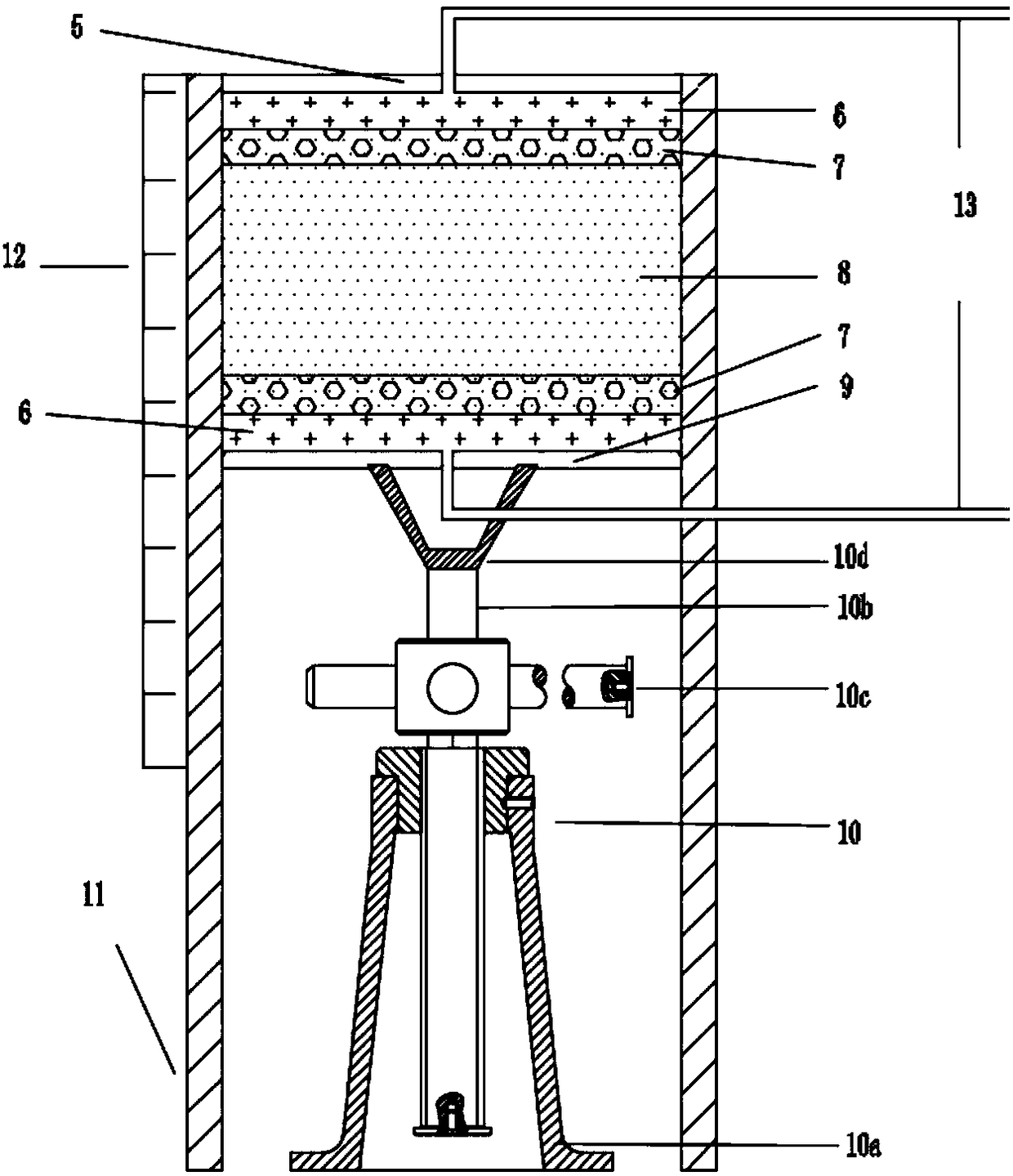

[0029] A quick mud dewatering device, mainly comprising a mud dewatering box, a hydraulic jack 10 and a two-way vacuum filtration system; the mud dewatering box includes a cylindrical box 11, and the cylindrical box 11 is sequentially provided with a top plate 5, a geotechnical Fabric layer 6, sand cushion layer 7, mud layer 8, sand cushion layer 7, geotextile layer 6 and bottom plate 9; Described top plate 5, bottom plate 9, geotextile layer 6, sand cushion layer 7 diameters and cylindrical box 11 The inner diameters are matched; the side of the top plate 5 is provided with external threads, and the top of the cylindrical box 11 is provided with internal threads corresponding to the top plate 5; the top plate 5 is provided with a vacuum filtration channel 5a, and the bottom plate 9 is provided with a vacuum filtration channel 9a; Both the top plate 5 and the bottom plate 9 are made of impermeable material.

[0030] The top of the screw rod of the hydraulic jack 10 is welded w...

Embodiment 2

[0034] A quick mud dehydration device, on the basis of the structure of Embodiment 1, is equipped with a material system for injecting mud into the mud layer 8 of the mud dewatering box; the material system includes a mud mixing tank 1 and a pump 4 connected in sequence A valve 2 is arranged on the communication pipeline between the mud mixing barrel 1 and the pump 4, and the transportation pipe 3, and the transportation pipe 3 is connected to the mud layer 8.

[0035] The experimental device is less affected by air humidity, temperature, etc. during the test, which ensures the accuracy and reliability of the data.

[0036] The mud sample in the mud mixing tank is made according to the requirements of the geotechnical test and mixed evenly.

[0037] The using method of mud quick dehydration device in embodiment 2 comprises the following steps:

[0038] (1) Arrange the bottom of the mud dewatering tank, hydraulic jack and two-way vacuum filtration system: place the hydraulic j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com