Force-given effect flexible stake composite presser for groundsill and its uses

A composite foundation and flexible pile technology, applied in sheet pile wall, foundation structure engineering, soil protection and other directions, can solve the problems of difficult to meet the requirements of fast and efficient reinforcement treatment, large impact of facilities, low technical and economic benefits, etc. The effect of the quick reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

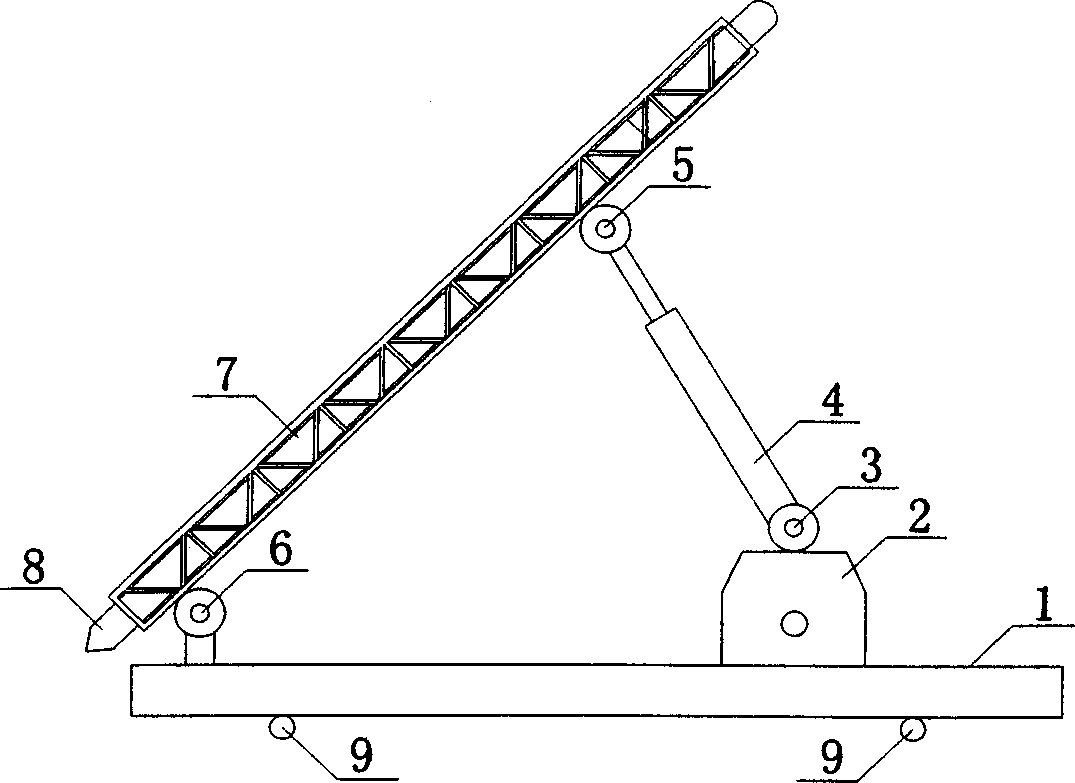

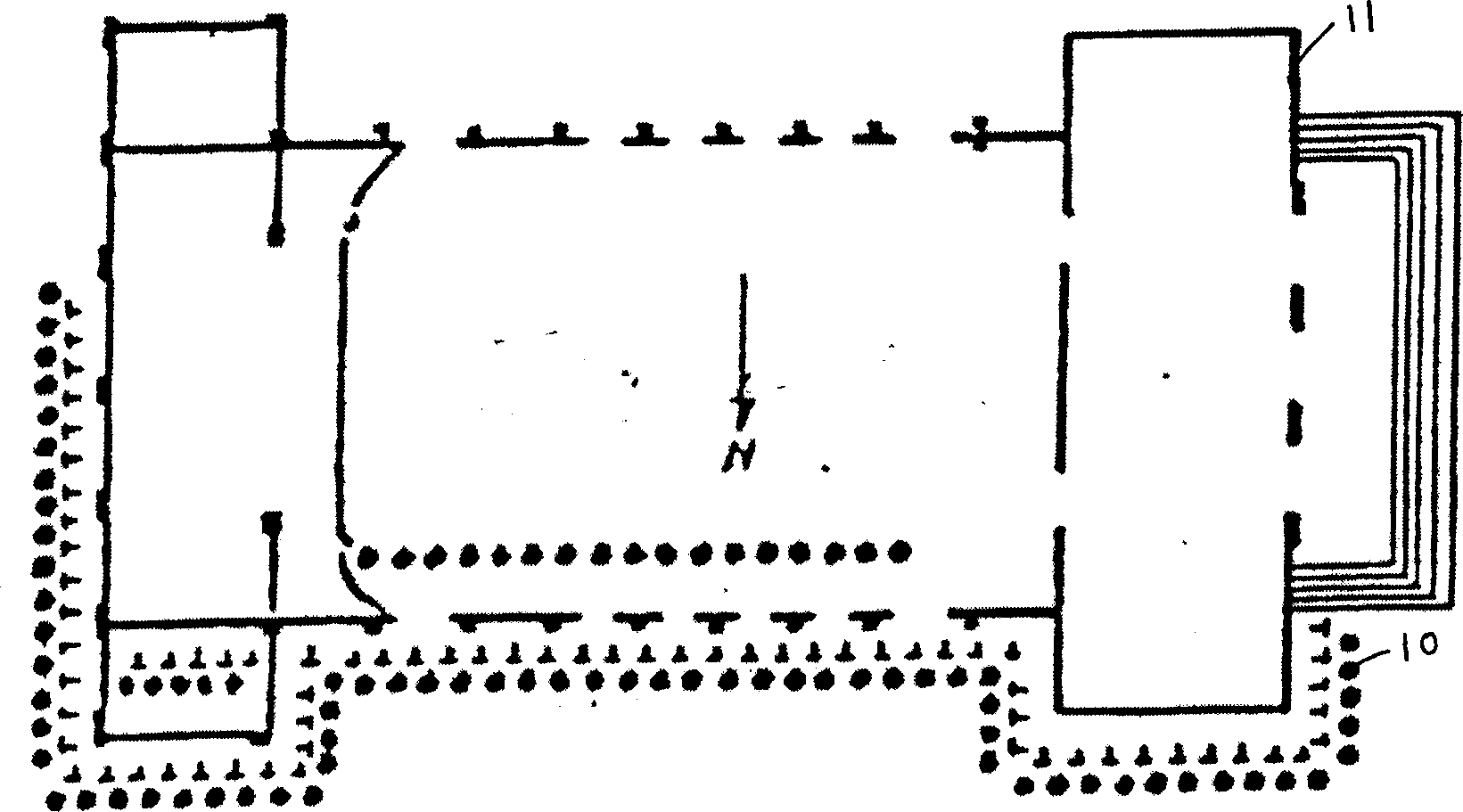

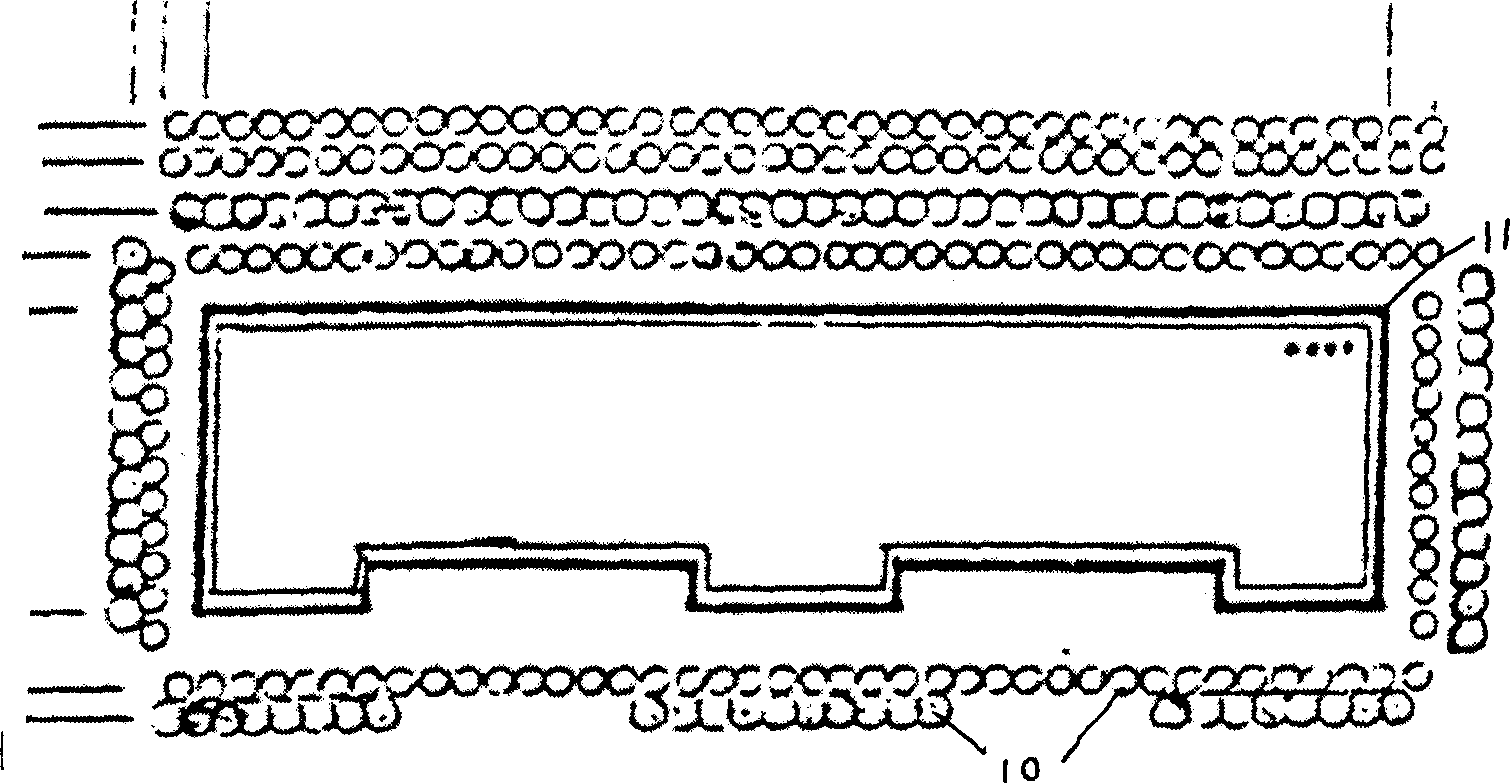

[0037] (1) The flexible pile composite foundation pile driver with the action of the given force can meet the operational performance requirements of the construction method of the static pressure pile composite foundation made of granular materials. The structure of the pile driver is divided into the following parts:

[0038] a) Chassis: welded by vertical and horizontal I-beams, it can support the entire pile driver, and there are four retractable feet fixed on both sides.

[0039] b) Walking: It is divided into the walking part of moving machine steps and the rolling walking part of rubber wheels. The step-by-step walking part is the shifting movement of the pile construction; the rolling walking part is the temporary installation of rubber wheels during long-distance transportation and is towed away by a trailer.

[0040] c) Counterweight: To provide reaction force during pile construction, plus the weight of the pile machine itself, to ensure the maximum pile pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com