Storage pot shock insulation rubber support

A shock-isolating rubber and storage tank technology, applied in the direction of non-rotational vibration suppression, can solve the problems of fire toxic substances, displacement displacement and diffusion of storage tanks, etc., and achieve the effect of simple installation and construction, uniform bearing capacity and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

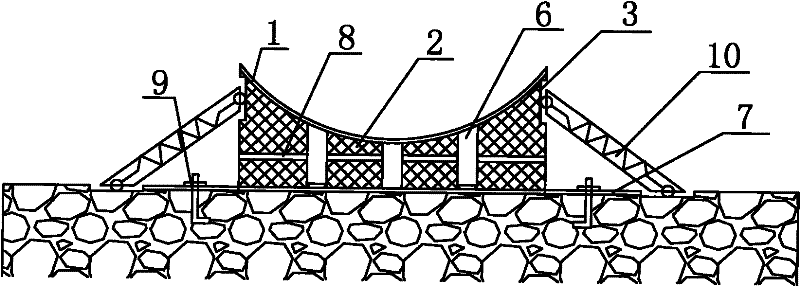

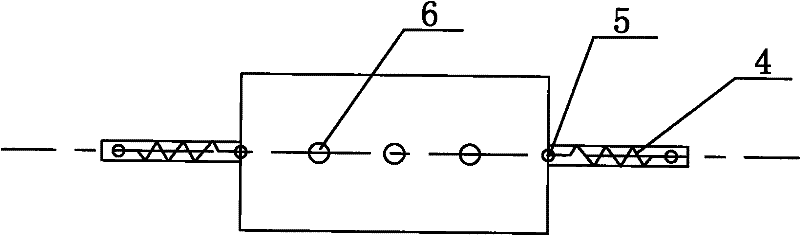

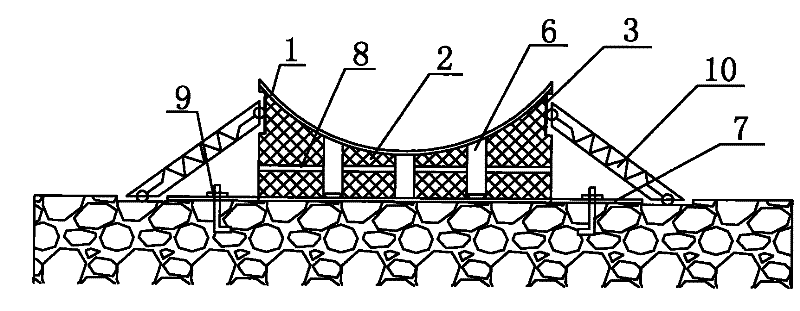

[0026] Such as figure 1 and figure 2 A shock-isolation rubber bearing for a storage tank shown includes an upper support plate 1, a lower connecting plate 7, and a high elastic rubber 2 arranged between the upper supporting plate 1 and the lower connecting plate 7, and the interior of the high elastic rubber 2 is inlaid There are a plurality of high damping materials 6 and internal reinforcing steel plates 8, and the high damping materials 6 and internal reinforcing steel plates 8, the upper supporting plate 1, the lower connecting plate 7 and the high elastic rubber 2 form a vibration isolation body. Among them, anti-aging agent and flame retardant with excellent aging resistance and flame retardancy are added to the high elastic rubber 2, so that the bearing has good aging resistance and flame retardancy, and the high damping material 6 can effectively absorb the energy generated by vibration or earthquake . On the other hand, in order to ensure that the support will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com