Shearing force groove structure for underwater concrete bottom sealing and construction method of shearing force groove structure

An underwater concrete and shear trough technology, applied in infrastructure engineering, construction, etc., can solve problems such as engineering accidents, difficulty in meeting engineering needs, and difficulty in completely penetrating the water-proof curtain of a confined aquifer, and achieve reliable connection, Guaranteed water tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

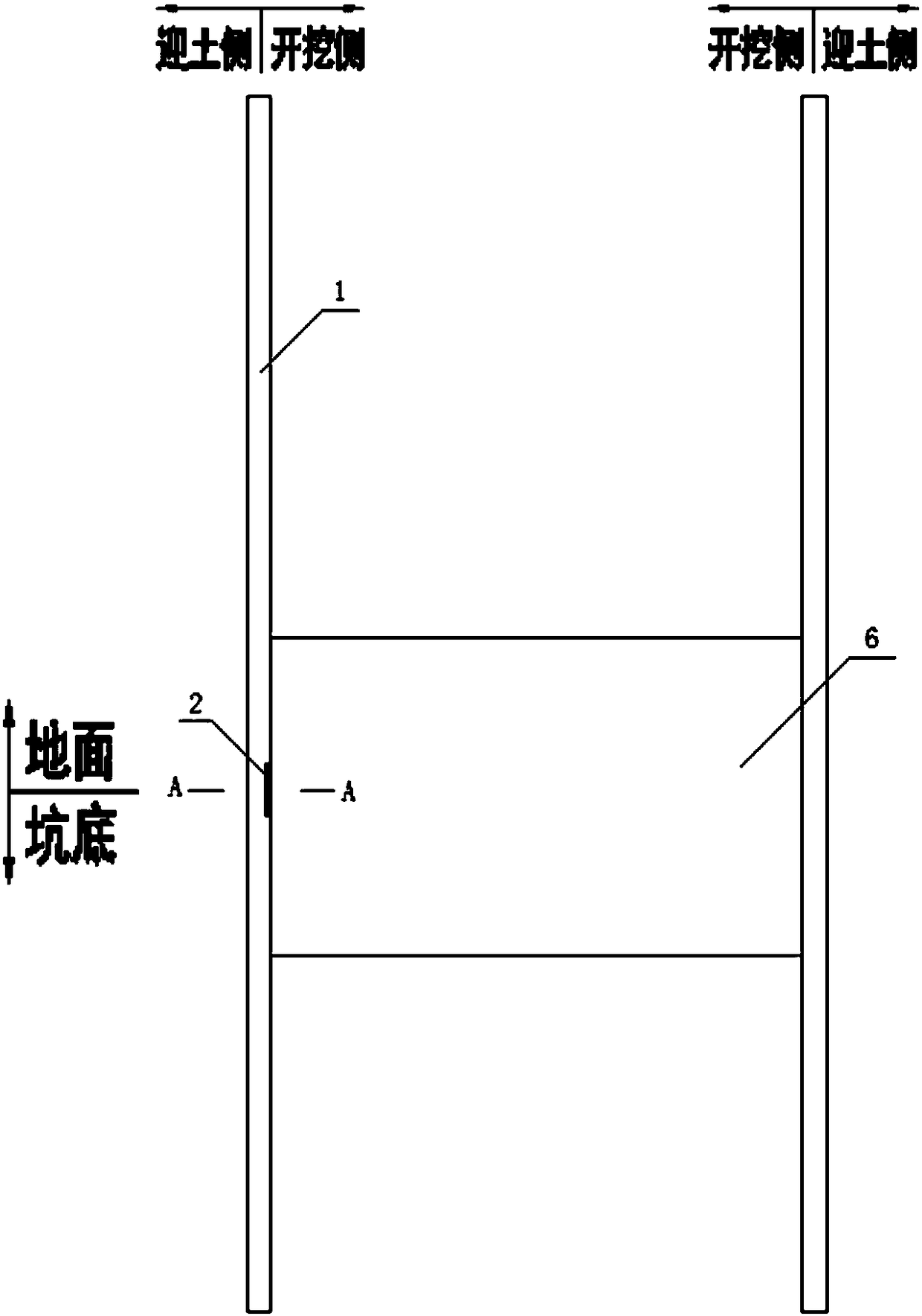

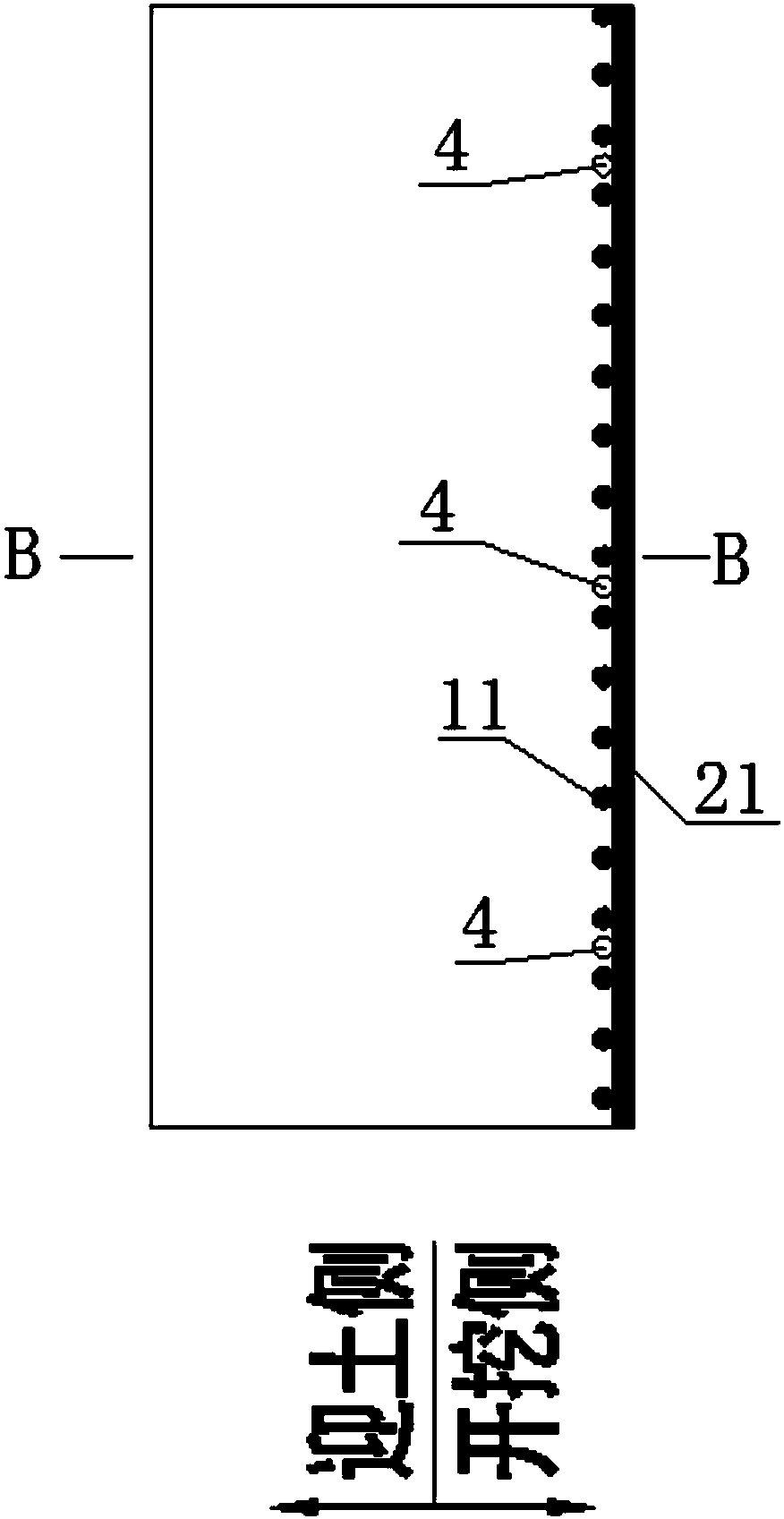

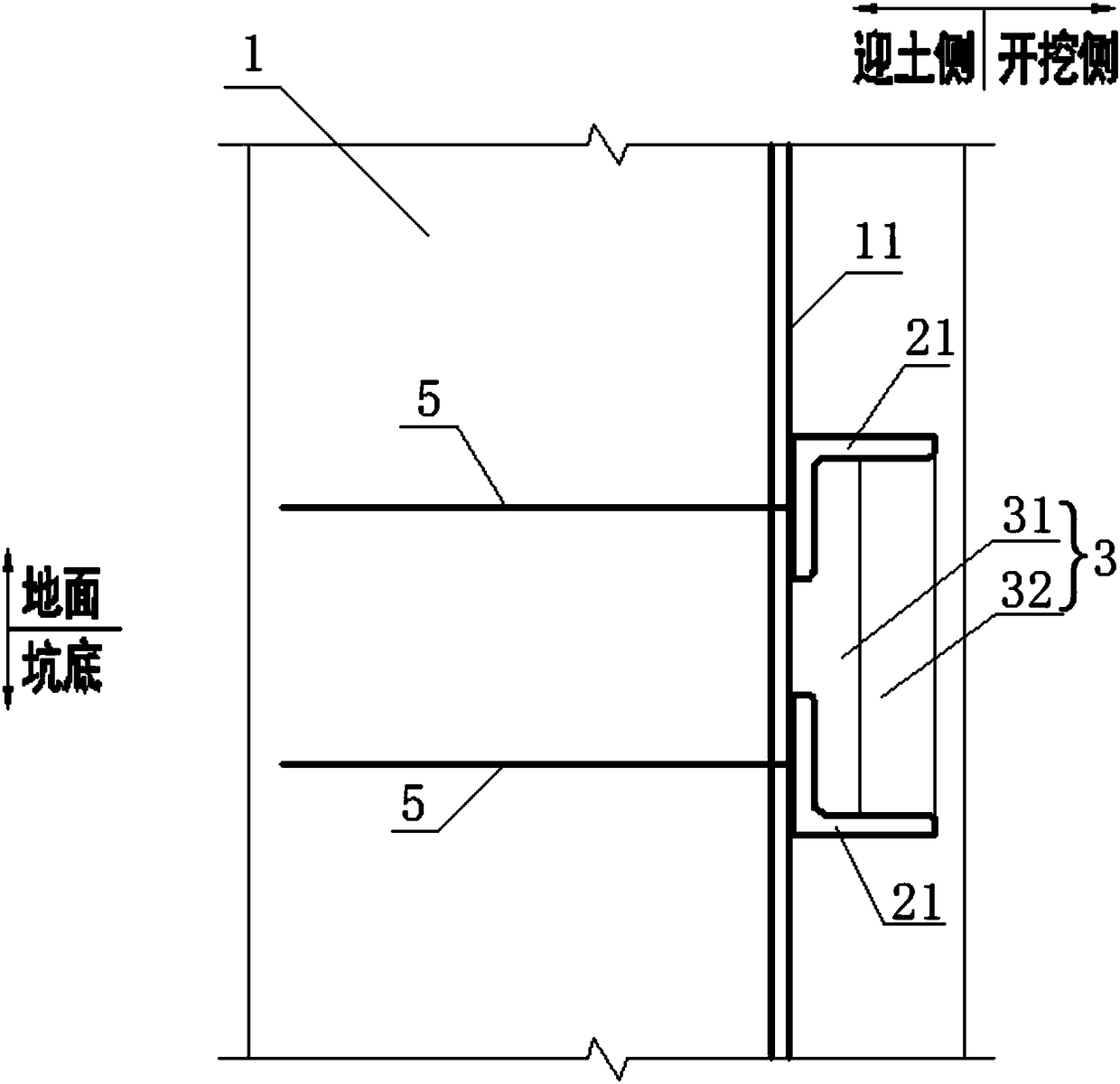

[0035] Such as figure 1 , figure 2 , image 3 with Figure 4As shown, a shear groove structure used for underwater concrete bottom sealing includes a foundation pit excavated on the ground, and the foundation pit is surrounded by an enclosure structure 1 higher than the ground, and also includes a pair of angle steels 2, a transition Plate 3 and a plurality of pre-buried flushing pipes 4, the pair of angle steels 2 are arranged around the inside of the enclosure structure 1 at intervals, and the two angle steels 21 of the pair of angle steels 2 are arranged at opposite intervals, and are respectively located on the upper and lower sides of the ground On both sides, two rows of anchoring reinforcement bars 5 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com