Equipment fabricated beam foundation and construction method thereof

A beam-type foundation and prefabricated technology, applied in the field of equipment-assembled beam-type foundation and its construction, can solve the problems of large amount of concrete, many wet operations on site, long construction period, etc. Build fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

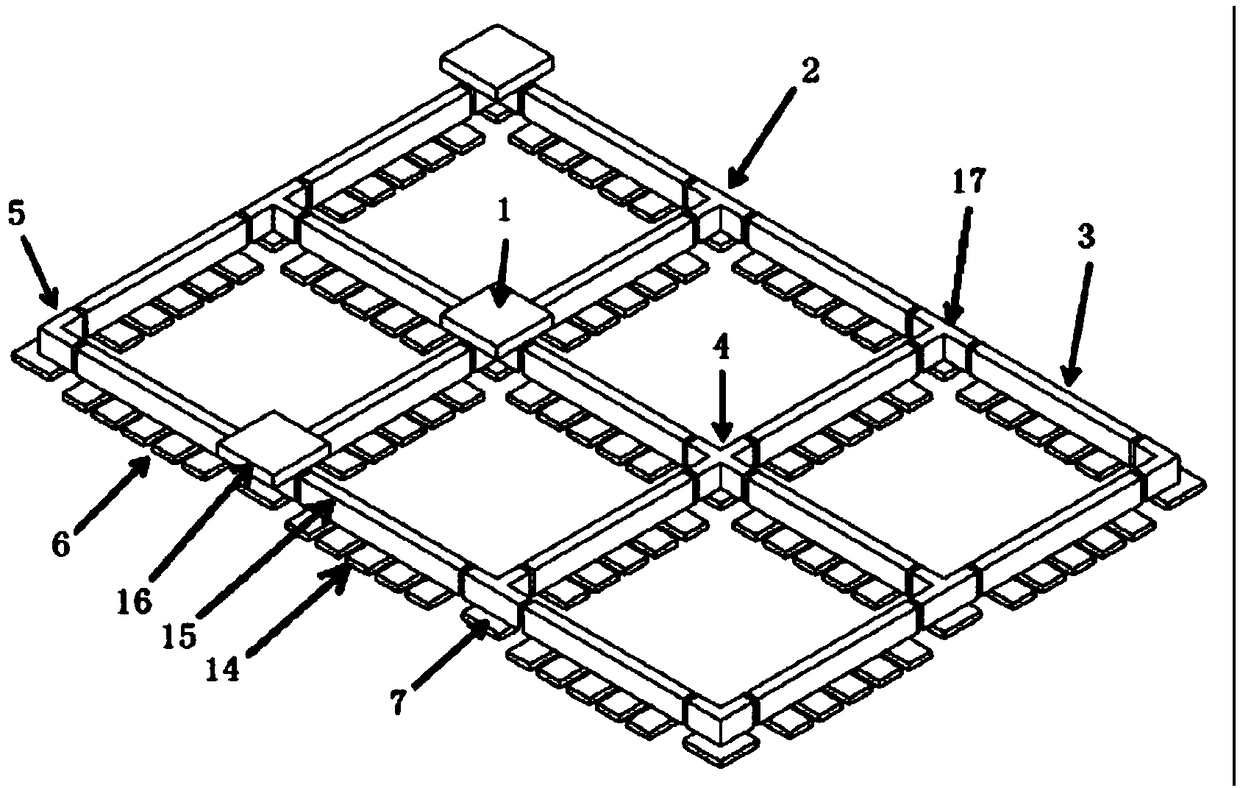

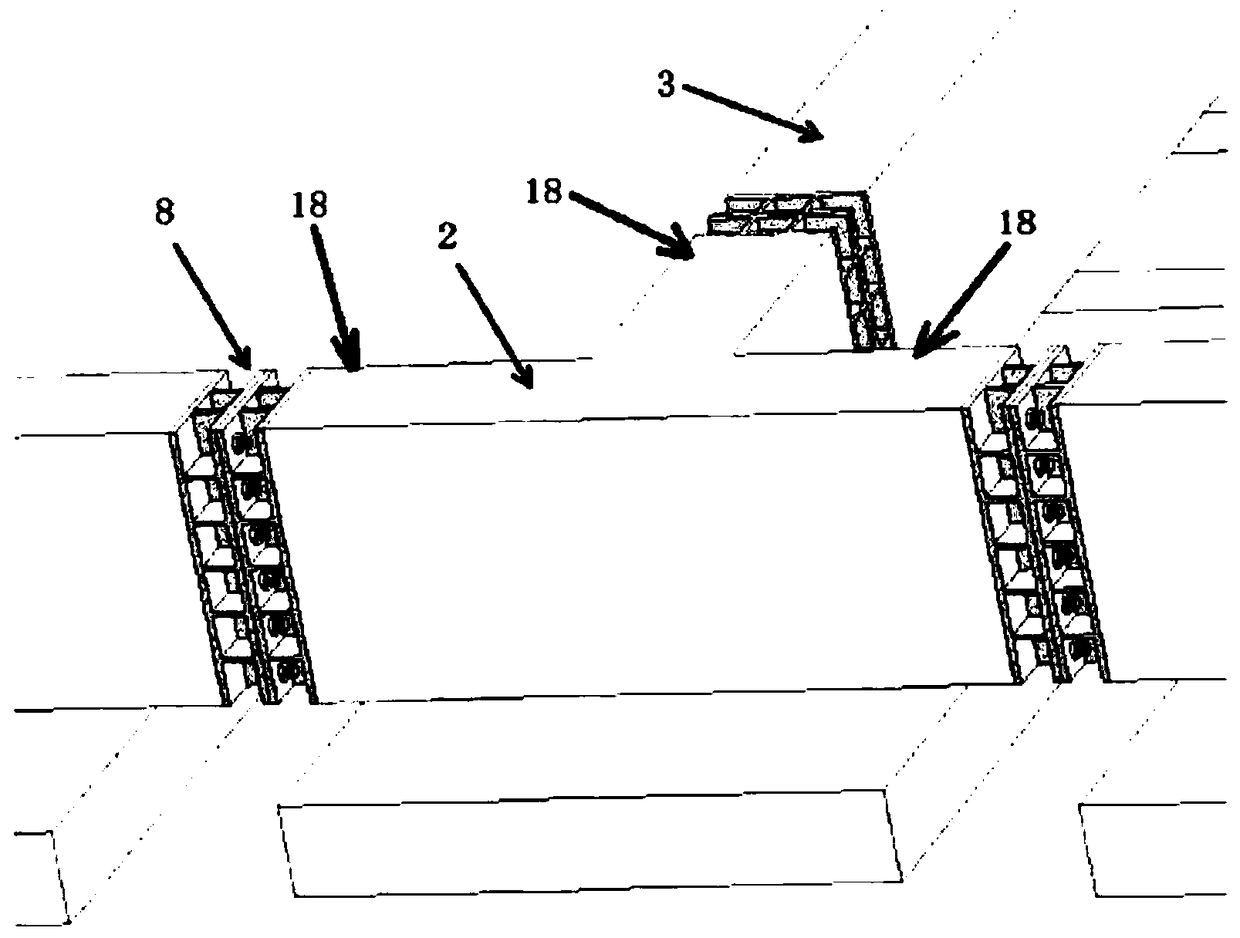

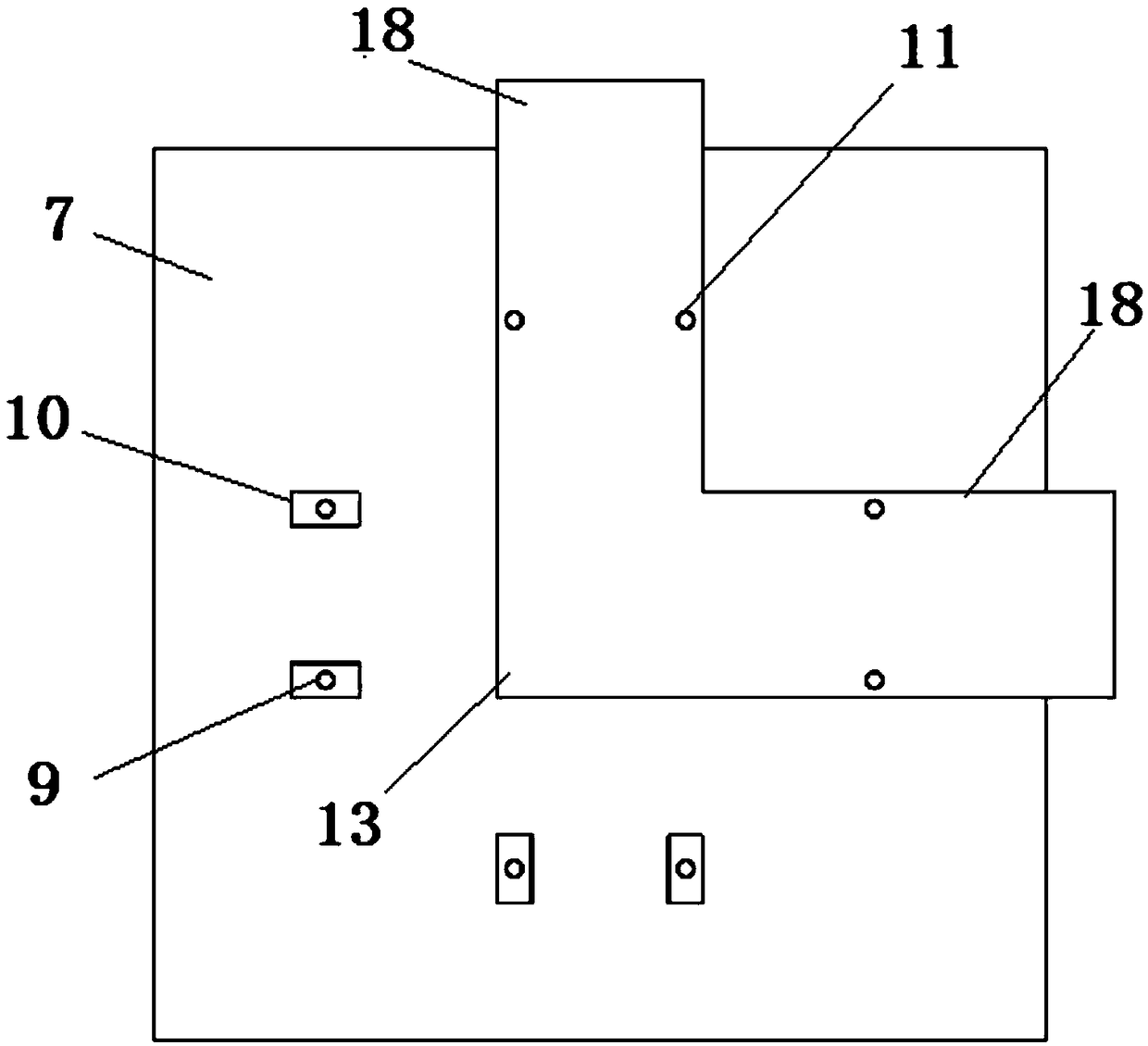

[0038] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 The equipment-assembled beam foundation shown in , is provided with a floor layer 14, a connecting beam layer 15, and an abutment layer 16 in sequence from bottom to top, and each layer of components is assembled and spliced by modular components on site. Modular components can be prefabricated in concrete or in other materials. After modularization, the specifications of each component are standardized, and the volume is small, which is convenient for any replacement of the same model during transportation and on-site assembly, thus greatly reducing the cost of materials.

[0039] The bottom plate layer 14 is spliced piece by piece by the modular straight beam bottom plate 6 and the node beam bottom plate 7, as figure 1 In the embodiment, the straight beam bottom plate 6 can be a rectangular prefabricated plate, and the node beam bottom plate 7 can be a square p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com