Patents

Literature

61results about How to "Reduce settlement difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low implantation line double-wire section terminal spine type bearing rail beam limiting structure in medium and low speed magnetic levitation transportation engineering

InactiveCN105887586AAvoid the problem of uneven track surfaceIncrease lateral frictionBallastwayLow speedRebar

The invention discloses a low implantation line double-wire section terminal spine type bearing rail beam limiting structure in medium and low speed magnetic levitation transportation engineering. The limiting structure comprises bearing rail beam lower subgrade filling, a bearing rail beam underlayer, two adjacent sections of bearing rail beams, vertical slab staggering prevention lapping plates, horizontal slab staggering prevention bosses and a bearing rail beam backfill material, wherein the vertical slab staggering prevention lapping plates are fixedly arranged on the bearing rail beam lower subgrade filling, and the lower ends of the vertical slab staggering prevention lapping plates stretch into the bearing rail beam lower subgrade filling. According to the invention, slab staggering prevention reinforced concrete lapping plates are arranged at bearing rail beam section positions, the bearing rail beam is arranged on the same reinforced concrete slab staggering prevention plate with a certain rigidity, and the problem that the rail surface is unsmooth due to differential settlement of the bearing rail beam lower subgrade is effectively solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

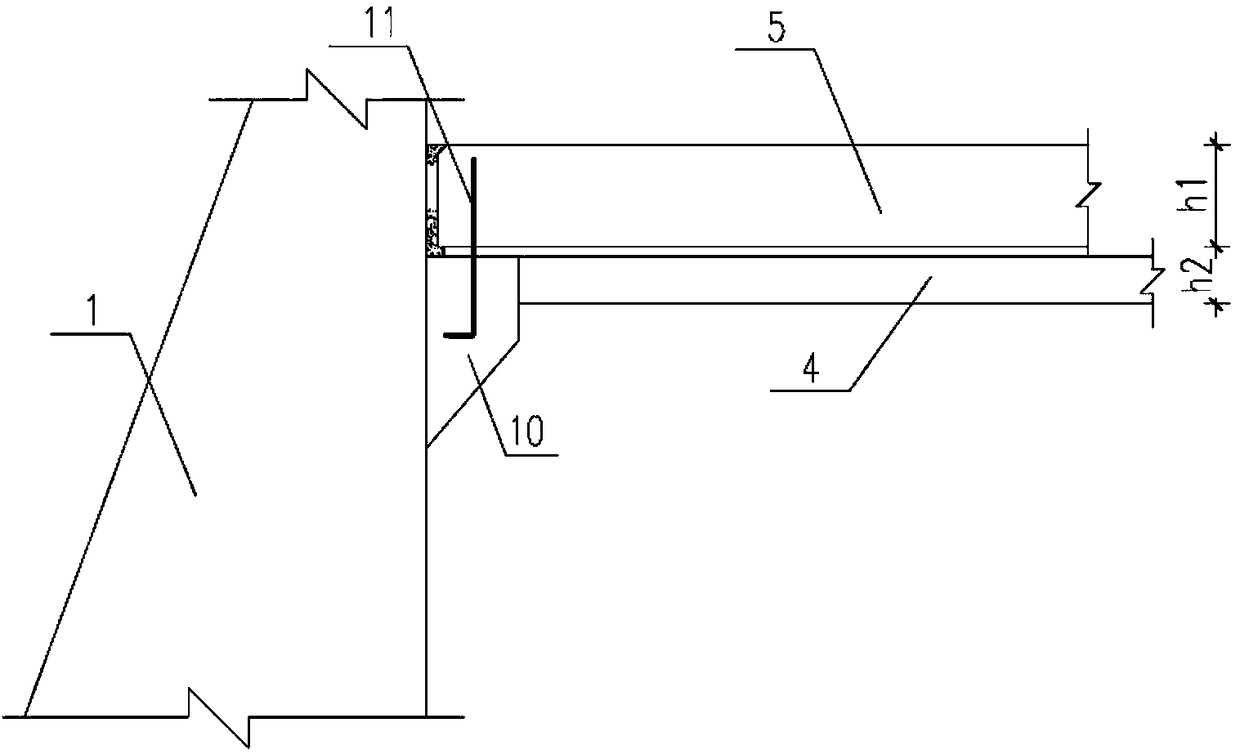

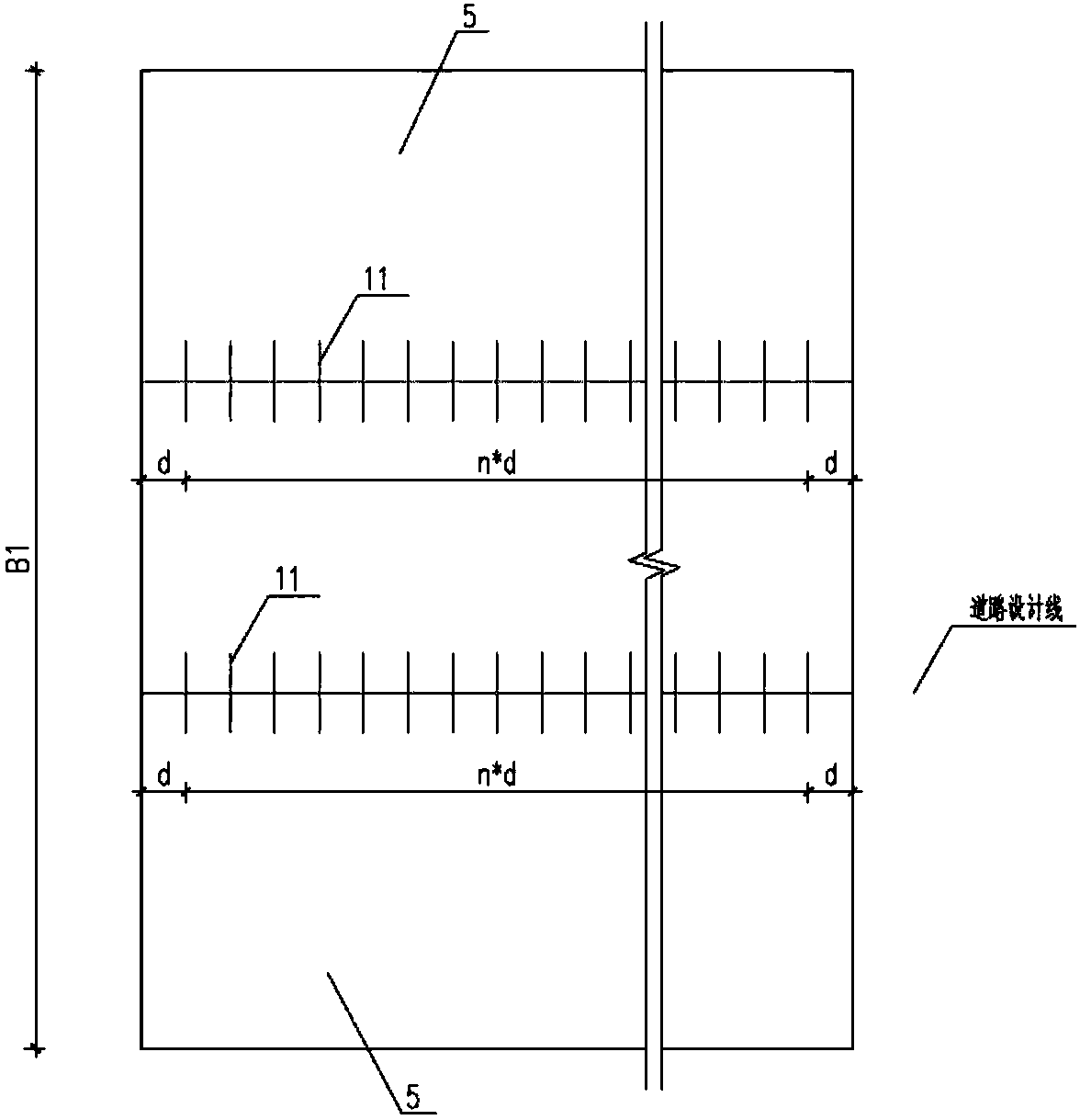

Roadbed reinforcement structure for preventing vehicle bump at bridge head and construction method thereof

InactiveCN108999045AAlleviate or solve disease problemsImprove bearing capacityRoadwaysAbutmentSubgrade

The invention discloses a roadbed reinforcement structure for preventing vehicle bump at bridge head, comprises an anti-settling plate arranged at the middle position of the bridge abutment and the backfill area behind the bridge abutment, wherein the anti-settling plate is connected with the bridge abutment rib plate through the brackets, a lower backfill area is arranged below the anti-settlingplate, an upper backfill area is arranged above the anti-settling plate, and a side of the anti-settling plate far away from the bridge abutment is a general roadbed backfill area. The invention alsodiscloses a construction method of a roadbed reinforcement structure for preventing vehicle bump at a bridge head. In the invention, the anti-settlement plate separates the backfill behind the abutment into two layers, reduces the height of the backfill behind the abutment, further reduces the settlement difference between the rigid abutment structure and the flexible embankment, strictly controlsthe compactness of the backfill on the abutment, thereby achieving the purpose of eliminating the uneven settlement between the abutment and the embankment, and effectively preventing the vehicle bump phenomenon at the bridge head.

Owner:WISDRI ENG & RES INC LTD +1

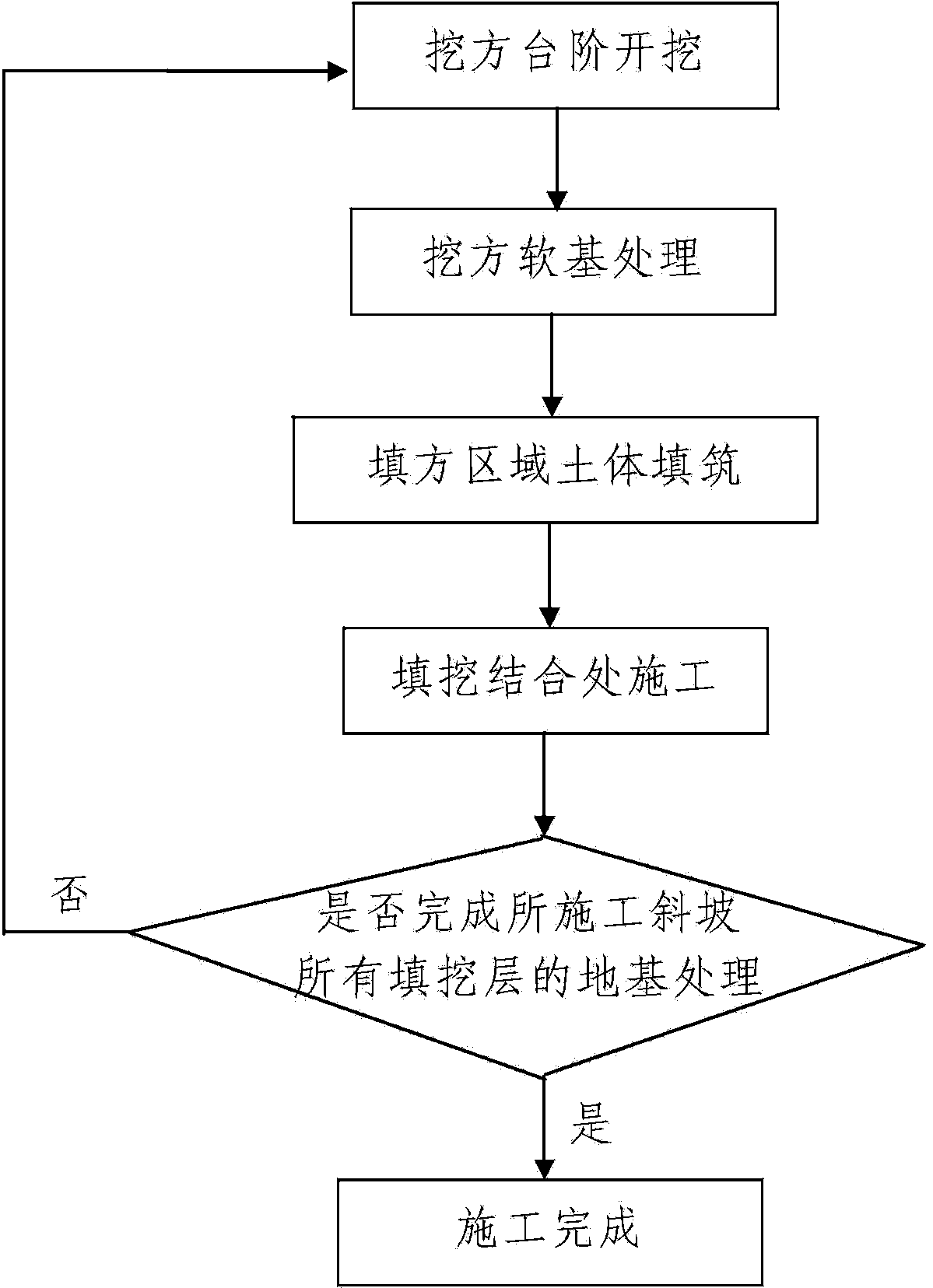

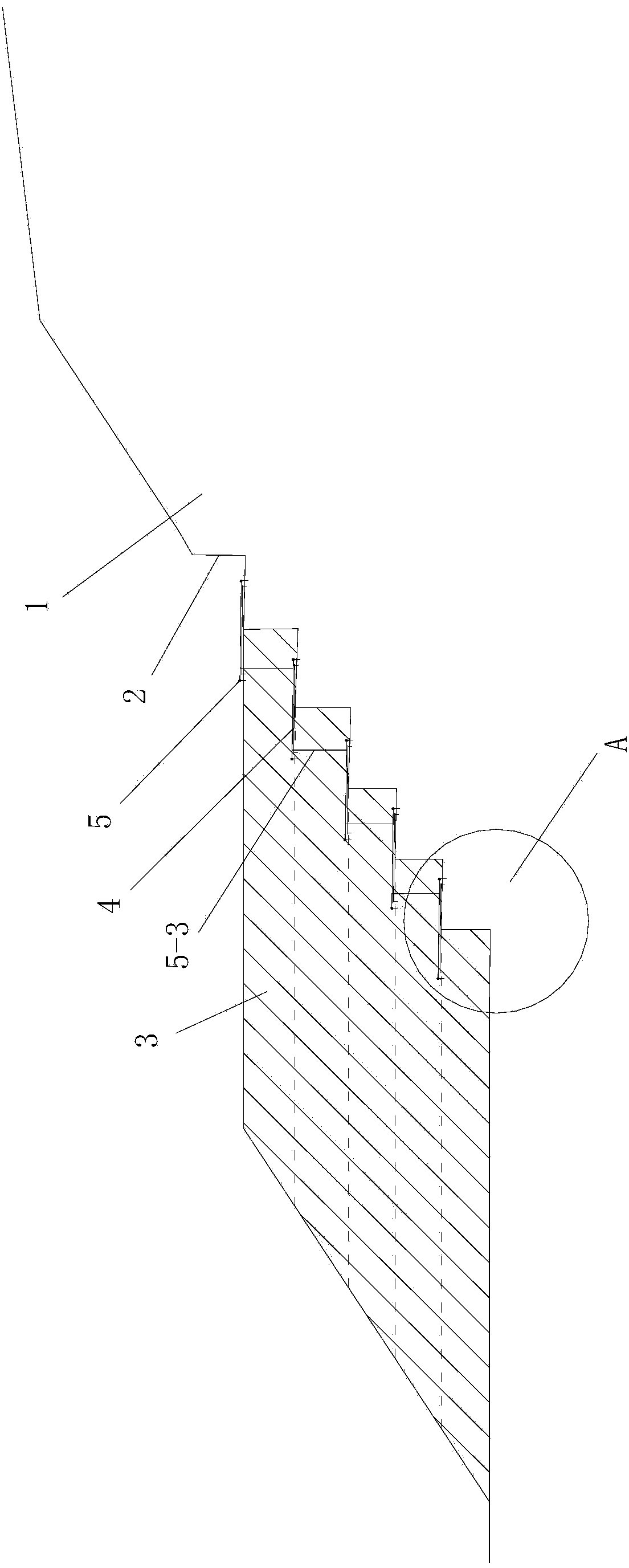

Foundation treatment method of collapsible loess slope cut-and-fill joint part

InactiveCN104264680AThe method steps are simpleSimple and fast operationEmbankmentsExcavationsTreatment effectEngineering

The invention discloses a foundation treatment method of a collapsible loess slope cut-and-fill joint part. The cut-and-fill joint part of a constructed slope is subjected to foundation treatment by M cut-and-fill layers from top to bottom, and a cut-and-fill layer at the bottom of the M cut-and-fill layers is a bottom cut-and-fill layer. The foundation treatment method of the collapsible loess slope cut-and-fill joint part includes a bottom cut-and-fill layer foundation treatment step, a last cut-and-fill layer foundation treatment step and a once or twice repeating step. The bottom cut-and-fill layer foundation treatment step includes excavating a cut step, treating a soft cut foundation and a fill foundation, building a fill area soil body and constructing the cut-and-fill joint part, wherein the construction process of the cut-and-fill joint part includes mounting a geogrid and constructing a rigid connection framework. The once or twice repeating step includes repeating the former two steps until the foundation treatment process of the M cut-and-fill layers is completed. The foundation treatment method is simple in steps, convenient to implement, good in foundation treatment effect and capable of solving the problem that joint effect of cutting and filling of the existing collapsible loess slope cut-and-fill joint part is poor and differential settlement of the cut-and-fill joint part is easy to cause and the like.

Owner:XIAN UNIV OF SCI & TECH +1

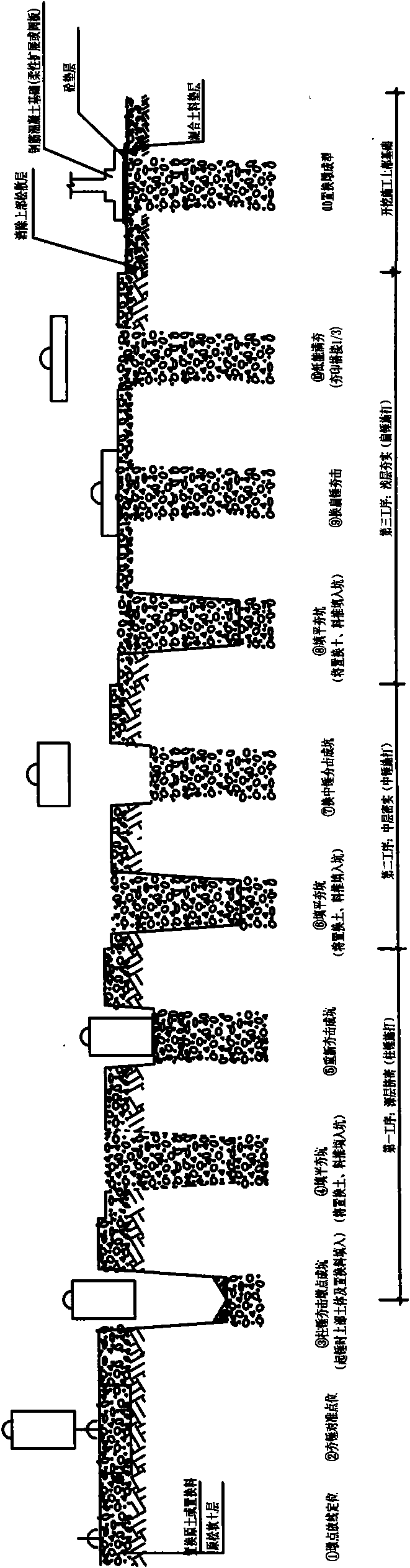

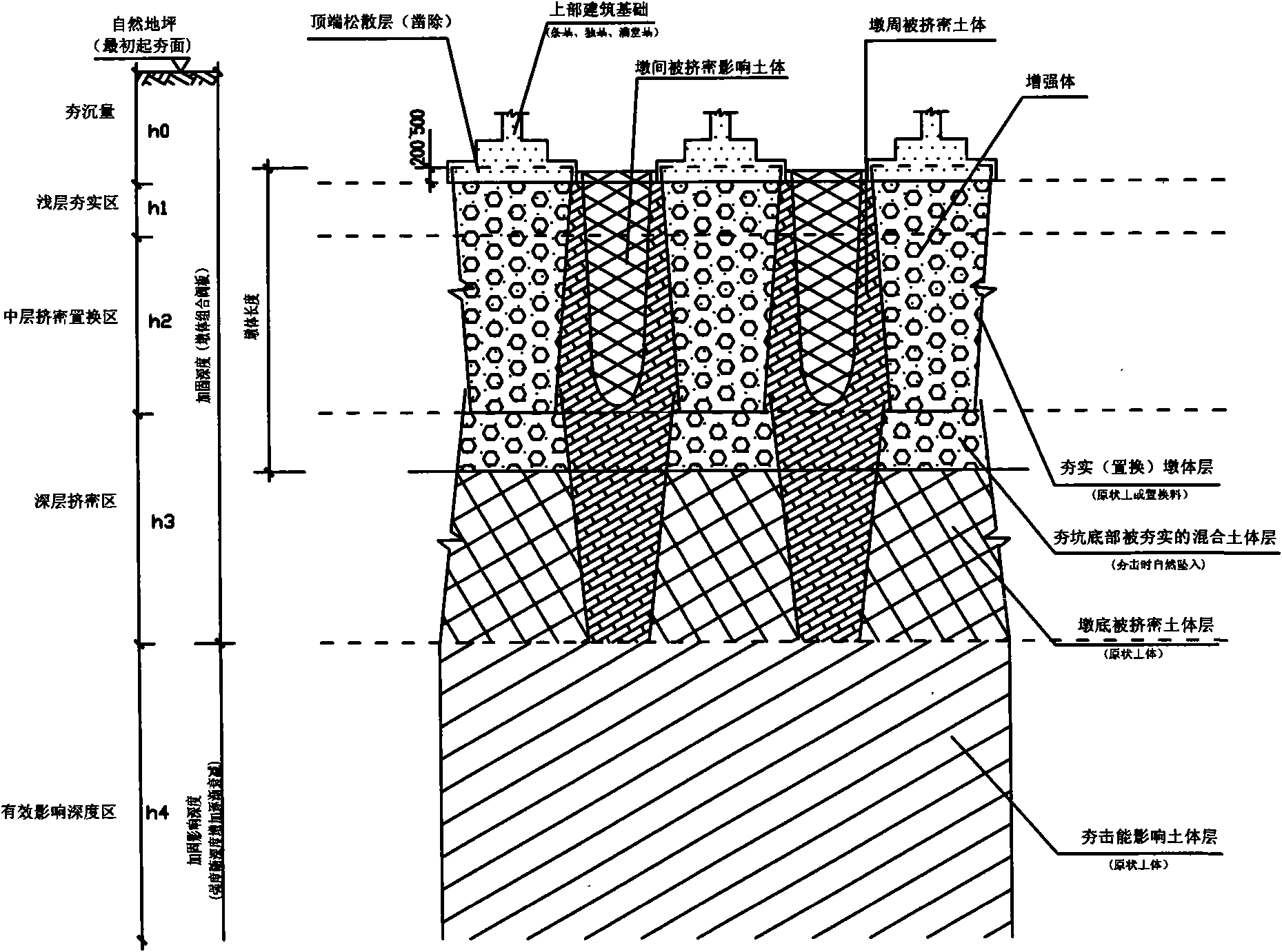

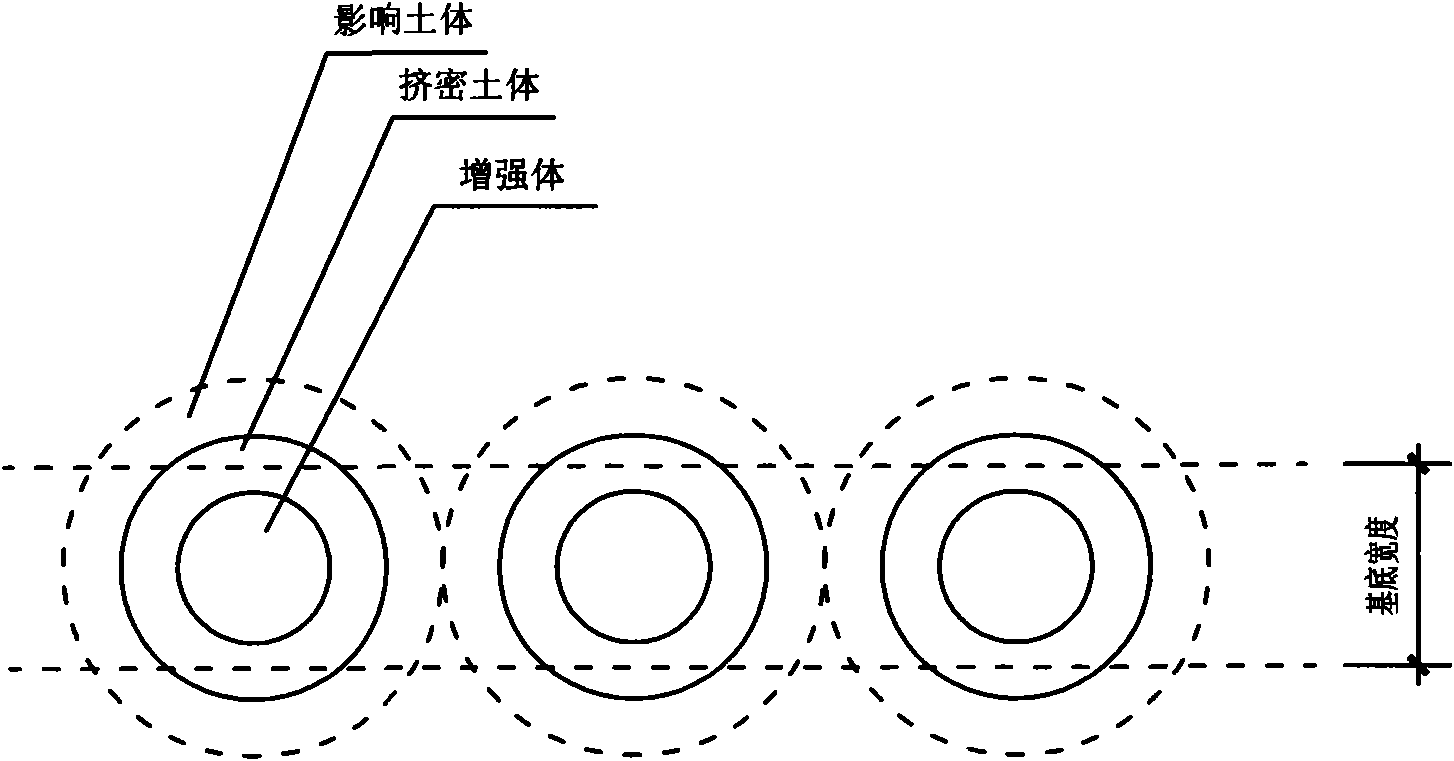

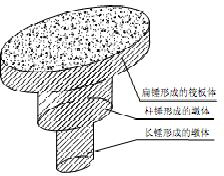

Method for treating foundation by combined hammers

The invention discloses a method for treating foundation by combined hammers. Three hammer bodies, including a column hammer, a middle hammer and a flat hammer which are of different shapes, intensities of pressure and specific gravities, are utilized for tamping loose foundation soil layer by layer according to certain programs and technical requirements, so as to realize the aim of consolidating the foundation soil in deep, middle and superficial layers. Compared with the common heavy-tamping method and other pile work composite foundation treatment methods, the method of the invention can make the effective consolidation depth and the reinforced effect of compacting soil among piers prominent and can treat the loose and soft foundation soil of which the thickness reaches nearly 20 meters, the depth and the diameter of a tamped pit can be respectively adjusted, and the tamped pit can be backfilled with original soil or other replacement materials to form a tamped pier or a replacement pier; and therefore the bearing capacity of the foundation can be greatly improved, and the settling amount and the differential settlement of buildings can be directly reduced. The method can fully utilize various on-site soil materials and utilize huge amounts of waste skeletal materials of construction waste from city removal, reduce the cost of treating the foundation and save high energy consumption materials (rolled steel products and cement), and has obvious effects of environment protection and energy conservation.

Owner:刘献刚

Extradeep extruding and ramming method

InactiveCN1441122ASolve the technical problem of poor dynamic compaction effectImprove efficacySoil preservationSoil horizonEngineering

The extradeep extruding and ramming method includes leveling ground, the first spot ramming, the second spot ramming and final widespread ramming. The said reinforcing ramming process can raise effect strengthening depth by over one time without needing raising single-ramming power and elevating power of rammer compactor, raise foundation strength and stability, decrease settling volume, raise bearing capacity and reach the effects of extradeep extrusion and deep replacement. The present invention provides simplest construction method for reinforcing deep soft ground.

Owner:SPECIAL SOFT FOUND BRANCH NO 2 CONSTR ENG CO LTD NANCHANG COUN

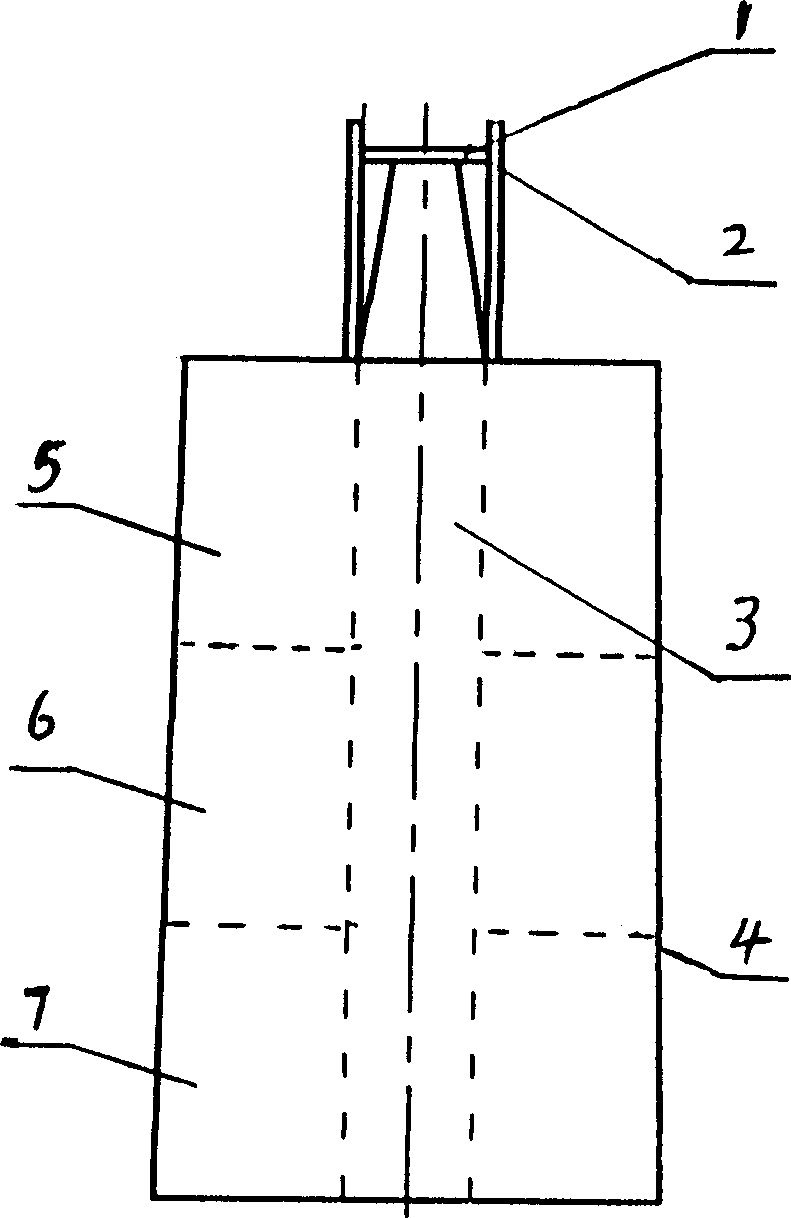

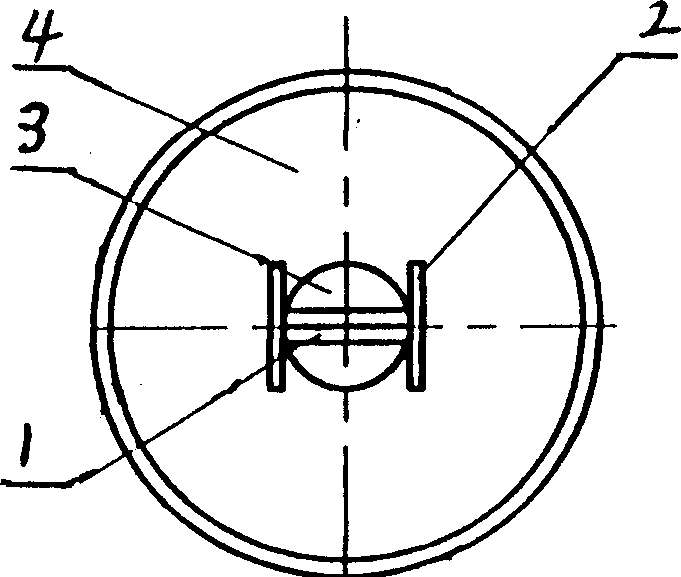

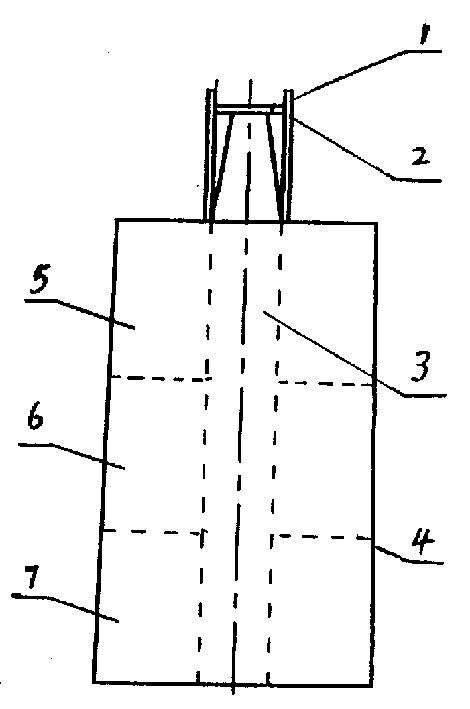

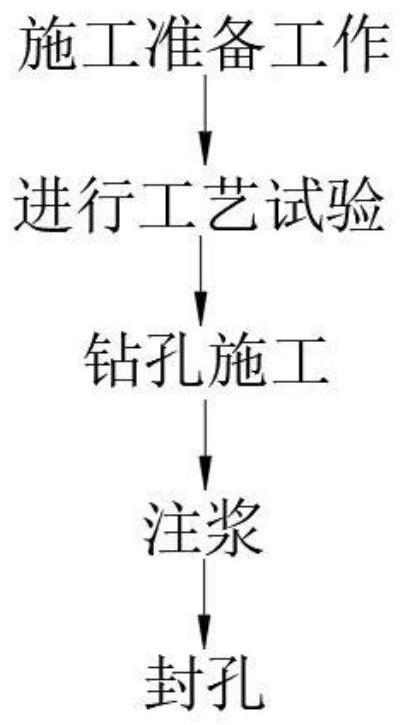

Subway foundation pit deep-buried karst cave treatment method

PendingCN113186924AReduce settlement differenceSatisfy operational securityFoundation engineeringArchitectural engineeringKarst

The invention discloses a subway foundation pit deep-buried karst cave treatment method, and relates to the field of foundation pit karst cave construction. The treatment method comprises the following steps: S1, carrying out construction preparation work, specifically, mastering and knowing the karst grouting project general situation of a construction area, and carrying out construction site leveling, surveying and setting out and settlement observation pile arrangement; S2, carrying out a process test, determining a filling material and a grouting material of the karst cave and proportioning parameters of the grouting material, selecting a proper filling material, and preparing grouting slurry; S3, carrying out drilling construction, and carrying out construction edge detection on the karst cave to determine the type of the karst cave and the position of a hole; S4, carrying out grouting construction; and S5, carrying out hole sealing, specifically, cleaning a sleeve valve grouting pipe, installing a sealing device at the end of the hole, and after the grouting quality of the karst cave is checked to be qualified, carrying out hole sealing and treatment on the karst cave. According to the method, 'head falling' and 'collapse' of shield construction can be prevented, excessive ground surface settlement or collapse accidents can be prevented, post-construction settlement difference is reduced, and operation safety is met.

Owner:CHINA RAILWAY 25TH BUREAU GRP +1

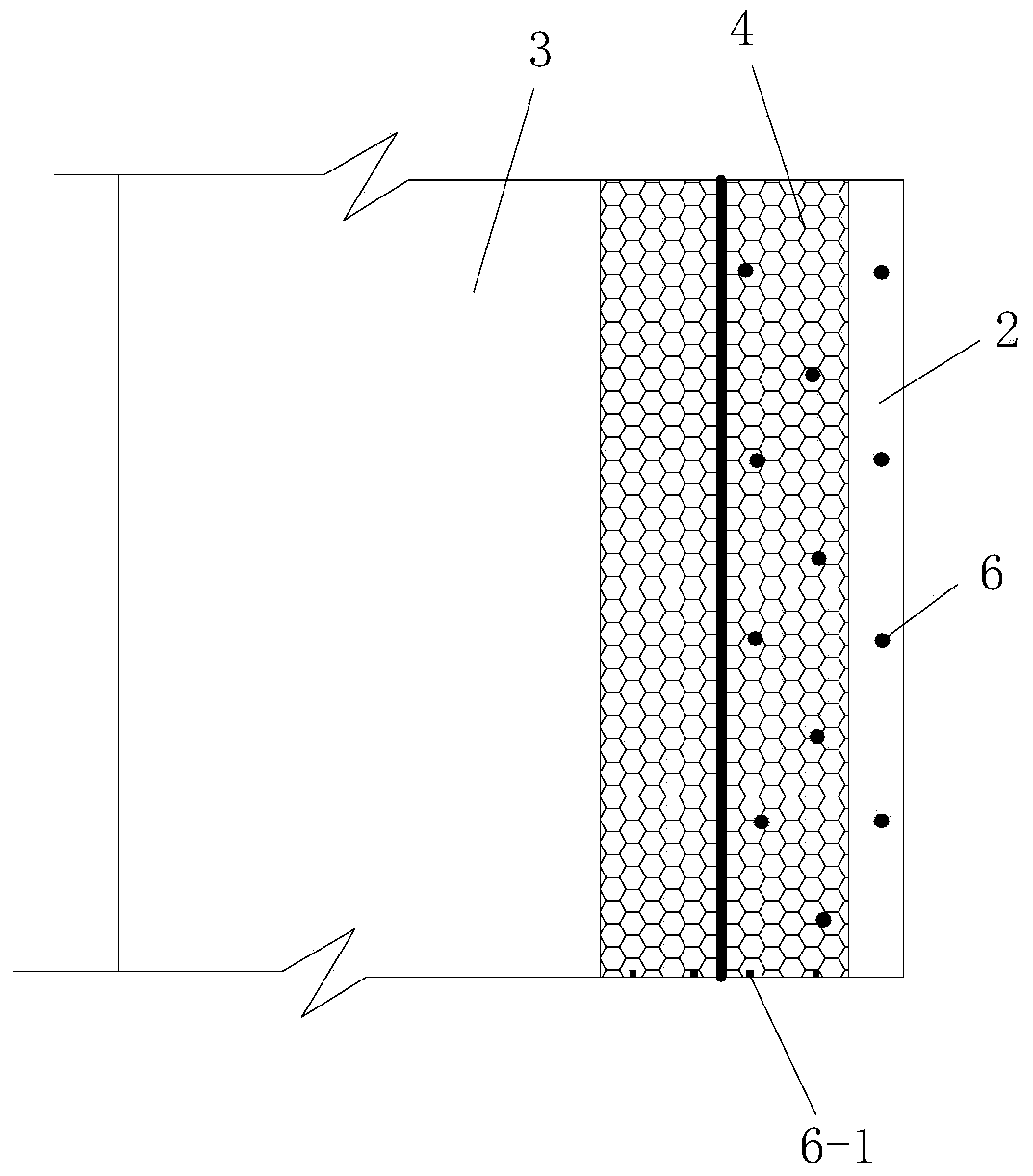

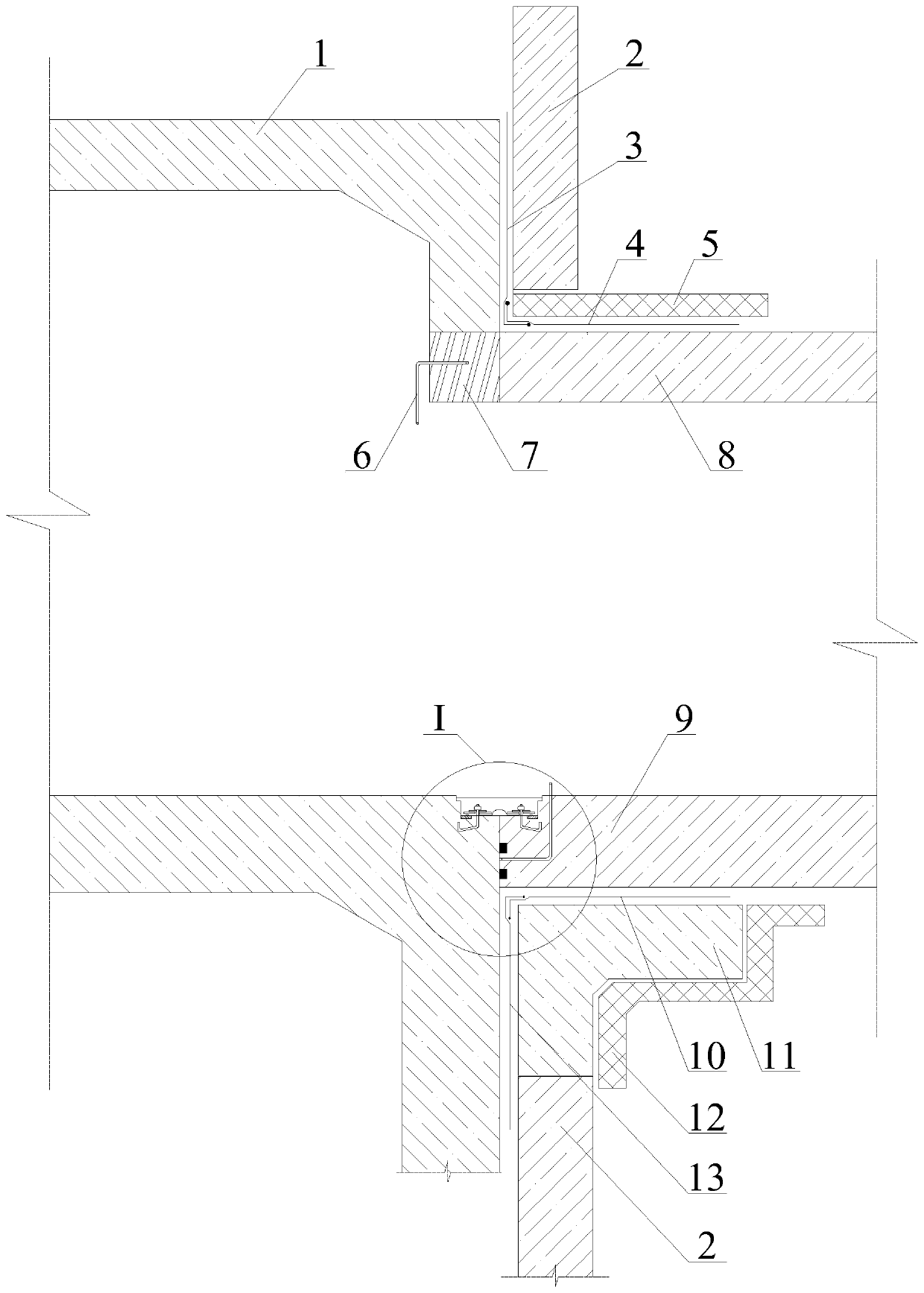

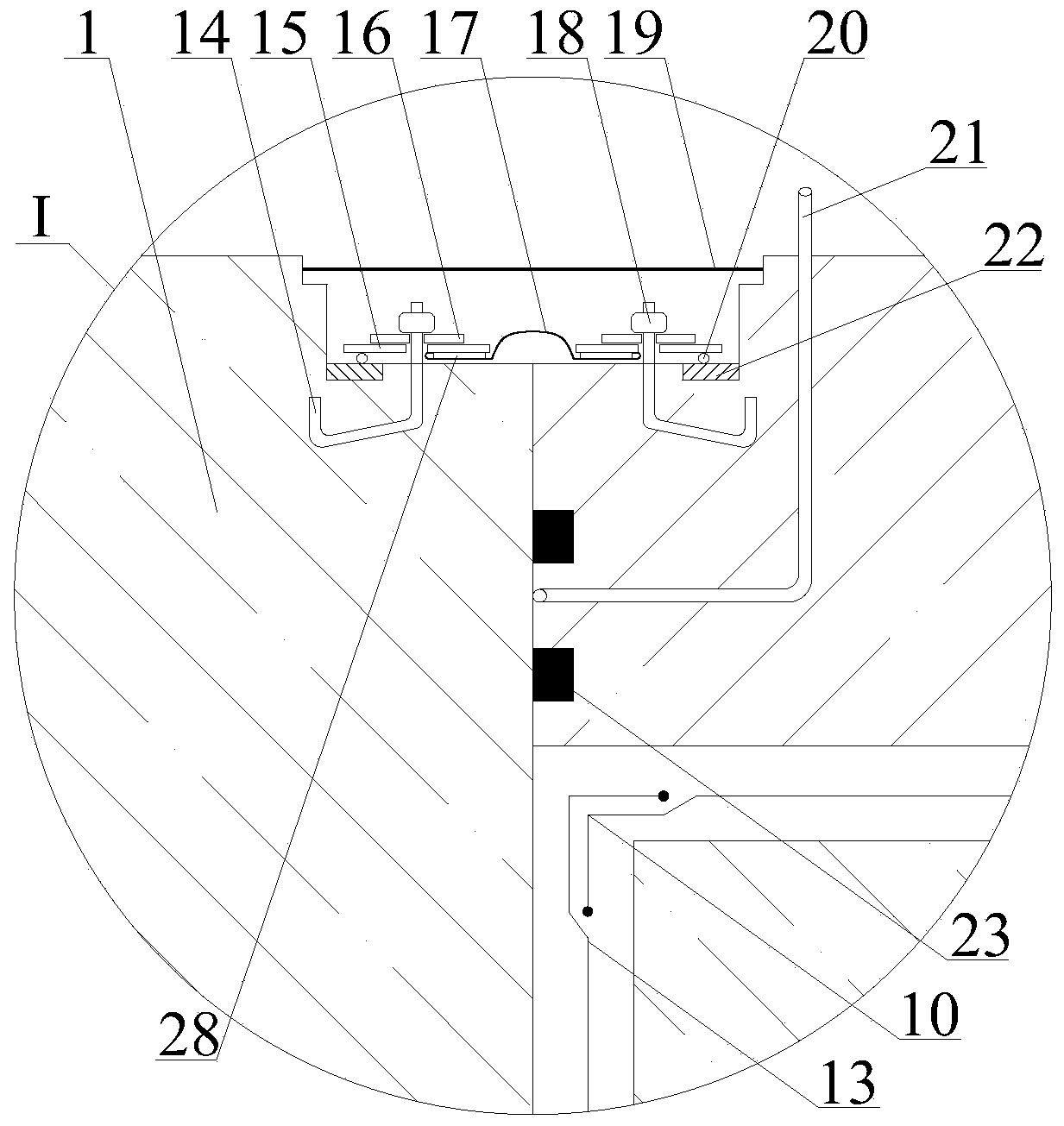

Waterproof structure at joint between station body and auxiliary passage as well as construction method

PendingCN110374138ASolve the waterproof problemPrevent immersionArtificial islandsUnderwater structuresReinforced concreteWater leakage

The invention belongs to the technical field of urban rail transit engineering construction, and particularly relates to a waterproof structure at a joint between a station body and an auxiliary passage as well as a construction method. The waterproof structure at the joint between the station body and the auxiliary passage comprises a station body structure and an auxiliary passage structure which are positioned at the joint, wherein an L-shaped precast reinforced concrete beam connected with the auxiliary passage structure and the station body structure is mounted at the bottom of the auxiliary passage structure. The construction method of the waterproof structure at the joint between the station body and the auxiliary passage comprises the following steps: the station body structure isconstructed; station body tenons are constructed on the station body structure; the auxiliary passage structure is constructed and combined with the station body tenons to form a mortise and tenon structure; and the waterproof follow-up treatment is performed and the construction is completed. Through the construction of the mortise and tenon structure as well as the mounting of the L-shaped precast reinforced concrete beam, the stiffness difference and the settlement difference between the station body structure and the auxiliary passage structure can be reduced, and the water leakage phenomenon can be avoided.

Owner:ANHUI WATER RESOURCES DEV +1

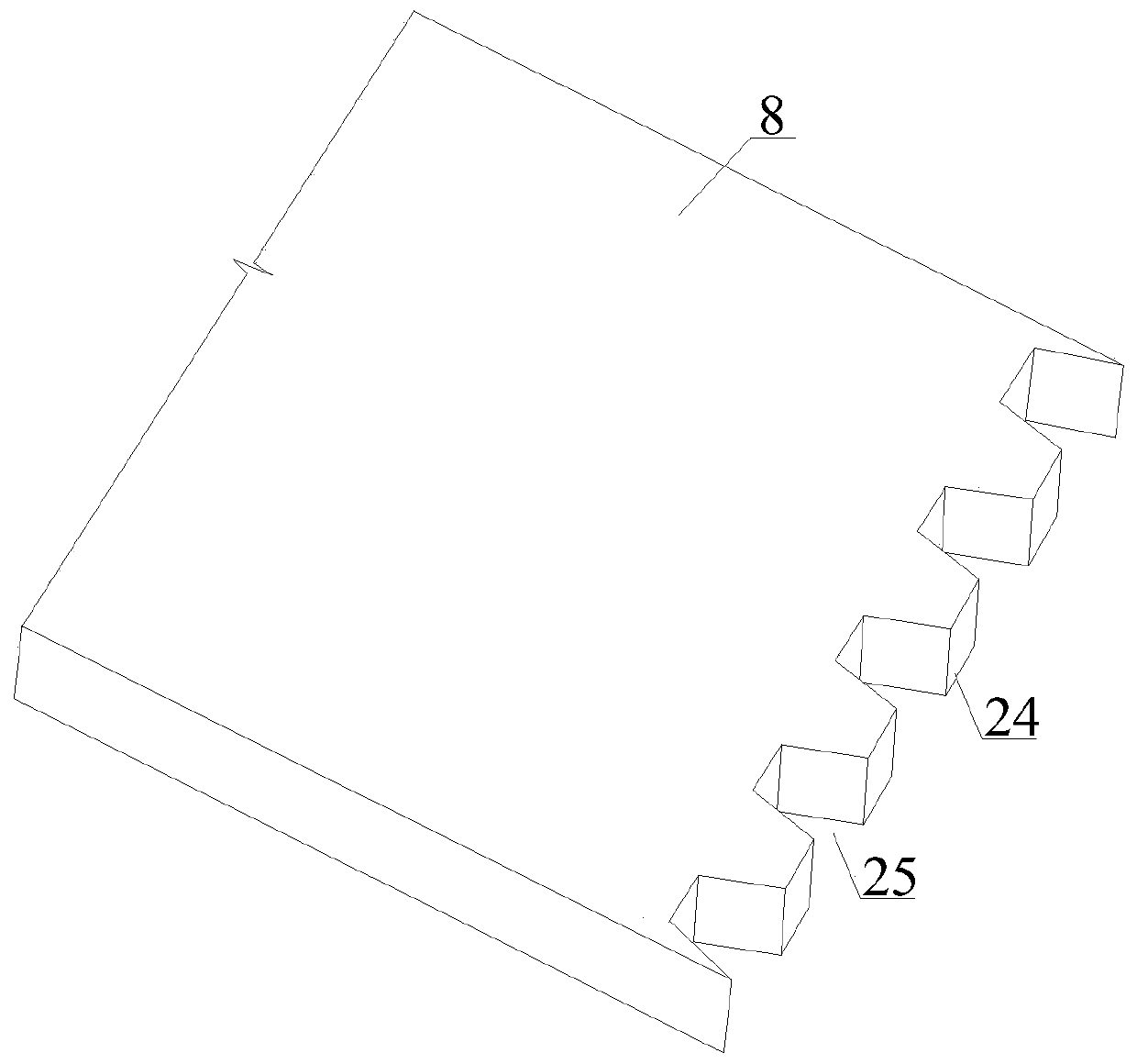

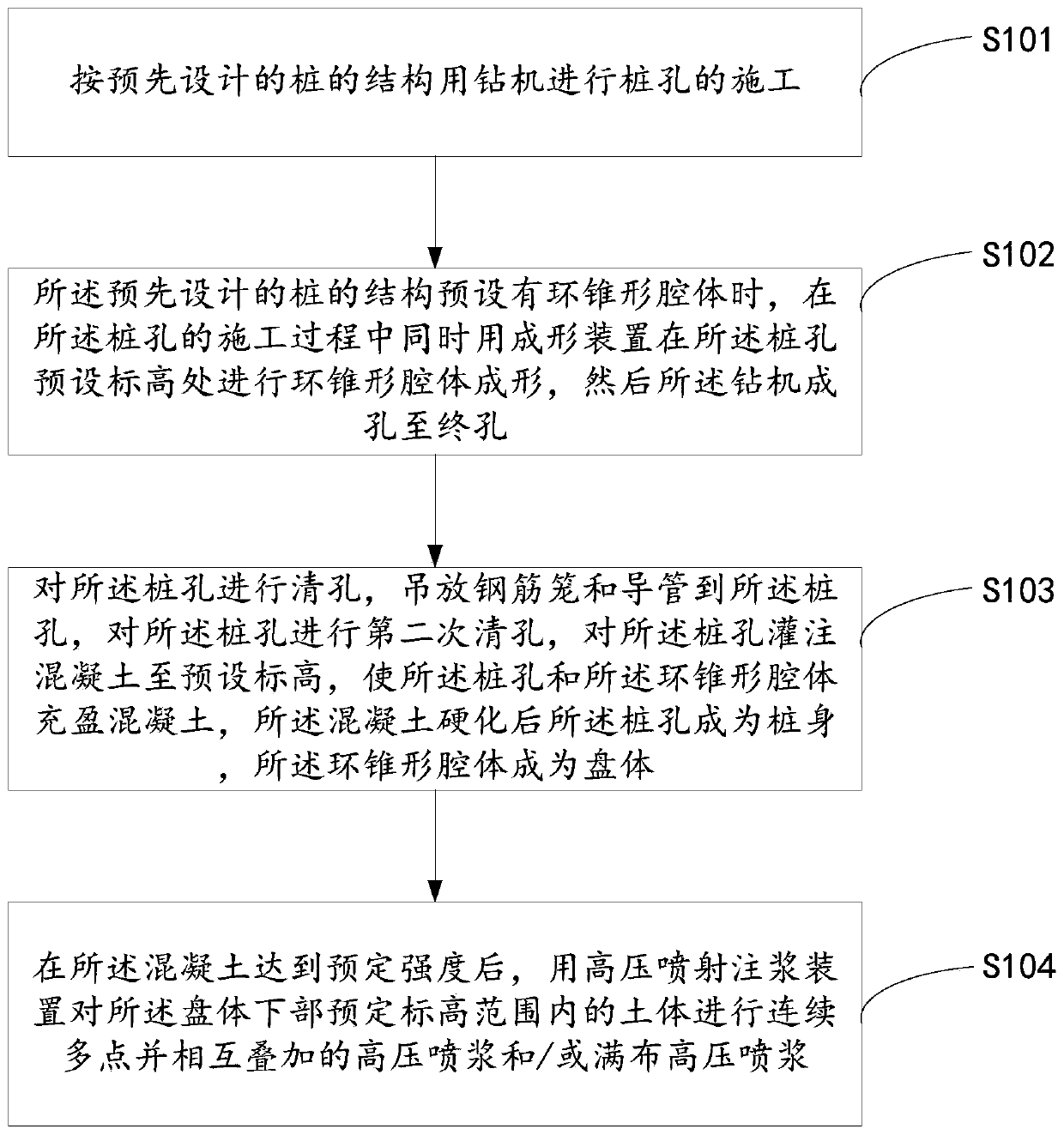

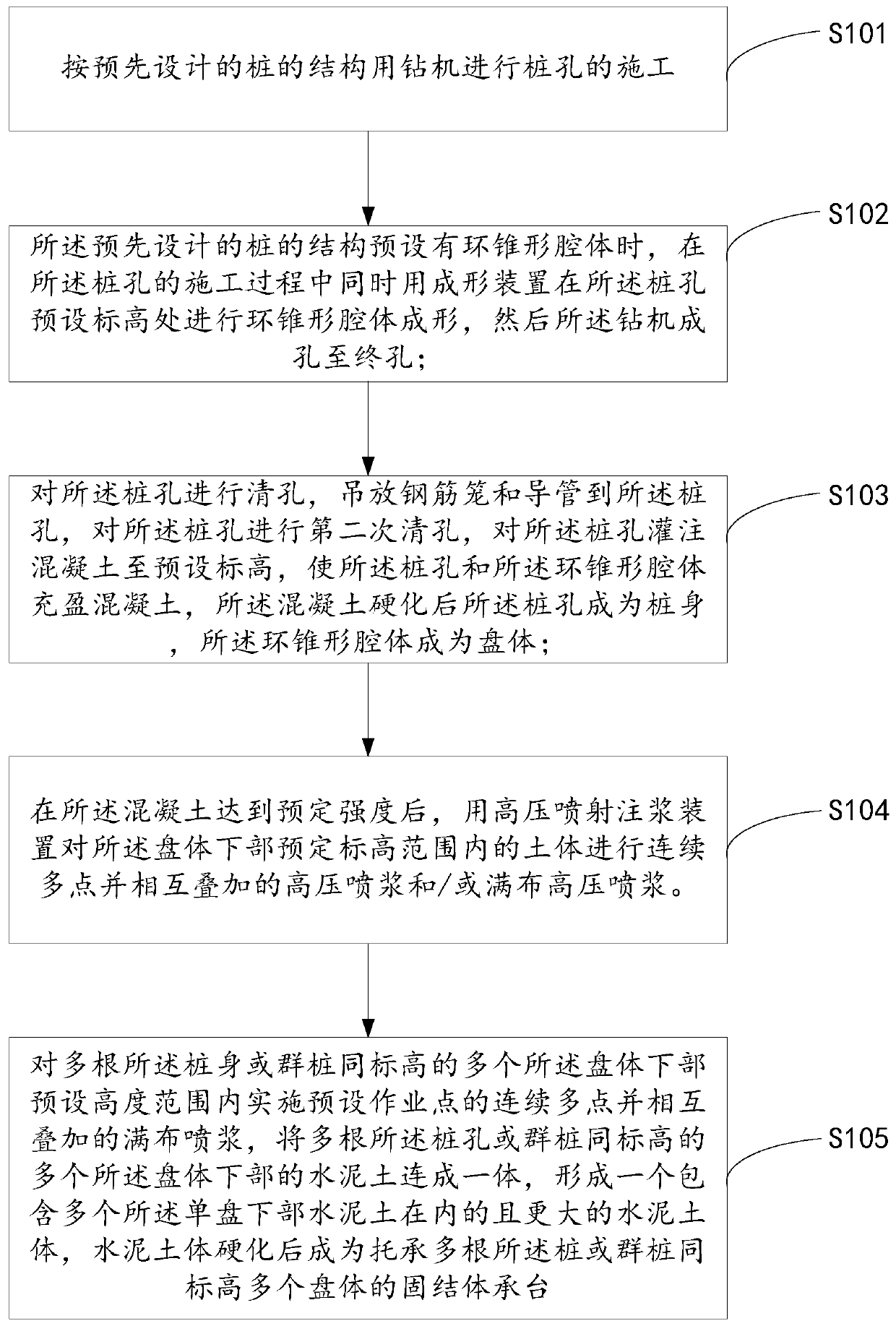

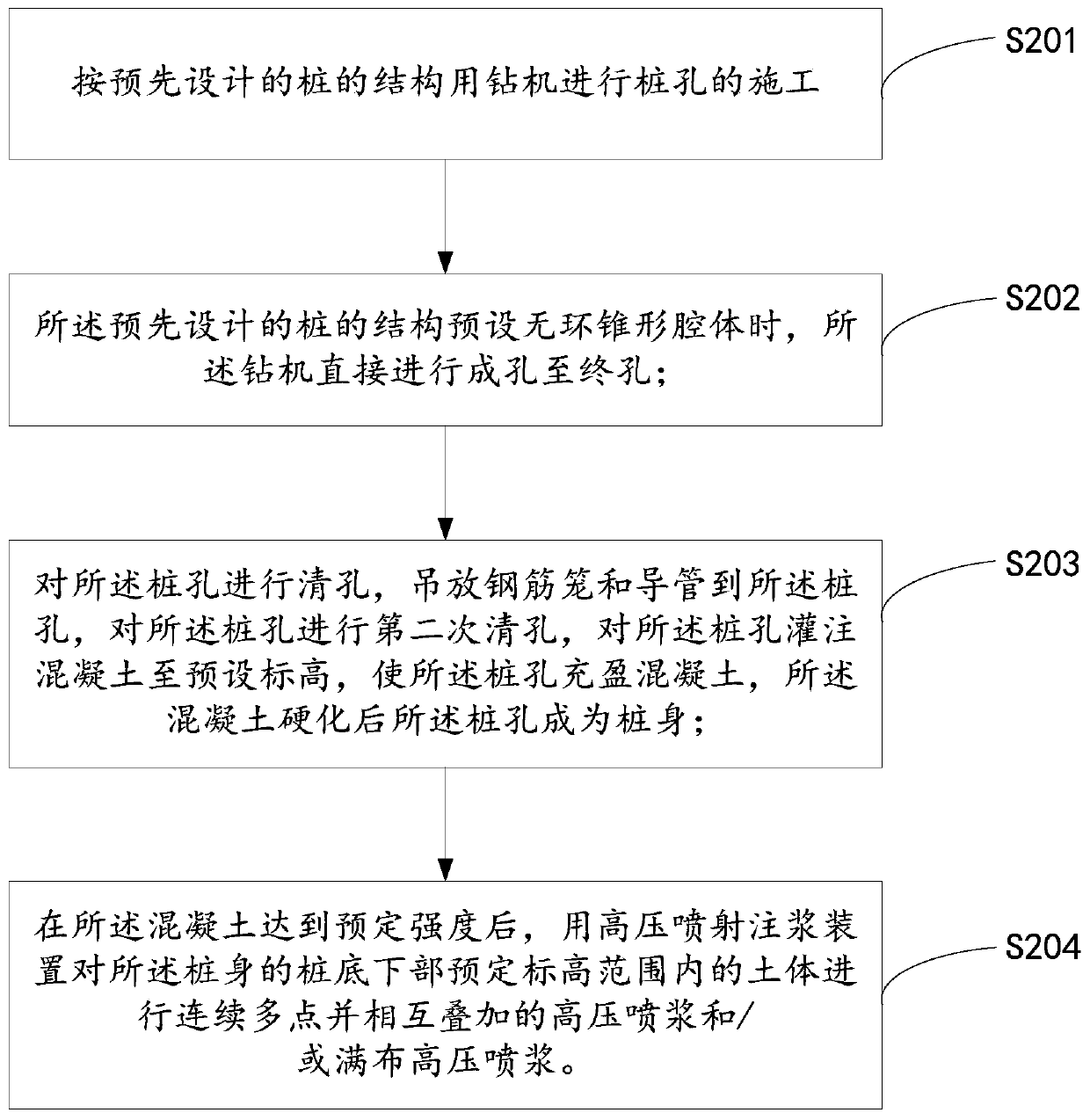

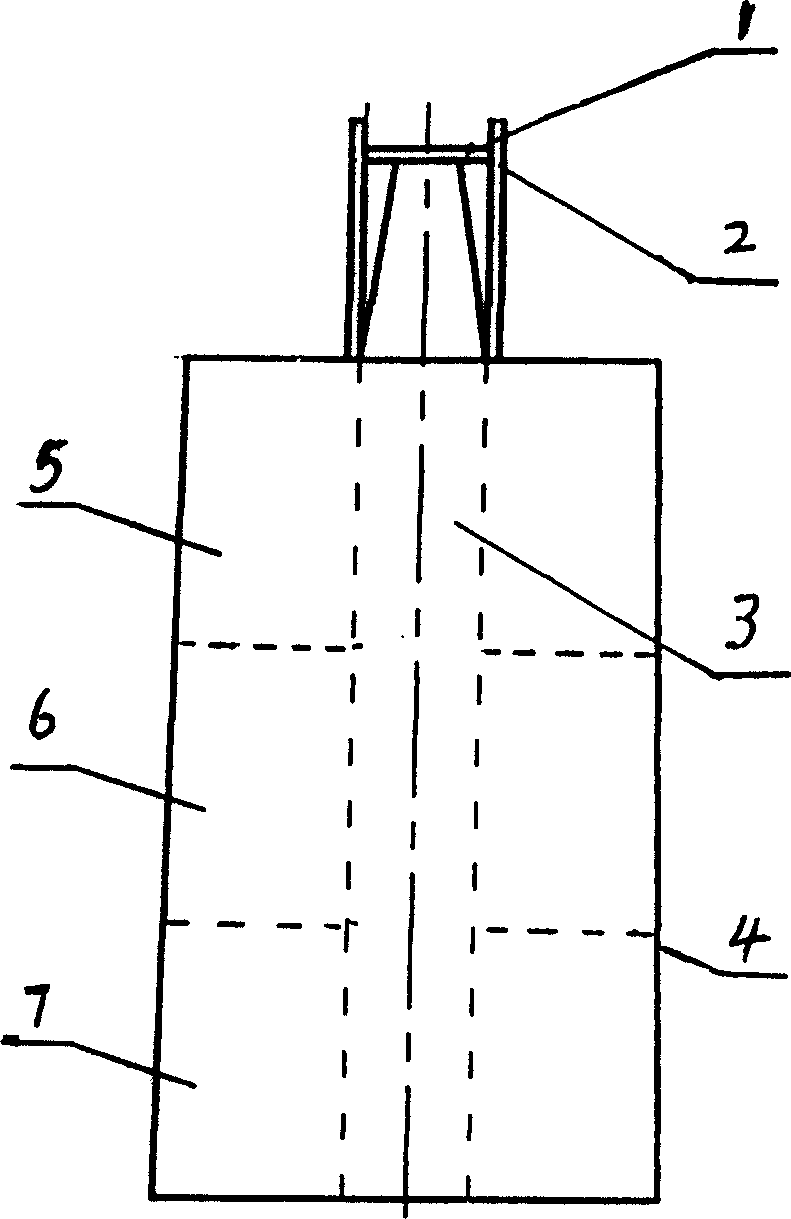

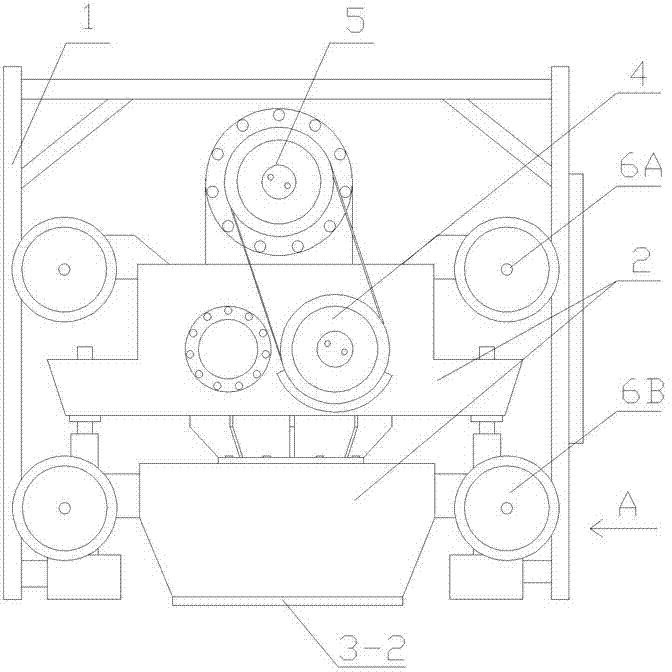

Construction method and device for cast-in-place concrete pile

ActiveCN109778847AReduced settlement differenceImprove ergonomicsBulkheads/pilesHigh pressureMulti point

The invention discloses a construction method and device for a cast-in-place concrete pile. The technology is characterized in that a preset annular conical cavity is formed in a drilling machine holeforming process; an annular conical cavity with one or more intervals along a pile hole is formed after hole drilling is completed; after hole cleaning, steel reinforcement cage lifting and placing,secondary hole cleaning and concrete pouring are carried out, the pile hole becomes a pile body, and the cavity becomes a disc body. After concrete is poured into the end hole, the pile hole of the preset ring-free conical cavity becomes a pile body; after the concrete reaches the preset strength, continuous multi-point superposition and / or full distribution of high-pressure guniting is carried out within a preset height range of the lower portion of the disc body and / or the lower portion of the pile bottom. Cement soil formed by mixing slurry and a soil body is connected into a whole throughslurry spraying; and after hardening, an integral consolidation body is formed to support a tray body (including a plurality of tray bodies) and / or a pile bottom (including a pile group bottom), so that the bearing capacity of a pile foundation is greatly improved, and sedimentation and differential sedimentation are remarkably reduced.

Owner:祝波 +1

Construction method of super high-rise building reinforced layer steel structure outrigger truss

The invention provides a construction method of a super high-rise building reinforced layer steel structure outrigger truss, belonging to the technical field of construction engineering. The method comprises the steps of construction preparation, outrigger truss processing and pre-assembly, outrigger truss lower chord member installation, floor concrete pouring, outrigger truss upper chord installation, web member installation, wall column steel bar binding, wall column formwork erection, beam plate formwork erection and steel bar binding, beam plate column concrete pouring, stress monitoring and analysis, web member post-welding, finishing coat and fire-proof paint brushing. According to the construction method of the super high-rise building reinforced layer steel structure outrigger truss, the whole truss is decomposed into parts and components which can be hoisted by field lifting equipment by utilizing the connection relationship of all rod pieces of the outrigger truss, so that integral hoisting is changed into high altitude bulk, the difficulty that the outrigger truss needs to be lifted by a large crane is overcome, and the construction is better in flexibility and operability.

Owner:CHINA CONSTR EIGHTH ENG DIV

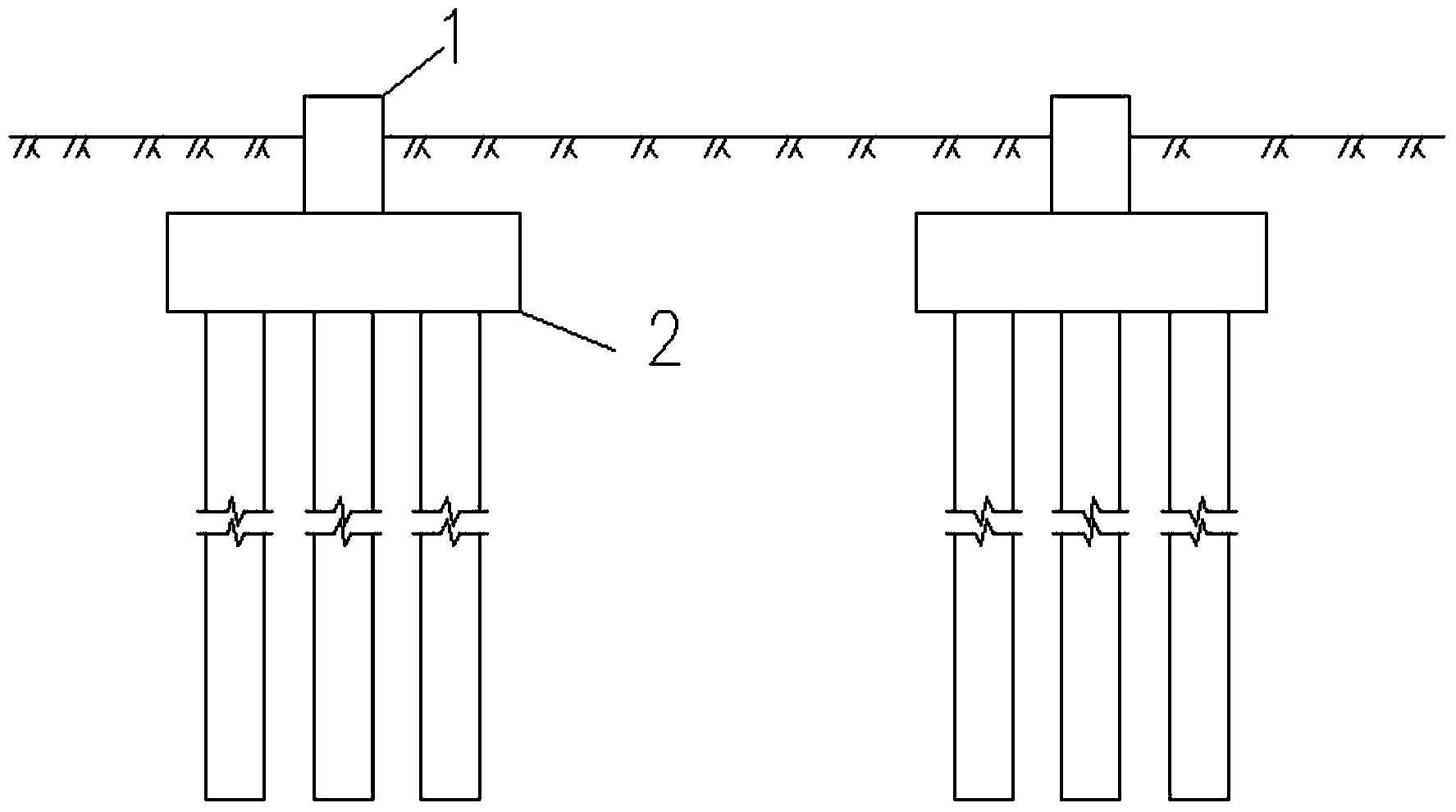

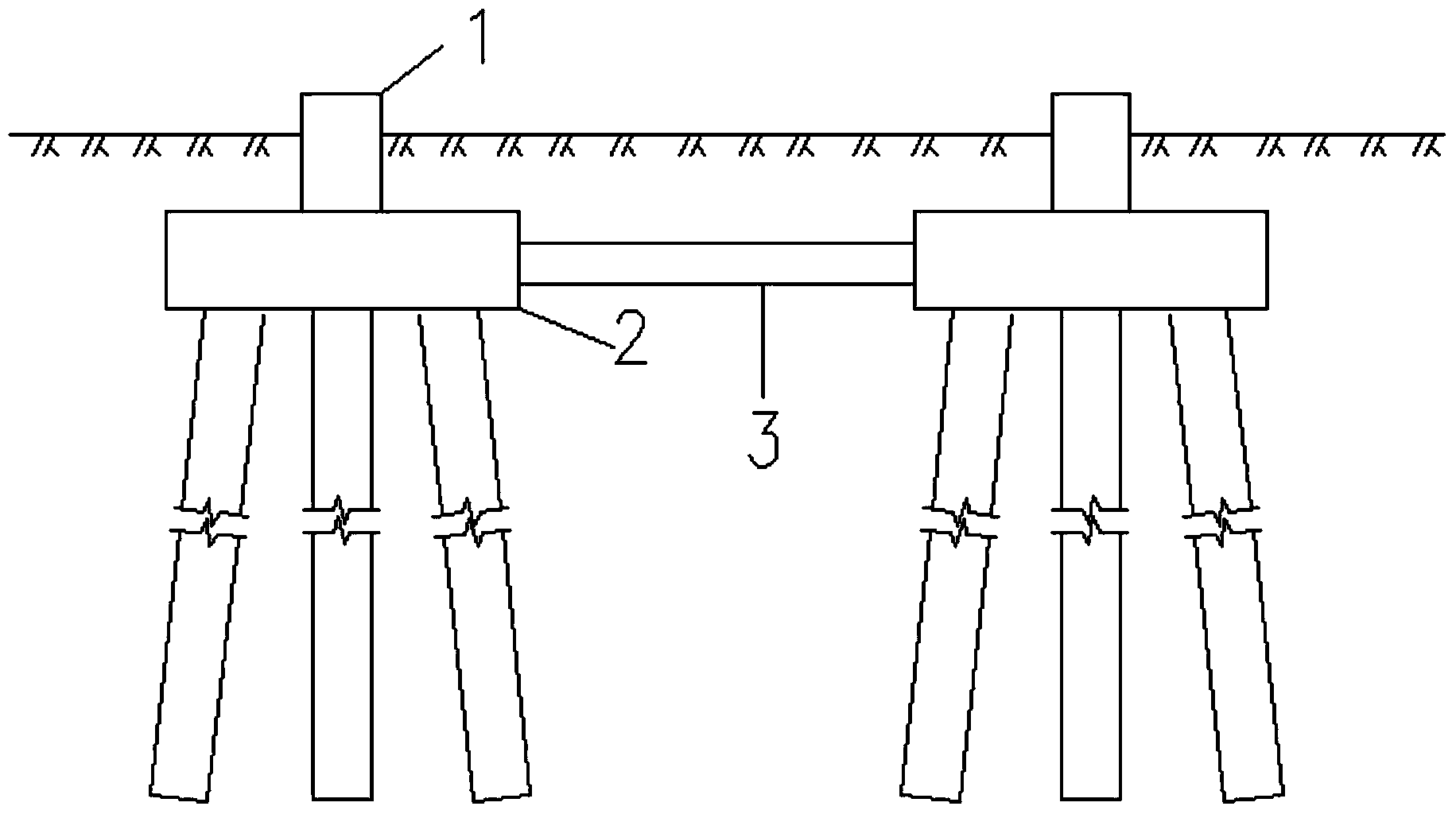

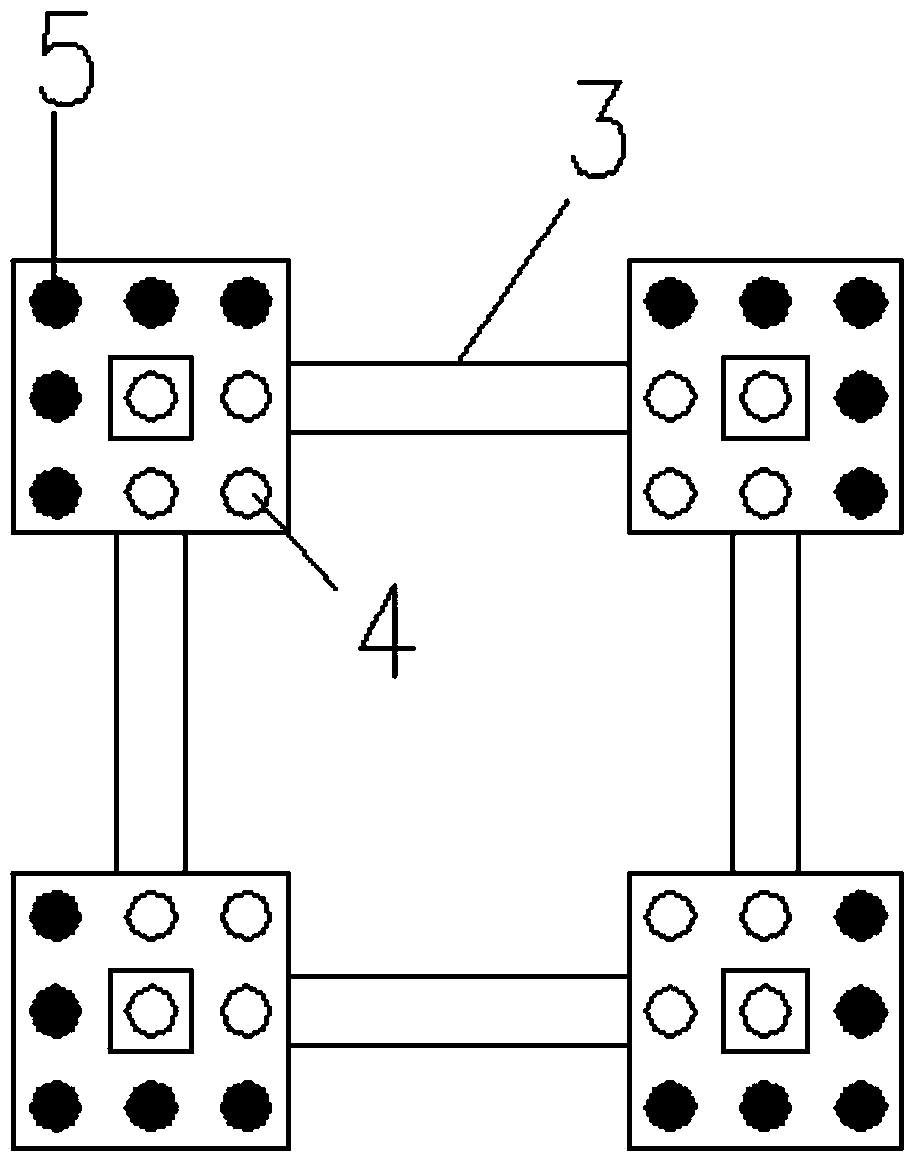

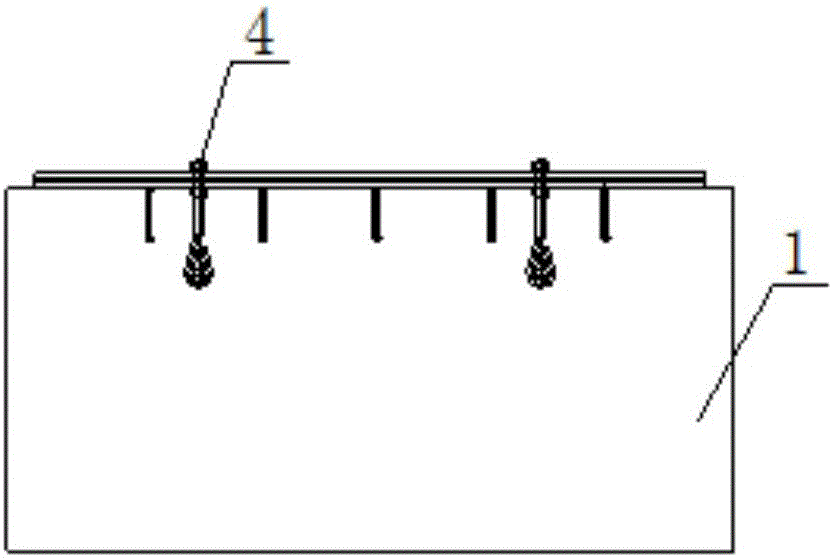

Miniature vertical-oblique combined pile for power transmission tower

InactiveCN104264703AForce coordinationAvoid destructionFoundation engineeringHorizontal forceTransmission tower

The invention relates to a miniature vertical-oblique combined pile for a power transmission tower. The miniature vertical-oblique combined pile comprises standing columns, bearing platforms, a connecting beam and miniature piles. One standing column is disposed in the middle of the top end of each bearing platform. The adjacent bearing platforms are connected through the connecting beam. The miniature piles are evenly disposed at the bottom of each bearing platform. The miniature vertical-oblique combined pile has the advantages that the bearing platforms are connected into an integral structure by the connecting beam, force borne between the bearing platforms is coordinated, sedimentation difference between foundations can be reduced, and destroying of the power transmission tower on the upper portion due to uneven sedimentation of several tower legs is avoided; by the miniature vertical and oblique piles, the requirements of pressure resistance, pulling resistance and overturn resistance are satisfied, horizontal force resistance is increased, force bearing performance by completely using the vertical piles can be improved effectively, and foundation deformation under complex loads is reduced.

Owner:STATE GRID CORP OF CHINA +3

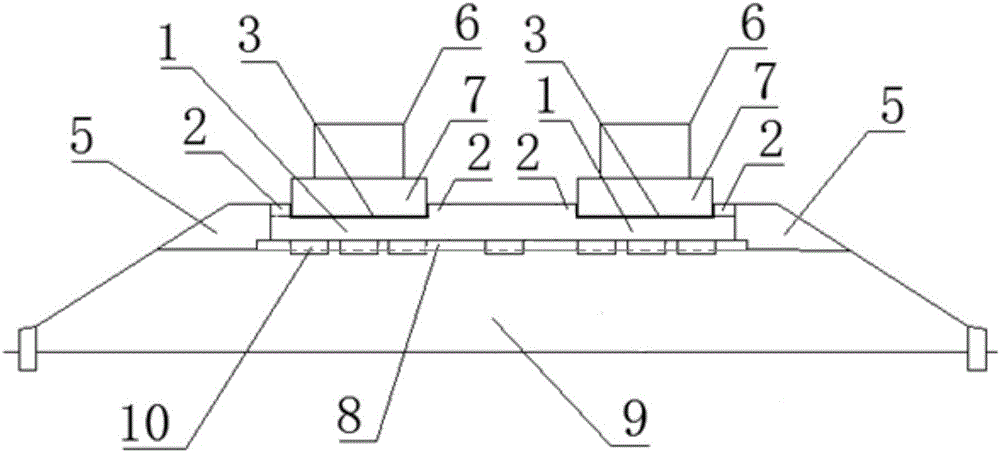

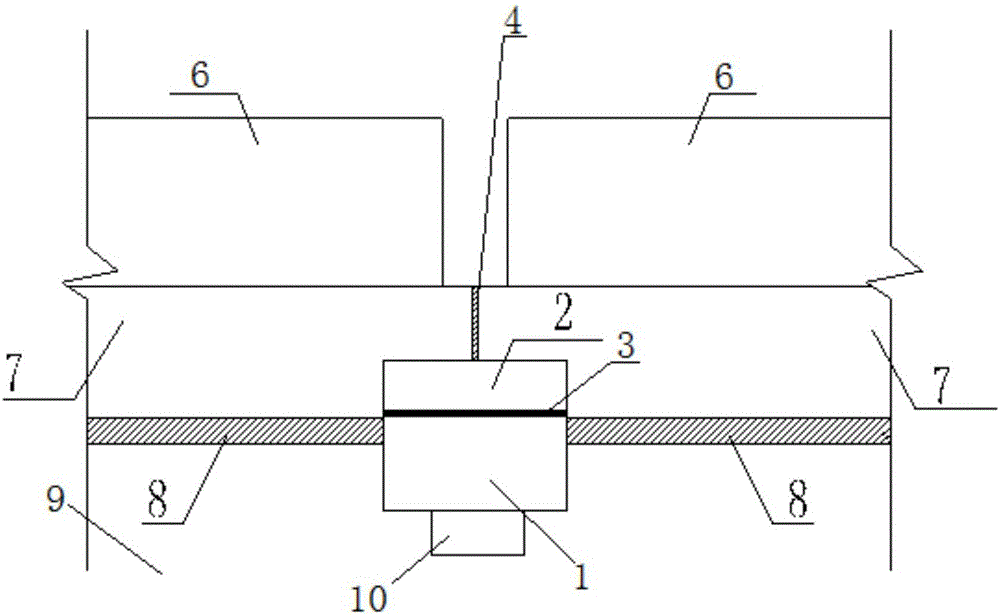

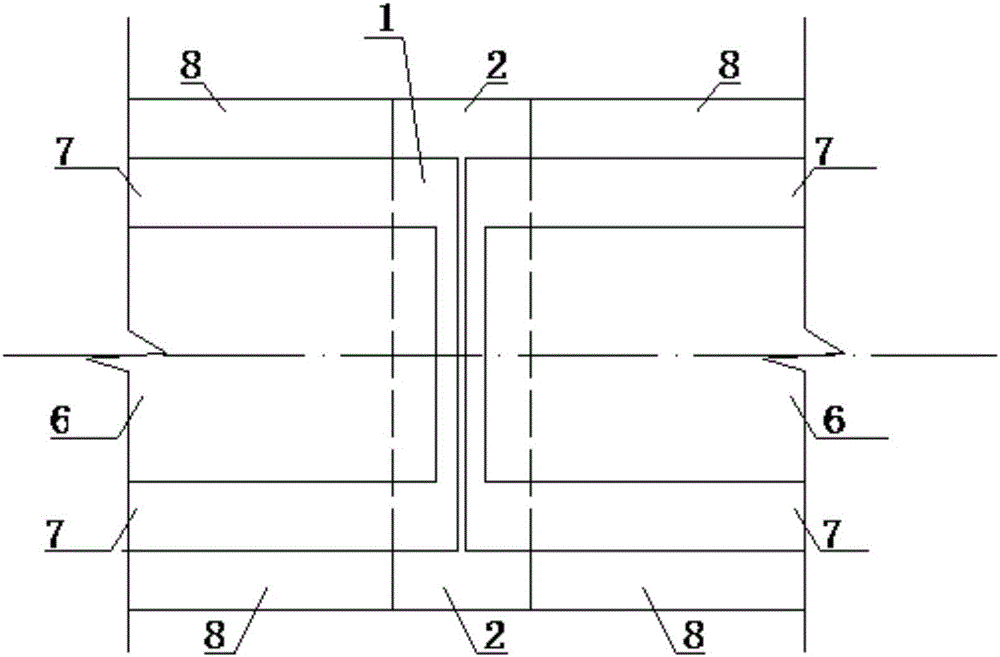

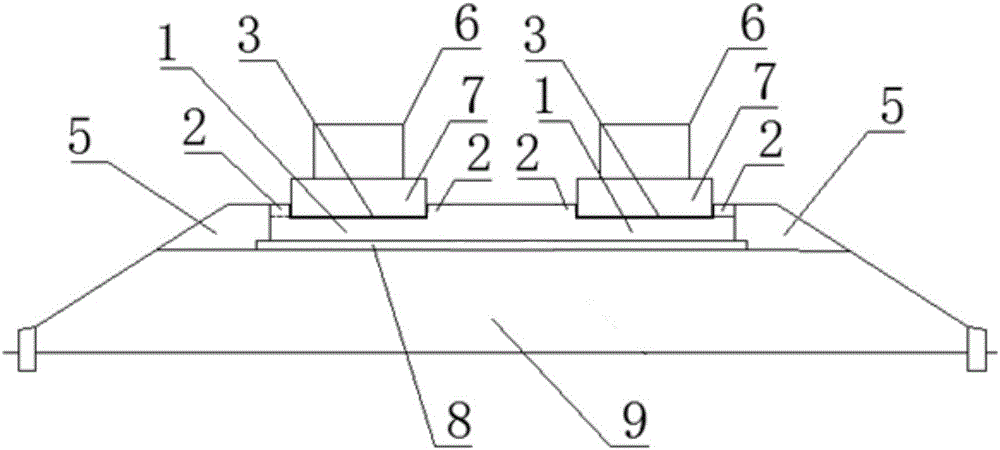

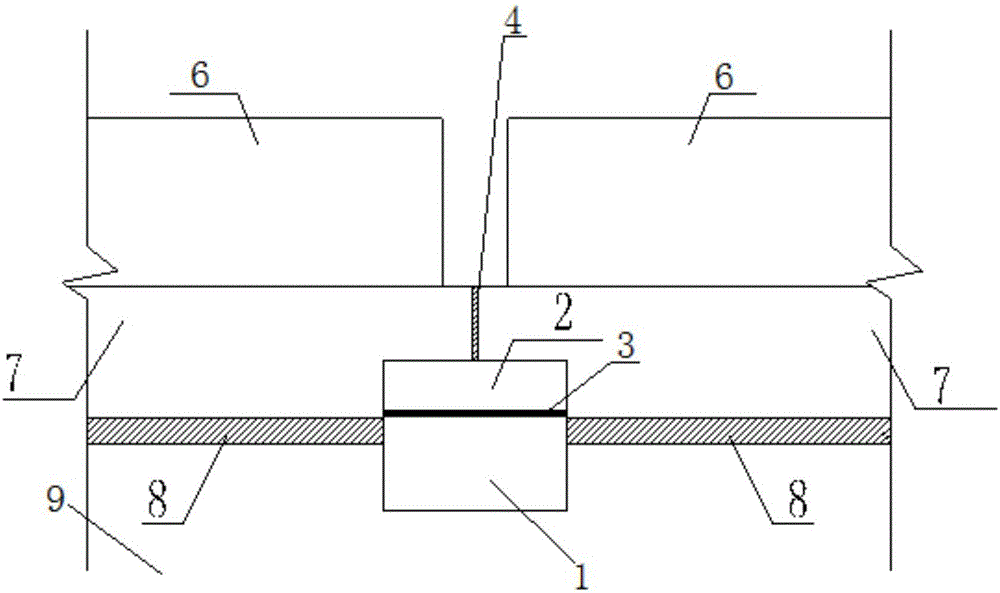

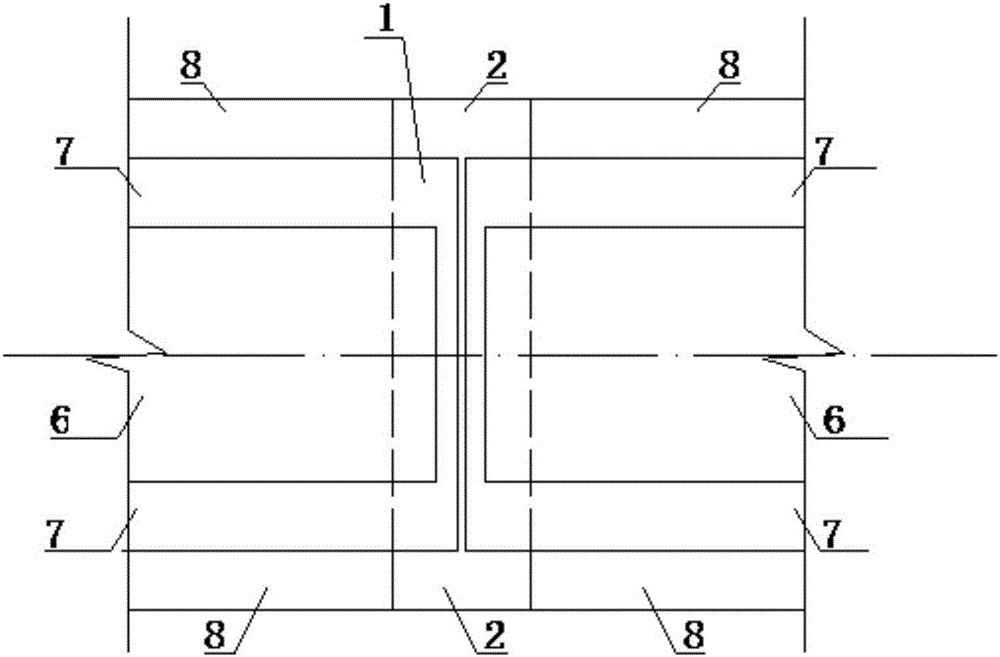

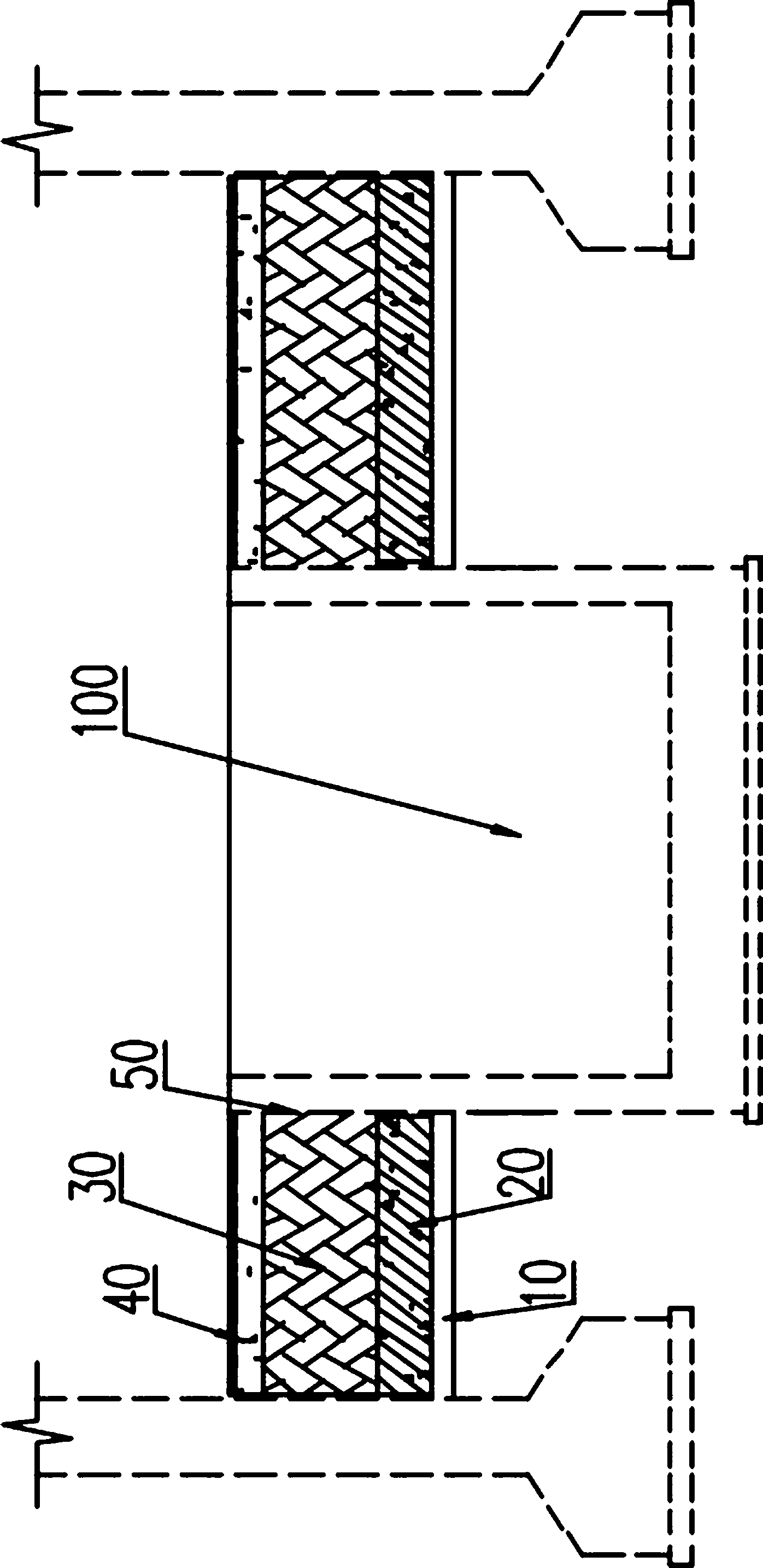

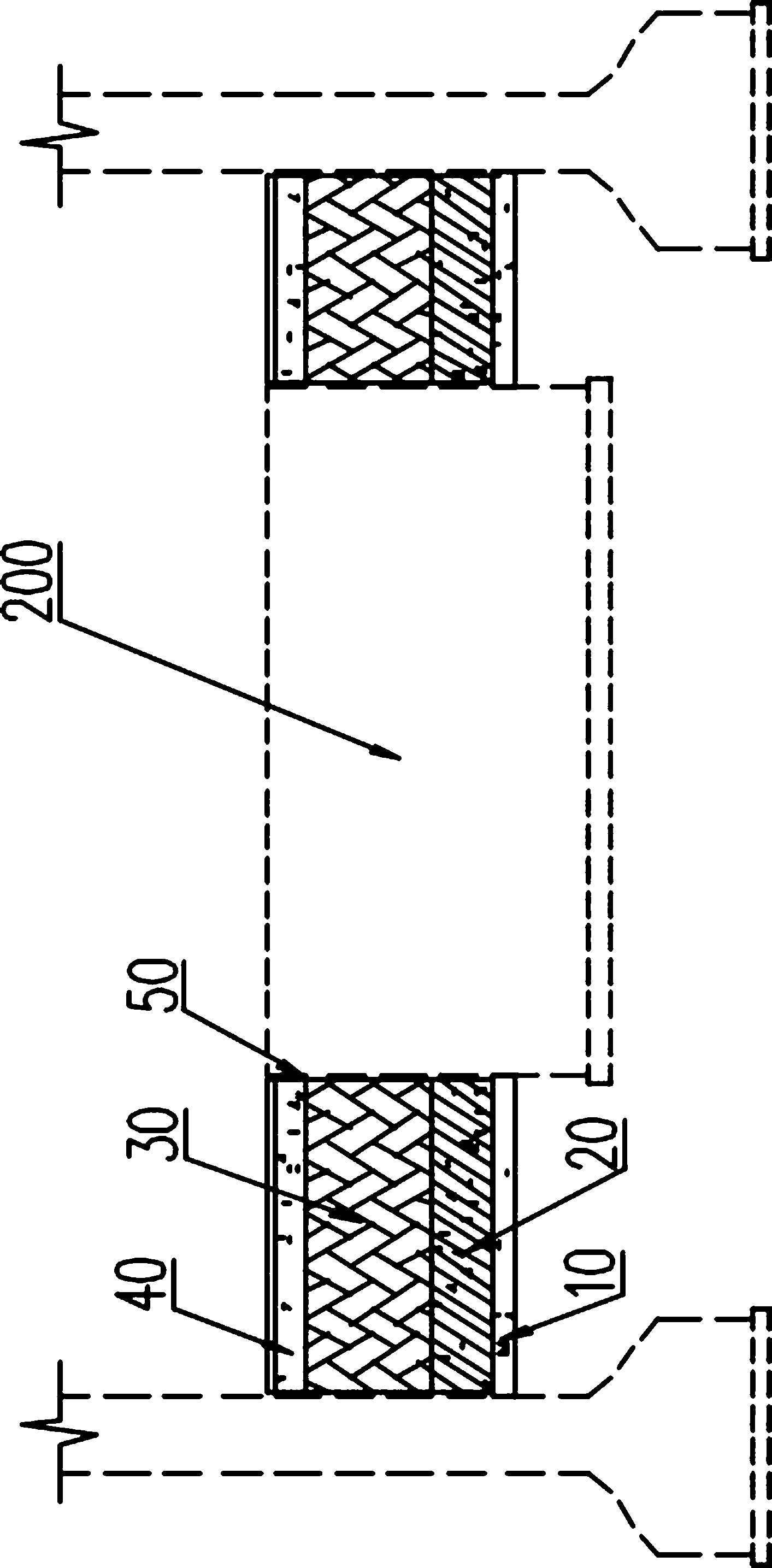

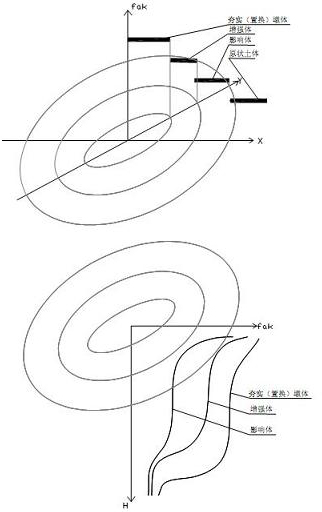

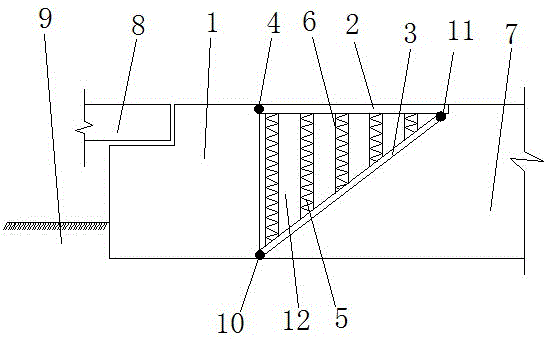

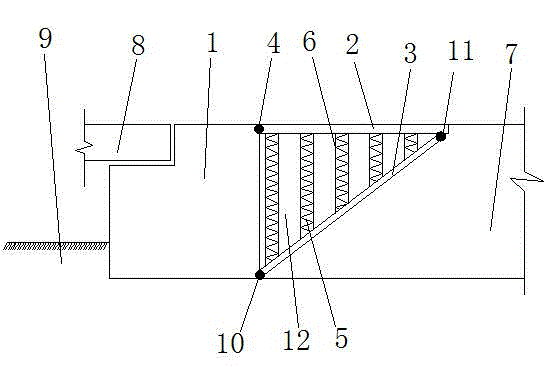

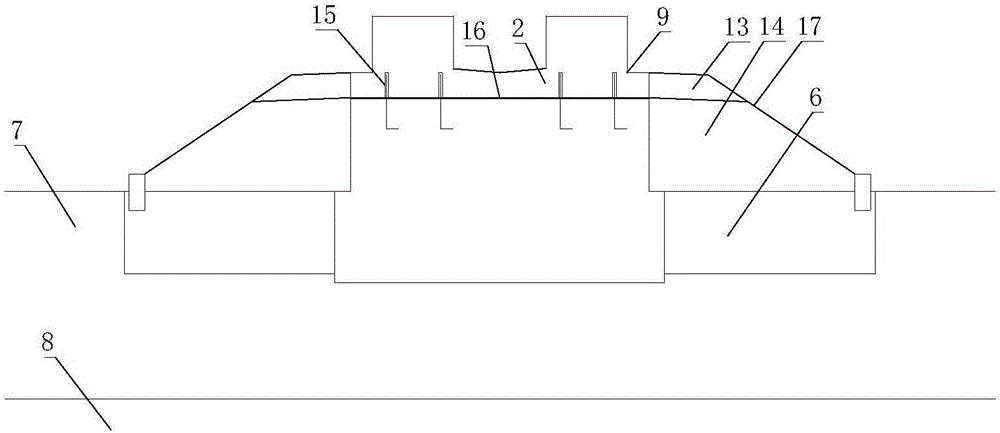

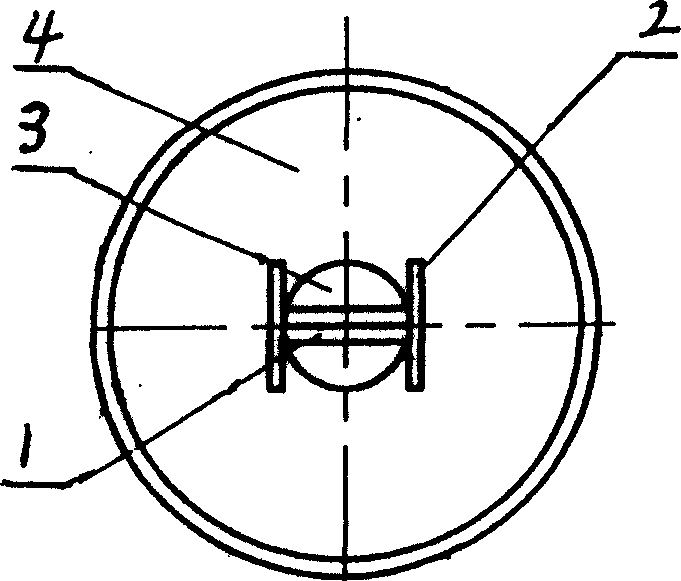

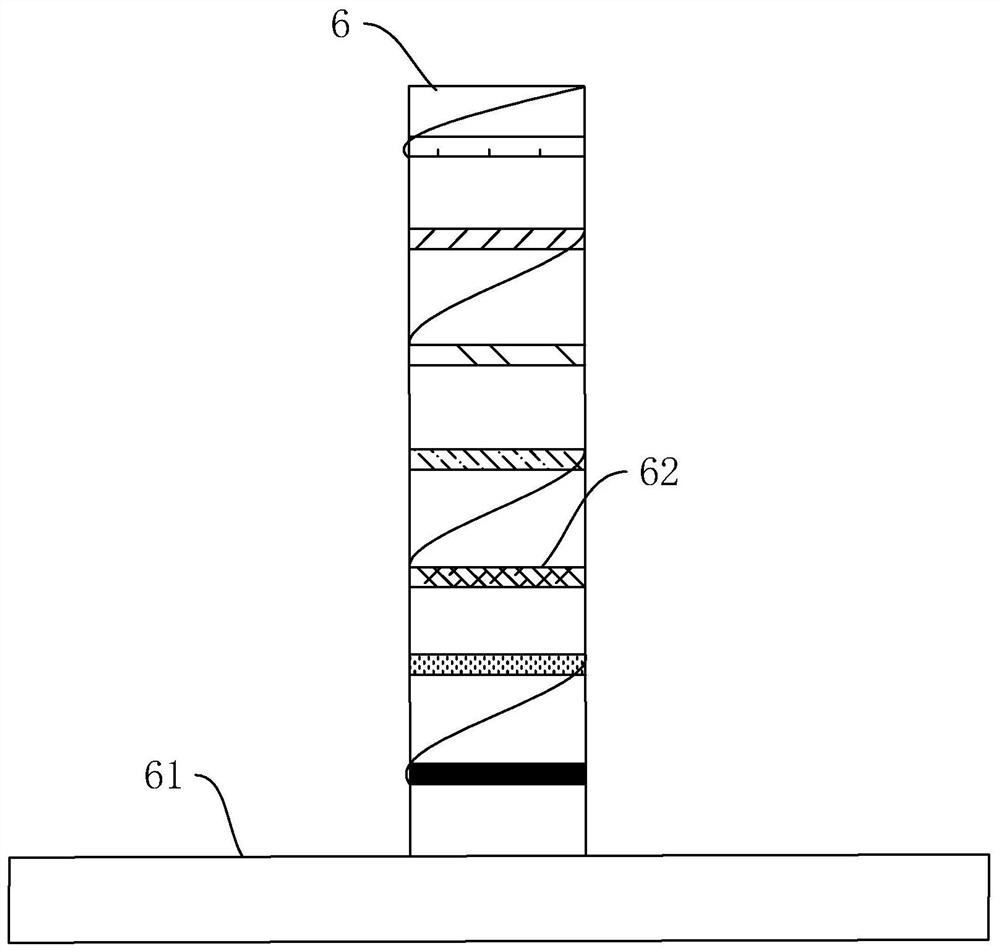

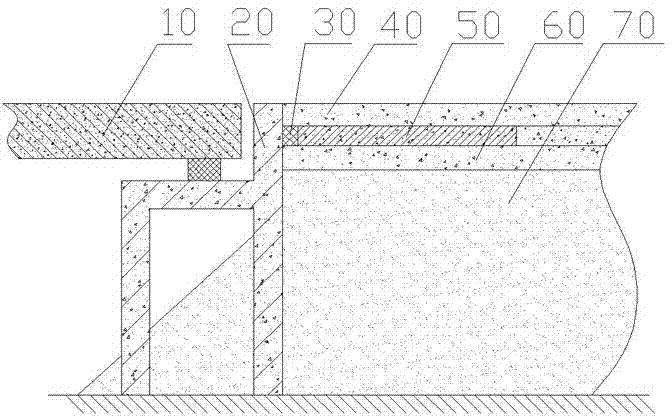

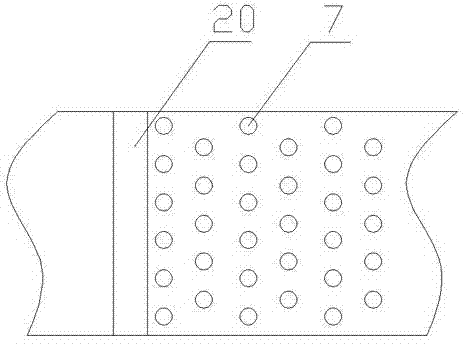

Intra-segment limit structure for bearing-trail beams at double-line section of middle-low speed magnetic levitation traffic engineering low-laying line

InactiveCN105821725AAvoid the problem of uneven track surfaceIncrease lateral stiffnessRailway tracksLow speedReinforced concrete

The invention discloses an intra-segment limit structure for bearing-trail beams at a double-line section of a middle-low speed magnetic levitation traffic engineering low-laying line. The limit structure comprises roadbed stuffing below the bearing-trail beams, a bedding layer under the bearing-trail beams, two adjacent bearing-trail beams, vertical dislocation-prevention lapping plates, transverse dislocation-prevention bosses and bearing-trail beam backfill stuffing. The vertical dislocation-prevention lapping plates are fixedly arranged on the roadbed stuffing below the bearing-trail beams and the lower ends of the vertical dislocation-prevention lapping plates extend into the roadbed stuffing below the bearing-trail beams. According to the invention, the dislocation-prevention reinforced concrete lapping plates are arranged between the segment positions of the bearing-trail beams, the bearing-trail beams are arranged on the same reinforced concrete dislocation-prevention bedplate with certain rigidity, and thus the problem of the uneven rail surface as the foundation below the bearing-trail beams has differential settlements is effectively avoided.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Active comprehensive load reduction structure and method for high-fill roadbed culvert

The invention provides an active comprehensive load reduction structure and method for a high-fill roadbed culvert. The load reduction structure comprises a culvert, a load reduction groove and a pressurization type self-adaptive system. The culvert is arranged on a foundation and comprises a culvert base plate, culvert side walls arranged at the two ends of the culvert base plate and a culvert cover plate. The load reduction groove is fixed to the top of the culvert cover plate, and the load reduction groove is filled with a light flexible material. Earth-stone side walls are arranged on thetwo sides of the culvert correspondingly, and the tops of the earth-stone side walls protrude out of the load reduction groove. The pressurization type self-adaptive system comprises a single-chip microcomputer, a plurality of pressure sensors and a plurality of jacking and stretching devices. The single-chip microcomputer is arranged in the culvert, and the multiple pressure sensors are arrangedat the position where stress on the top of the culvert is concentrated and electrically connected with the single-chip microcomputer. The jacking and stretching devices are electrically connected withthe single-chip microcomputer and used for initial jacking of the bottom of the upper wall and later stress adjustment. The technical scheme provided by the invention has the beneficial effects thata load reduction effect is obvious, acontrollable stress of the culvert can be realized, and data support is provided for scientific research in related fields.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

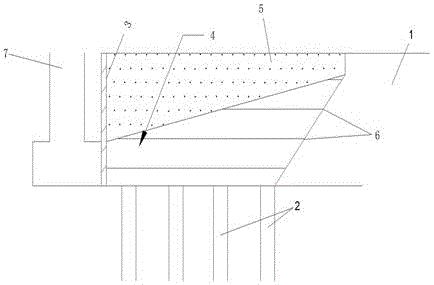

Structure of apparatus and buttress integrated foundation in steam turbine room

InactiveCN102828528ALow costShorten the construction periodArtificial islandsUnderwater structuresButtressEngineering

The invention discloses a structure of apparatus and buttress integrated foundation in a steam turbine room; the structure comprises a raft; a pad layer is arranged below the raft; plain fills for backfilling after all the apparatus and buttress integrated foundation in the steam turbine are constructed, are arranged above the raft. With the adoption of the basic structure of the integrated raft, the repeated construction problem that the earth has to be excavated and backfilled for multiple times when needing to change and enlarge the apparatus and buttress integrated foundation in the steam turbine, is avoided; the unnecessary waste in the construction is avoided, the construction cost is saved, and the construction period is shortened. And the foundation structure using the above integrated raft further can effectively reduce the differential settlement between the foundations of the apparatus.

Owner:SHANGHAI INTELLIGENCE POWER ENG CO LTD

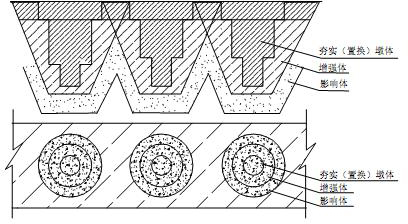

Combined-rammer construction technology for foundation treatment

InactiveCN102535429AEffective reinforcementWalking engineering construction guaranteeSoil preservationTreatment effectLateral compression

The invention discloses a combined-rammer construction technology for foundation treatment. In the construction technology, a plurality of rammers with different diameters, shapes and pressure intensities are adopted and combined reasonably, and replacement or compacted pier bodies are formed through deep-layer compaction, middle-layer compaction and superficial-layer compaction in virtue of different dynamical pressure equivalents produced by the different rammers, so as to achieve the purpose of improving the effective reinforced depth of a soil body and the bearing capacity of a foundation; and the soil among piers are reinforced and compacted effectively under the action of lateral compression generated during the construction of the pier bodies. The construction technology is the third-generation foundation treatment technology adopting dynamic compaction and dynamic compaction replacement methods, not only gives full play to the technological advantages of a traditional dynamic compaction (replacement) method and a novel pillar-rammer dynamic compaction (replacement) method, but also is developed to a new height, and becomes a fire-new construction technology which is suitable for various soft foundations and has a better reinforcement treatment effect.

Owner:刘献刚

Connecting structure between bridge abutment and road bed for solving problem of vehicle bump at bridge head

ActiveCN106192724AReduce maintenance costsEasy to useBridge structural detailsBridge erection/assemblyAbutmentRoad surface

The invention discloses a connecting structure between a bridge abutment and a road bed for solving the problem of vehicle bump at a bridge head. The connecting structure is positioned between the bridge abutment and the original road bed and comprises cement flyash gravel (CFG) piles, a soil filling structure, a cemented soil grouting treatment zone and geonets, wherein the CFG piles are positioned at the bottommost layer, effectively reinforce the original road bed and are used for reducing the settlement of the original road bed; the soil filling structure is positioned above the CFG piles, separated by the geonets, layered in parallel and filled with filler, each layer of geonet is locked together with each layer of filler of the soil filling structure to form a stable plane, the stable plane is used for effectively reducing and controlling the deformation of the connecting structure, and the layers of the soil filling structure are compacted after being filled so as to reduce the settlement of the connecting structure; and the cemented soil grouting treatment zone is positioned at the upper part of the soil filling structure and presents a wedge shape, one end of the cemented soil grouting treatment zone is connected with the back of bridges and culverts behind the bridge abutment, and the other end of the cemented soil grouting treatment zone is connected with the original road bed. The connecting structure disclosed by the invention prolongs the service life of a road surface, reduces the maintenance cost and improves the degrees of driving safety and comfort of a vehicle.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

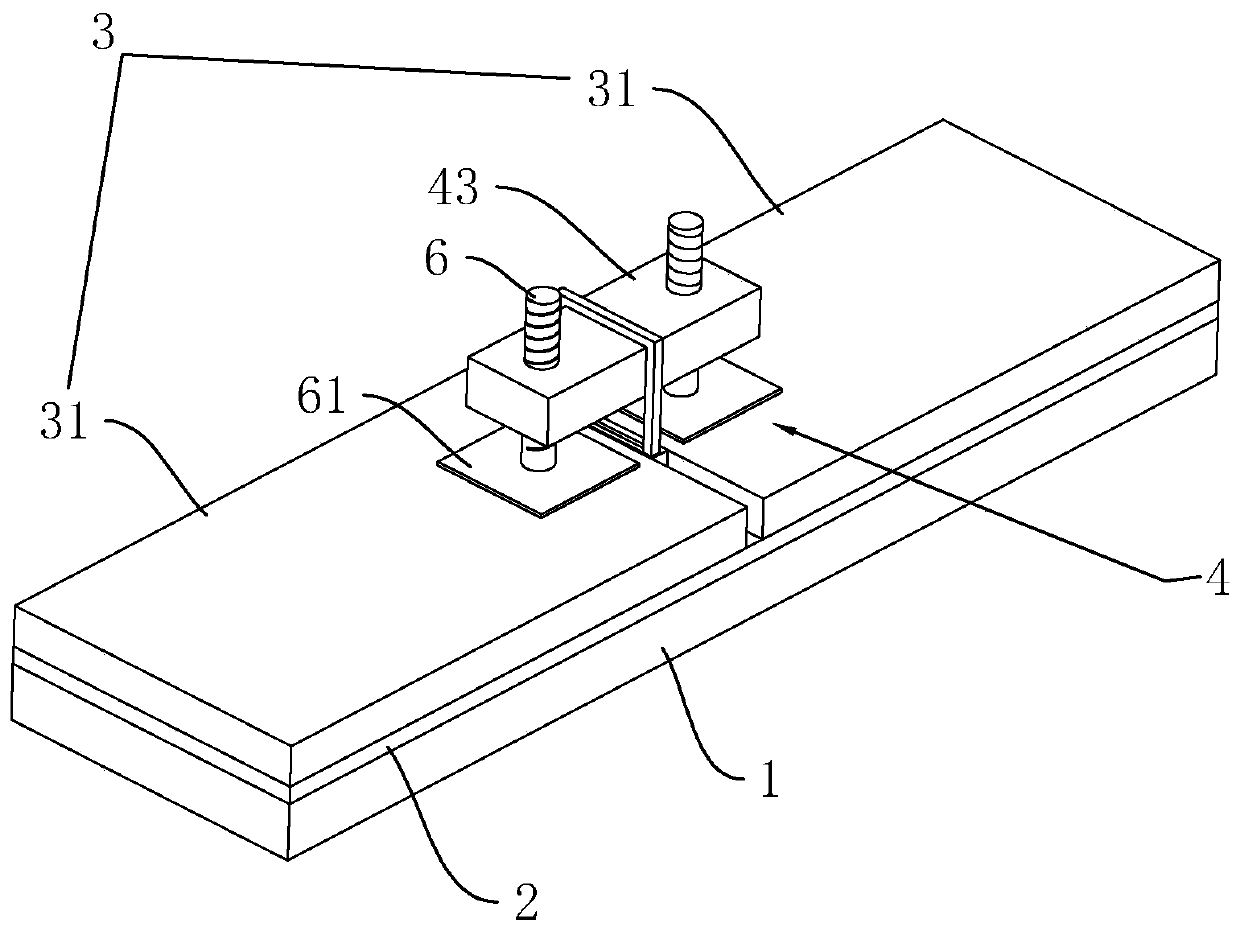

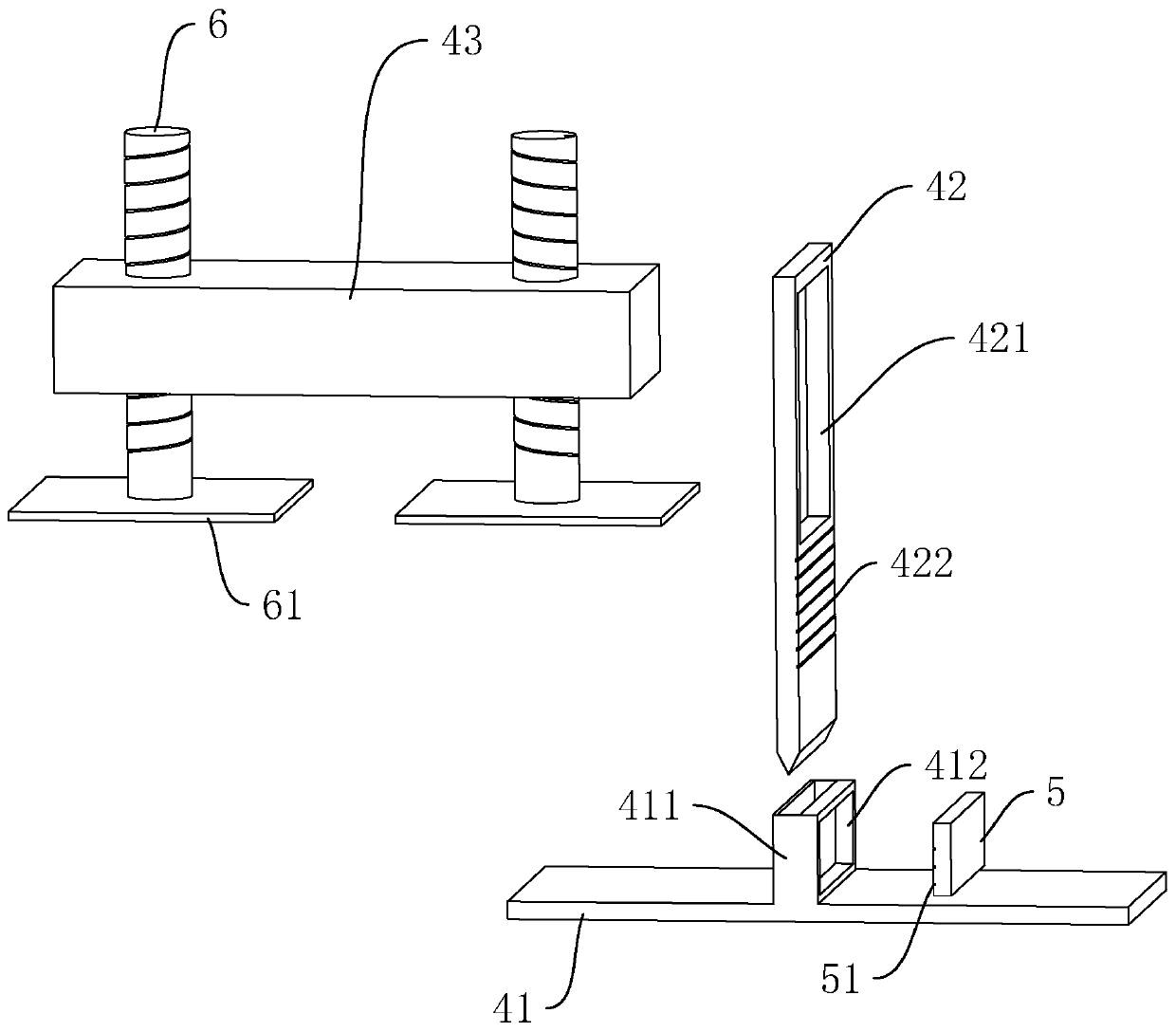

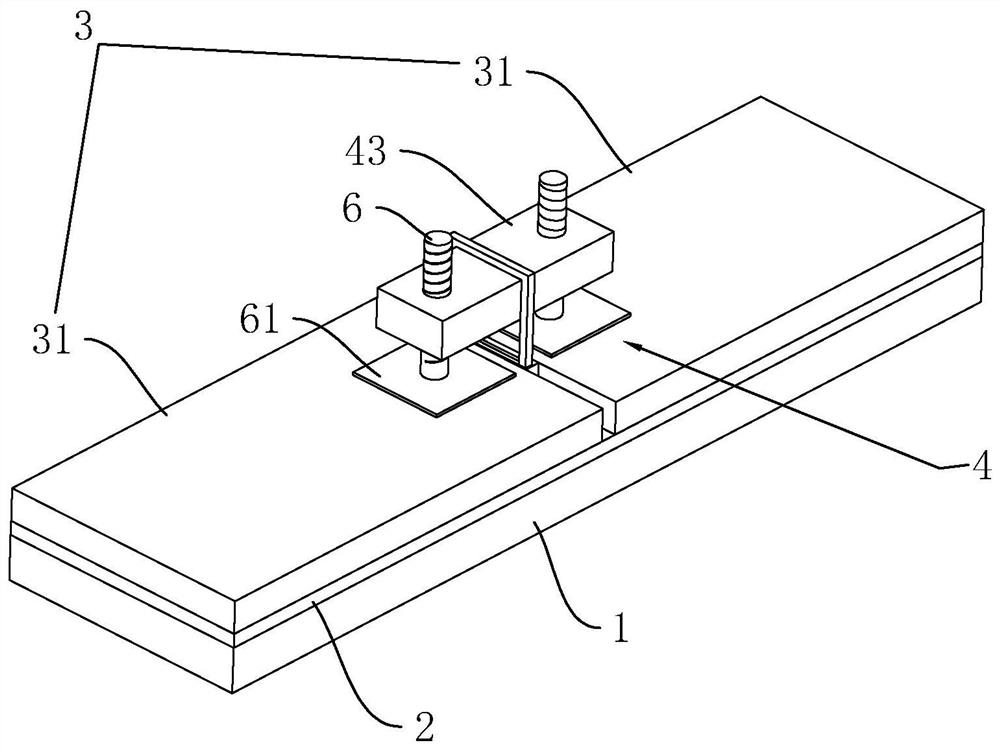

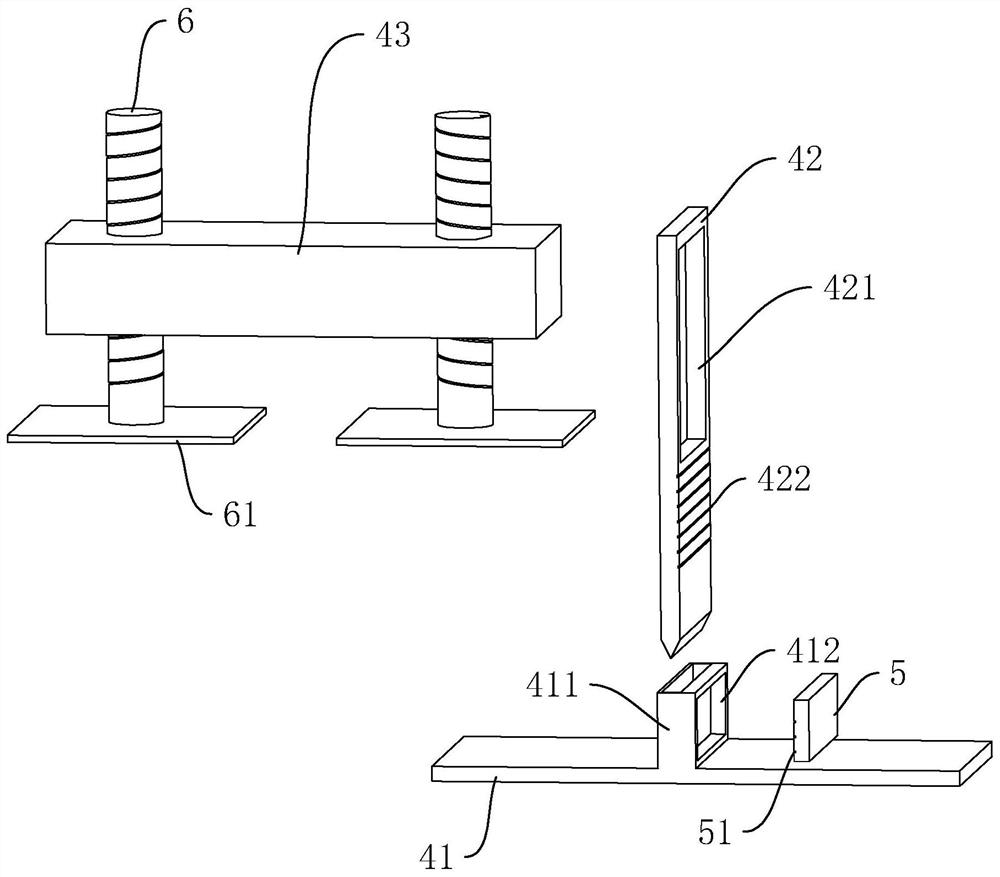

Stone floor system and construction method thereof

The invention discloses a stone floor system and a construction method thereof, relates to the field of building decoration, and aims to solve the problem of higher influence on stone floor pavement flatness by self weight and dry humidity of cement mortar in the prior art. The stone floor system is characterized by comprising a gravel leveling layer, a cement pulp layer and a floor layer; and thefloor layer comprises multiple floors. The stone floor system further comprises a leveling mechanism; the leveling mechanism comprises a lower bearing plate, butting columns and upper pressing plates; the two ends of the lower bearing plate are in butt joint with the lower parts of two adjacent floors at the same time; the butting columns are positioned between two adjacent floors; the lower endsof the butting columns are in butt joint with a base layer ground, and the upper ends extend out planes of upper surfaces of the floors and are transversely provided with through holes; the upper pressing plates penetrate through the through holes; and the two ends are in butt joint with the upper surfaces of two adjacent floors. The stone floor system and the construction method thereof can reduce the troubles caused by self weight of stones and the dry humidity of the cement mortar, and improve the overall flatness of the floors.

Owner:深圳市新雅建设工程有限公司

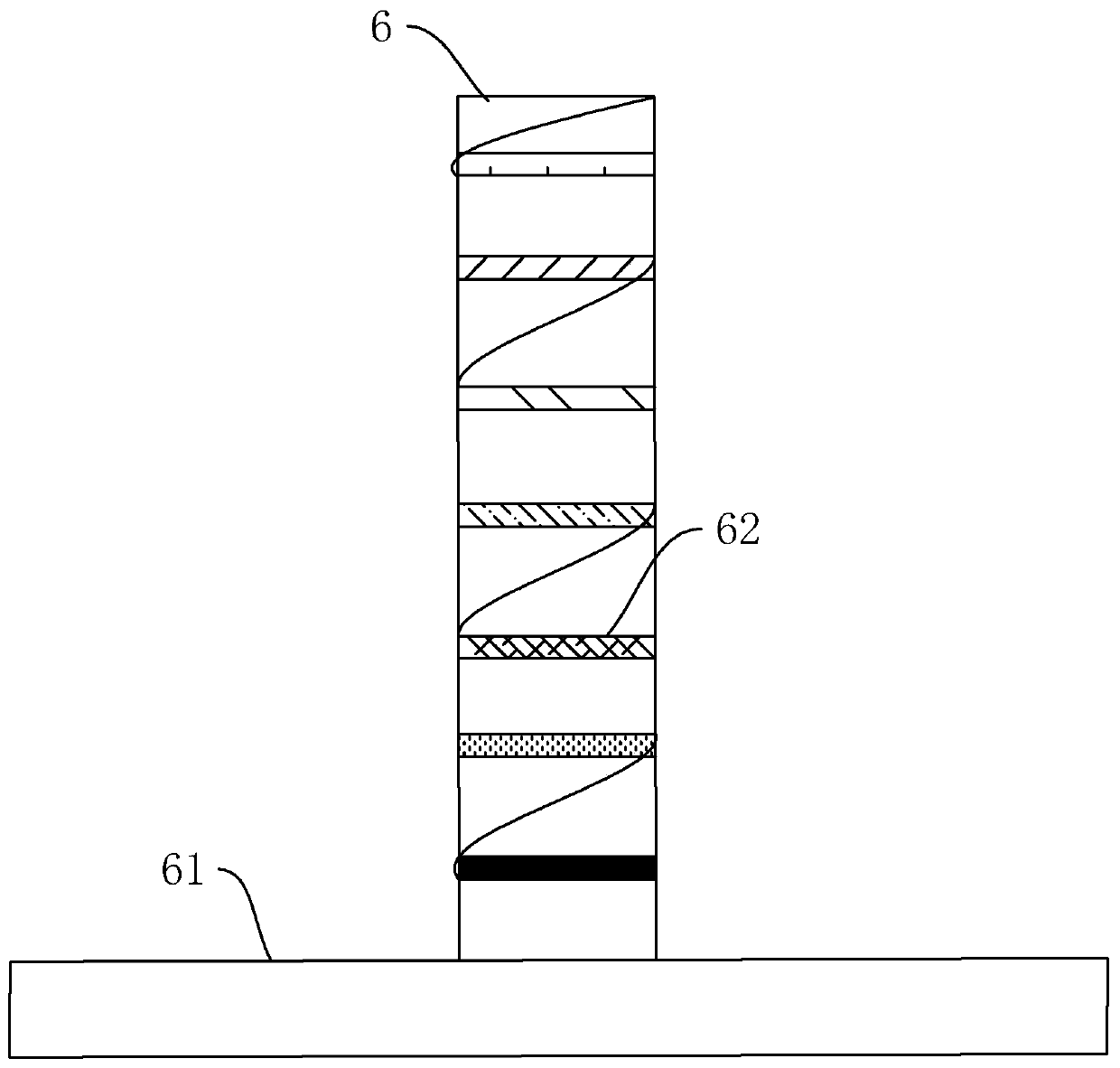

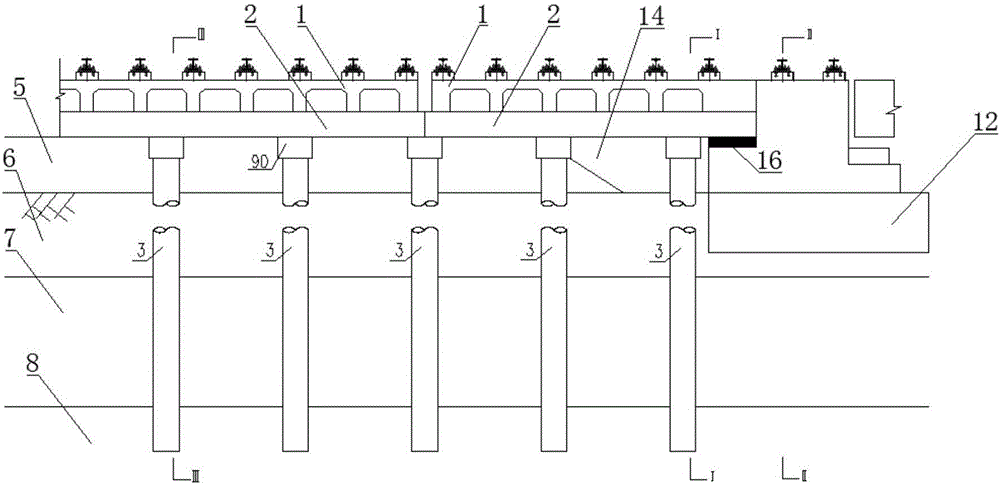

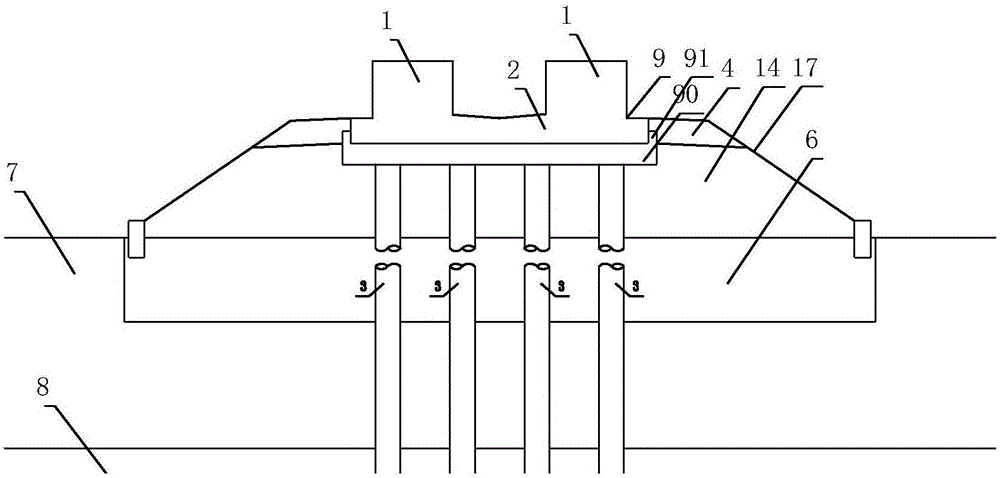

Rib column distributed turnout foundation structure of middle-low speed magnetic levitation low-arranged line

ActiveCN105951537AMeet strength requirementsMeet stability requirementsRailway tracksFoundation engineeringLow speedReinforced concrete

The invention discloses a rib column distributed turnout foundation structure for a middle-low speed magnetic levitation low-arranged line. The rib column distributed turnout foundation structure for the middle-low speed magnetic levitation low-arranged line comprises turnout zone foundation treatment reinforced concrete rafts, reinforced concrete turnout beam bar-type rib column foundations, reinforced concrete cast-in place piles, steel plates and embedded bolts. The turnout zone foundation treatment reinforced concrete rafts are arranged horizontally, and the multiple reinforced concrete cast-in place piles are arranged at the bottom end faces of the turnout zone foundation treatment reinforced concrete rafts; the reinforced concrete cast-in place piles penetrate a soft stratum to extend into a bearing stratum, to decrease the deformation of turnout beams in the rotation process. The rib column distributed turnout foundation structure for the middle-low speed magnetic levitation low-arranged line ensures that the turnout beams are not deformed greatly in the rotation process due to inadequate foundation stiffness, and meets the requirements for foundation strength and stability by the turnout beams.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

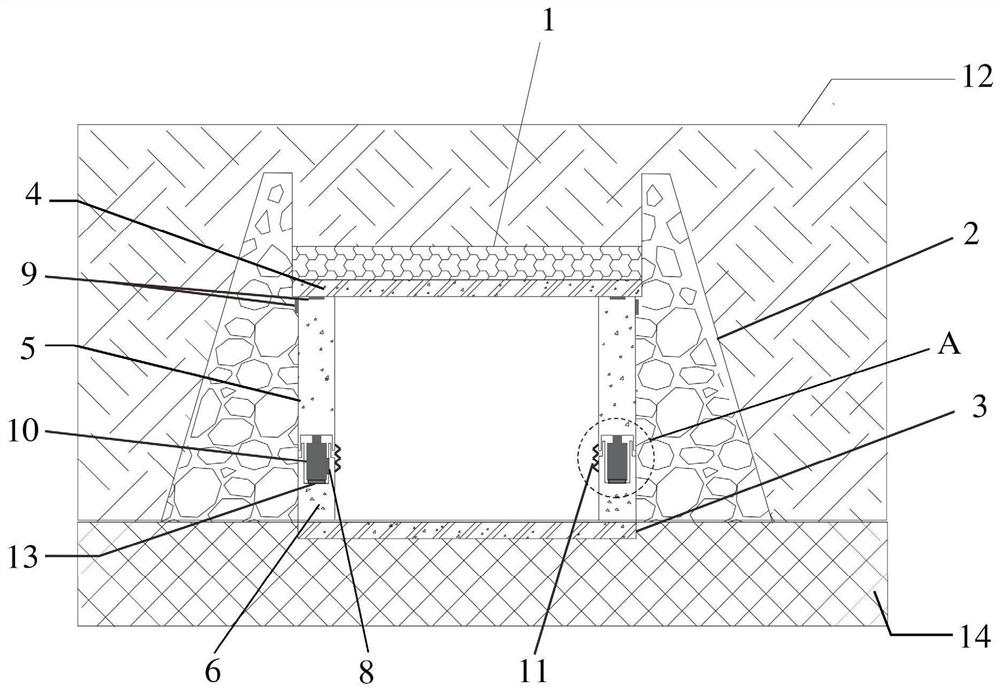

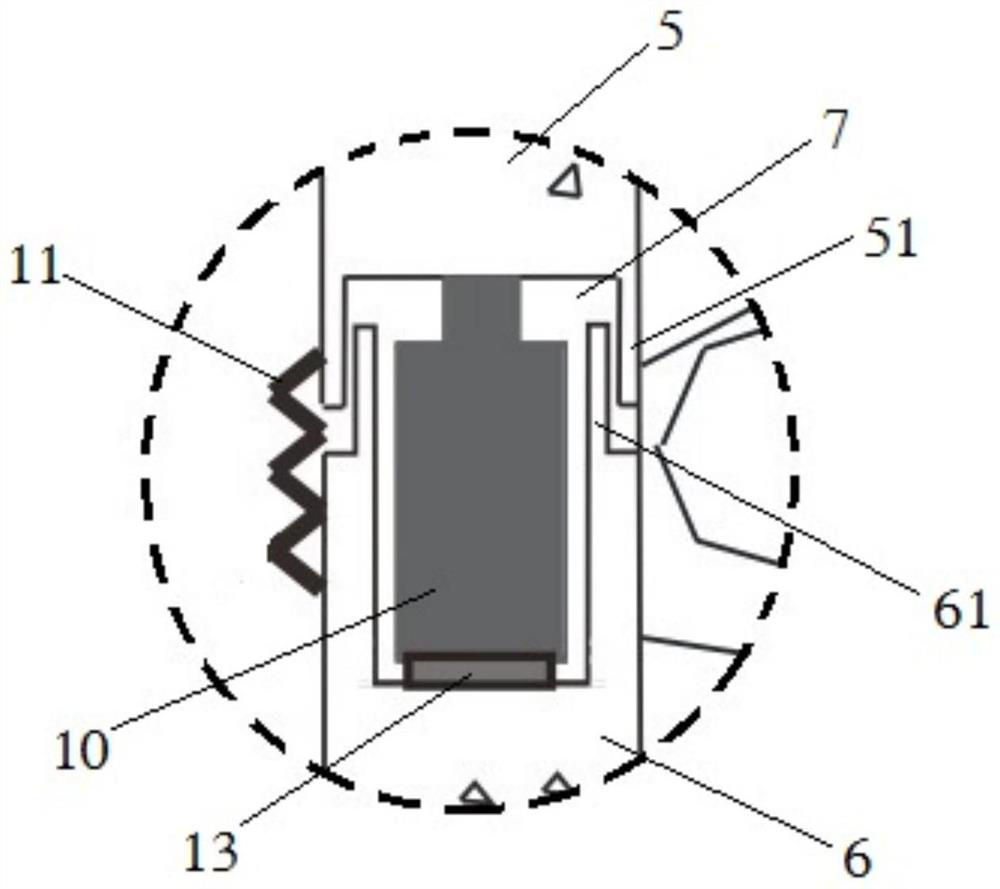

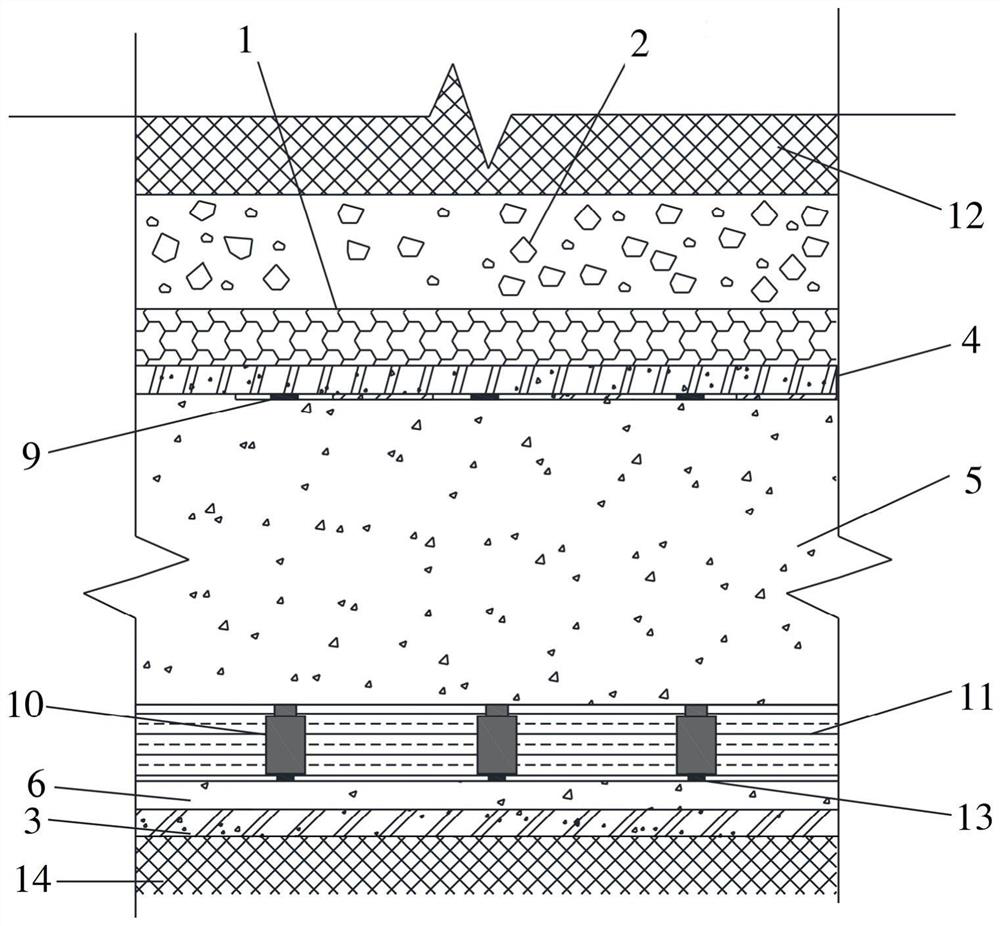

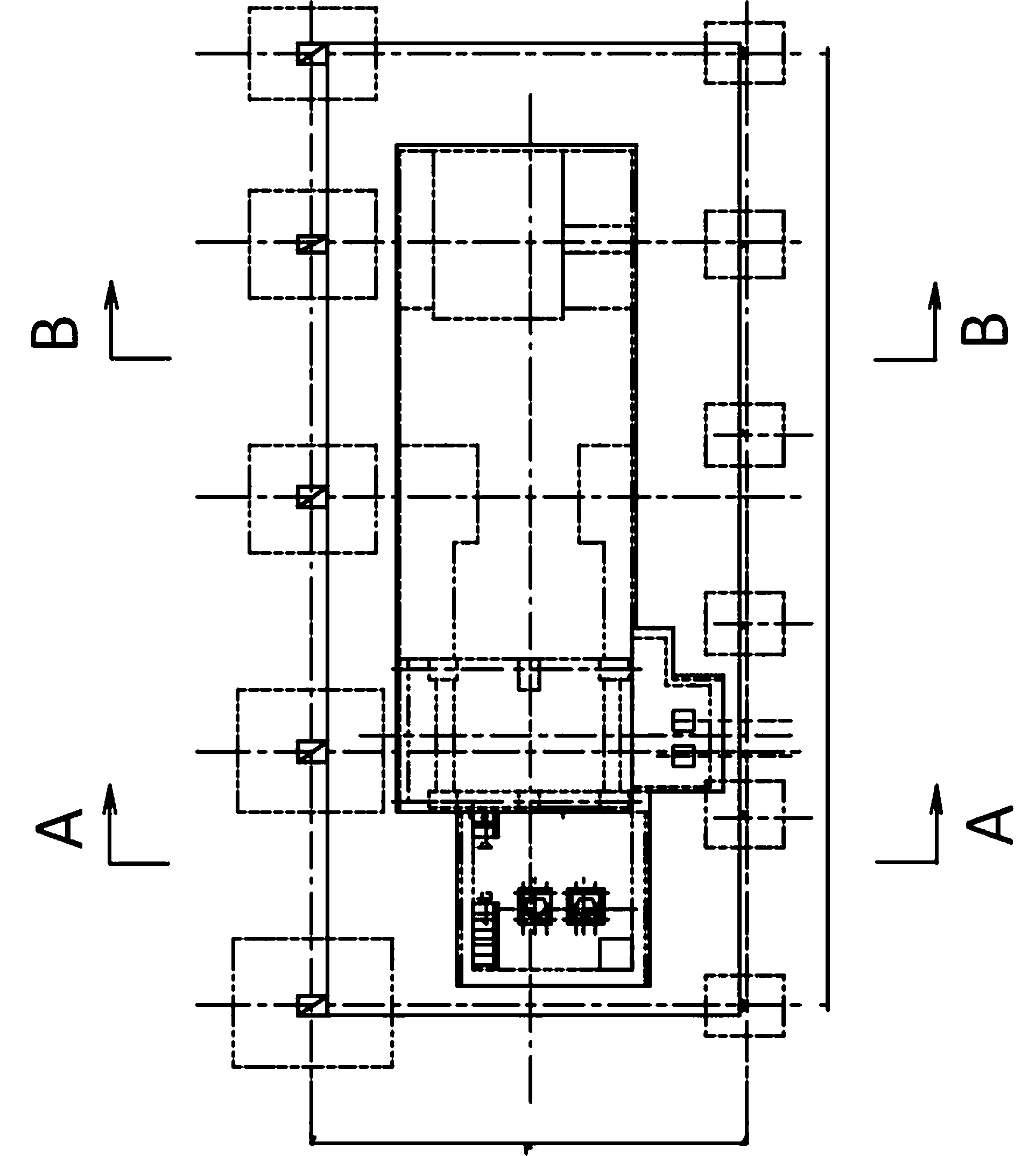

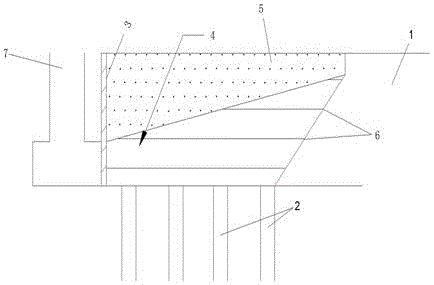

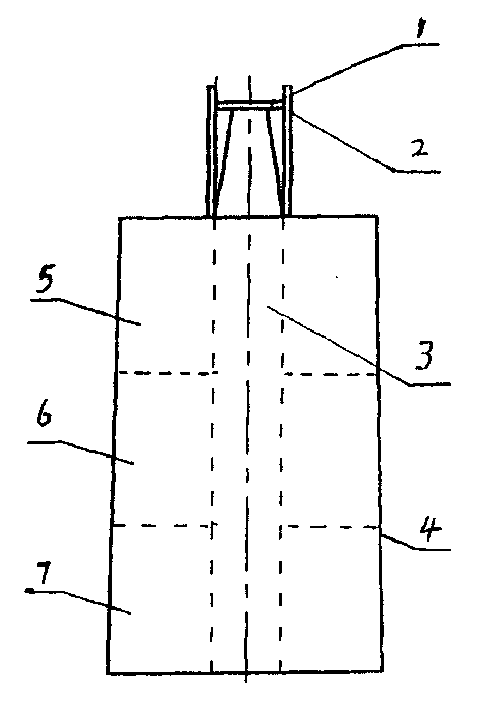

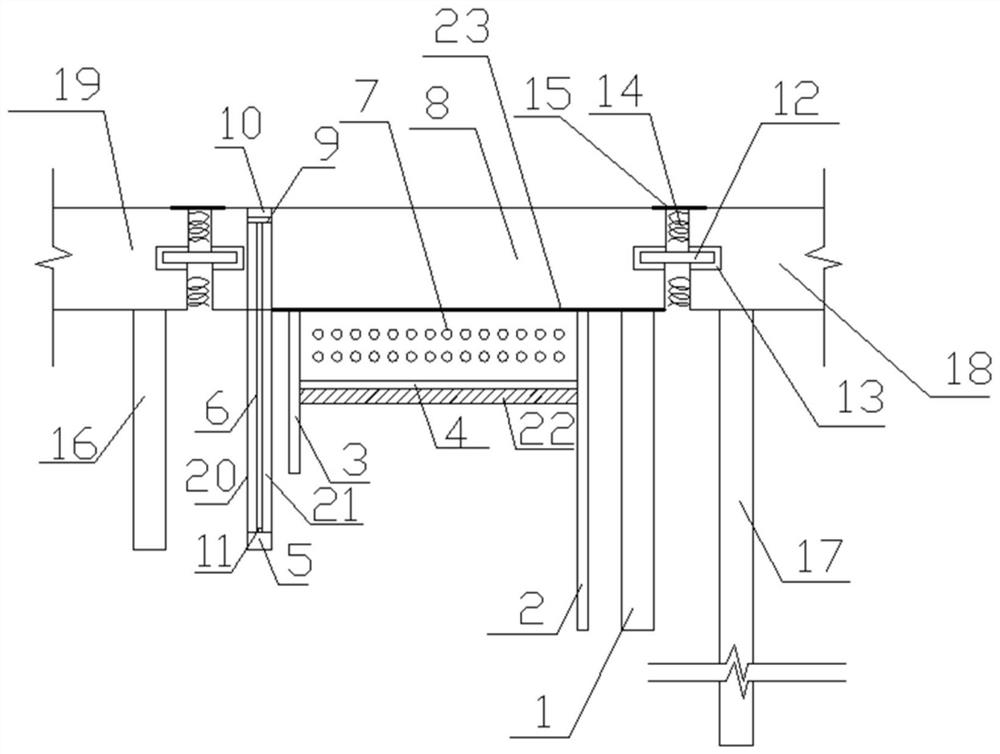

Frame spring combined bridge-road transition section structure integrated with bridge abutment

ActiveCN104790290BReduce settlement differenceTransitional realizationBridge structural detailsReinforced concreteAbutment

The invention relates to a frame and spring combination type bridge and road transition section structure integrated with a bridge abutment. The frame and spring combination type bridge and road transition section structure comprises the bridge abutment, a beam and a subgrade body and further comprises a steel reinforced concrete transition section frame and a plurality of high-strength spring bundles. The steel reinforced concrete transition section frame comprises a prefabricated horizontal steel reinforced concrete plate and a prefabricated oblique steel reinforced concrete supporting plate. The prefabricated horizontal steel reinforced concrete plate is connected with the upper end of the bridge abutment through a first high-strength hinged bolt, the prefabricated oblique steel reinforced concrete supporting plate is connected with the lower end of the bridge abutment through a second high-strength hinged bolt, and the other end of the prefabricated horizontal steel reinforced concrete plate is connected with the other end of the prefabricated oblique steel reinforced concrete supporting plate through a third high-strength hinged bolt. The prefabricated oblique steel reinforced concrete supporting plate is fixedly attached to the subgrade body. The high-strength spring bundles are vertically installed between the prefabricated horizontal steel reinforced concrete plate and the prefabricated oblique steel reinforced concrete supporting plate. The frame and spring combination type bridge and road transition section structure solves the problem that a sedimentation difference is caused by a rigidity difference between special-shaped buildings in a transport line.

Owner:LANZHOU RAILWAY SURVEY & DESIGN INST

Frame and spring combination type bridge and road transition section structure integrated with bridge abutment

ActiveCN104790290ASolve the stiffness problemReduce settlement differenceBridge structural detailsReinforced concreteAbutment

The invention relates to a frame and spring combination type bridge and road transition section structure integrated with a bridge abutment. The frame and spring combination type bridge and road transition section structure comprises the bridge abutment, a beam and a subgrade body and further comprises a steel reinforced concrete transition section frame and a plurality of high-strength spring bundles. The steel reinforced concrete transition section frame comprises a prefabricated horizontal steel reinforced concrete plate and a prefabricated oblique steel reinforced concrete supporting plate. The prefabricated horizontal steel reinforced concrete plate is connected with the upper end of the bridge abutment through a first high-strength hinged bolt, the prefabricated oblique steel reinforced concrete supporting plate is connected with the lower end of the bridge abutment through a second high-strength hinged bolt, and the other end of the prefabricated horizontal steel reinforced concrete plate is connected with the other end of the prefabricated oblique steel reinforced concrete supporting plate through a third high-strength hinged bolt. The prefabricated oblique steel reinforced concrete supporting plate is fixedly attached to the subgrade body. The high-strength spring bundles are vertically installed between the prefabricated horizontal steel reinforced concrete plate and the prefabricated oblique steel reinforced concrete supporting plate. The frame and spring combination type bridge and road transition section structure solves the problem that a sedimentation difference is caused by a rigidity difference between special-shaped buildings in a transport line.

Owner:LANZHOU RAILWAY SURVEY & DESIGN INST

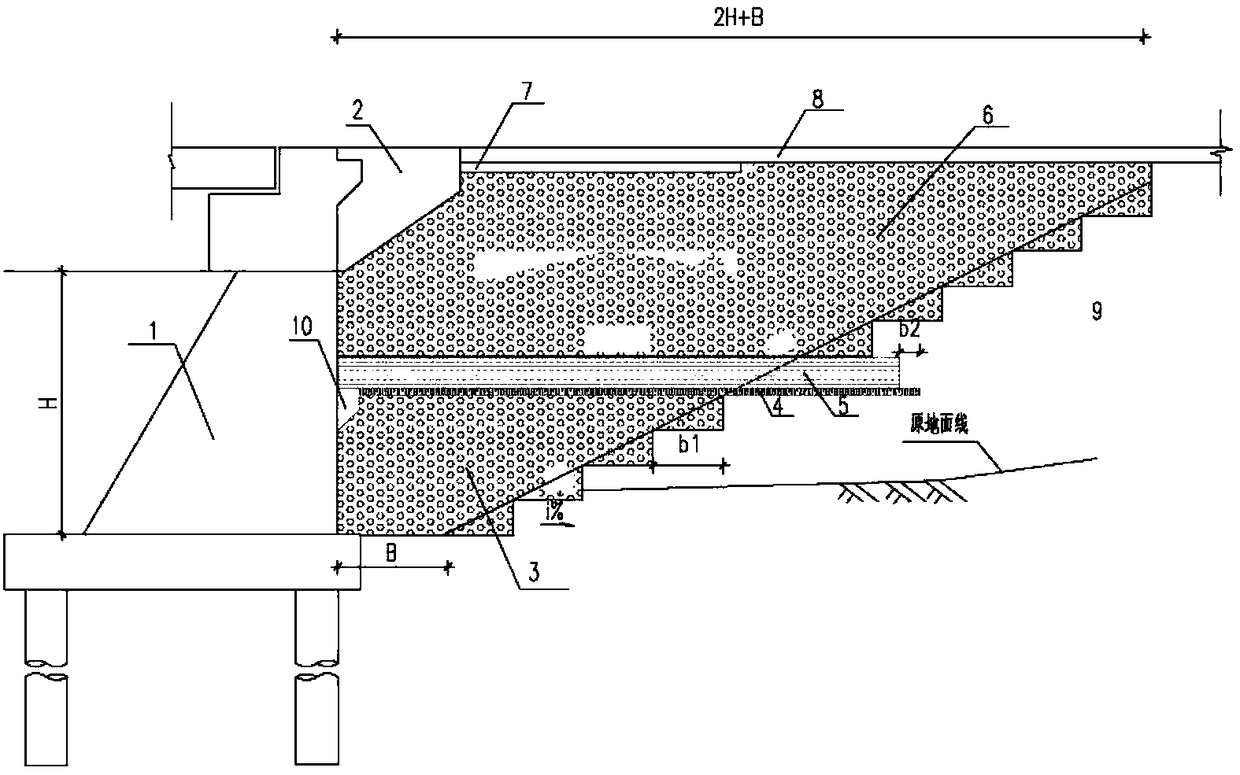

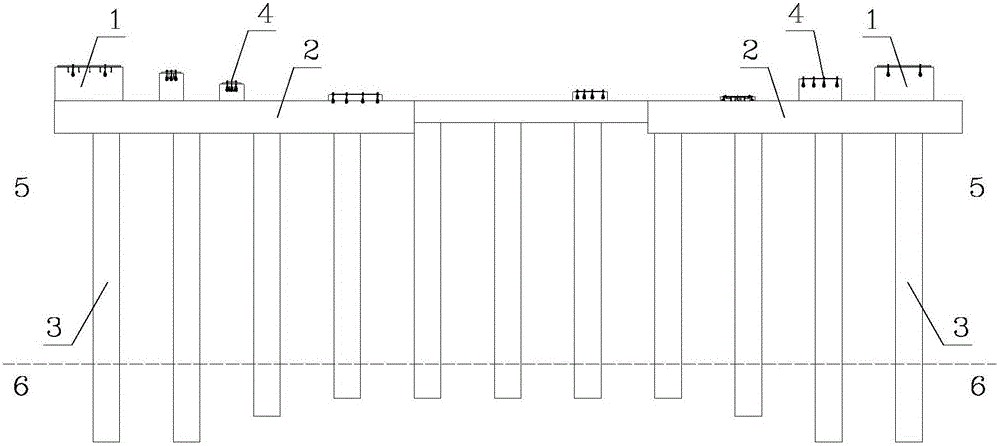

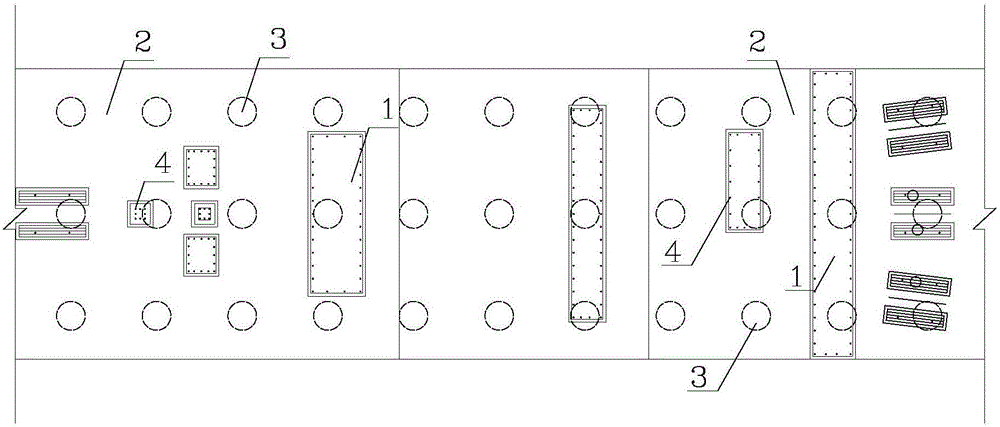

Medium-low speed maglev traffic engineering double-line filling section pile foundation support beam type rail bearing beam transition section structure

ActiveCN106283950AHigh structural reliabilityAvoid stiffnessBallastwayFoundation engineeringStructural deformationLow speed

The invention belongs to the technical field of medium-low speed maglev traffic engineering low-set lines and discloses a medium-low speed maglev traffic engineering double-line filling section pile foundation support beam type rail bearing beam transition section structure. The transition section structure comprises multiple pile foundation bearing structures, a reinforced concrete support beam, reinforced concrete rail bearing beam base plates, two rows of reinforced concrete beam type structures, lower roadbed filler of a rail bearing beam, two-side backfill filler of the rail bearing beam, a bridge abutment, a trapezoid filling body and end walls, wherein the reinforced concrete beam type structures are connected to the top ends of the reinforced concrete rail bearing beam base plates in a supported mode, and the two-side backfill filler of the rail bearing beam is supported by the lower roadbed filler of the rail bearing beam. The transition section structure is higher in long-term stability, the high requirement for rail bearing beam structural deformation and post-construction settlement is met, the requirement for long-term stability, durability and construction quality controllability of a foundation bed is met, and smooth transition between a maglev elevated structure and a low-set line transition section F rail is effectively achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Construction method for solving problem of vehicle bump at bridge head

InactiveCN106192649AReduce maintenance costsReduce jumpingRoadwaysSoil preservationAbutmentRoad surface

The invention discloses a construction method for solving the problem of vehicle bump at a bridge head. The construction method comprises the following steps: arranging a connecting structure which comprises cement flyash gravel (CFG) piles, a soil filling structure, a cemented soil grouting treatment zone and geonets; sequentially leveling and compacting the original road bed under the soil filling structure through vibration; laying the CFG piles under the soil filling structure; laying the geonets and the soil filling structure from bottom to top from the bottom layer; and grouting and curing cemented soil to finish the whole construction process. The method disclosed by the invention has simplicity of operation, can greatly reduce the maintenance cost in bridge head treatment of a road construction administration section, effectively decreases the problems of vehicle bump at the bridge head, improves driving comfort and safety, has high construction quality, reduces the differential settlement between a bridge abutment and the original road bed to a large extent, and prolongs the service life of a road surface.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

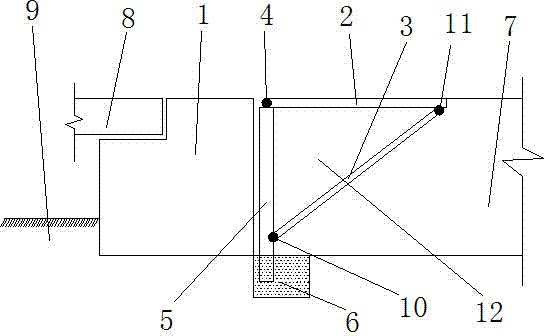

Pile column and framework combined bridge-road transition section structure separated from bridge abutment

InactiveCN104775353AReduce settlement differencePrevent secondary settlementBridge structural detailsBridge materialsReinforced concreteAbutment

The invention relates to the technical field of bridge subgrade settlement difference control in traffic engineering, in particular to a pile column and framework combined bridge-road transition section structure separated from a bridge abutment. The pile column and framework combined bridge-road transition section structure comprises the bridge abutment, a beam body, a subgrade body, a pile column behind the abutment and a reinforced concrete framework, wherein the pile column behind the abutment is fixedly arranged behind the bridge abutment; the reinforced concrete framework comprises a reinforced concrete prefabricated horizontal plate and a reinforced concrete prefabricated diagonal bracing plate; the reinforced concrete prefabricated horizontal plate and the upper end of the pile column behind the abutment are connected by a first high-strength hinged bolt; the reinforced concrete prefabricated diagonal bracing plate and the lower part of the pile column behind the abutment are connected by a second high-strength hinged bolt; the other end of the reinforced concrete prefabricated horizontal plate and the other end of the reinforced concrete prefabricated diagonal bracing plate are connected by a third high-strength hinged bolt; the reinforced concrete prefabricated diagonal bracing plate is fixed on the subgrade body in an attaching manner; the settlement of a bridge-road transition area is effectively controlled by the reinforced concrete framework; the problem that settlement difference exists among special-shaped structures due to rigidity difference in a traffic line is solved.

Owner:中国铁路兰州局集团有限公司

Extradeep extruding and ramming method

InactiveCN1189628CHigh strengthImprove stabilitySoil preservationEngineeringUltimate tensile strength

Owner:SPECIAL SOFT FOUND BRANCH NO 2 CONSTR ENG CO LTD NANCHANG COUN

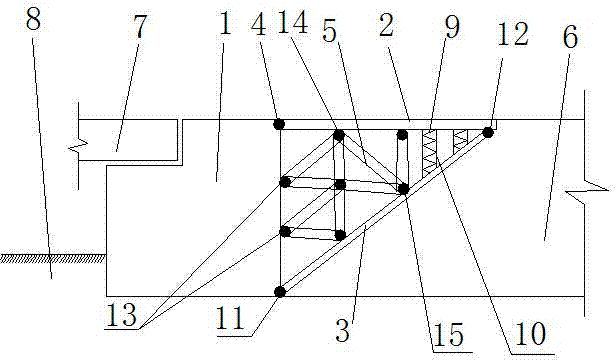

Framework, truss and high-strength spring combined bridge-road transition section structure integrated with bridge abutment

ActiveCN104775352ASettlement controlSolve the stiffness problemBridge structural detailsReinforced concreteAbutment

The invention discloses a framework, truss and high-strength spring combined bridge-road transition section structure integrated with a bridge abutment. The framework, truss and high-strength spring combined bridge-road transition section structure comprises a foundation, the bridge abutment, a beam body, a roadbed body, a framework transition section structure, a high-strength spring bundle and a reinforced concrete prefabricated truss member, wherein the framework transition section structure comprises a reinforced concrete prefabricated horizontal plate and a reinforced concrete prefabricated diagonal bracing plate; the reinforced concrete prefabricated horizontal plate and the upper end of the bridge abutment are connected by a bolt; the reinforced concrete prefabricated diagonal bracing plate and the lower end of the bridge abutment are connected by the other bolt; the other end of the reinforced concrete prefabricated horizontal plate and the other end of the reinforced concrete prefabricated diagonal bracing plate are connected by another bolt; a cavity is formed by the reinforced concrete prefabricated horizontal plate, the bridge abutment and the reinforced concrete prefabricated diagonal bracing plate; the reinforced concrete prefabricated truss member and the high-strength spring bundle are arranged in the cavity; the reinforced concrete prefabricated diagonal bracing plate is in contact with the roadbed body in an attaching manner; the roadbed body provides powerful support for a structure with a framework, a truss and a high-strength spring; the reinforced concrete prefabricated truss structure can be used for effectively controlling the settlement of a bridge-road transition area.

Owner:LANZHOU JIAOTONG UNIV

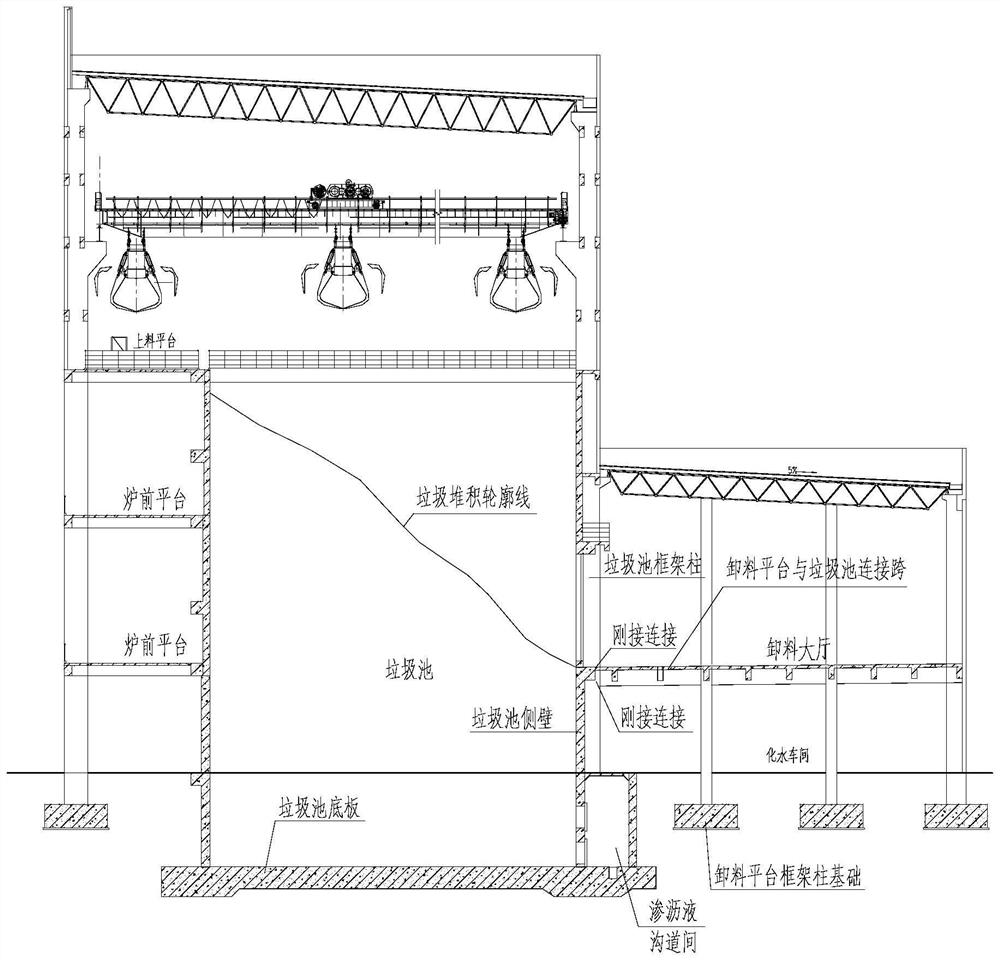

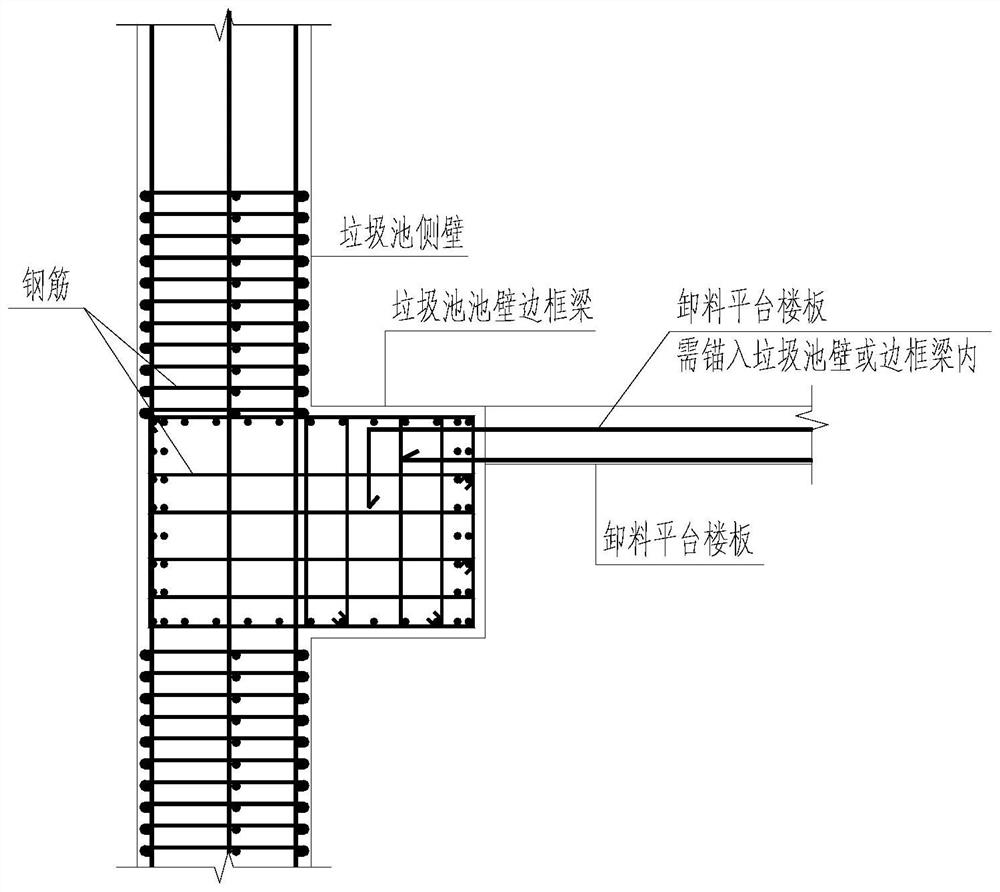

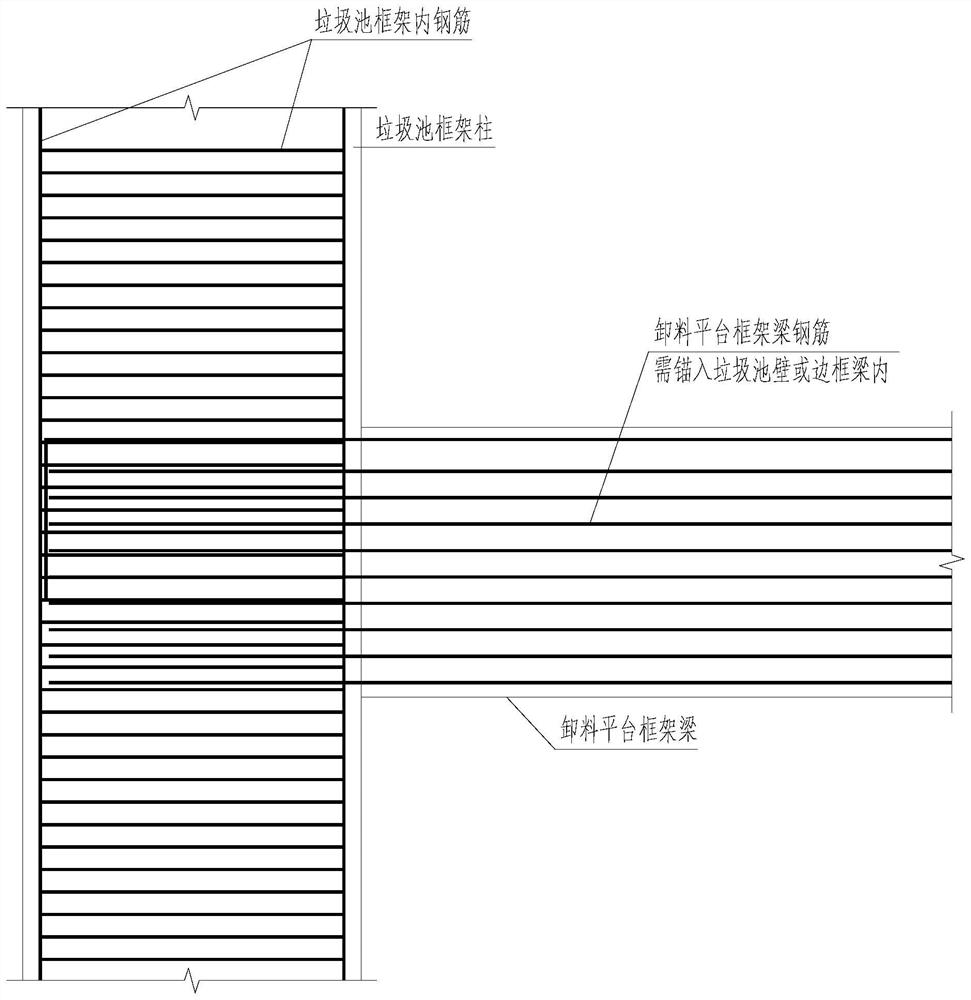

Garbage pool bottom plate and unloading platform frame column foundation settlement difference treatment system and method

PendingCN114775700AReduce settlement differenceReduce stressArtificial islandsFloorsFloor slabArchitectural engineering

The invention provides a garbage pool bottom plate and unloading platform frame column foundation settlement difference treatment system and method. A garbage pool, a peripheral frame and an unloading platform are subjected to first-stage construction except the part of a connecting span of the unloading platform and the garbage pool; second-stage construction is conducted on the discharging platform and the garbage pool connecting span floor slab and the discharging platform and the garbage pool connecting span frame beam, and water injection pre-sedimentation treatment is conducted when the garbage pool is constructed to the preset height; the unloading platform and garbage pool connecting cross frame beam is supported at the top of a bracket on the side of a garbage pool frame column, and a rotating gap with a preset width is reserved between the unloading platform and garbage pool connecting cross frame beam and the garbage pool frame column; the unloading platform and the garbage pool connecting cross floor slab are supported at the tops of the lifting lugs on the side of the frame beam of the side wall of the garbage pool, and a rotating seam with a preset width is reserved between the unloading platform and the garbage pool connecting cross floor slab and the frame beam of the side wall of the garbage pool; according to the method, the construction period and cost of foundation treatment are saved, only the discharging platform is connected and spans in the second stage for construction in the water injection pre-pressing stage, continuous construction can be conducted in the garbage pool and other areas of the discharging platform, and the engineering construction period is shortened.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Stone floor system and its construction method

ActiveCN110374300BReduce settlement differenceReduce height differenceFlooringArchitectural engineeringStructural engineering

The invention discloses a stone floor system and a construction method thereof, relates to the field of architectural decoration, and aims to solve the problem that the existing stone floor laying flatness is greatly affected by its own weight and the dry humidity of cement mortar. The main points of the technical scheme are: It includes a gravel leveling layer, a cement slurry layer and a floor layer. The floor layer includes a plurality of floors and a leveling mechanism. The leveling mechanism includes a lower bearing plate abutting column and an upper pressure plate. Both ends are in contact with the lower parts of two adjacent floors at the same time, the abutment column is located between the two adjacent floors, the lower end of the abutment column is in contact with the base floor, and the upper end protrudes from where the upper surface of the floor is located. A through hole is opened in the plane and transverse direction, and the upper platen is pierced with the through hole, and the two ends are respectively abutted against the upper plate surfaces of two adjacent floors. The stone floor system and the construction method thereof of the present invention can reduce the interference caused by the self-weight of the stone and the dry humidity of the cement mortar, and improve the overall flatness of the floor.

Owner:深圳市新雅建设工程有限公司

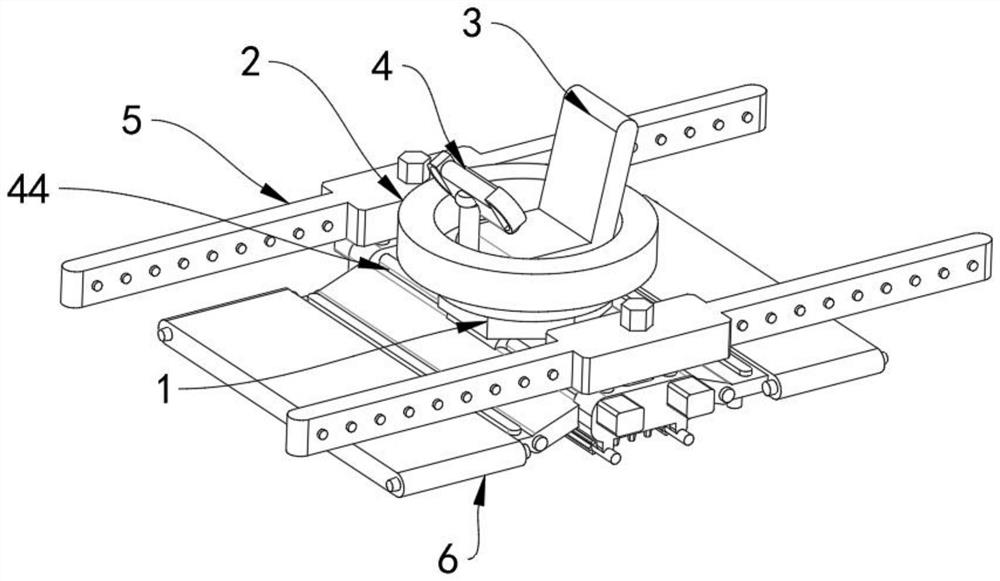

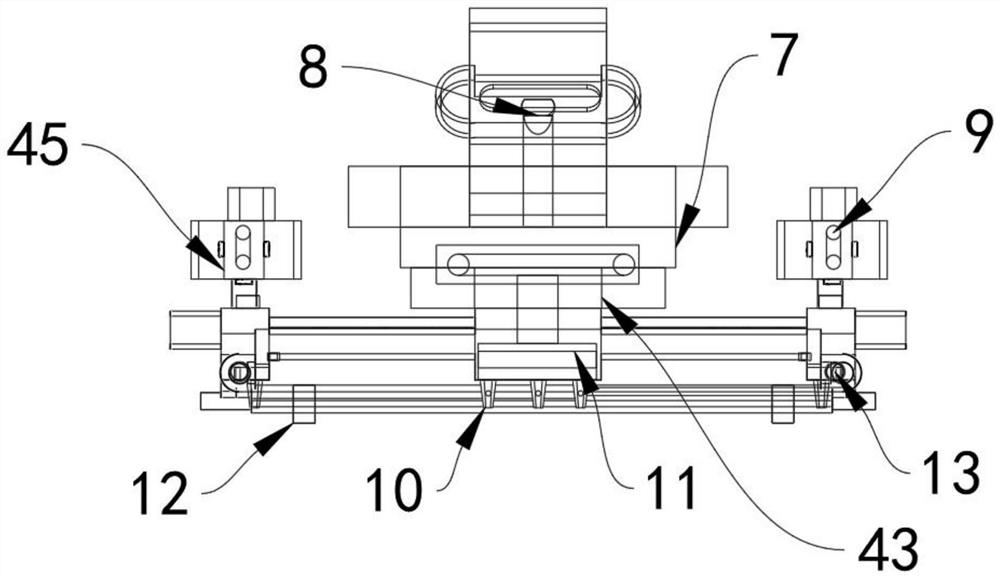

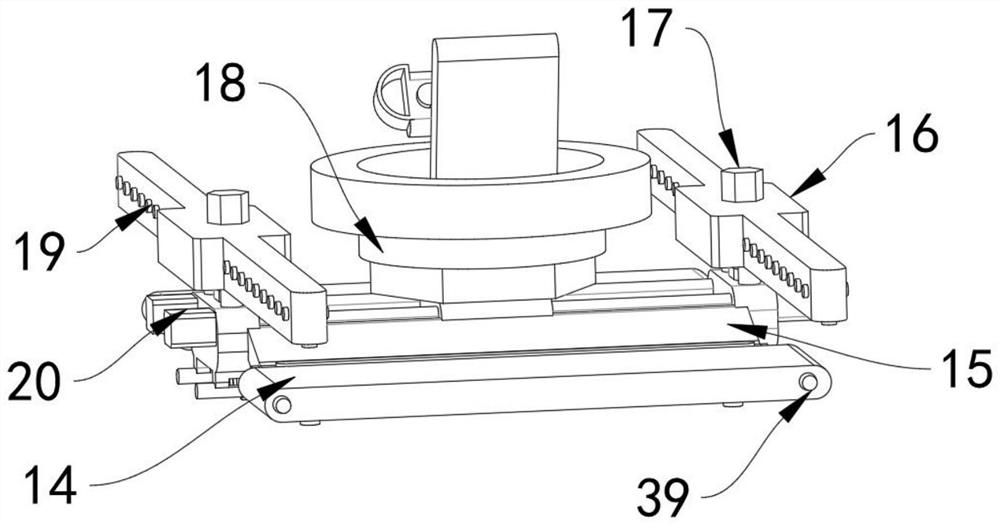

Pavement paving and leveling device for highway construction

InactiveCN113737615AReduce settlement differenceAvoid breakingRoads maintainenceArchitectural engineeringControl arm

The invention discloses a pavement paving and leveling device for highway construction. The pavement paving and leveling device comprises a main control rotating end and a control arm-chair arranged at the upper end of the main control rotating end, three bearing plates, which are arranged at the lower end of the main control rotating end; rolling leveling structures, which are arranged at the front end and the rear end of each bearing plate; a fixed oscillation column,which is arranged below the rolling leveling structure; two crushing rollers, which are arranged below the bearing plates; five movable fine vibration ends, which are arranged at the lower ends of the bearing plates; and spraying cooling structures, which are arranged on the two sides of the main control rotating end. In the using process, by means of mutual cooperation of a multi-rolling structure and a vibration structure, it is guaranteed that a road is flat, the using requirement is met, and the service life is prolonged, so that the problems that the road leveling effect is reduced, the flatness is low, and the service life of the road is shortened are effectively solved.

Owner:张海忠

Construction method for treating vehicle jump at bridge head in highway

ActiveCN102979021BPrevent lateral pressureAvoid destructionRoadwaysBridge erection/assemblyRoad surfaceEngineering

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

Butt strap structure construction method for bridgehead bumping

InactiveCN111622104ALower the water tableReduce settlementPaving detailsBridge structural detailsWater stopRebar

The invention discloses a butt strap structure construction method for bridgehead bumping. The butt strap structure construction method is characterized by comprising the following construction stepsof: (1) constructing cement mixing piles; (2) excavating a surface soil body of the concrete butt strap part; (3) implanting longitudinal drainage plates and water stop plates into the soil body; (4)paving a sandstone cushion layer at the part where transverse drainage plates is placed, and tamping the sandstone cushion layer; (5) inserting the transverse drainage plates into the grooves of the longitudinal drainage plates and the water stop plates; (6) drilling a water pumping holes in the left sides of the longitudinal drainage plates; (7) communicating the steel bars buried in the longitudinal drainage plates with a cathode of a power source, meanwhile, communicating the steel bars buried in the water stop plates with an anode of the power source, and pumping water synchronously through water pumping holes; (8) laying light filler on the transverse drainage plates, and arranging geotechnical cloth on the light filler; (9) inserting a dowel bar into the groove of a pavement slab; and (10) filling the deformation joint with hemp threads, and then laying a steel cover plate at the top of the deformation joint.

Owner:罗海军

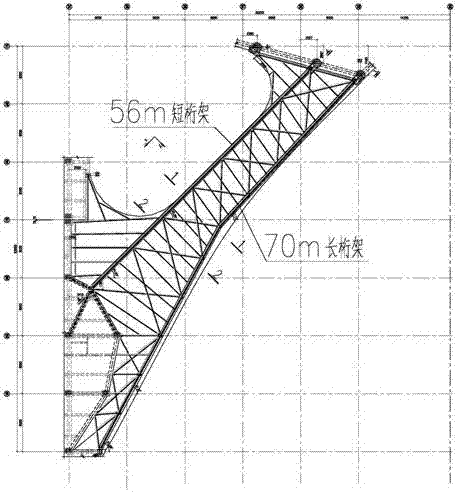

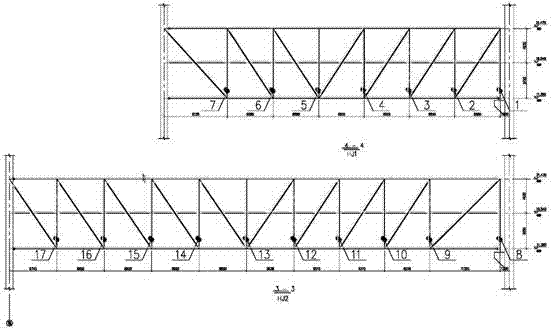

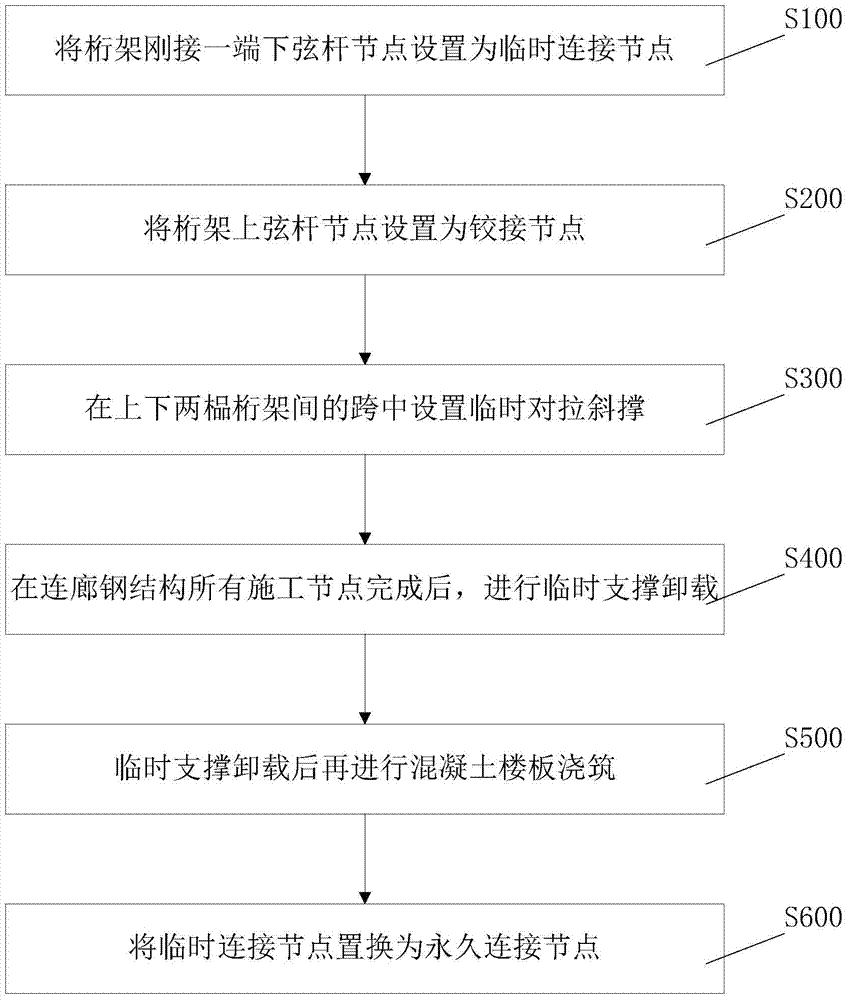

A construction control method for corridors composed of long-span trusses with different lengths

ActiveCN105369891BSolve level problemsReduce settlement differenceBuilding constructionsFloor slabCasting

The invention provides a construction control method of a corridor consisting of large-span trusses different in length. The construction control method comprises the following steps that the lower chord node at the rigid connection end of each truss is configured to serve as a temporary connection node; the upper chord nodes of the trusses are configured to serve as hinge nodes; temporary opposite-pull diagonal bracings serving as temporary supports are arranged at the midspans between the upper trusses and the lower trusses; the temporary supports are dismounted after all construction nodes of a corridor steel structure are completed; concrete floor slab casting is performed after the temporary supports are dismounted; the temporary connection nodes are replaced by permanent connection nodes. By means of the construction control method of the corridor consisting of the large-span trusses different in length, the construction control problem produced under the situation that a large-span corridor truss structure is different in truss length and more greatly influences a support seat structure is solved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com