Construction method and device for cast-in-place concrete pile

A construction method and concrete technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of disturbed undisturbed soil, poor actual controllability, increased construction difficulty, etc., to reduce project cost, reduce settlement difference, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

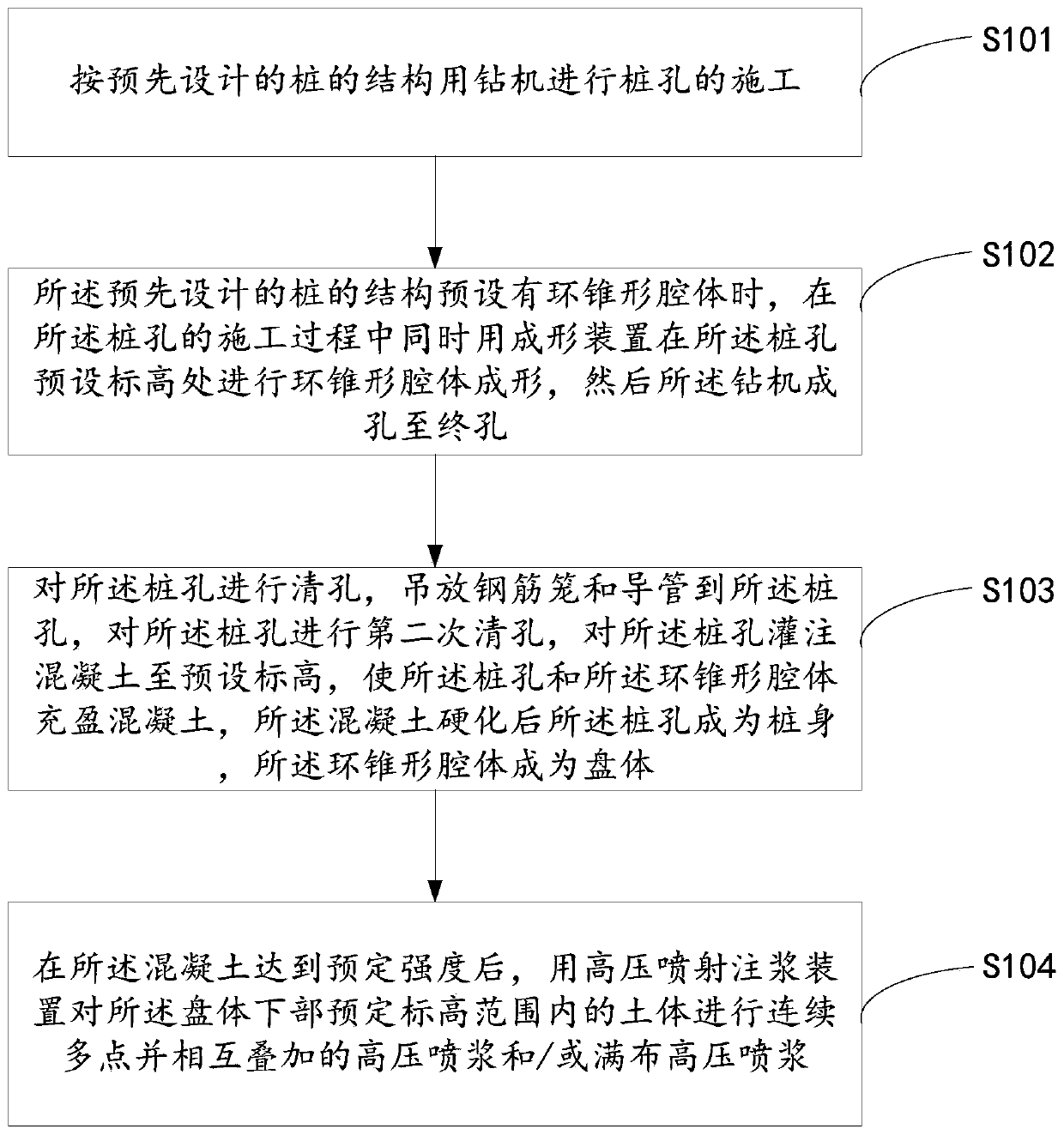

[0039] refer to figure 1 , a construction method for concrete pouring piles, comprising:

[0040] S101. Use a drilling rig to construct pile holes according to the pre-designed pile structure.

[0041] Before constructing the pile hole with a drilling rig according to the pre-designed pile structure, continuous multi-point and superimposed high-pressure spray grouting is implemented in advance within the predetermined height range at the preset elevation of the pile hole, and the cement soil within the height range reaches After presetting the strength, use a drilling rig to construct pile holes according to the pre-designed pile structure.

[0042] According to the pre-designed pile structure, the process of pile hole positioning, burying casing and drilling rig placement before hole formation is carried out.

[0043] The hole-forming process of the drilling rig is drilling with mud retaining walls or other forms of non-mud retaining walls; the drilling rig is an integrated...

Embodiment 2

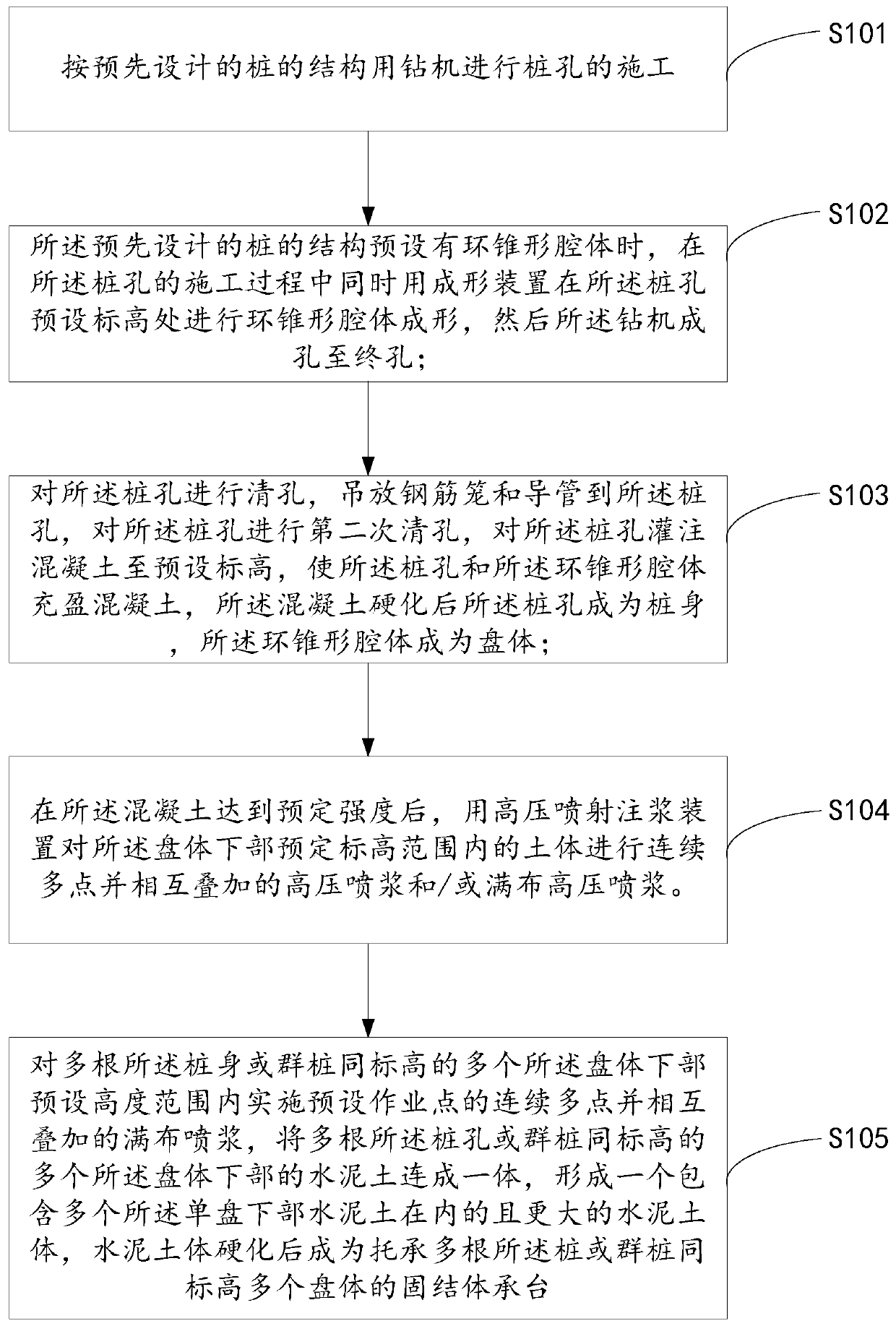

[0057] refer to figure 2 , this embodiment adds the following steps on the basis of Embodiment 1:

[0058] S105. Implement continuous multi-point preset operation points within the predetermined height range of the lower part of the plurality of trays of the same elevation of the plurality of piles or pile groups and spray grouting on each other, and place the plurality of piles The pile body or the pile group is integrated with the cement soil at the lower part of the plurality of trays at the same level to form a larger cement soil body including the cement soil at the lower part of the single tray. After the cement soil hardens It becomes a consolidated body cap supporting a plurality of piles with the same elevation as a plurality of plates.

[0059] For multiple piles or pile groups, continuous multi-point superimposed high-pressure shotcrete can be implemented within the preset height range of the lower parts of multiple plates of the same elevation according to the pr...

Embodiment 3

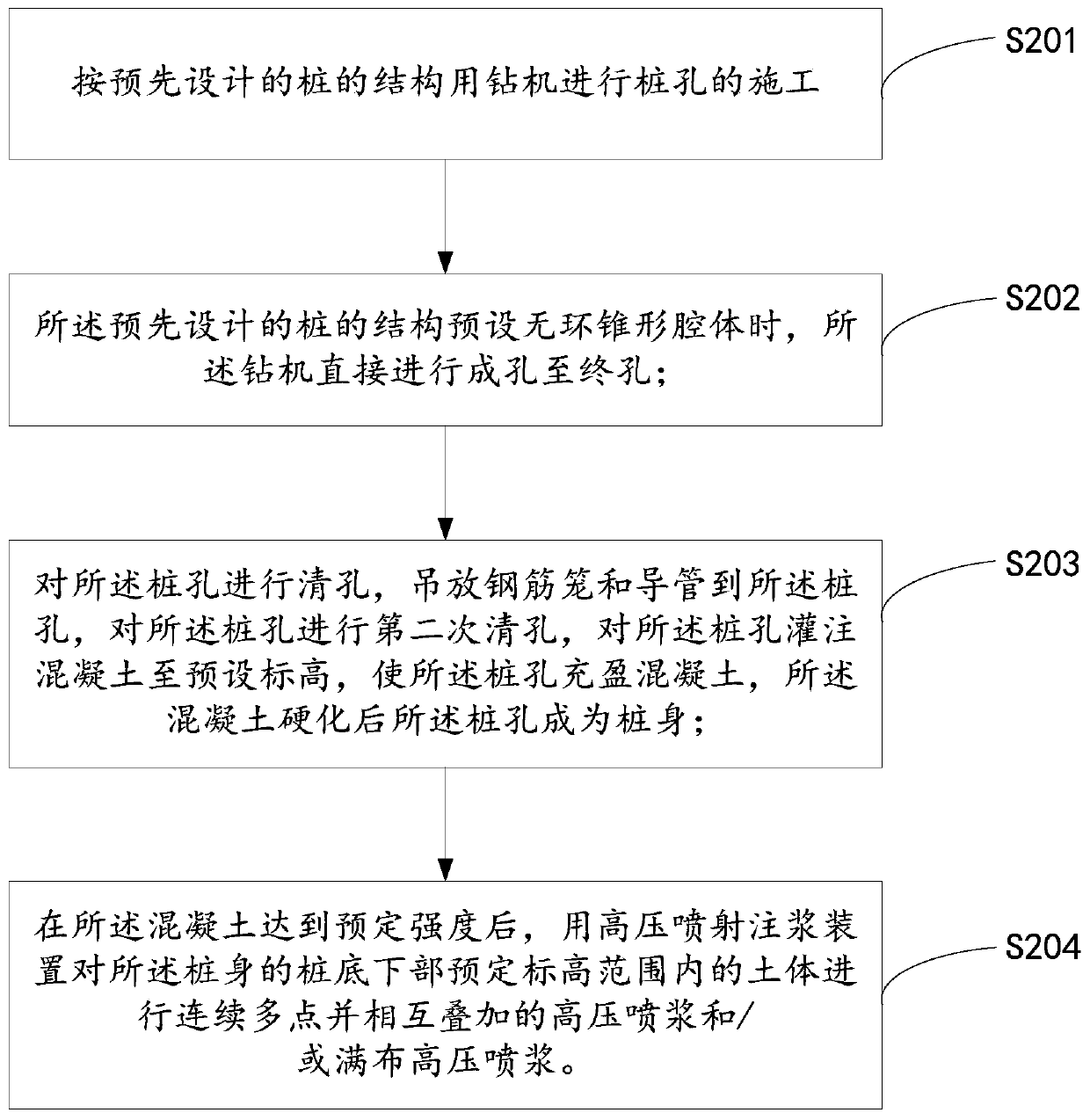

[0061] refer to image 3 , a construction method for concrete pouring piles, comprising:

[0062] S201. Use a drilling machine to construct pile holes according to the pre-designed pile structure.

[0063] According to the pre-designed pile structure, the process of pile hole positioning, burying casing and drilling rig placement before hole formation is carried out.

[0064] The hole-forming process of the drilling rig is drilling with mud retaining walls or other forms of non-mud retaining walls; the drilling rig is an integrated device composed of a drilling rig or a drilling rig and a cone-shaped cavity former for pile hole rings, and its control and operation methods are: Automatic or manual operation and control mode.

[0065] S202. When the structure of the pre-designed pile presets a ringless tapered cavity, the drilling machine directly performs hole forming to the final hole.

[0066] The drilling rig drills into the hole until it reaches the design pile bottom el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com