Garbage pool bottom plate and unloading platform frame column foundation settlement difference treatment system and method

A technology of unloading platform and foundation settlement, which is applied in the processing of building materials, infrastructure engineering, floor slabs, etc. Avoid cracking or damage and ensure the effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

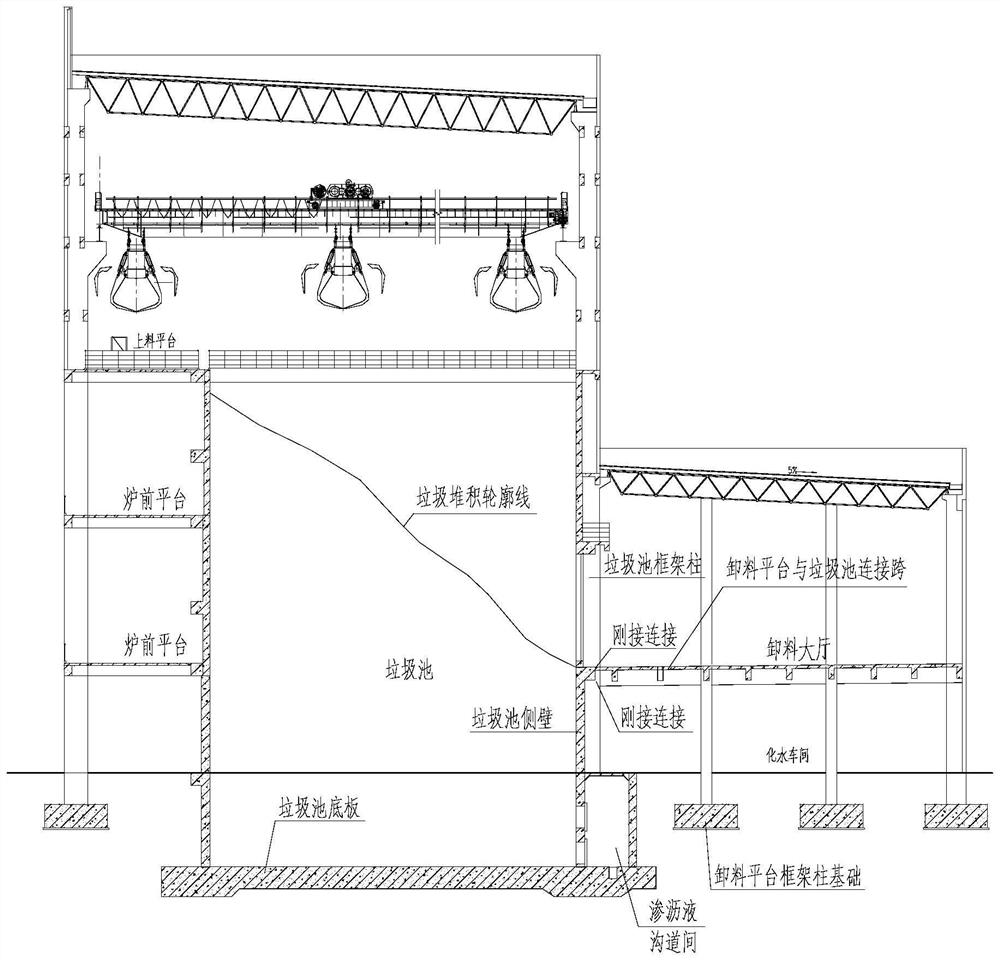

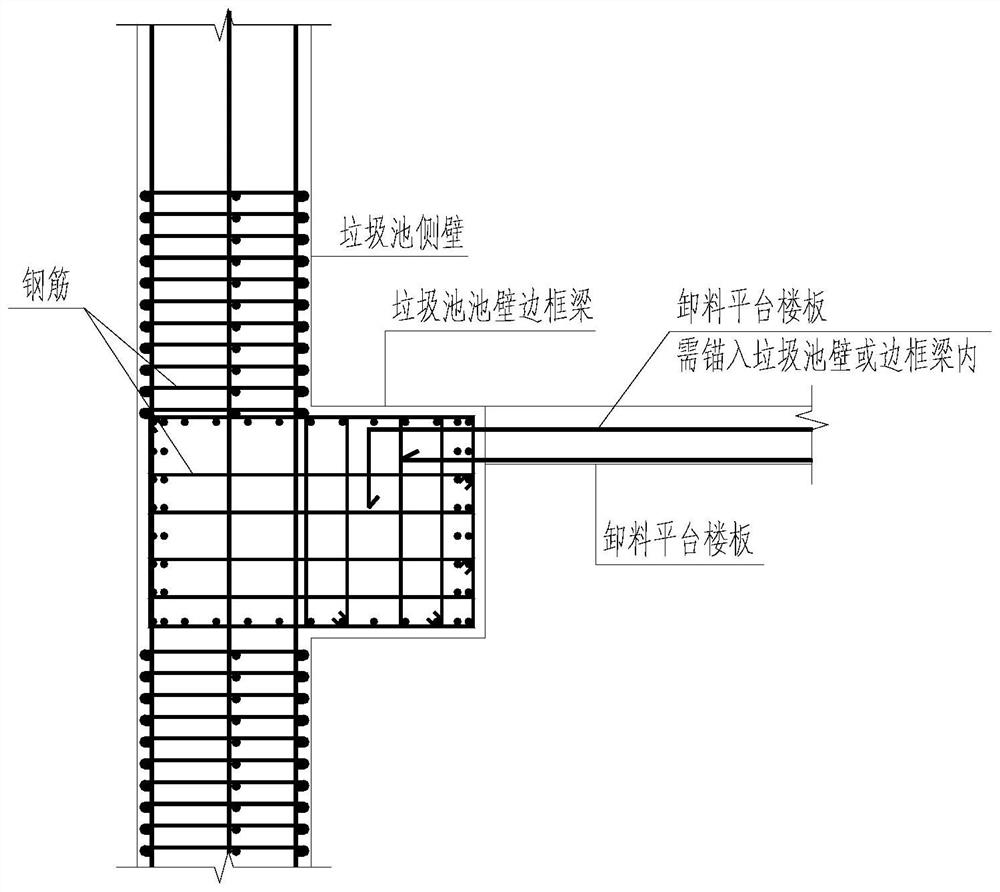

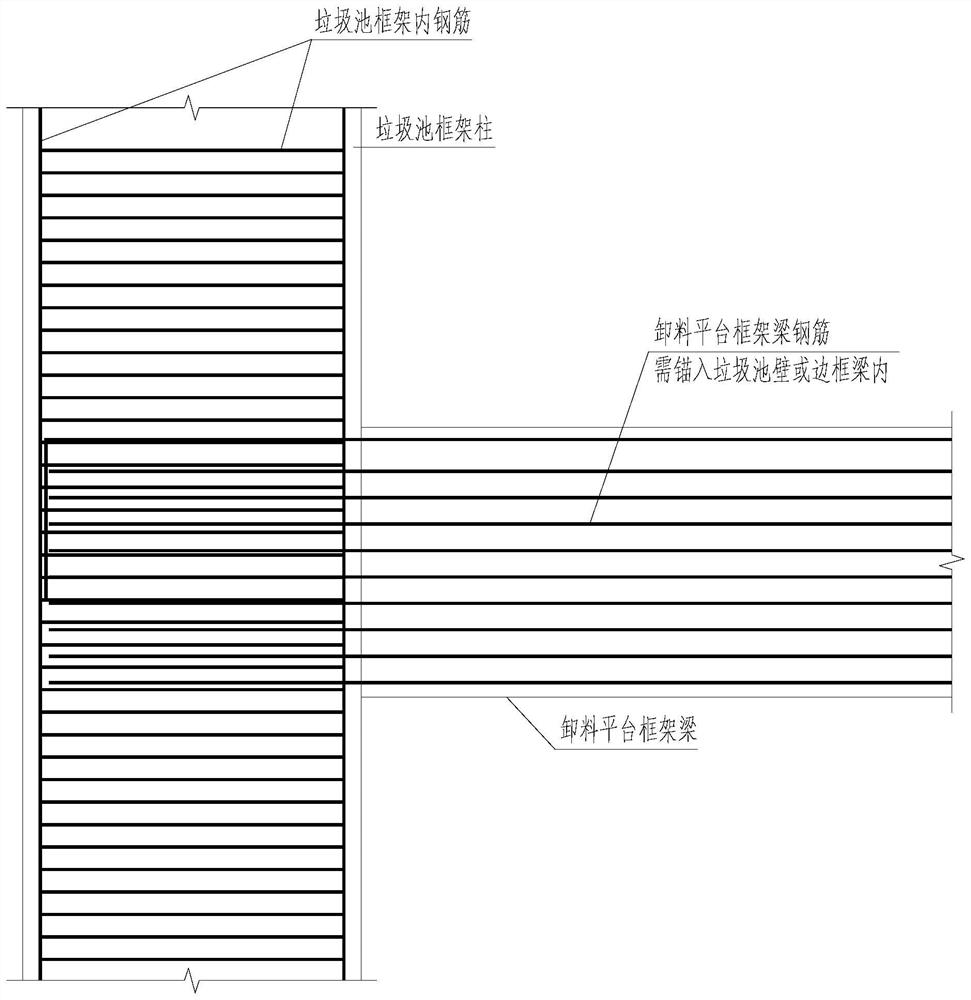

[0064] like Figure 5 , Image 6 As shown in the figure, this embodiment provides a method for treating the settlement difference between the bottom plate of the garbage pool of the garbage power plant and the frame column foundation of the unloading platform, including: the bottom plate of the garbage pool 1, the frame column foundation of the unloading platform 2, and the side column of the garbage pool frame column. Leg 3. U-shaped steel bars are reserved at the top of the corbels on the side of the frame column of the garbage pool. 4. The side pick ears of the side wall of the garbage pool The pool connects the cross-frame beam with reserved inserts 7, the unloading platform connects with the garbage pool and the cross-floor reserved inserts 8, the unloading platform connects with the refuse pool across the floor slab 9, and the unloading platform connects with the refuse pool across the frame beam 10.

[0065] The construction part of the first stage includes: the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com