Construction method for treating vehicle jump at bridge head in highway

A technology of bridge head jumping and construction method, applied in the fields of bridge engineering and road engineering, can solve the problems of inability to solve the problem of the compaction of the back of the platform, the limitation of the use of large-scale compactors, and the narrow construction space of the back of the platform, etc., so as to reduce the settlement difference. , low cost and stable foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

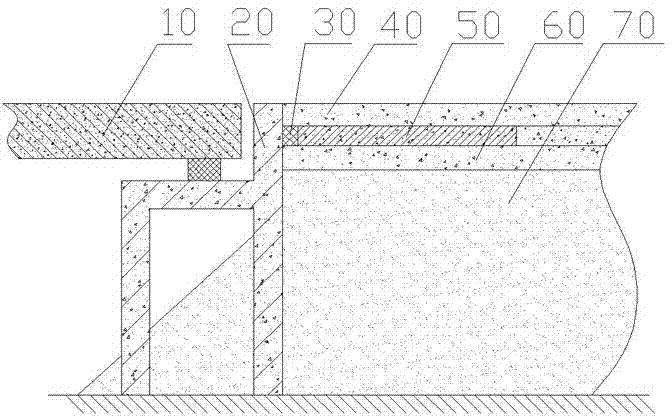

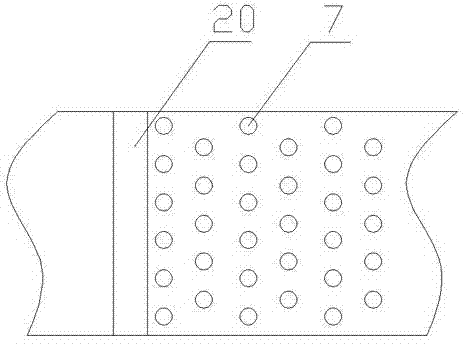

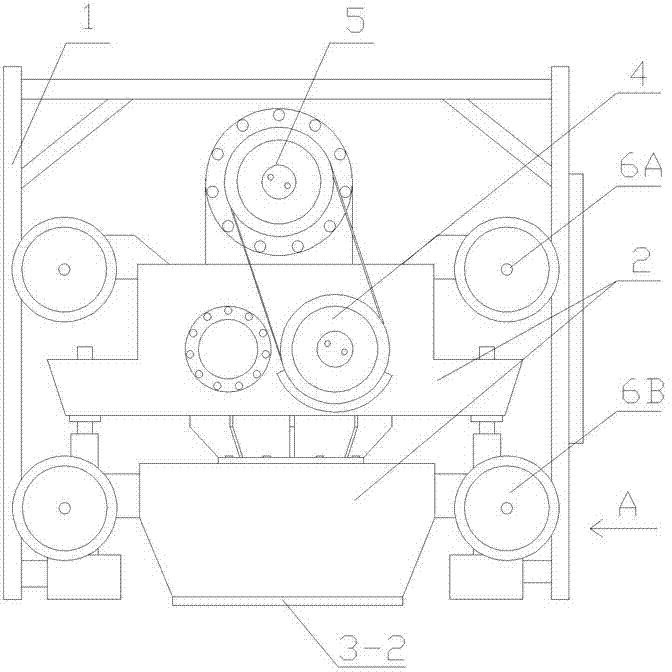

[0022] see figure 1 , the construction method of the present invention's control highway bridge head jumping, comprises subgrade treatment, base course treatment and road surface construction, specifically comprises the following steps.

[0023] Step A. Use plain soil or light materials to fill in layers at the back of the abutment. The compacted thickness of each layer shall not exceed 20cm. The compaction degree at the optimum moisture content shall be greater than 95%. The surface is tamped with a powerful tamping machine to form a stable platform back subgrade 70. The lightweight material refers to fillers with low density. Due to the low density of fillers, the settlement caused by the self-weight of the bridge head is small, which can greatly reduce the pressure on the foundation, thereby helping to solve the technical problem of bridge head jumping.

[0024] The compactness of tamping is greater than 100% at the optimum moisture content. In the prior art, low compactn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com