Stone floor system and its construction method

A floor and stone technology, applied in the direction of architecture, floor, building structure, etc., can solve the problems affecting the overall flatness of the stone floor and low stone floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

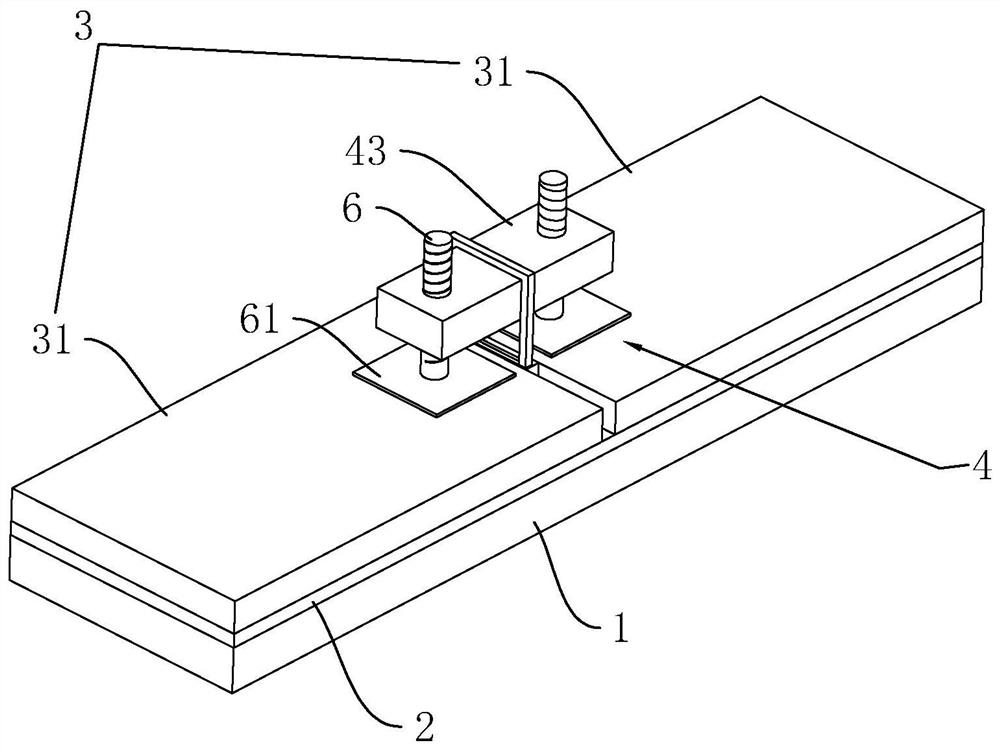

[0038] Stone floor system, see figure 1 , including a sand and gravel leveling layer 1, a cement slurry layer 2 and a floor layer 3 arranged on the base floor in sequence from bottom to top, the sand and gravel leveling layer 1 is made of coarse sand, cement and water, and it is paved on the base ground It is used for leveling; the grout layer 2 is made of cement and water, which is used for bonding the floor layer 3; the floor layer 3 includes a plurality of evenly laid floors 31 .

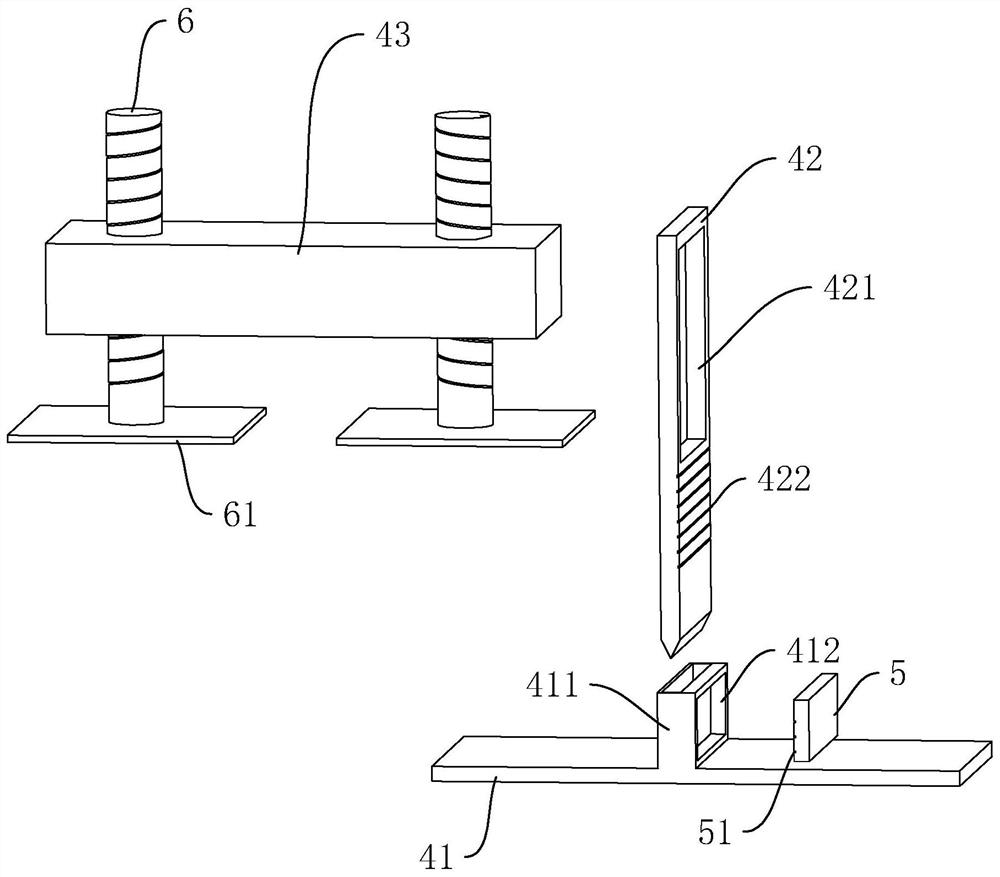

[0039] refer to figure 1 with figure 2 , in order to improve the flatness of the floor layer 3, a leveling mechanism 4 is provided for leveling its plurality of floors 31 during its laying stage. The leveling mechanism 4 includes a lower support plate 41 , an abutment column 42 vertically penetrating the lower support plate 41 , and an upper pressing plate 43 connected to the abutment column 42 .

[0040] In the state of use, both ends of the lower supporting plate 41 are placed horizontally ...

Embodiment 2

[0045] Stone floor system, see figure 2 The difference from Embodiment 1 is that the abutment column 42 is vertically slidably connected to the lower bearing plate 41. The reason for this arrangement is that the lower end of the abutment column 42 protrudes from the lower plate of the lower bearing plate 41 when it is in use. surface, and the installation of the lower bearing plate 41 is preferably inserted under the floor 31 after laying a floor 31, which causes the lower part of the abutment column 42 to easily draw a groove on the cement slurry layer 2 and sand and gravel leveling layer 1, increasing repair Step: After the abutment column 42 is set to vertically slide and connect to the lower bearing plate 41, it can be detachably connected to the lower bearing plate 41, and then the abutment column 42 can be installed after the lower bearing plate 41 is installed to avoid scratching. out of the ditch.

[0046] The abutting column 42 is plate-shaped; in order to still be ...

Embodiment 3

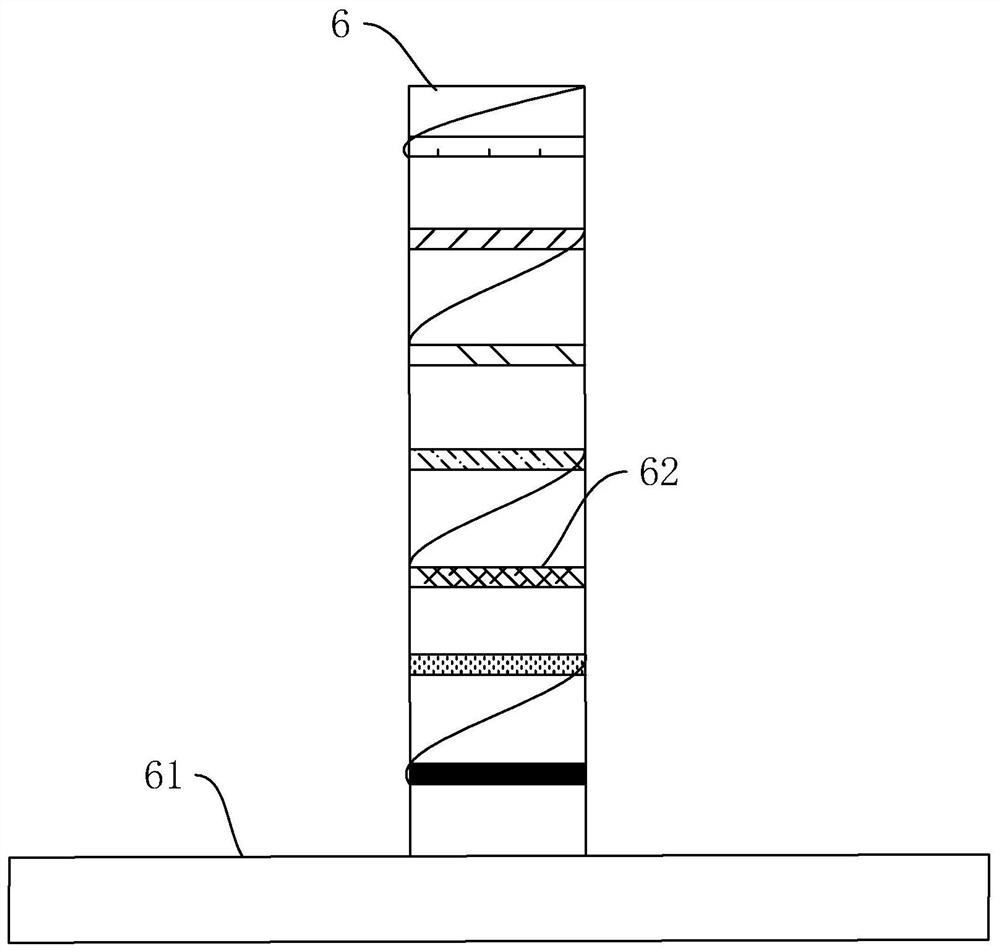

[0050] Stone floor system, see figure 2 , The difference with Embodiment 1 or 2 is that: the two ends of the upper pressing plate 43 protruding from the through hole 421 are vertically pierced with the fine-tuning screw 6 respectively, and the fine-tuning screw 6 and the upper pressing plate 43 are threadedly connected.

[0051] When in use, the staff first passes the upper pressing plate 43 through the through hole 421, and then turns the fine-tuning screw 6 to make it abut against the floor 31, so that the adjacent floor 31 can be kept flat; at the same time, the staff can also turn the fine-tuning screw 6. Fine-tuning the amount of pushing on the floor 31, that is, fine-tuning the flatness of the floor 31, so that the floor 31 can be laid more evenly.

[0052] The upper plate 43 and the fine-tuning screw 6 are preferably made of metal, because it is necessary to reduce the interference of deformation on the use effect; the lower bearing plate 41 and the abutting column 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com