Construction method for solving problem of vehicle bump at bridge head

A construction method and bridge jumping technology, applied in soil protection, infrastructure engineering, roads, etc., can solve the problems of different settlement time of roadbed and abutment, high filling height, secondary jumping, etc. The problem of jumping at the bridge head, the reduction of the settlement difference, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

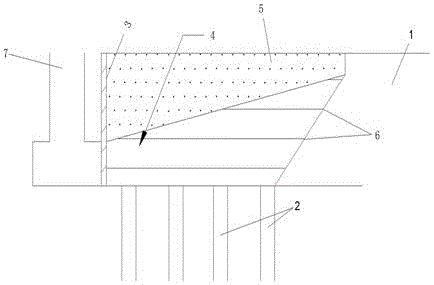

[0016] (1) Set up a connection structure, such as figure 1 As shown, the connection structure is located between the bridge abutment 7 and the original roadbed 1; the connection structure includes CFG piles 2, filling structures 4, cement-soil grouting treatment area 5 and geonet 6; CFG piles 2 are located in the lowest layer, which effectively The original roadbed 1 is reinforced to reduce the settlement of the original roadbed 1; the filling structure 4 is located on the CFG pile 2, and the filling structure 4 is separated by the geonet 6 and filled with filler in parallel layers. The layers of the filling structure 4 are locked together to form a stable plane, which is used to effectively reduce and control the deformation of the connection structure, and the layers of the filling structure 4 are compacted after filling, which can reduce the settlement of the connection structure. The cement-soil grouting treatment area 5 is located on the upper part of the filling structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com