Combined-rammer construction technology for foundation treatment

A technology for foundation treatment and construction technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of difficulty in suction hammer and soft ground driving, low bearing capacity increase, insufficient ramming pit depth, etc. To achieve the effect of large punching force, reducing foundation vibration, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the implementation steps.

[0045] A combined hammer method foundation treatment construction technology is characterized by:

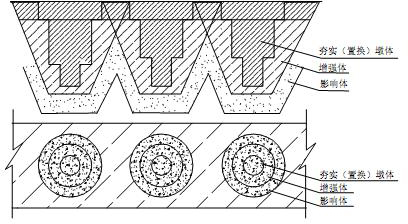

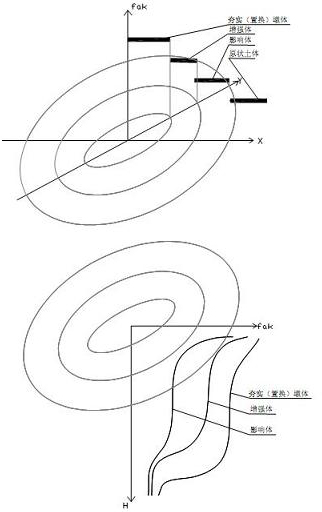

[0046] 1. When the surface soil of the construction site is soft soil such as silt and muddy soil, which cannot meet the requirements of crane walking and construction operation, the replacement material determined by the test tamping is used to cover the construction site, and the flat hammer is used for full tamping, and the tamping The lap joint is above 1 / 4 of the hammer diameter, and the hammer will stop when the characteristic value of the surface soil bearing capacity reaches 60Kpa;

[0047] 2. Leveling the field: first lay out the lines and arrange points according to the design requirements, and the tamping machine is in place, ready to hit;

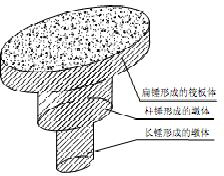

[0048] 3. Deep compaction in the first process: use a conical long hammer with a diameter of 1-1.5m and a hamm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com