Extradeep extruding and ramming method

A technology of dynamic ramming and ramming pits, which is applied in the fields of soil protection, construction, and infrastructure engineering. It can solve the problems of high cost, small number of large ramming machines, and inability to carry out construction, so as to reduce construction costs, save construction costs and Human and material resources, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

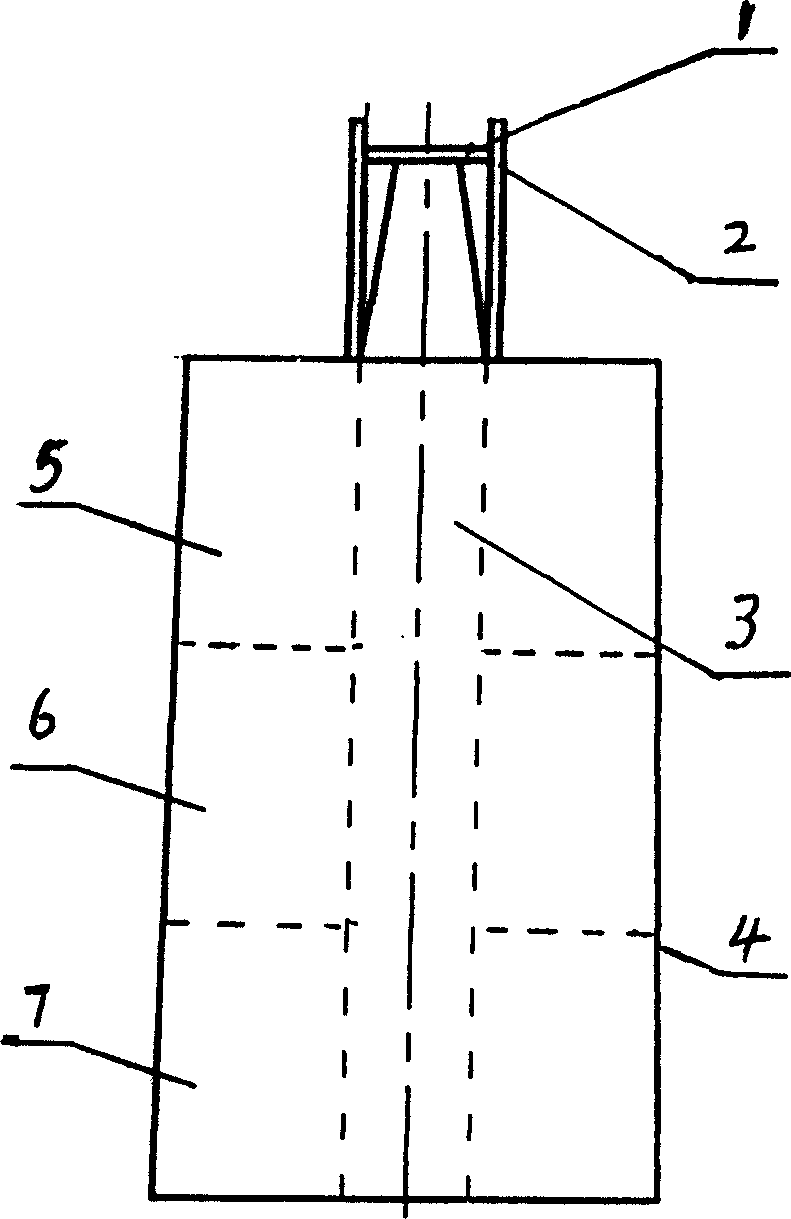

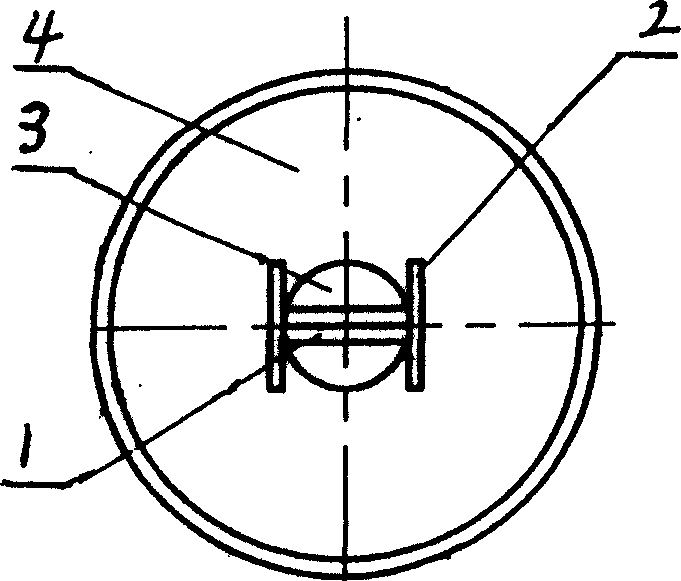

[0037] Ultra-deep compaction and dynamic compaction method:

[0038] (1) Site leveling: according to the design elevation, dig, fill and level the site earthwork;

[0039] (2), the first ramming point construction:

[0040] a. Pay-off point: according to the design requirements, locate the pay-off, and determine the ramming point;

[0041] b. One-time dynamic compaction: At the designated compaction point, use an ultra-deep compaction hammer to perform the first dynamic compaction construction. The static pressure at the bottom of the hammer is about 120KPa, and the depth of the compaction pit is controlled within 3m;

[0042] c. Backfilling of the rammed pit: in the compacted rammed pit, backfill the site soil and level the site;

[0043] d. Secondary dynamic compaction: Use the ultra-deep compaction hammer to carry out the dynamic compaction construction again, and the depth of the compaction pit is controlled within 2m;

[0044] e. Refilling of the rammed pit: backfill t...

Embodiment 2

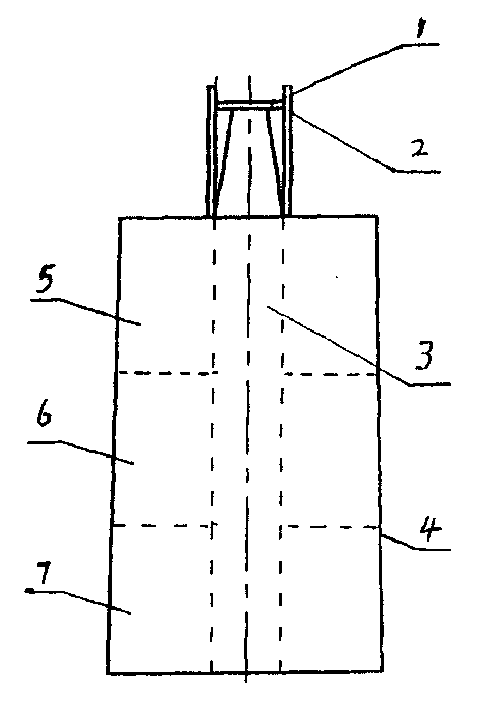

[0055] The ultra-deep compaction dynamic rammer of Example 2 is the same as that of Example 1, and the steps (1), (2) and (3) of the ultra-deep compaction dynamic compaction method of Example 2 are the same as those of Example 1, but different. The point is:

[0056] (4), the third ramming point construction:

[0057] a. Pay-off point: locate the pay-off again, and determine the ramming point;

[0058] b. One-time dynamic compaction: At the designated compaction point, use an ultra-deep compaction hammer to carry out the first dynamic compaction construction. The static pressure at the bottom of the hammer is about 120Kpa, and the depth of the compaction pit is controlled within 3m;

[0059] c. Backfilling of the rammed pit: In the compacted rammed pit, backfill with sand and gravel materials, and level the site;

[0060] d. Secondary dynamic compaction: Use the ultra-deep compaction hammer to carry out the dynamic compaction construction again, and the depth of the compacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com