Roadbed reinforcement structure for preventing vehicle bump at bridge head and construction method thereof

A technology for strengthening structures and jumping vehicles at the bridge head, which is applied in roads, roads, buildings, etc., can solve the problems of accelerating the damage of boards, bridge abutments and expansion joints, increasing bridge maintenance costs, reducing road use functions, etc., and achieving the elimination of unevenness Settlement, reduce settlement difference, improve the effect of subgrade bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

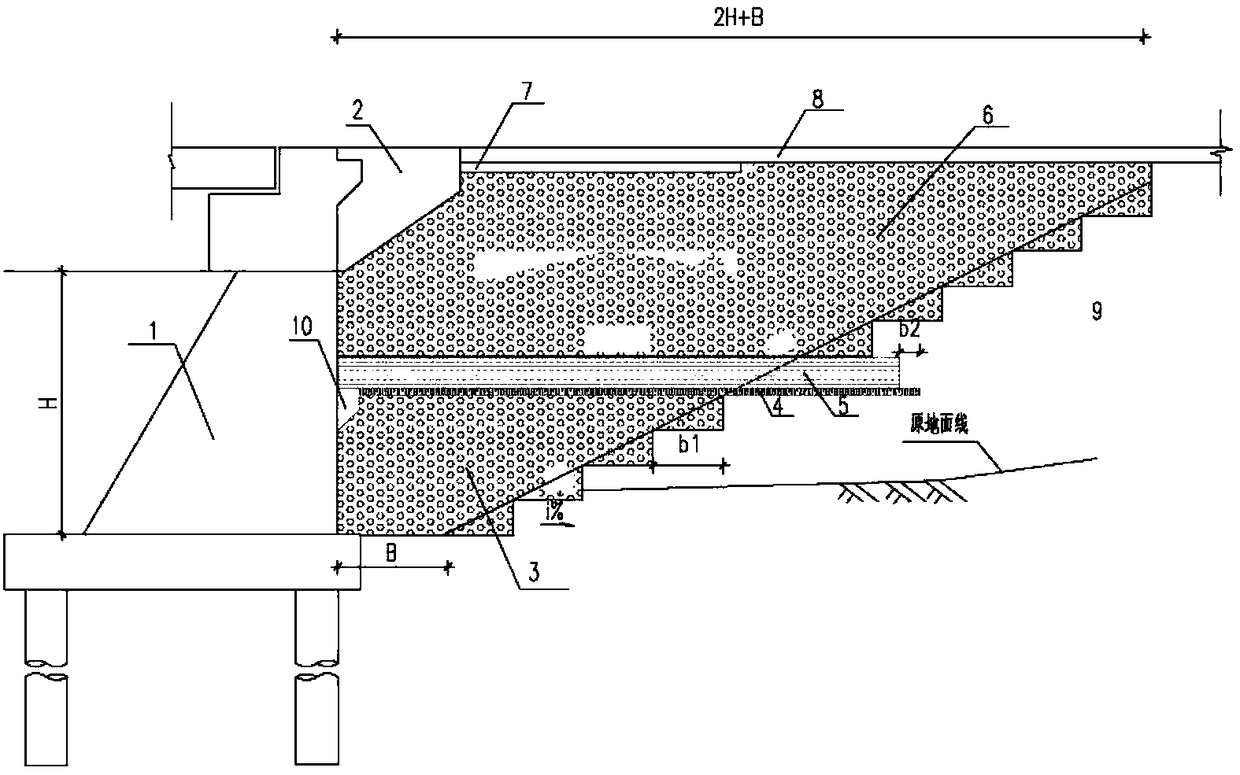

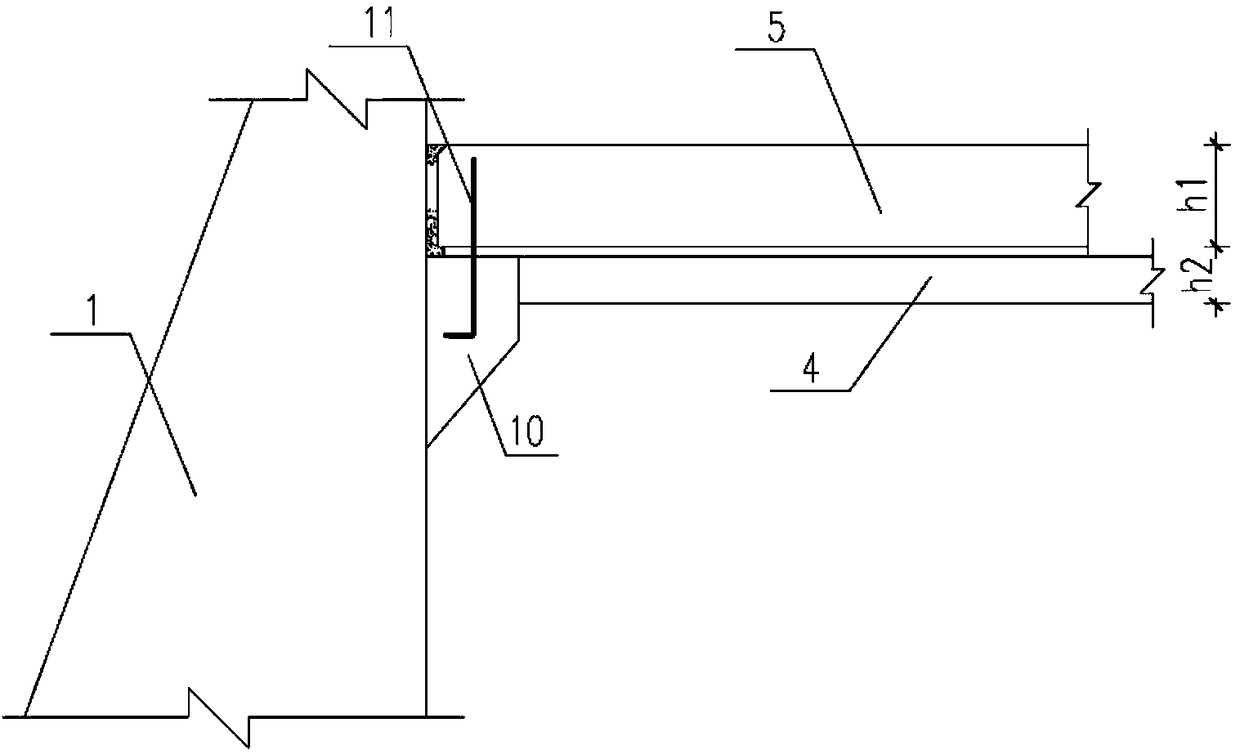

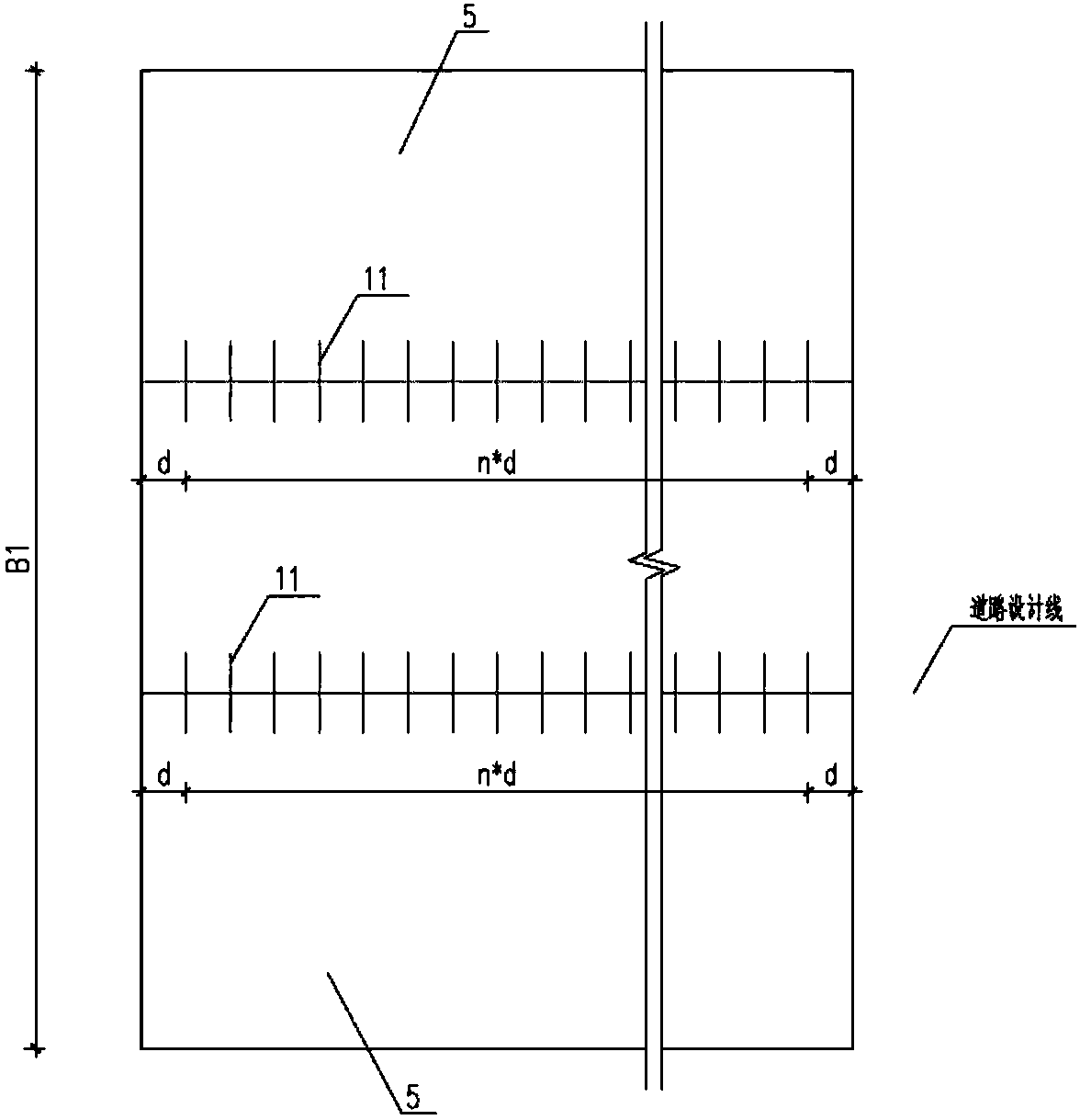

[0045] as attached Figures 1 to 3 As shown, a subgrade reinforcement structure for preventing vehicle jumping at the bridge head includes an anti-settlement plate 5, which is arranged in the middle of the abutment and the backfill area behind the abutment, and the anti-settlement plate passes through the corbel 10 and the rib plate of the abutment 1 connection, below the anti-settlement plate 5 is the lower backfill area 3, above the anti-settlement plate 5 is the upper backfill area 6, and the side of the anti-settlement plate away from the abutment is the general subgrade section backfill area 9. Below the anti-settling plate 5, a cushion layer 4 is also arranged, and the length of the cushion layer 4 extends into the backfill area of the general subgrade section by 2m. The length of the cushion layer 4 is 0.5m longer than the length of the anti-sedimentation plate 5 . Wherein, the anti-sedimentation plate 5 and the corbel 10 are fixed firmly by the reserved steel bar 11...

Embodiment 2

[0052] The present invention also provides the construction method of the subgrade reinforcement structure for preventing the vehicle from jumping at the bridge head, specifically comprising:

[0053] Step 1. Construction of abutment ribs. Complete the abutment concrete pouring in accordance with the construction sequence of tying the reinforced abutment and corbel structure—installing the abutment formwork—pouring the abutment concrete—removing the abutment formwork—and curing the abutment concrete. Design strength.

[0054]This step is basically a routine step, and it is only necessary to set the corbel at the middle of the abutment rib.

[0055] Step 2. During the construction of the subgrade section in the fill area of the general road behind the abutment, the side slope shall be graded according to the side slope of 1:1.5, and a step width of 2m shall be reserved on the side slope, and an inward slope of 4% shall be set so that the abutment The post-filling area overla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com