Frame and spring combination type bridge and road transition section structure integrated with bridge abutment

A transitional, combined technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of inability to cure the settlement difference in the transition zone, and achieve the effect of reducing settlement, reducing settlement difference, and overcoming excessive self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

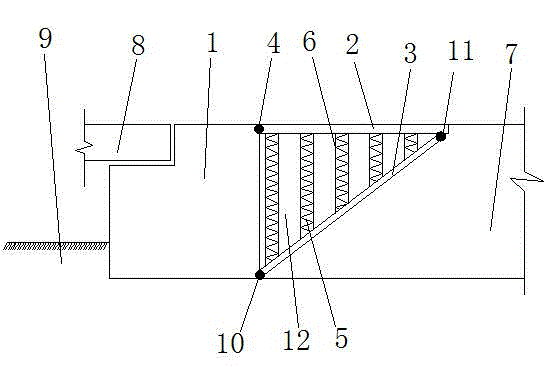

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 Shown: a frame spring combined bridge transition section structure integrated with the abutment, including the abutment 1, the beam body 8 and the road base body 7, as well as the reinforced concrete transition section frame and several high-strength spring beams 5; The frame of the reinforced concrete transition section includes a prefabricated reinforced concrete horizontal slab 2 and a prefabricated reinforced concrete slant slab 3; The lower end of platform 1 is connected by the second high-strength hinged bolt 10, and the other end of the reinforced concrete prefabricated horizontal plate 2 is connected with the other end of the reinforced concrete prefabricated slanted brace 3 by the third high-strength hinged bolt 11; the reinforced concrete prefabricated slanted brace 3 is fitted and fixed Install several high-strength spring beams 5 verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com