A kind of scraper used for scraping the flat surface of tightly fitted bolts

A bolt and plane technology, applied in the field of scraping and scraping on the plane of tight-fitting bolts, can solve the problems of low scraping accuracy and easy falling off, and achieve the effect of preventing the scraping accuracy from decreasing, uniform bearing capacity and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

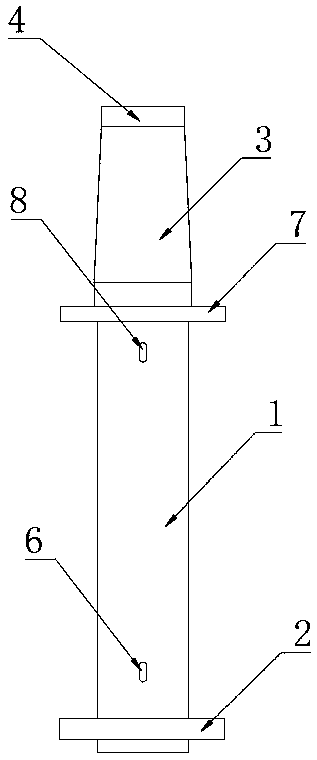

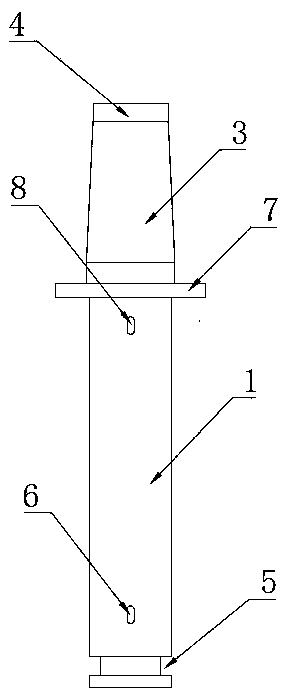

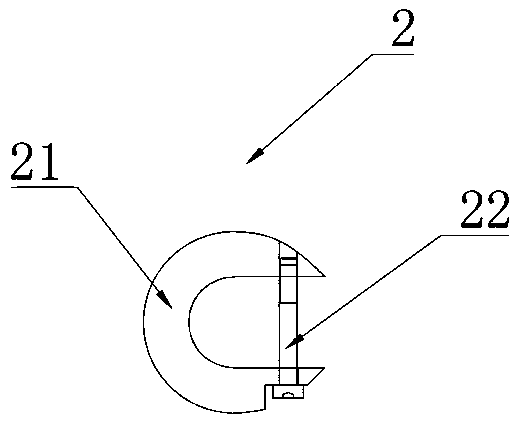

[0018] Example: such as Figure 1 to Figure 3 As shown, a scraper for flat scraping with bolts tightly fitted, is characterized in that the scraper includes a scraper body 1 and a positioning clip 2, the scraper body 1 is cylindrical, and the scraper body 1 The upper end of the tapered handle 3 is provided with a tapered handle 3, the top surface of the tapered handle 3 is provided with a convex strip 4, the lower end of the scraper body 1 is provided with an annular groove 5, and the positioning clamp 2 is set on the scraper body 1 In the annular groove 5, the top surface of the positioning clip 2 is perpendicular to the center line of the scraper body 1, and the lower end of the side of the scraper body 1 is provided with a first keyway 6, and the first keyway 6 is arranged on Above the ring groove 5.

[0019] In this embodiment, the upper end of the scraper body 1 is provided with an annular flange to form a pressure ring 7, and the upper side of the scraper body 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com