Bagging system for sponge inner sleeve

A sponge and bagging technology, applied in the direction of external support, transportation packaging, packaging, etc., can solve the problems of stacking and storing multiple sponges, sticking sponges together, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

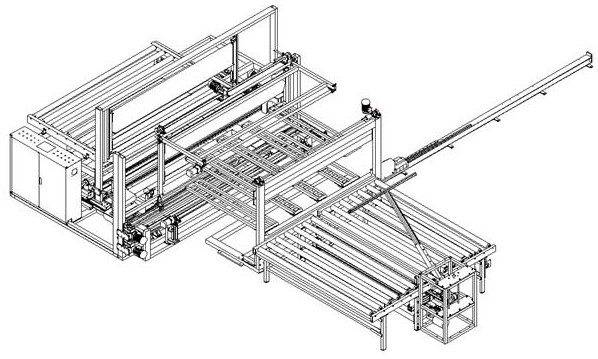

[0084] Such as Figure 1-Figure 20 A bagging system for inner sponge is shown, which includes a feeding unit, a bagging unit, a cutting and overlocking unit, and a discharging unit arranged in sequence.

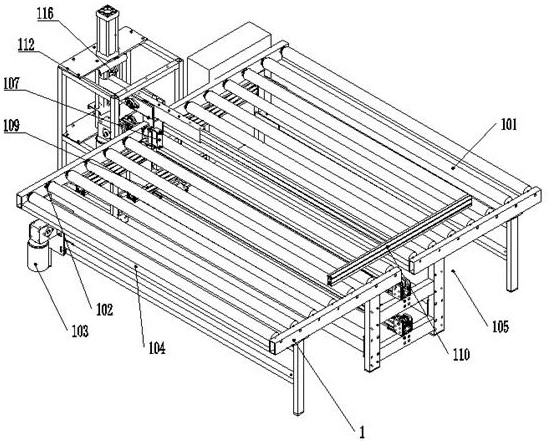

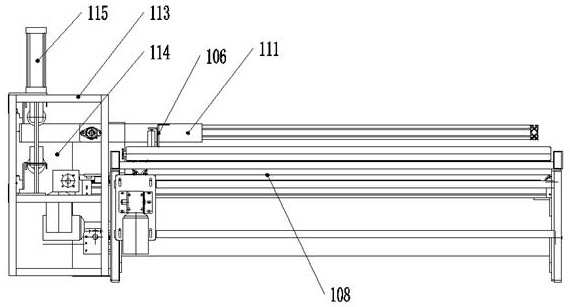

[0085] Such as Figure 2-Figure 6 As can be seen from the schematic diagram shown, the feeding unit includes

[0086] A feeding bracket 1, on which a number of conveying rollers 101 are installed, the two sides of the conveying rollers 101 roll and cooperate with the feeding bracket 1 through the rotating shaft, and each conveying roller 101 is installed on the rotating shaft on the same side There are interlocking sprockets 102, and each interlocking sprocket 102 realizes linkage through interlocking chain connection, wherein any interlocking sprocket 102 is driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com