A method for paving full asphalt pavement of large particle size rock-filled subgrade

An asphalt pavement, large particle size technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of poor coordination ability of semi-rigid base deformation, waste of resources and funds, environmental protection pressure, uneven deformation of rock-filled roadbed, etc. The effect of good interlayer stress, improved driving safety, and excellent waterproof and drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

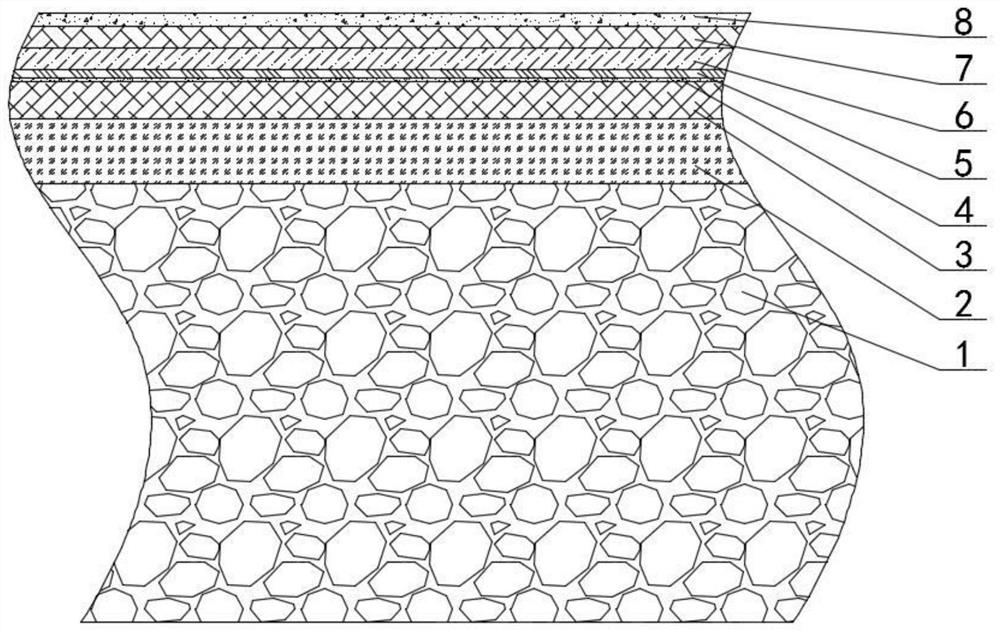

[0031] as attached figure 1 As shown, the full asphalt pavement structure of the large particle size rockfill subgrade in this embodiment consists of a subgrade main part 1, a lower transition layer 2, an upper transition layer 3, a permeable layer, a sealing layer 4, a composite functional layer 5, an anti-crack drainage layer 6, The waterproof anti-rutting layer 7 and the noise-reducing wear layer 8 are formed.

[0032] The main part 1 of the subgrade, the lower transition layer 2 and the upper transition layer 3 are paved from bottom to top to form a large-size rock-fill subgrade. The permeable layer, sealing layer 4, composite functional layer 5, anti-cracking and drainage layer 6, waterproof and anti-rutting layer 7, and noise reduction and wear layer 8 are paved from bottom to top to form an asphalt mixture structure layer.

[0033] (1) Subgrade main part 1

[0034] The thickness is 3m, and it is filled with large-sized crushed stones of 10cm-30cm. The pass rate of 20c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com