Carbon fiber bar skeleton of composite material in four-dimensional carbon fiber bar

A carbon fiber rod and composite material technology, applied in the field of carbon fiber rod skeleton, can solve the problems of defects, structural collapse, bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

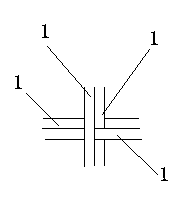

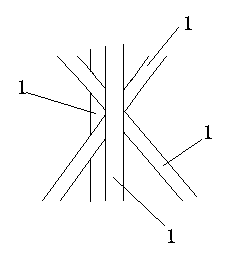

[0016] The feature in the figure is that there are four groups of carbon fiber rod skeletons, and the carbon fiber rod skeletons are divided into four groups, left, right, front and back. Each group of carbon fiber rod skeletons is composed of several rows, and the rows are parallel to each other. All carbon fiber rods between adjacent groups are perpendicular to each other on the vertical projection plane. Each group of carbon fiber rod skeletons has the same angle with the horizontal plane. Four groups of carbon fiber rod skeletons are located on the same horizontal plane. The row spacing of the carbon fiber rod skeleton and the root spacing of each row are equal, and the four carbon fiber rods in the same row of the four groups of carbon fiber rod skeletons are tangent to each other at one point, and the tangency points between the four carbon fiber rods in the same row are located at same level. It is characterized in that: the carbon fiber rod is a round rod.

[0017] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com