Device and method for enhancing stability of steel casing during pore-forming construction

A steel casing and stability technology, which is applied in the fields of soil protection, foundation structure engineering, and foundation structure testing, etc., can solve the problem of poor soil stability at the bottom of the casing, waste of manpower, material and financial resources, and failure of drilling rig piles. To reduce the probability of lateral and vertical displacement, avoid pile position misalignment, and achieve uniform bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

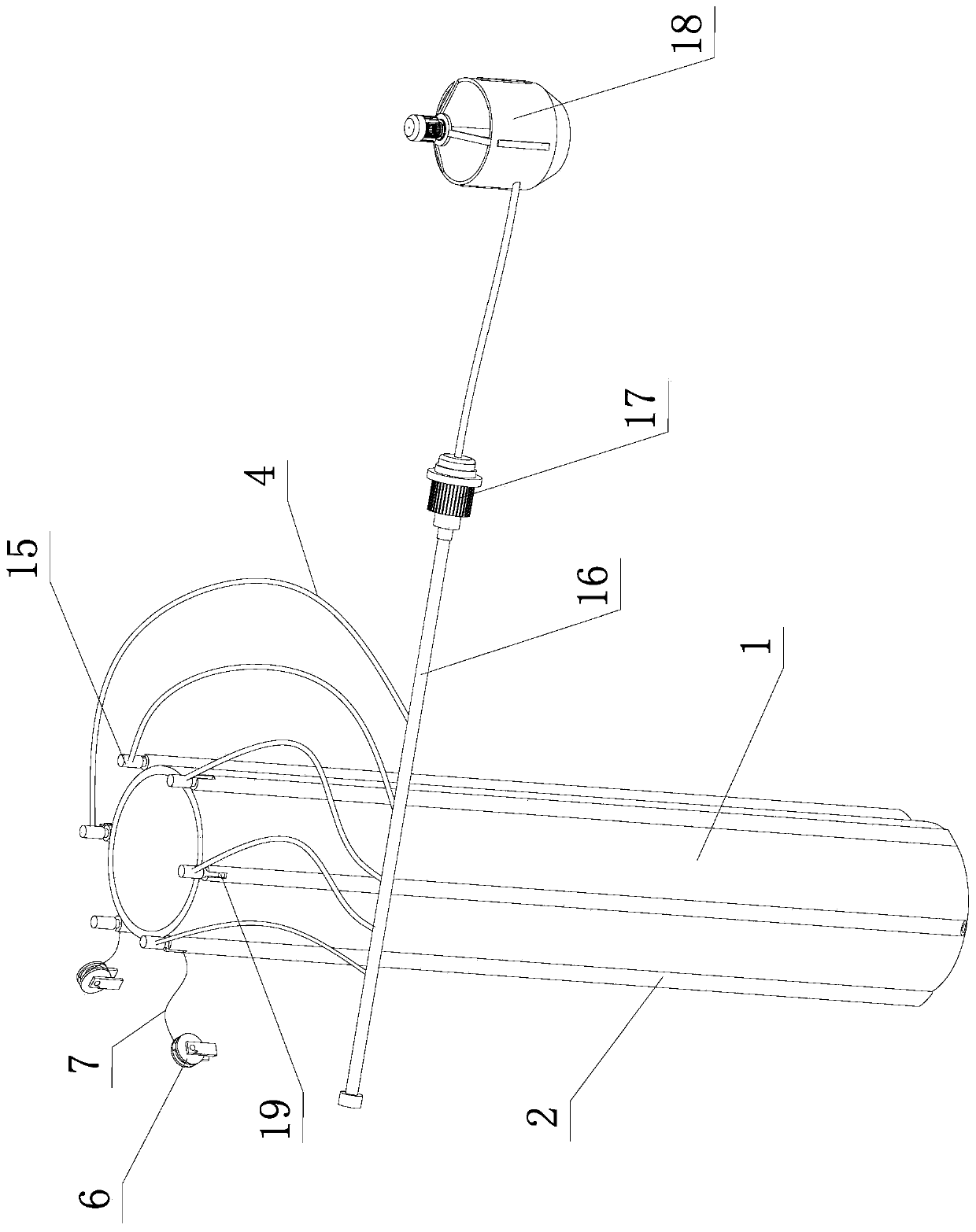

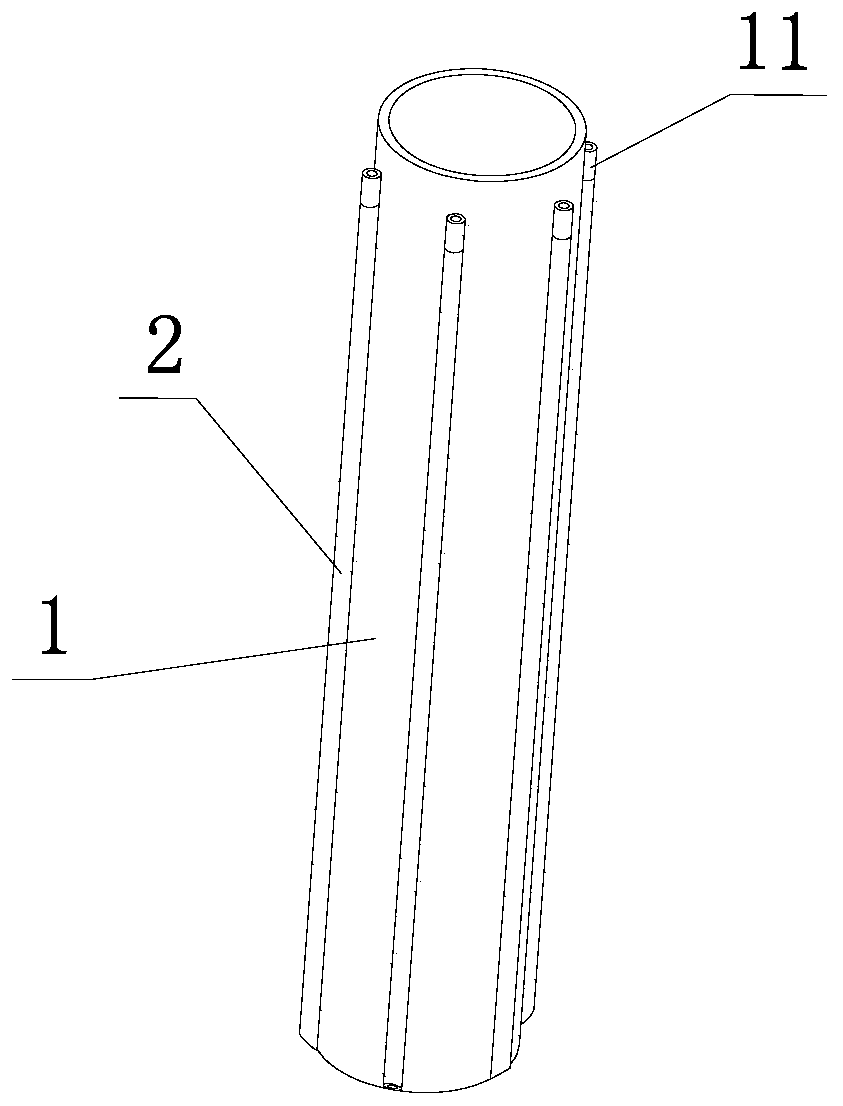

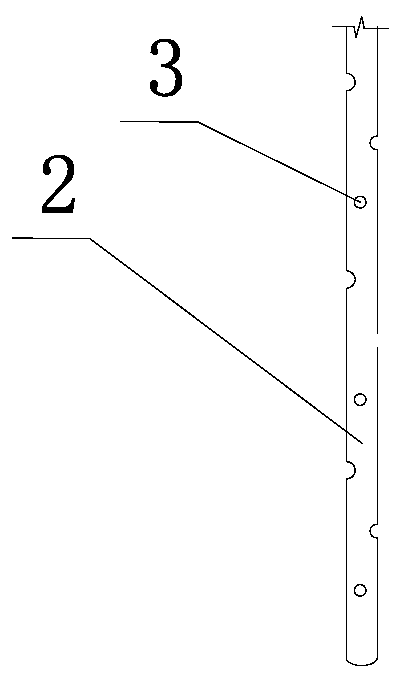

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the device for strengthening the stability of the steel casing during the hole forming construction of the present invention includes a steel casing 1, the outer wall of the steel casing 1 is welded with multiple grouting conduits for pouring cement slurry into the soil 2. Each grouting conduit 2 is provided with a plurality of grouting holes 3 of different heights, and the grouting holes 3 on each grouting conduit 2 are distributed downward in a spiral line, and every two adjacent grouting holes The circumferential spacing of 3 is 120 degrees.

[0030]The device also includes a plurality of grouting pipes 4 for communicating with the upper opening of the grouting conduit 2; specifically, during grouting, the outlet of each grouting pipe 4 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com