Expansion deformation connecting device and processing method thereof

A technology for connecting devices and connecting components, which is applied to bridge parts, bridge materials, bridges, etc., can solve problems such as subsidence, achieve uniform bearing capacity, and avoid the effect of being compressed and uplifted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

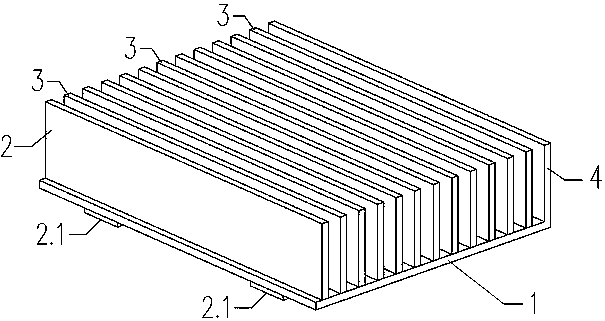

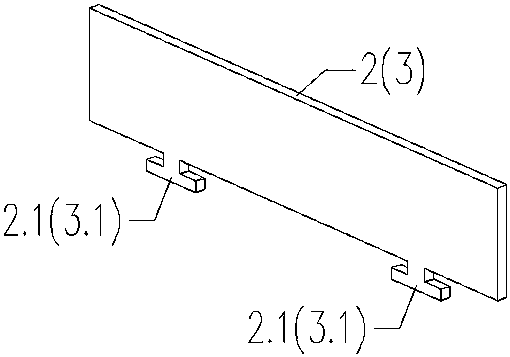

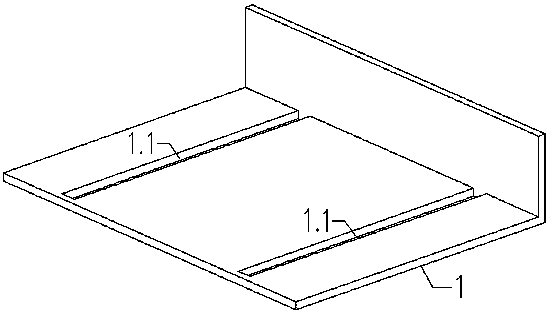

[0033] The telescopic and deformable connection device includes a horizontal support plate 1, a plurality of vertical support plates, the vertical support plates are vertically arranged on the horizontal support plate 1, and the vertical support plates include corresponding fixed end vertical supports located at both ends. The support plate 4, the movable end vertical support plate 2 and the movable middle vertical support plate 3 in the middle; the horizontal support plate 1 is longitudinally provided with two or more parallel horizontal support plate chute 1.1, The bottoms of the movable end vertical support plate 2 and the movable middle vertical support plate 3 are provided with corresponding convex structure 2.1 and convex structure 3.1 corresponding to the horizontal support plate chute, and are clamped on the horizontal support plate slide. In the groove 1.1, an elastic filler is arranged between two adjacent vertical support plates.

[0034] Preferably, one end of the ...

Embodiment 2

[0041] The telescopic and deformable connection device includes a horizontal support plate 1, a plurality of vertical support plates, the vertical support plates are vertically arranged on the horizontal support plate 1, and the vertical support plates include corresponding fixed end vertical supports located at both ends. The support plate 4, the movable end vertical support plate 2 and the movable middle vertical support plate 3 in the middle; the horizontal support plate 1 is longitudinally provided with two or more parallel horizontal support plate chute 1.1, The bottoms of the movable end vertical support plate 2 and the movable middle vertical support plate 3 are provided with corresponding convex structures 2.1 and 3.1 corresponding to the horizontal support plate chute, and snapped into the horizontal support plate chute 1.1 ; An elastic filler is arranged between two adjacent vertical support plates.

[0042] Preferably, the horizontal support plate (1) and the fixed ...

Embodiment 3

[0051] The telescopic and deformable connection device includes a horizontal support plate 1, a plurality of vertical support plates, the vertical support plates are vertically arranged on the horizontal support plate 1, and the vertical support plates include corresponding fixed end vertical supports located at both ends. The support plate 4, the movable end vertical support plate 2 and the movable middle vertical support plate 3 in the middle; the fixed end vertical support plate 4 is bent 90° by one end of the horizontal support plate 1 made. That is to say, after the horizontal support plate 1 is bent by 90°, the end that is equal in height to the movable end vertical support plate 2 or the movable middle vertical support plate 3 becomes a deformed fixed end vertical support plate 4, the remaining other end has just become a new horizontal support plate 1, and its effect is exactly the same as the horizontal support plate 1 in the foregoing embodiment.

[0052] Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com