An anchored water injection process string and its use method

A process pipe string and setting technology, which is applied in the directions of earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of increasing the power of pipe starting, encountering a stuck pipe, and increasing the load of pipe starting, so as to solve the expansion and contraction deformation. , The effect of reducing the well occupation period and reducing the operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

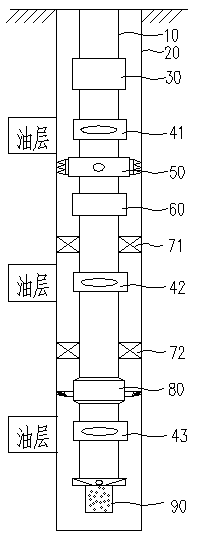

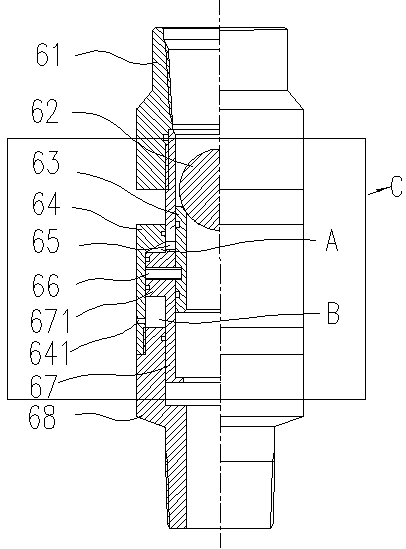

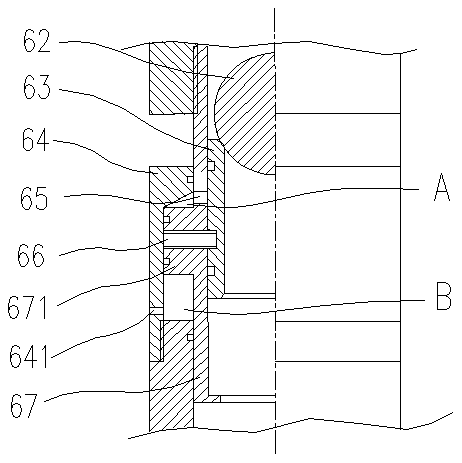

[0042] The embodiment of the present invention provides an anchored water injection process string and its use method. The water injection process string includes a casing, and an oil pipe is arranged in the casing, and a plurality of seals are arranged on the oil pipe according to the actual construction requirements of the water injection well. A spacer divides the tubing into multiple water injection intervals, and a water distributor is provided on the tubing corresponding to each water injection interval; an anchor is arranged between a pair of adjacent packers and the water distributor. anchoring device; the lower end of the anchoring device is also connected with a booster device. The booster device includes upper and lower joints connected with oil pipes, a central pipe is connected between the upper and lower joints, and the upper end of the central pipe is fixedly connected with the upper joint; the lower end of the central pipe extends to the inside of the lower join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com