Direct-driving (external-toothing) gear speed reducer

A gear reducer, direct-acting technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., to achieve stable operation, improved bearing capacity, and light weight.

Inactive Publication Date: 2006-03-08

王维民

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But it also has some problems. There are related information: When the transmission ratio of the harmonic transmission reducer is tens of revolutions per revolution, its transmission efficiency is 90%. It has a transmission efficiency of 70%

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

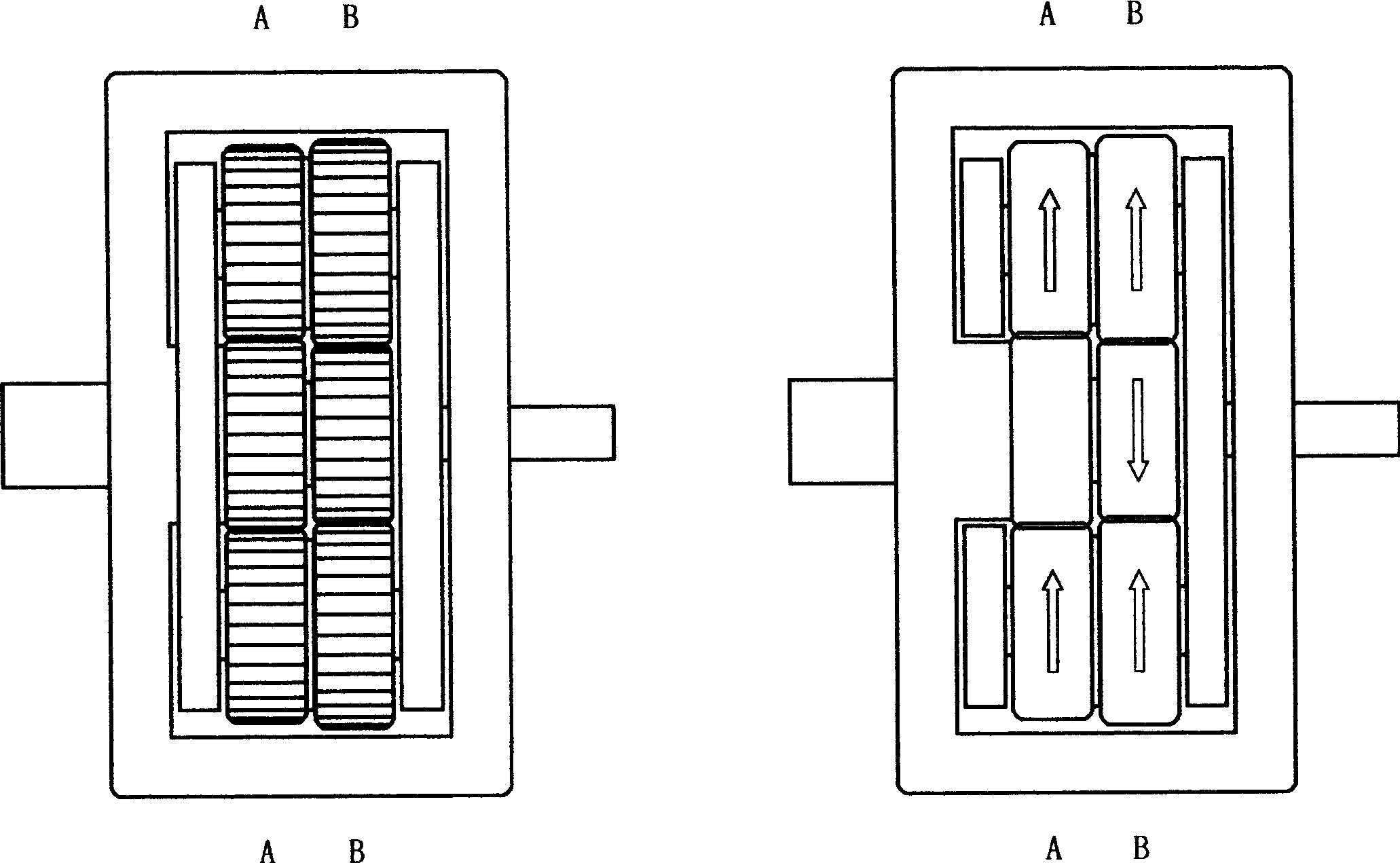

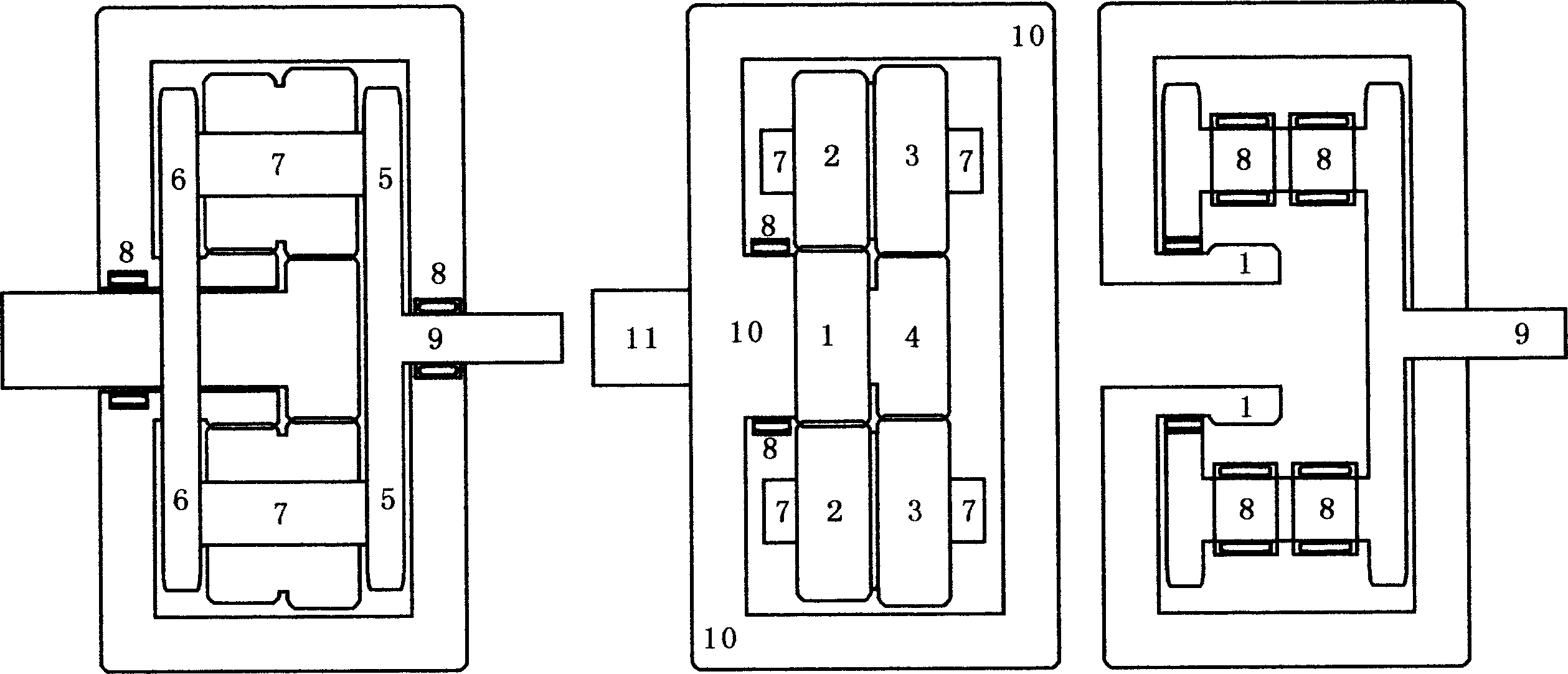

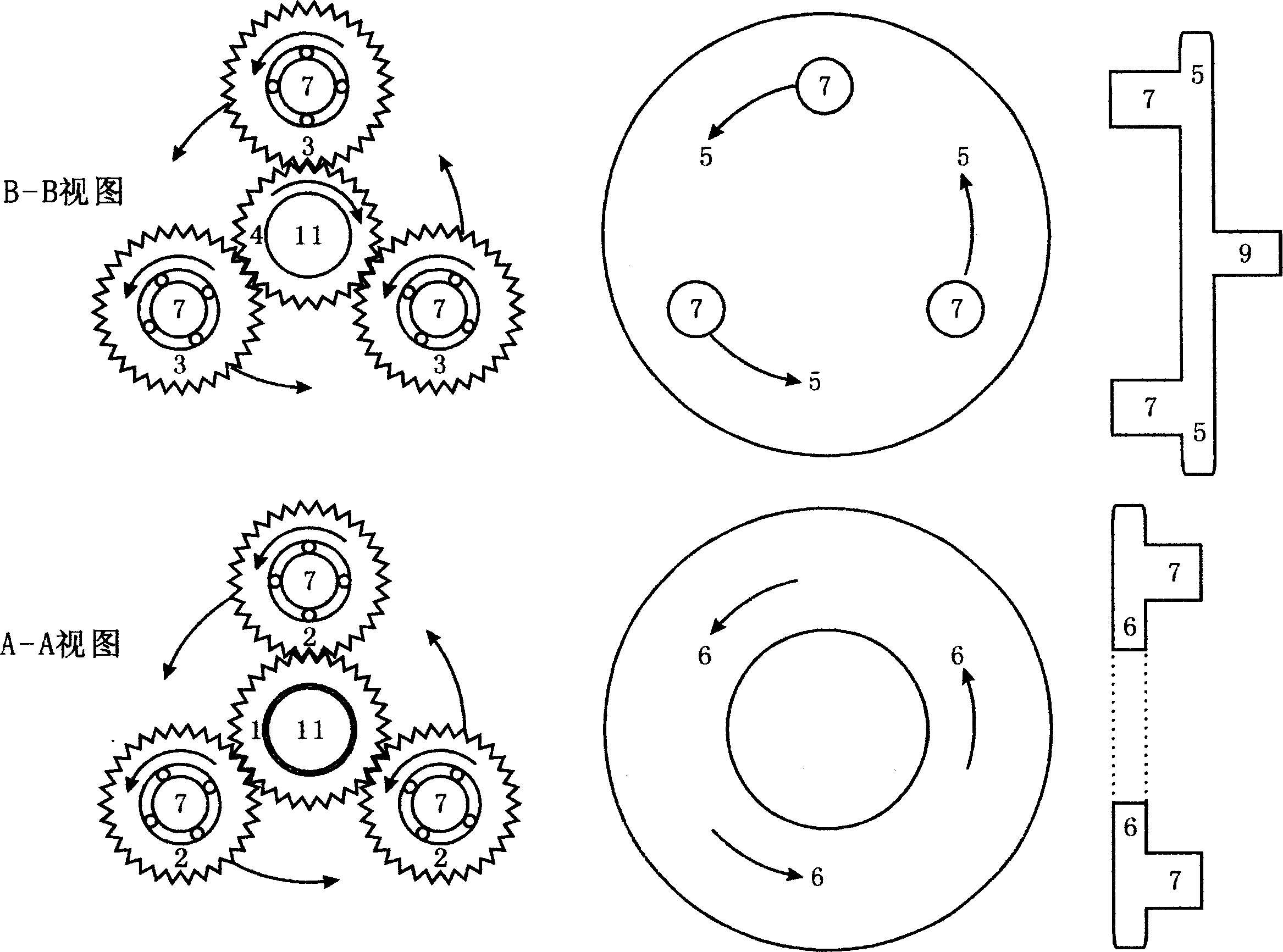

A direct driving (outer engaging) gear speed reducer, only adjusting the diameter ratio of two gears, various transmission ratio from tens to tens of thousands, in any transmission ratio, every gear driving output axle in minimum friction coefficient all the time, the loaded force in each gear is uniform by driving planetary gear set in accurate position. Said invention also can be used as speed increaser with increased bearing ability, simple structure, small volume and light weight.

Description

Technical field: The present invention relates to the technical field of speed reducer, because it is directly driven by lever arm balancing gravity, and all adopt external gear drive, so specifically it is a kind of "direct acting (external gear) gear reducer". Background technique: In the existing technical field, the harmonic drive reducer is a high-ratio reducer, and its first-stage retrieval transmission ratio can reach 500 revolutions per revolution, so it has a wide application prospect in high-ratio reduction equipment . But it also has some problems. There are related information: When the transmission ratio of the harmonic transmission reducer is tens of revolutions per revolution, its transmission efficiency is 90%. It has a transmission efficiency of 70%. Invention content: The object of the present invention is to provide a "direct-acting (external gear) gear reducer", which can overcome some deficiencies in the prior art. At the same time, compared with ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16H37/12F16H1/28

Inventor 王维民

Owner 王维民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com