Conveying equipment for glass processing production line

A conveying equipment and production line technology, applied in lighting and heating equipment, conveyor objects, transportation and packaging, etc., can solve problems such as glass damage, no good protective device at the turning point, discontinuous production process of deep-processing glass, etc., to reach the position The effect of stable relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

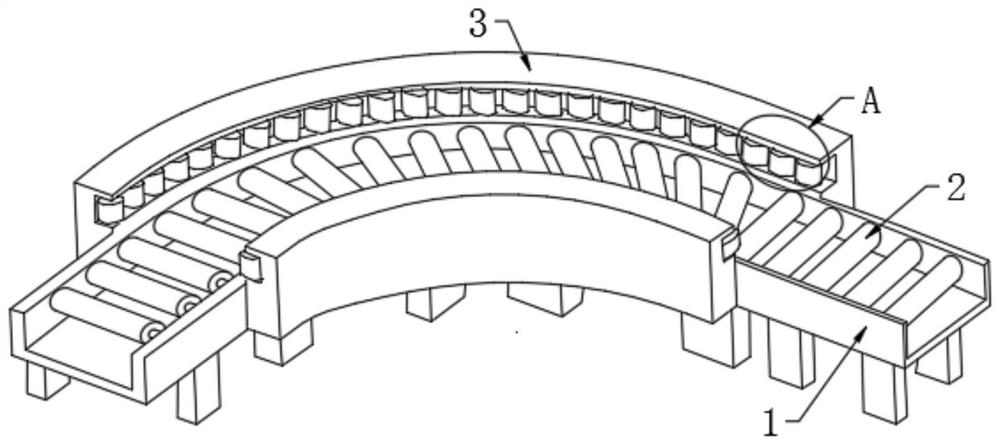

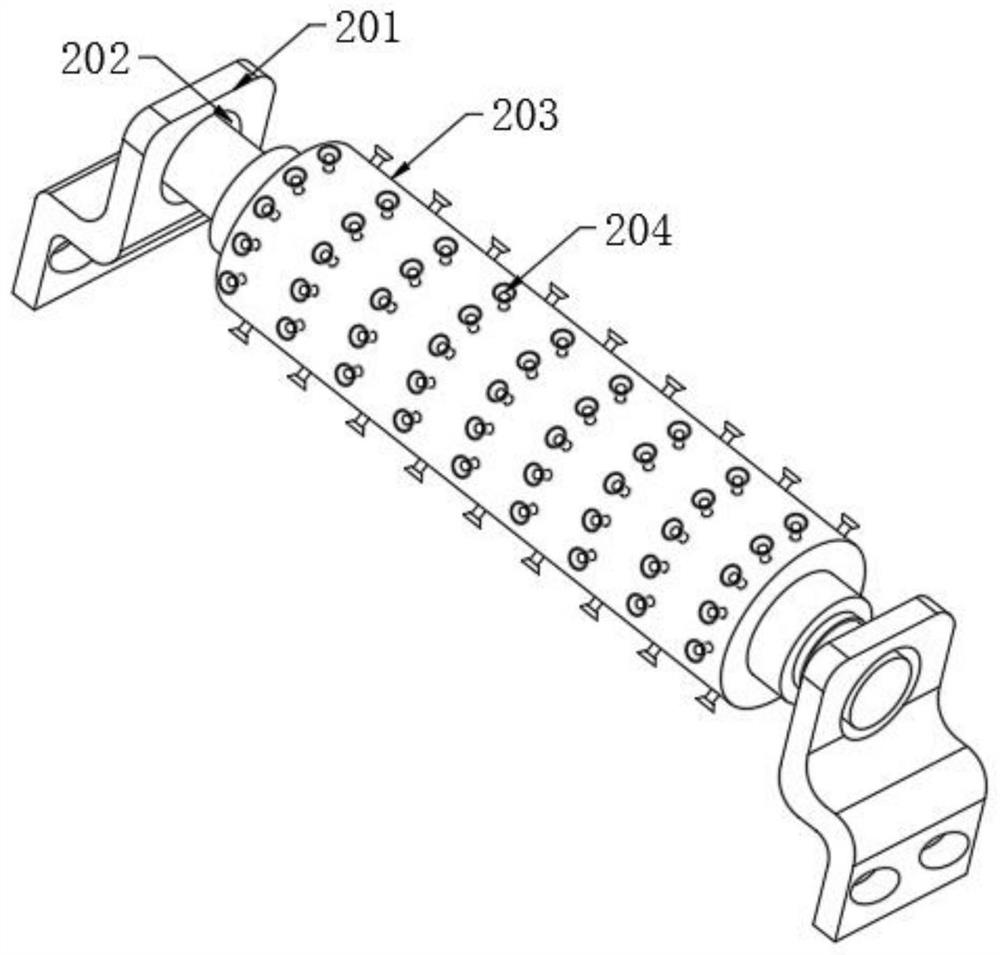

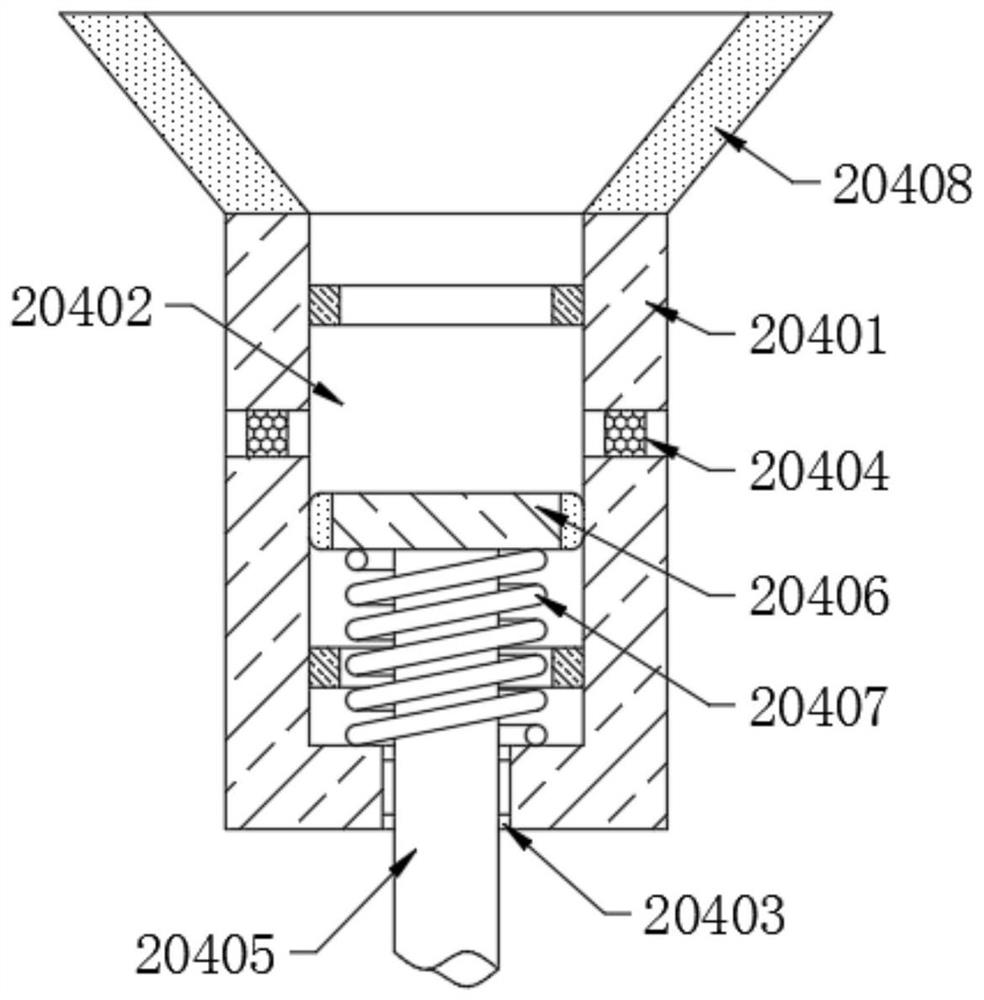

[0025] refer to Figure 1-5 In this embodiment, a conveying device for a glass processing production line is proposed, which includes a conveying frame 1, and a plurality of conveying mechanisms 2 are rotatably installed on the inner walls of both sides of the conveying frame 1. The conveying mechanism 2 includes two mounting frames 201, two Each mounting frame 201 is provided with a rotation hole 202, and the same power guide roller 203 is installed in rotation in the two rotation holes 202. The power guide roller 203 is provided with a plurality of anti-falling mechanisms 204, and both sides of the transmission frame 1 are equipped with There are protective frames 3, and a plurality of guiding mechanisms 4 are arranged in the two protective frames 3, and the guiding mechanisms 4 include a crossbar 401, and one side of the crossbar 401 is fixedly installed with three connecting frames 402, and on the three connecting frames 402 Guide wheels 403 are installed for rotation;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness coefficient | aaaaa | aaaaa |

| Stiffness coefficient | aaaaa | aaaaa |

| Stiffness coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com