Magnetic hobbing and pressing pad and pattern hobbing press with magnetic hobbing and pressing pad

A cutting and pressing machine and magnetic technology, applied in the field of cutting and pressing pads, can solve the problems of misalignment between the cutter and the pattern medium, cutting dislocation, wrong arrangement, etc. The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

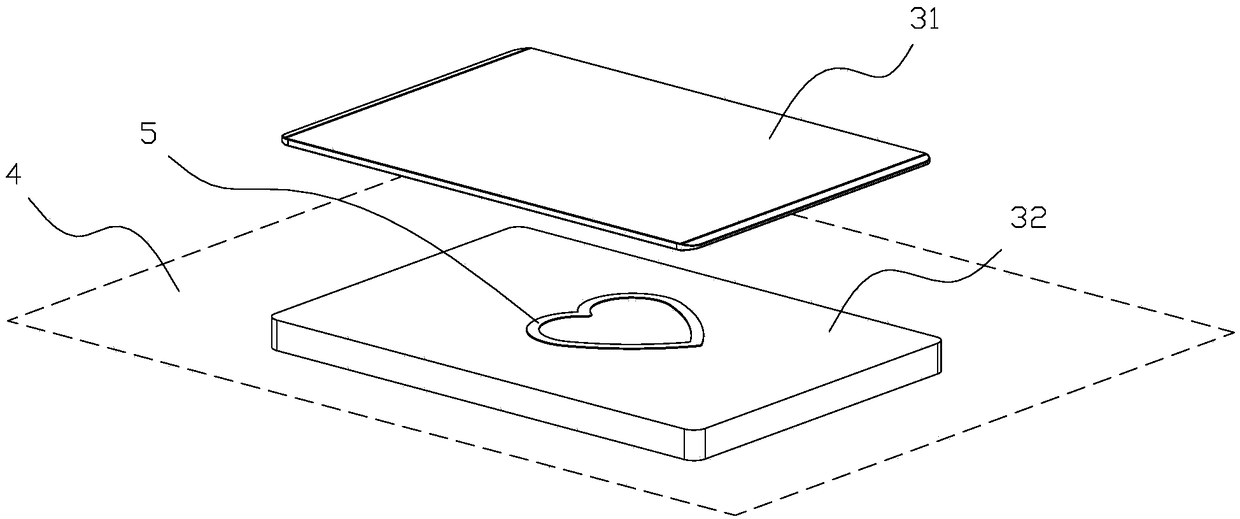

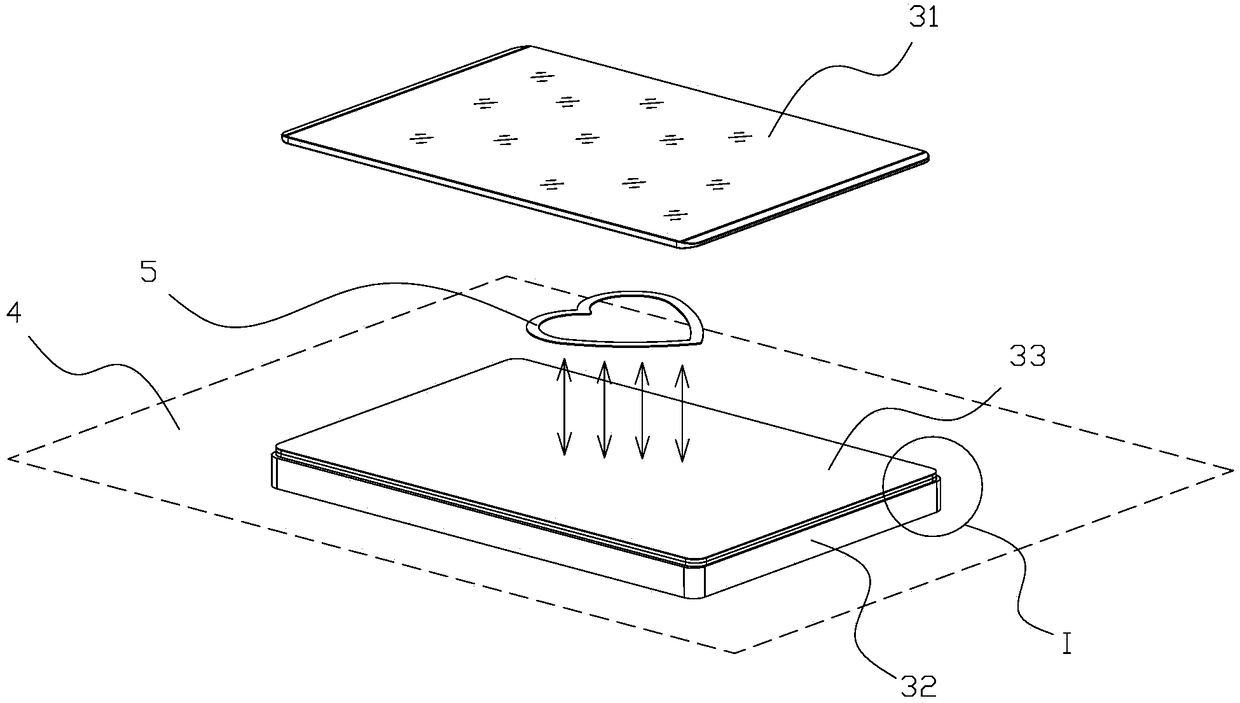

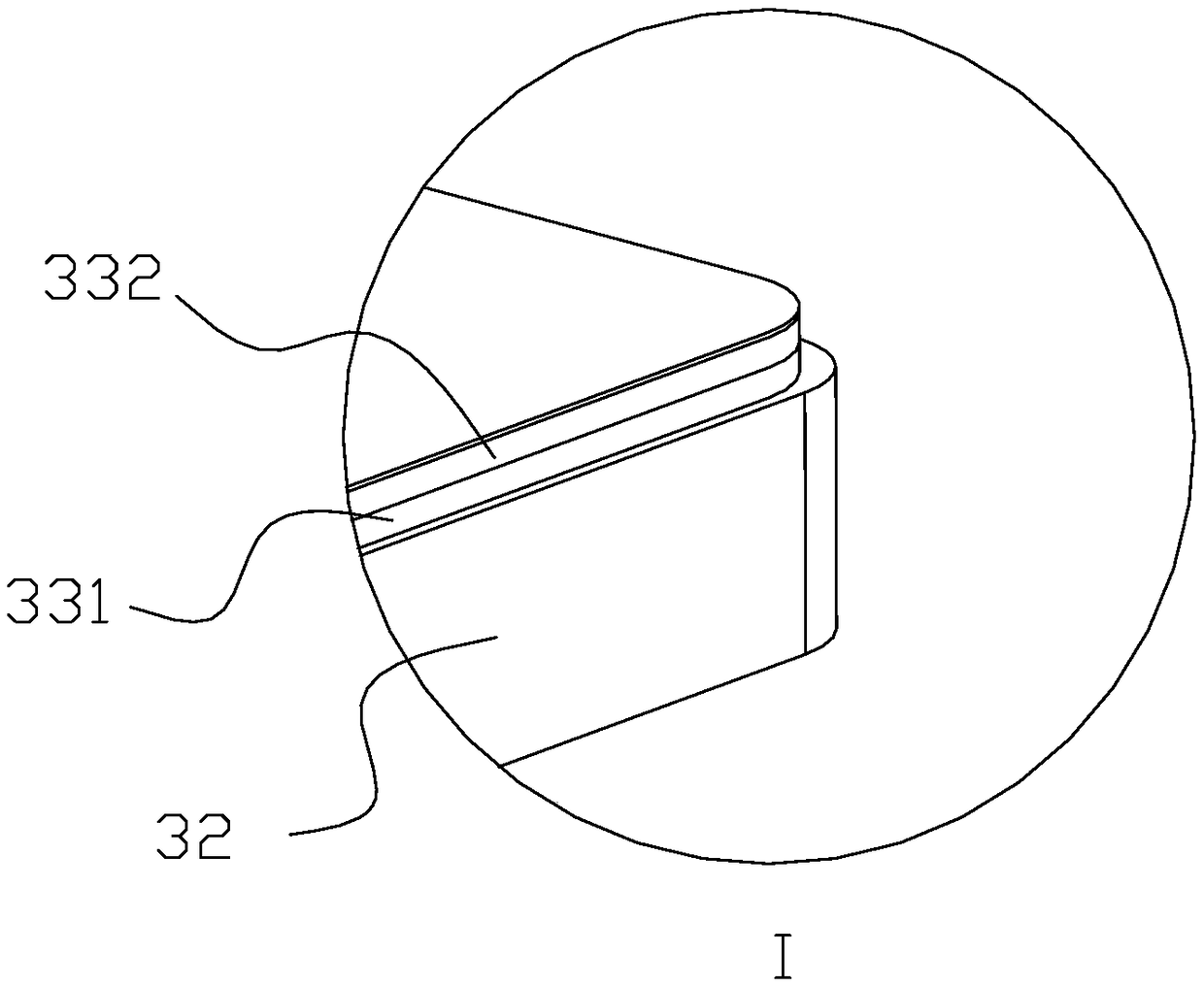

[0022] The present invention as figure 2 , 3 As shown, a magnetic cutting pad 33 includes a magnetic layer 331. The magnetic layer 331 can be made into an elastic structure or a hard structure as required. The magnetic cutting pad 33 is connected to the surface of the lower cutting plate 32 of the pattern cutting press. Magnetic The cutting pad 33 faces the patterned medium 4, and the magnetic field passes through the patterned medium 4 to attract the cutter 5, so that the patterned medium 4 is stably clamped between the cutter and the magnetic cutting pad 33, maintaining a stable positional relationship with each other.

[0023] further as figure 2 , 3 As shown, the magnetic cutting pad 33 also includes a cushion lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com