Swinging-type floating support structure

A floating support, swinging technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of large thermal expansion coefficient of the rack, long length, and the inability to maintain the relative positional relationship between the upper guide wheel and the upper guide rail. The effect of avoiding derailment, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

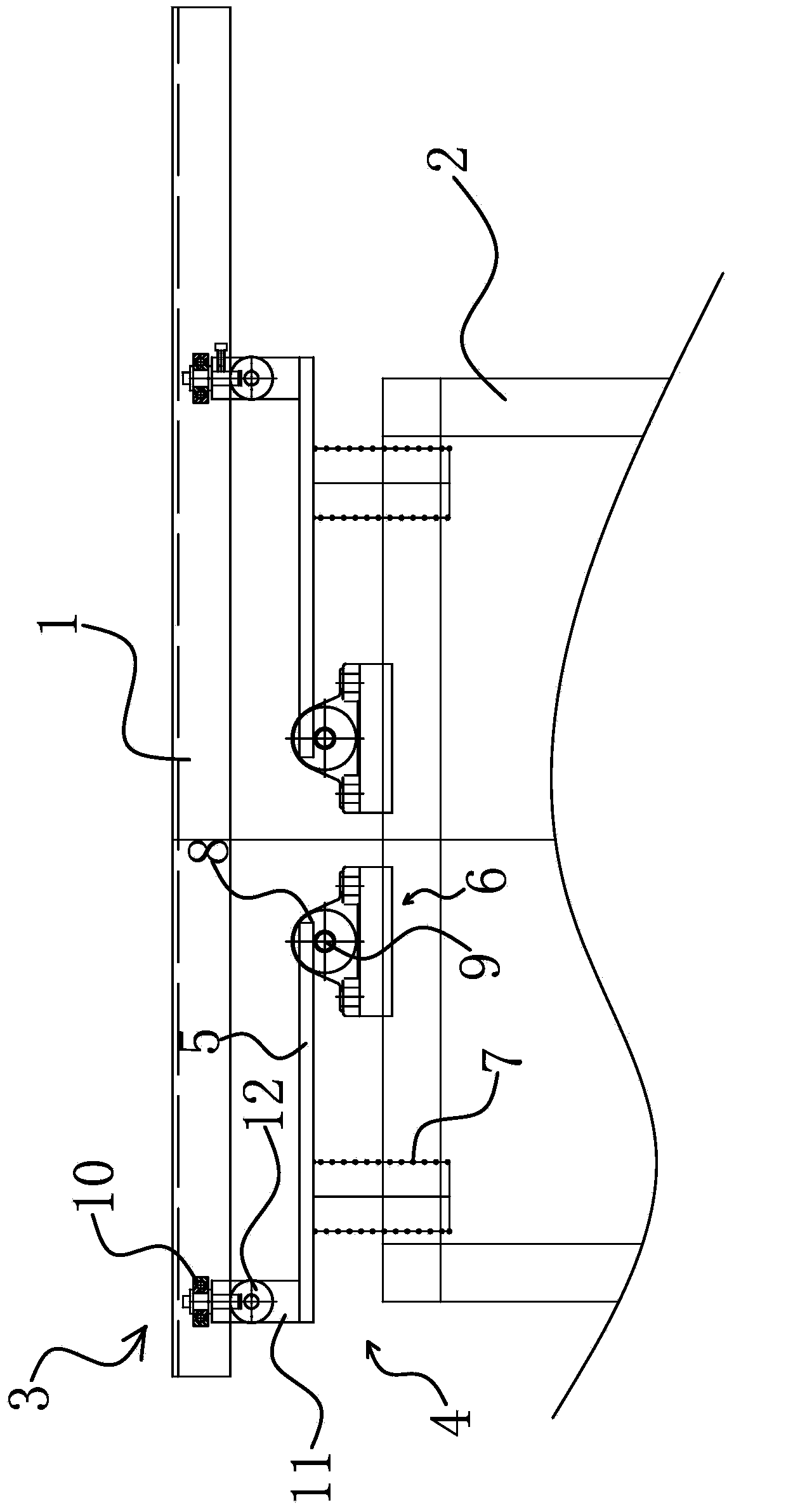

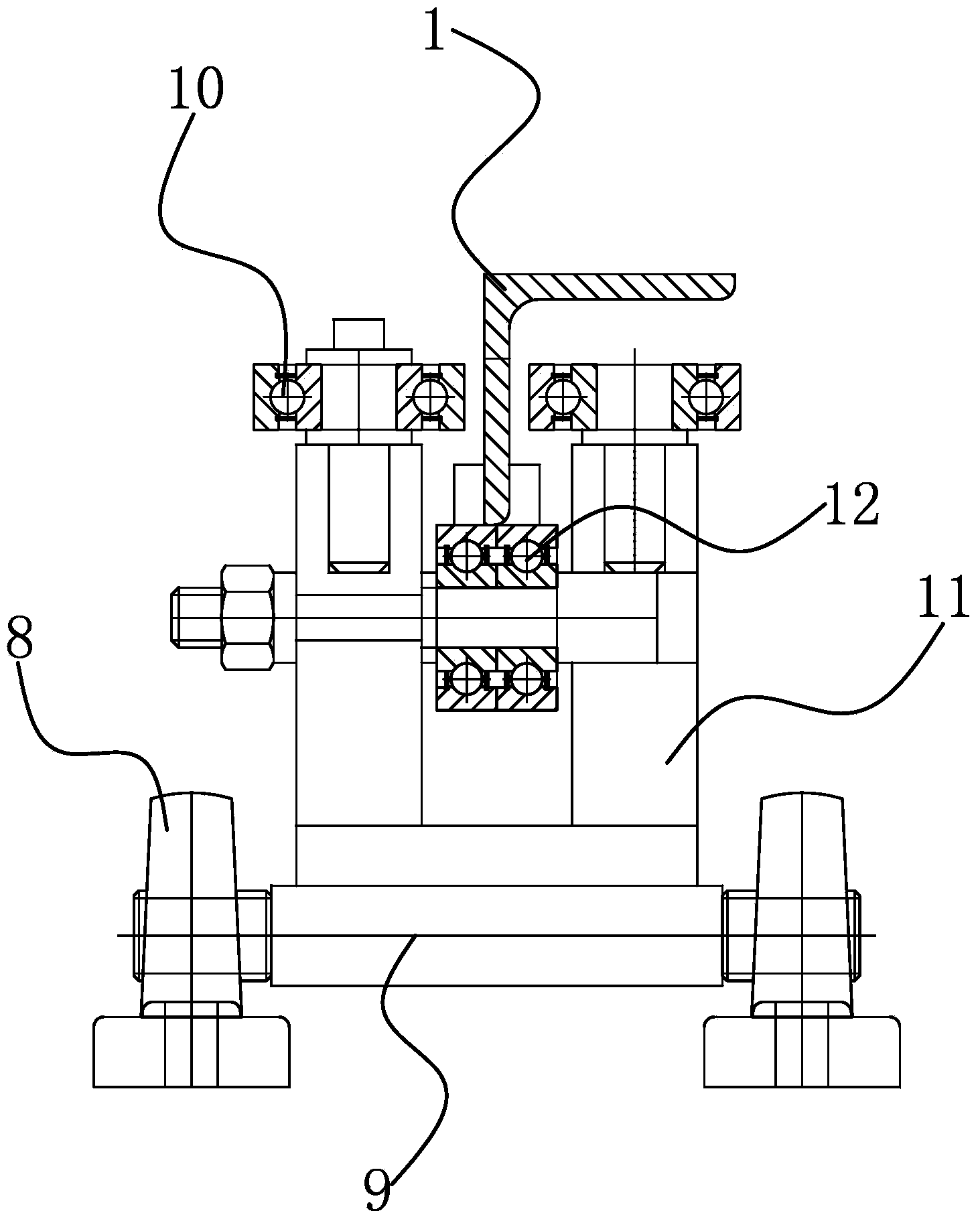

[0019] Such as Figure 1-2 As shown, the swinging floating support structure is arranged between the upper guide rail 1 and the frame 2, and is characterized in that the upper guide rail 1 is provided with a guide wheel group 3 that can move along the upper guide rail 1, and the guide wheel group 3 and Between the frame 2, the guide wheel group 3 can be tightly attached to the elastic floating support mechanism 4 of the upper guide rail 1. The elastic floating support mechanism 4 has a certain supporting effect on the guide wheel group 3. When the frame is thermally expanded, the elastic floating support mechanism 4 contracts to maintain the stability of the relative positional relationship between the guide wheel group 3 and the frame 2; when the frame During cold shrinkage, the elastic floating support mechanism 4 stretches to maintain the stability of the relative positional relationship between the guide wheel set 3 and the frame 2; when there is an error in the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com