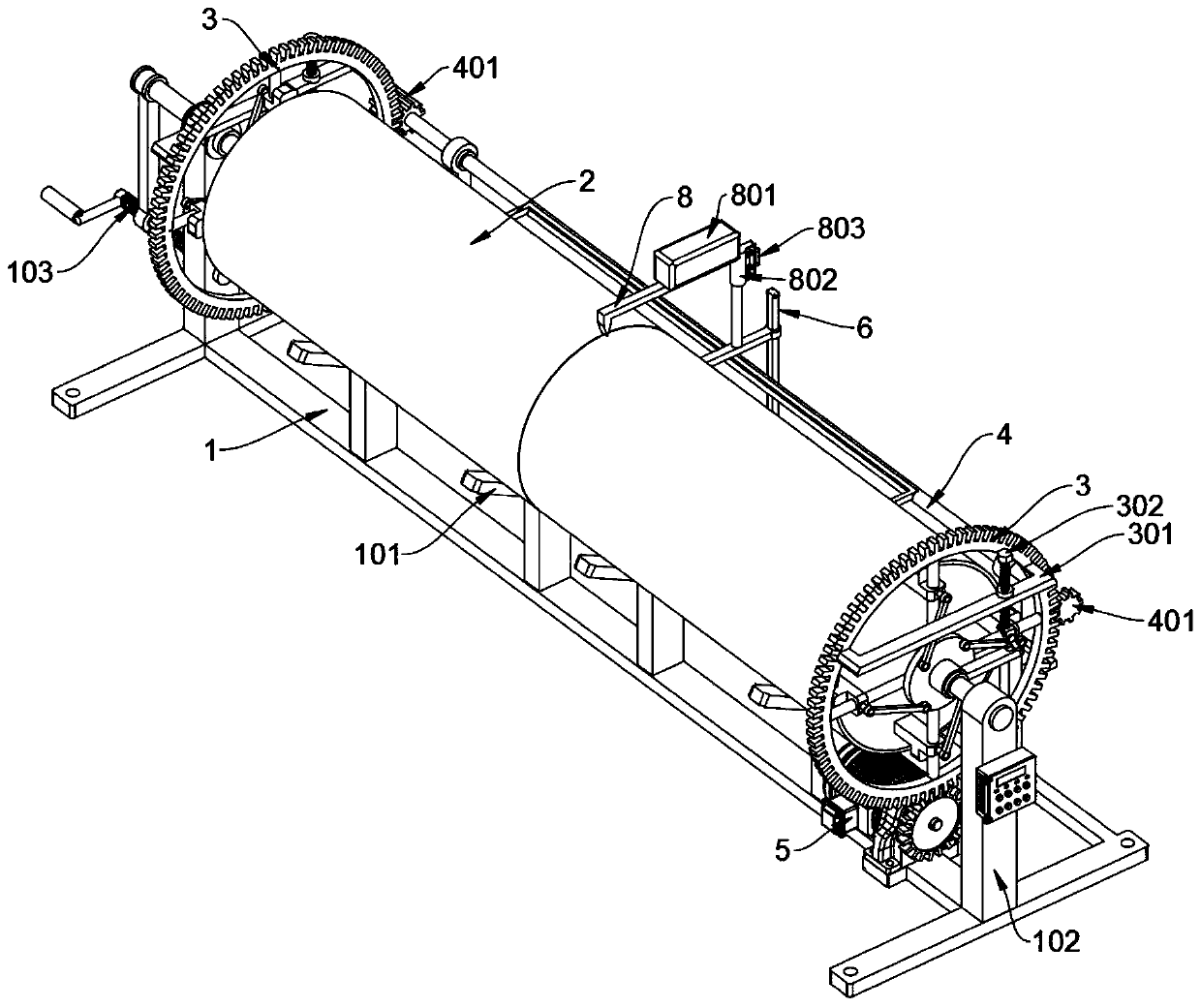

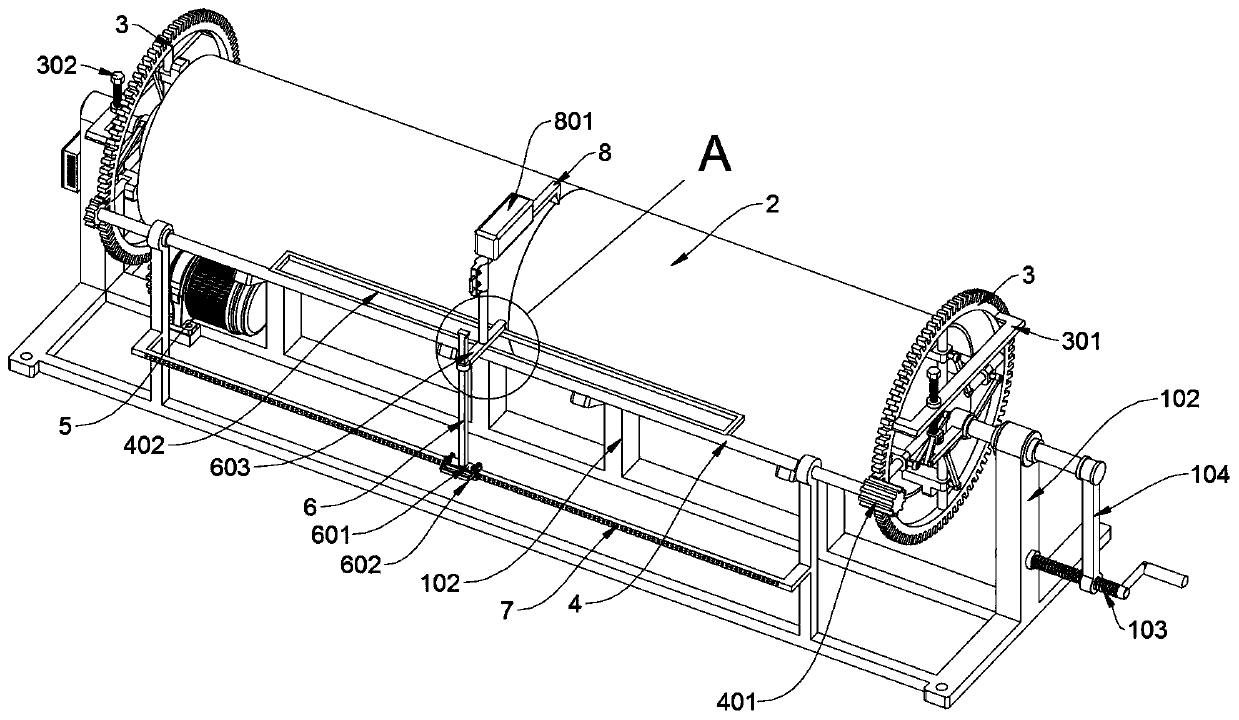

Multi-angle overturning welding device for long-distance large-diameter jacking pipe

A welding device and large-diameter technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient butt clamping and positioning operation, hand fatigue of welders, waste of manpower, etc., and achieve flexible use, wide application, The effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

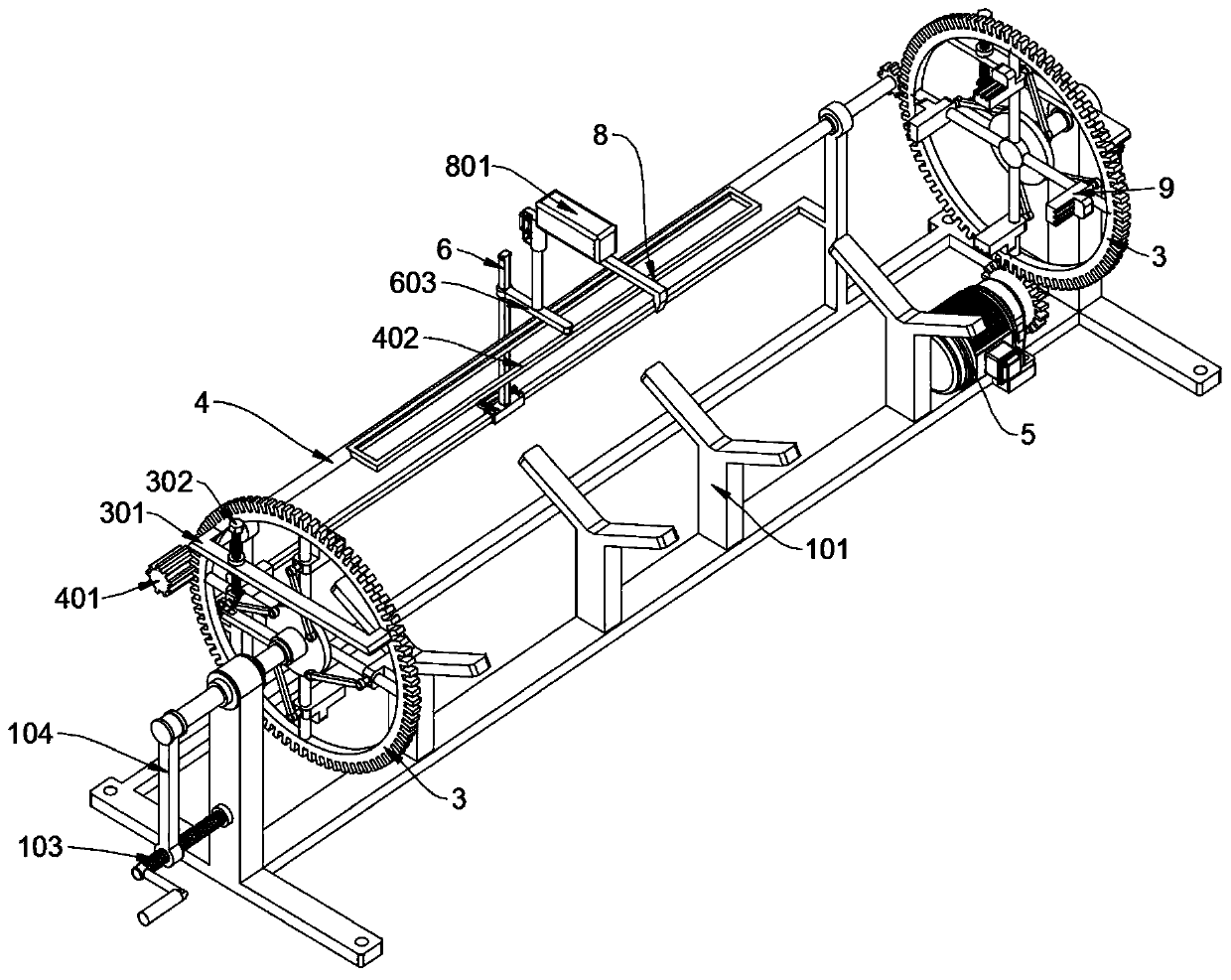

[0031]Embodiment 2: The top pressure block 9 includes a connecting rod 901, a turntable 902 and a swing plate 903, and a turntable 902 is installed on the roots of the rotating shafts of the two ring gears 3, and the outer eaves of the two turntables 902 are ring-shaped. The array is rotatably connected with four connecting rods 901; a sleeve is welded and fixed at the center of the two turntables 902, and a swing plate 903 is welded to the left side of the two sleeves, and four pressing blocks 9 and four The connecting rod 901 and the turntable 902 together form a wheel-driven four-bar linkage slider mechanism. Through this mechanism, the turntable 902 can be turned to make the four pressing blocks 9 slide synchronously to brace and position the jacking pipe 2 and connect and fix it with the ring gear 3. The two ring gears 3 can drive the two jacking pipes 2 to carry out rotary welding; the rear side of the top pressure block 9 is protrudingly provided with a clamping baffle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com