Side tooth gage reamer

A technology of reamer and edge teeth, which is applied in drilling equipment, earthwork drilling, drill bits, etc., can solve problems such as failure to work normally, wheel drop accidents, bearing wear, etc., and achieve the effect of enhancing the diameter-keeping effect and protecting the sealing system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

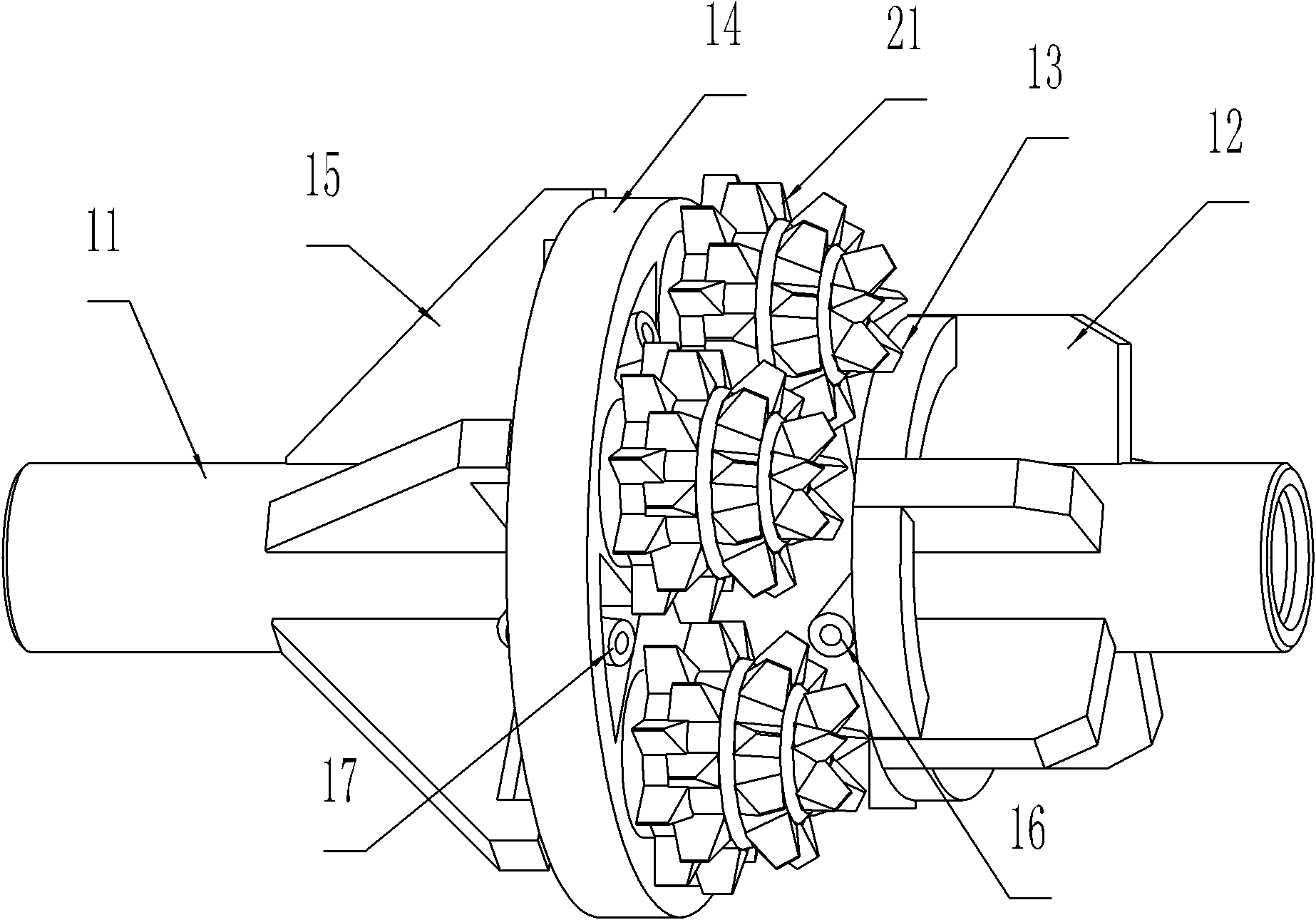

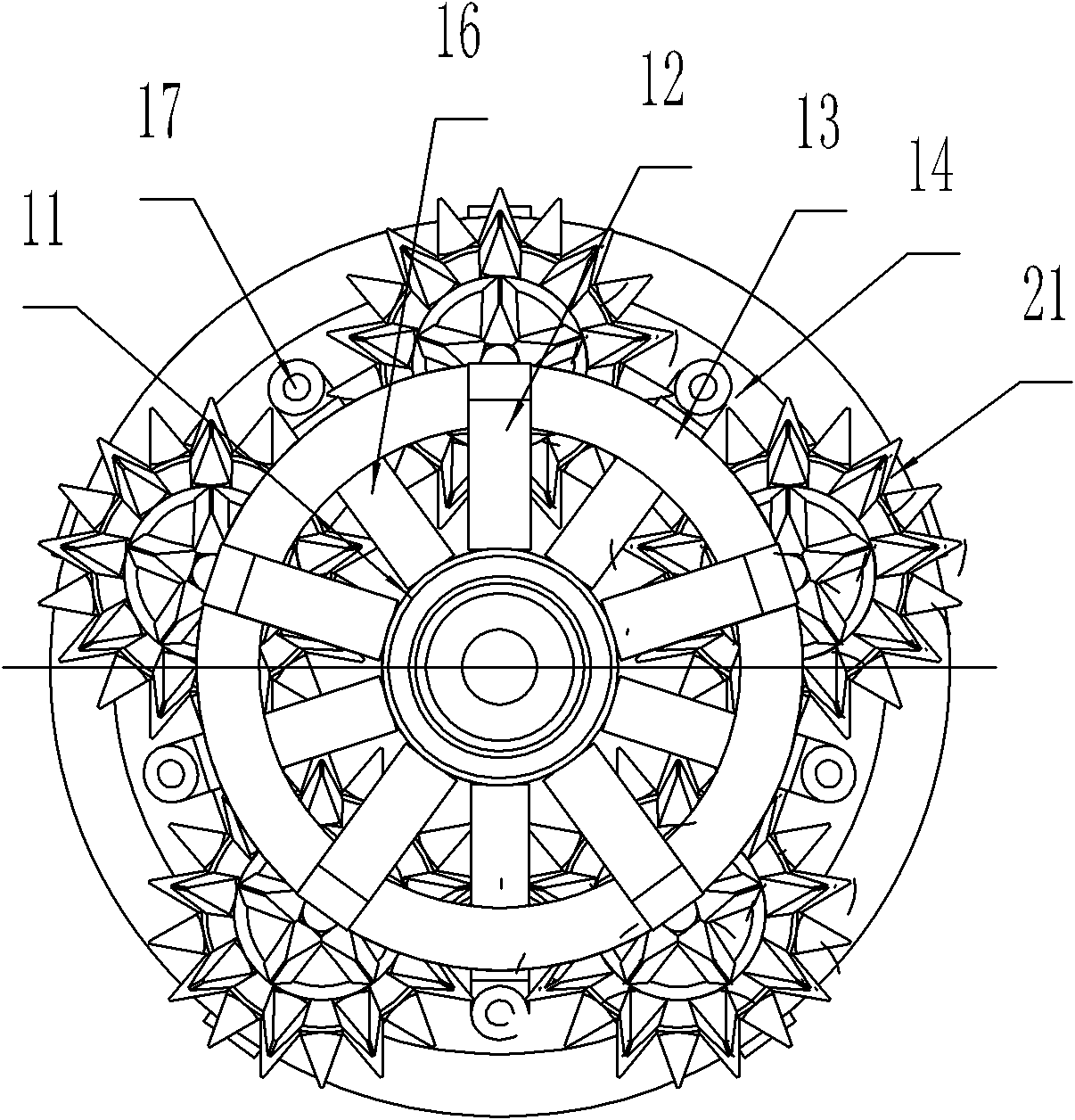

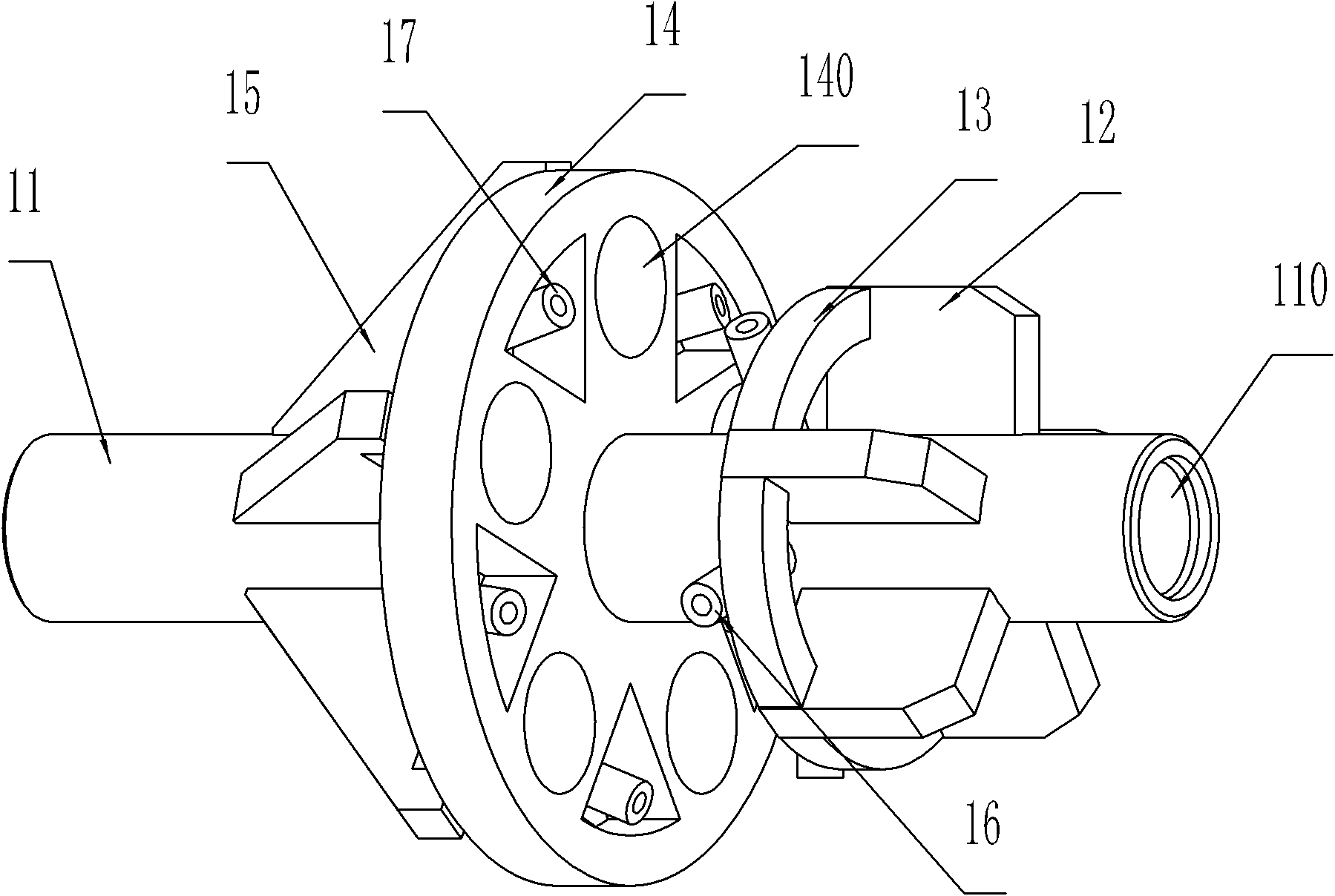

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a side tooth diameter reamer includes a reamer body 40 and a cone assembly composed of a cone and a cone seat. The reamer body is mainly provided with drill pipe joints at both ends. Threaded body mandrel 11, ring plate 13, main board 14, front guide plate 12, rear guide plate 15, radial water pipe 16, inclined water pipe 17 are formed, and described front guide plate, ring plate, main board, rear guide plate are from going to Afterwards, it is fixed on the mandrel of the body in turn, and no less than three cone seat mounting holes 140 are evenly distributed on the circumference of the main board, and the radial water pipe is placed behind the front guide plate and radially penetrates the mandrel of the body , the inclined water pipe is placed between the cone assemblies on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com