Patents

Literature

55results about How to "Fast and efficient cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

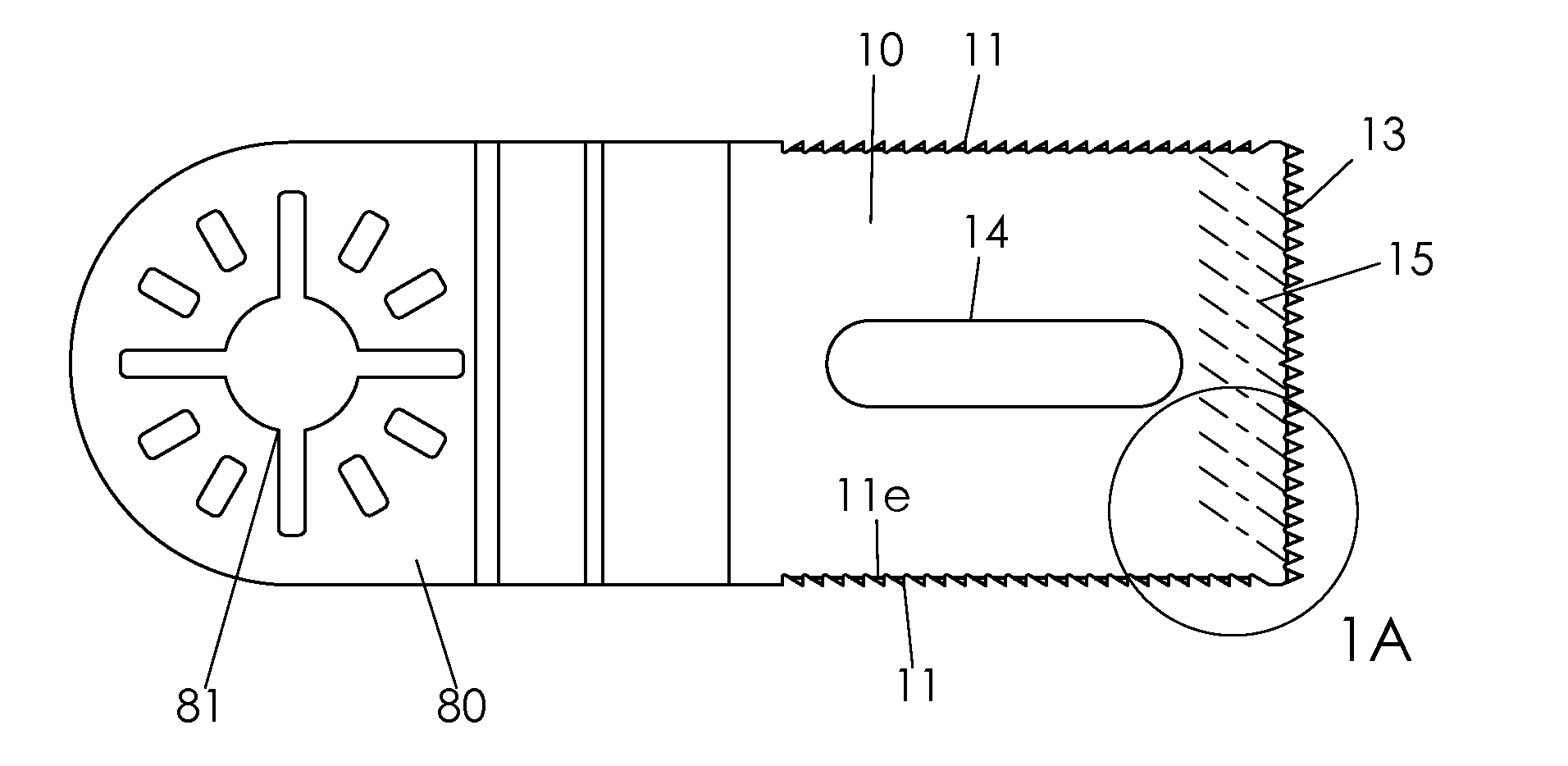

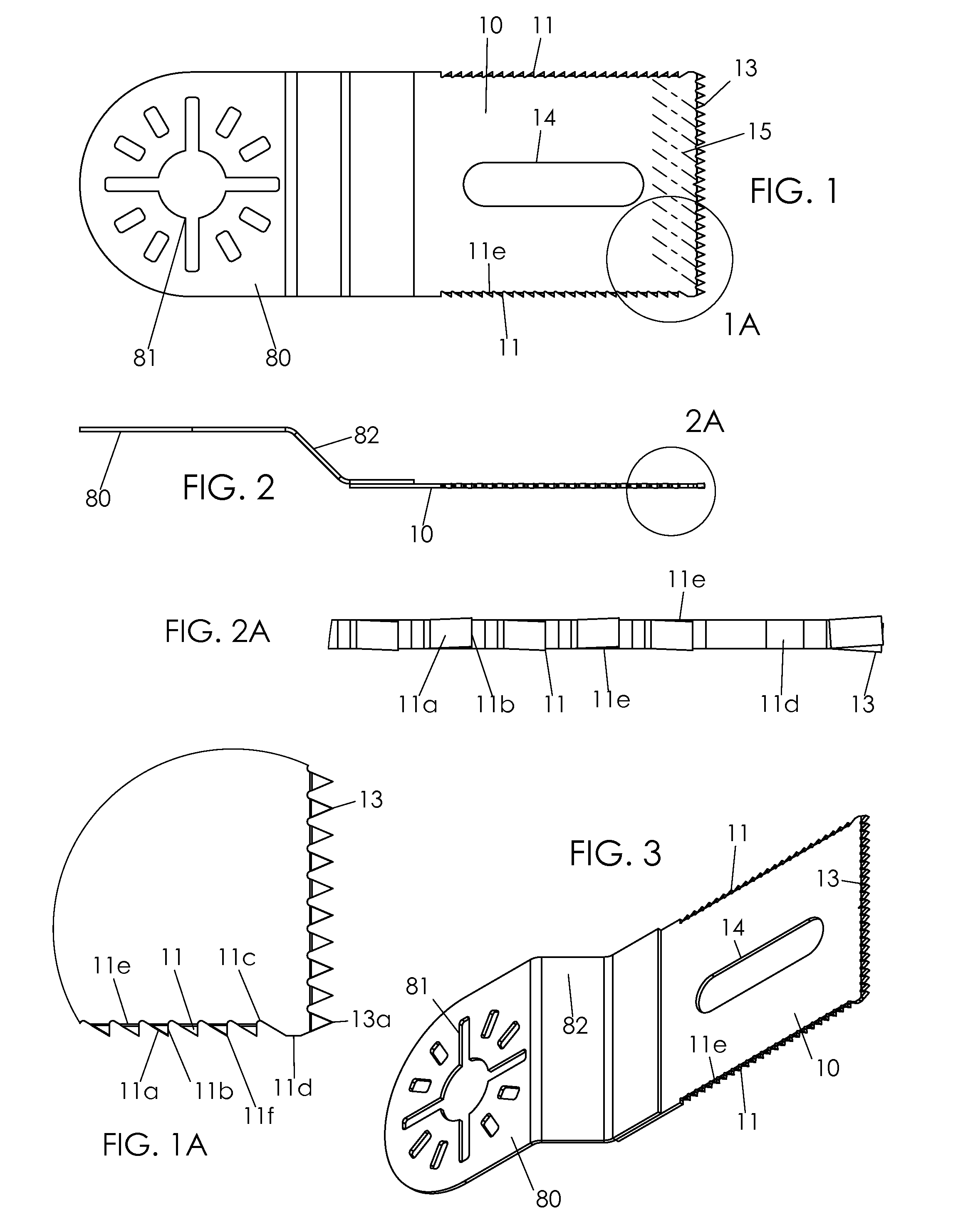

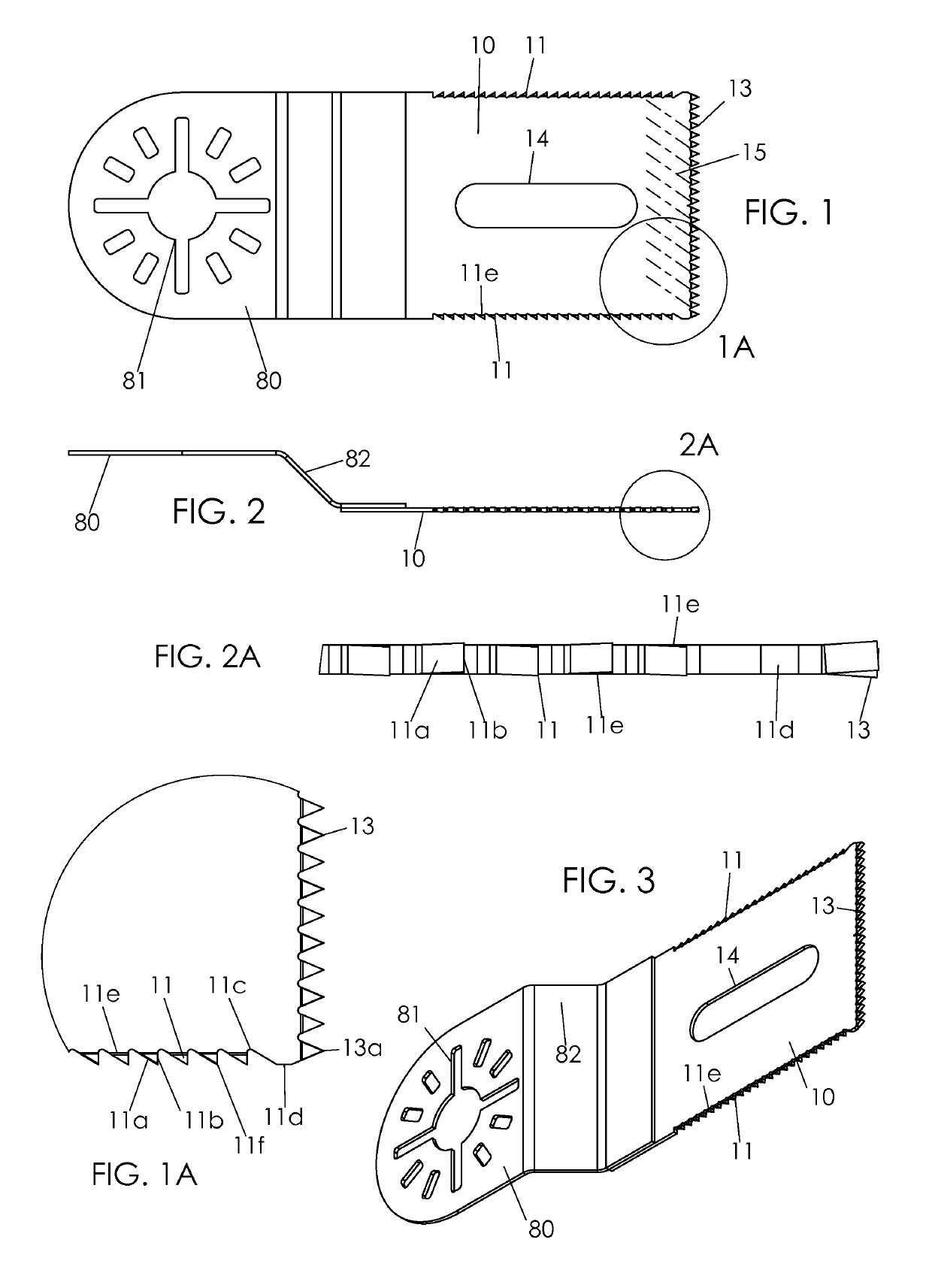

Cutting blade for oscillating tool

ActiveUS20160082605A1Smooth cutting actionFast and efficient cuttingPower driven reciprocating sawsMetal working apparatusEngineeringPower tool

An improved blade for use with an oscillating power tool is disclosed. A rectangular style blade includes side teeth to eject debris and allow rapid but well controlled blind plunge cuts. The side teeth are preferably asymmetric with a forward orientation to bias debris out and the blade inward. Preferably one or more openings or slots allow for additional debris removal. The side teeth also allow for controlled side cutting.

Owner:WORKTOOLS

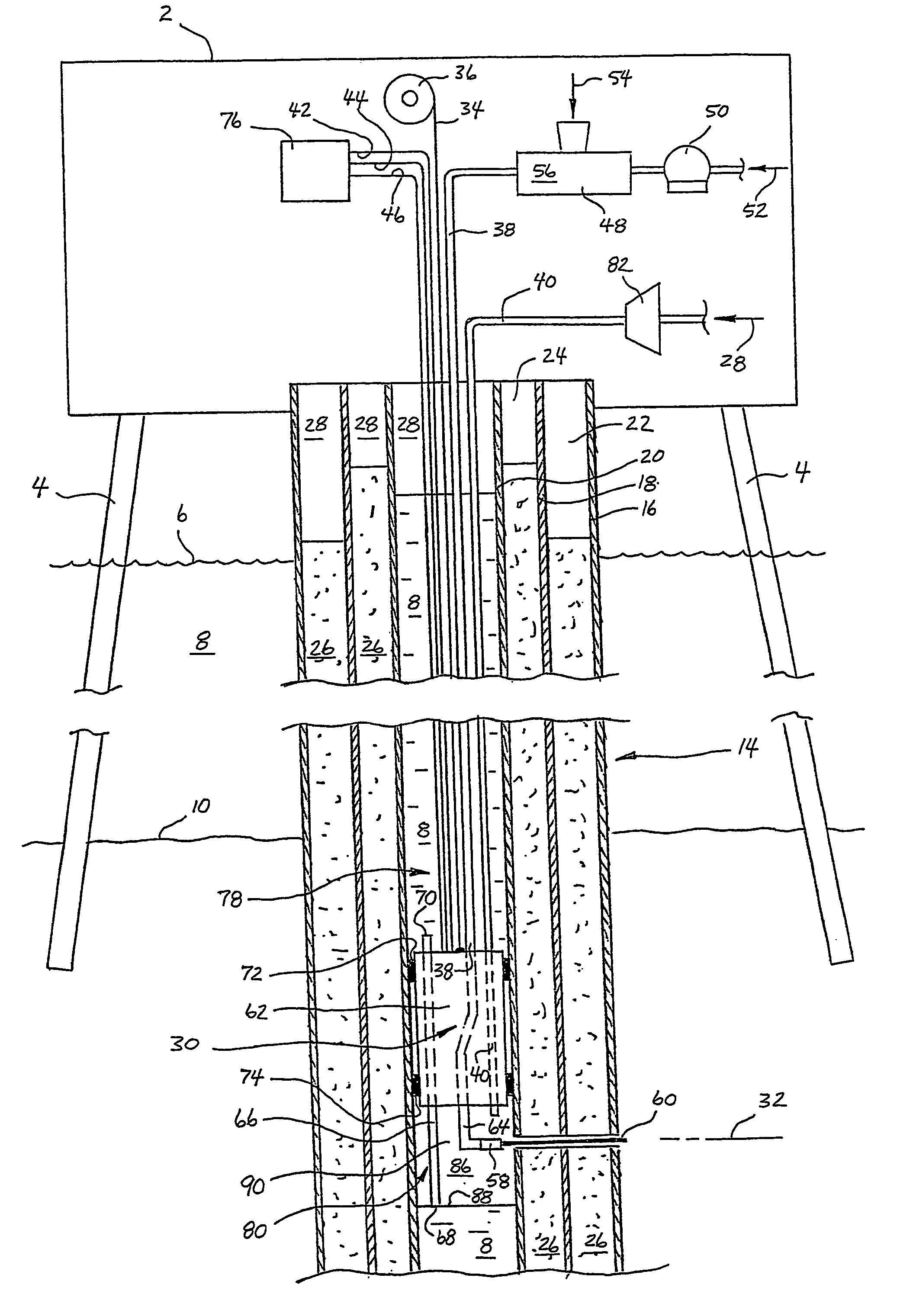

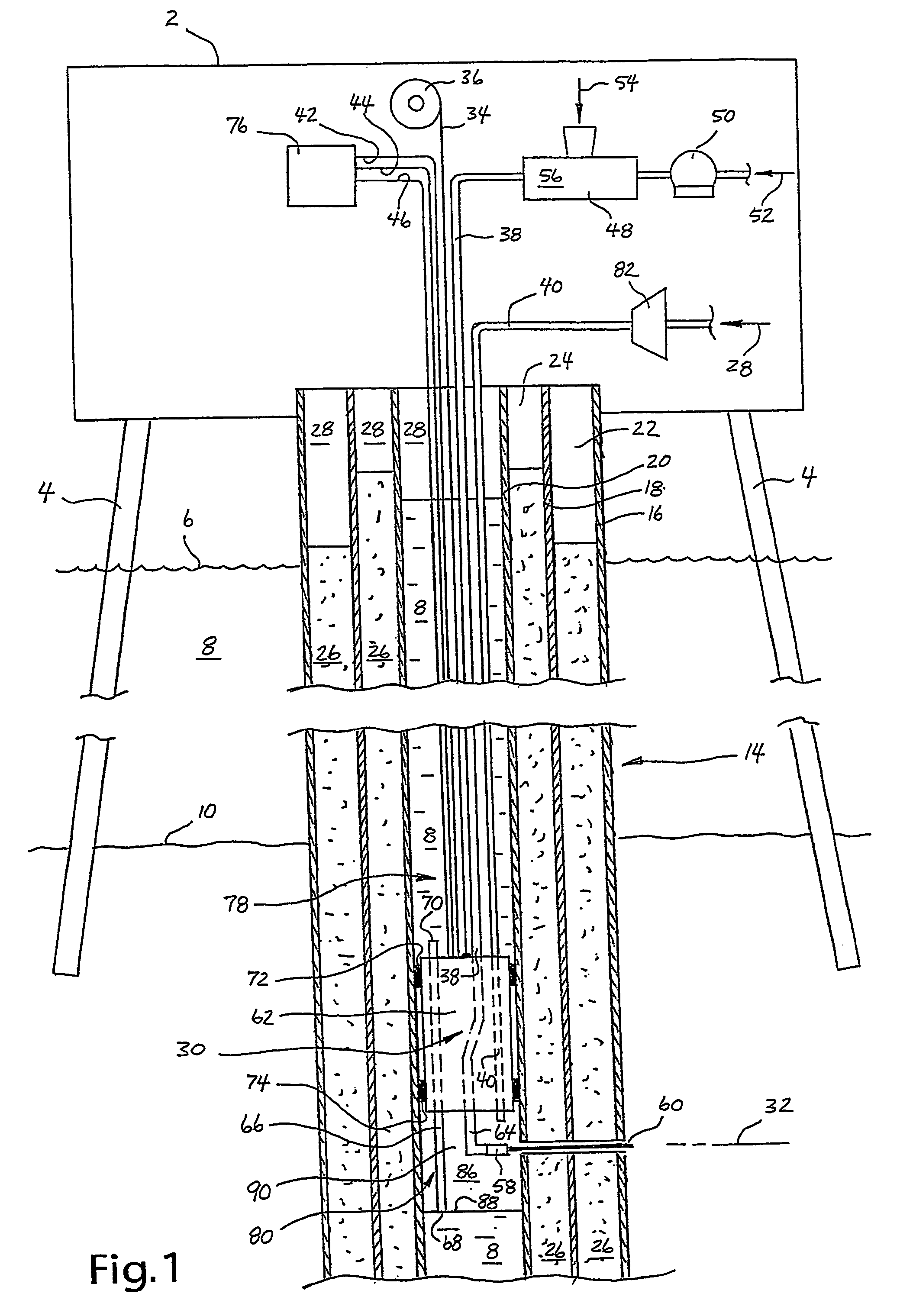

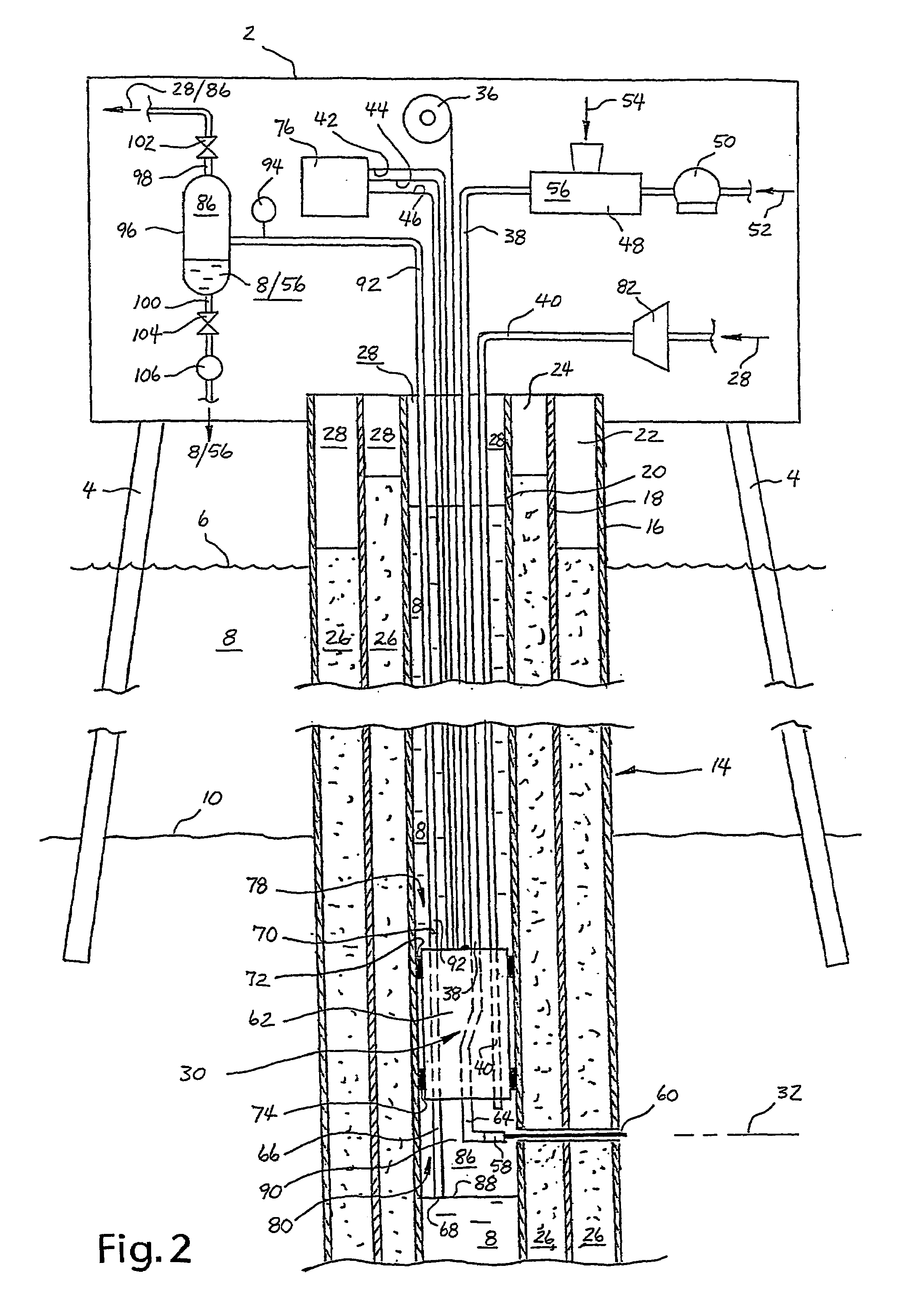

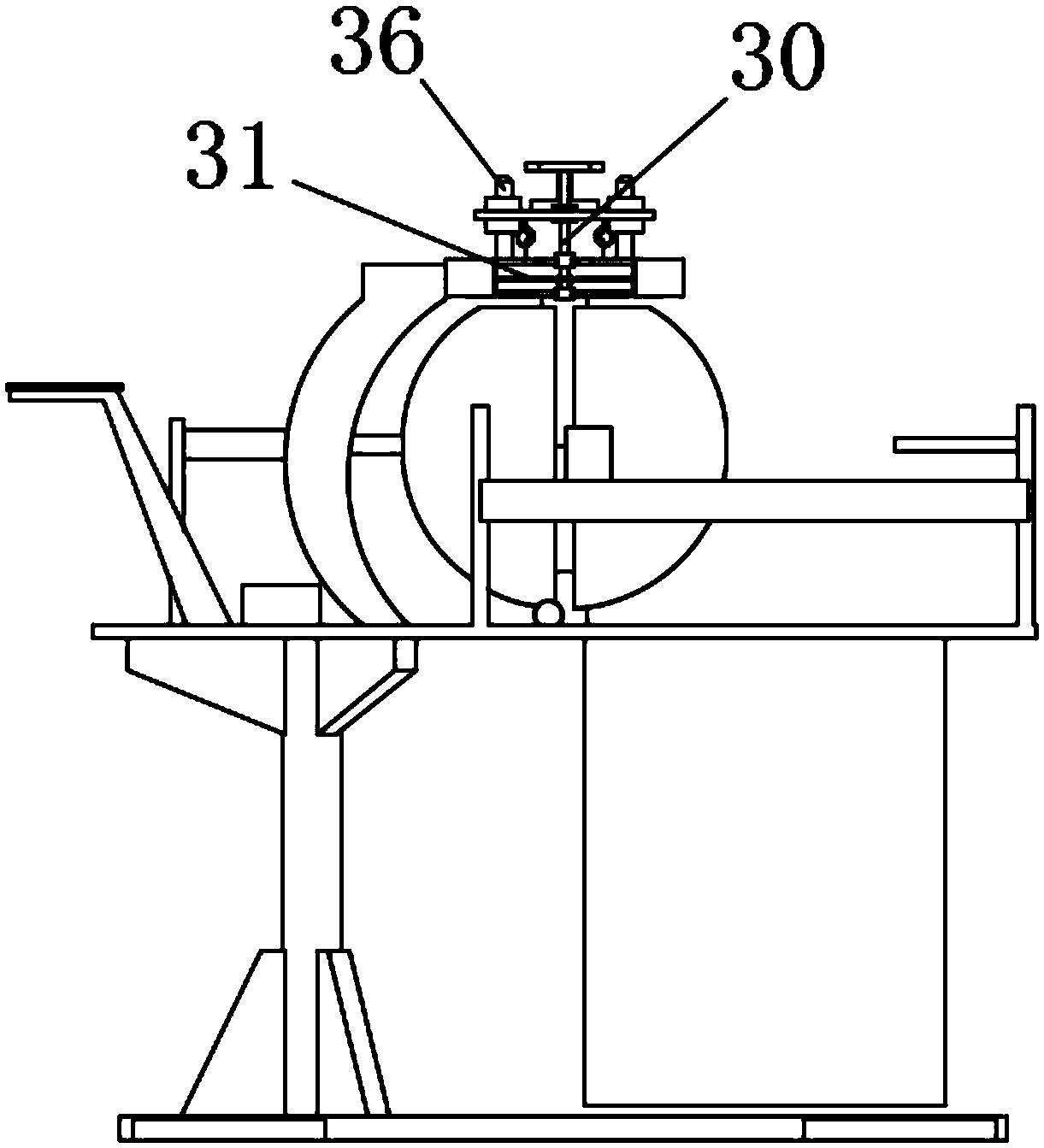

Device for a hydraulic cutting tool

ActiveUS7178598B2Weaken energyGas overpressure may optionally be increasedDisloding machinesUnderground miningEngineeringMechanical engineering

A device for a hydraulic cutting tool (30) for cutting of at least one pipe (16, 18, 20) or tubular object beneath a water floor (10), wherein the cutting is carried out from a surface facility (2). The cutting tool (30) is anchored in a pressure tight manner in the pipe (16), whereupon pressurised gas (86) is pumped into a pipe section (80) immediately below the cutting tool (30). With this, liquid (8), and eventually pressurised gas (86), will flow out of the pipe section (80) via a short drain pipe (66) through the cutting tool (30), so as to create a gas filled pipe volume (90) comprising the relevant cutting depth (32) in the pipe section (80). The invention differs from prior art by the outflowing liquid being led onwards up to the surface facility (2) via a drain line (92). The upper end portion of the drain line (92) is connected to at least one adjustable choke device (102, 104). This allows the gas overpressure in said pipe volume (90) to be controlled during the cutting, providing optimal operating conditions during the hydraulic cutting.

Owner:OCEANEERING NCA

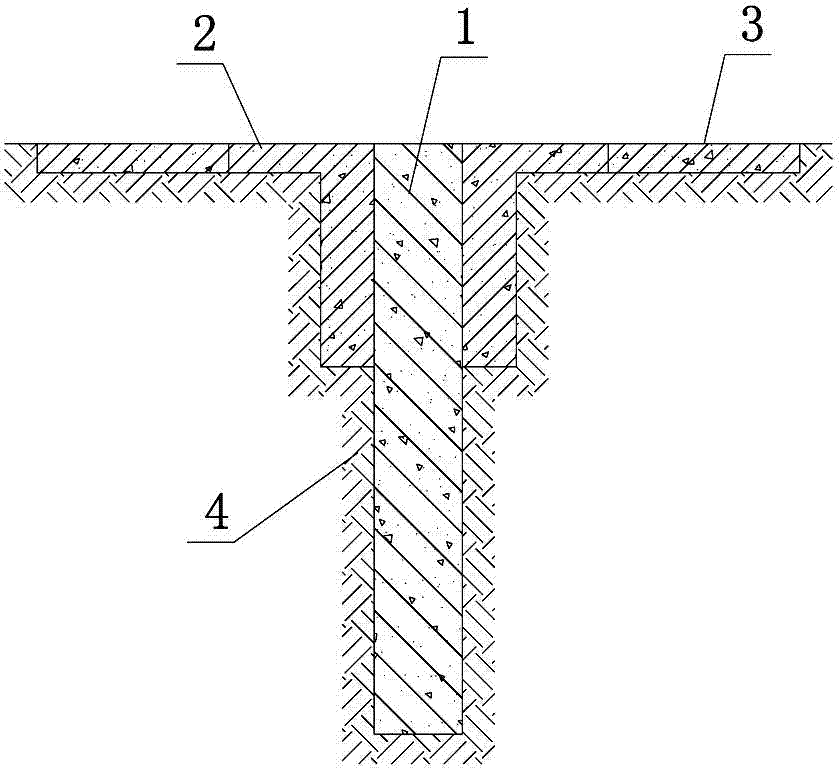

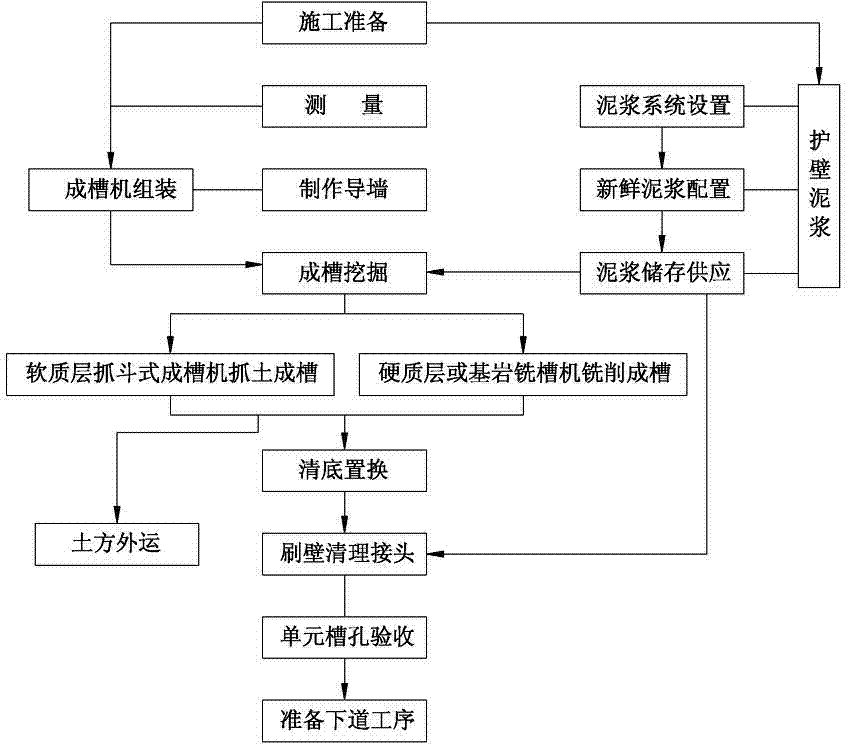

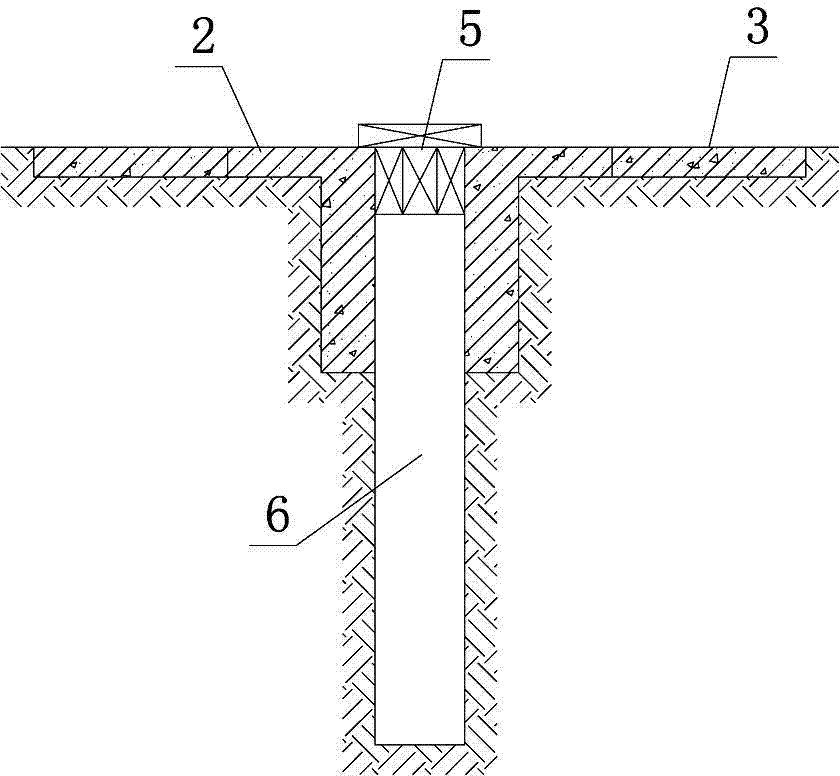

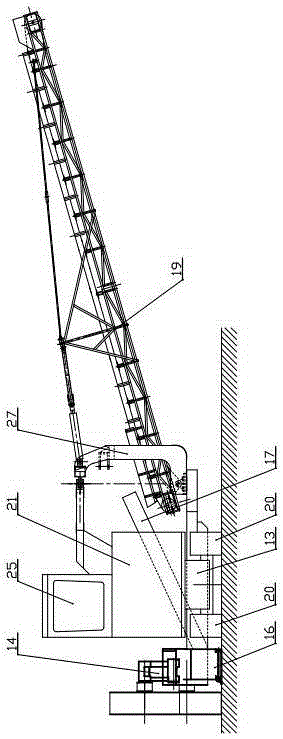

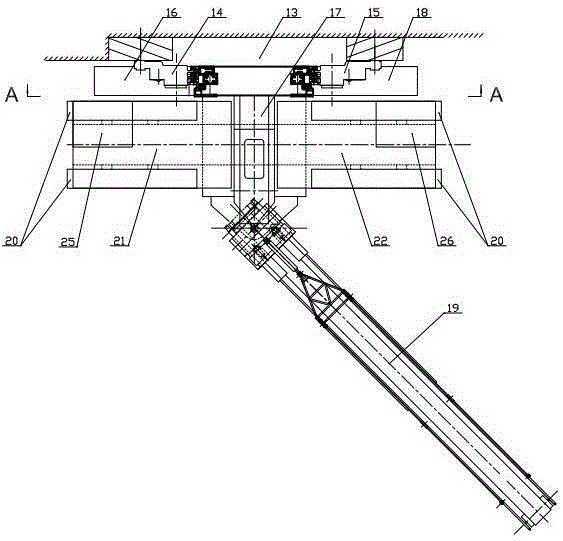

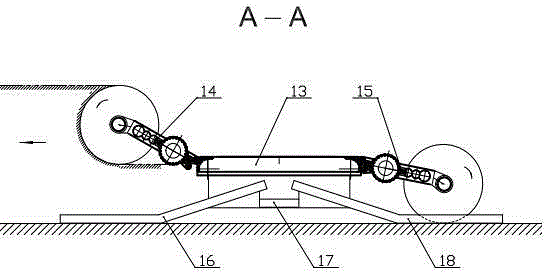

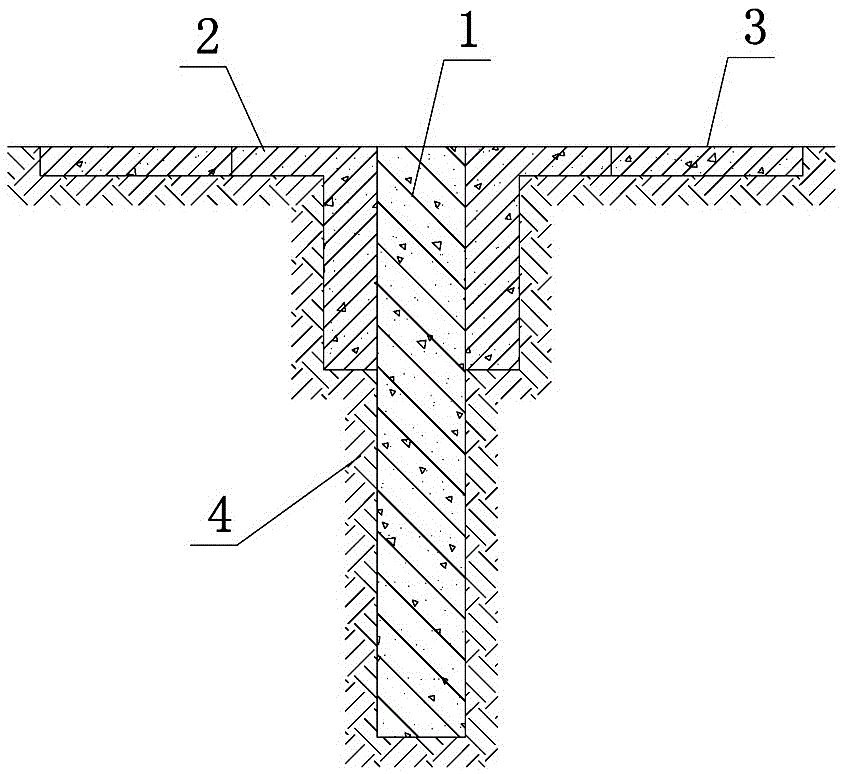

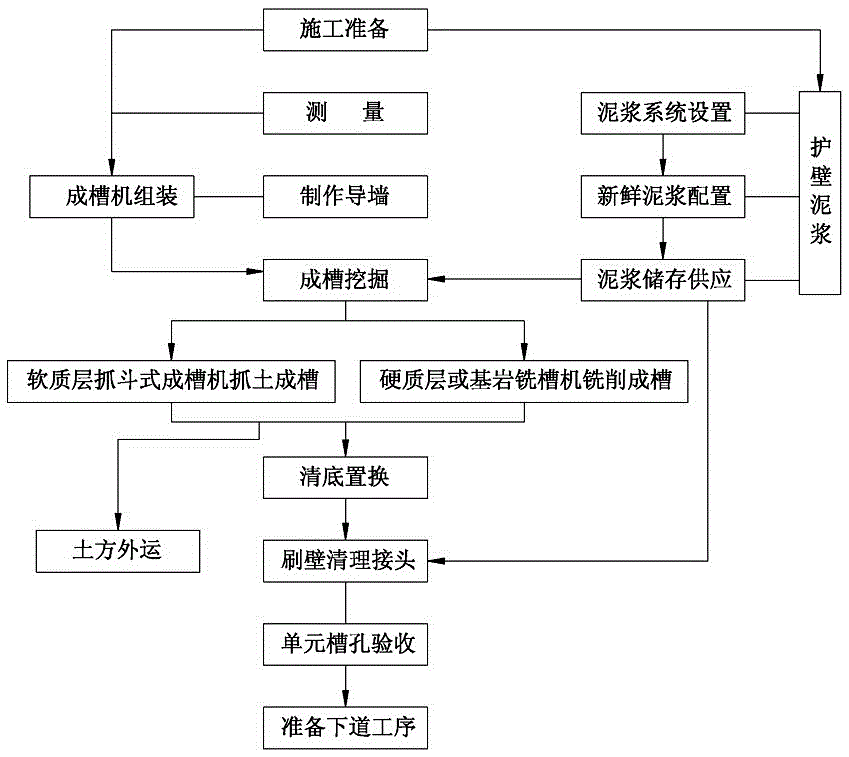

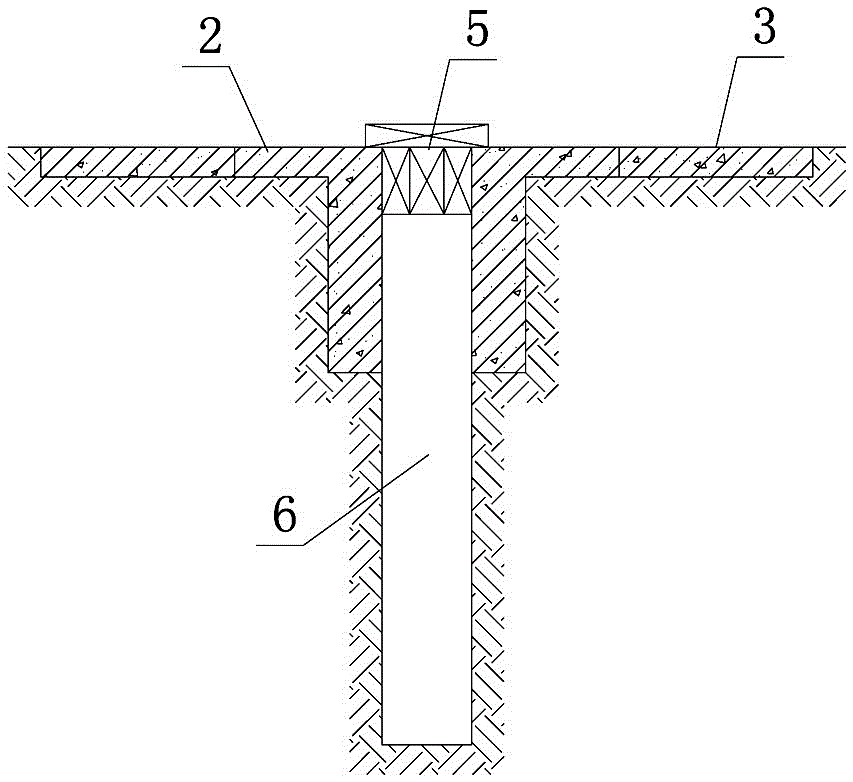

Super-deep underground continuous wall and construction method thereof

The invention relates to a super-deep underground continuous wall which comprises an underground continuous wall body. Guide walls are symmetrically arranged on the two sides of the wall body, the cross sections of the guide walls are in the shape of an L, the lower ends of the guide walls are located on underground rock-soil, and the lug edges of the guide walls are connected with a concrete pavement. The invention further discloses a construction method of the super-deep underground continuous wall. The method includes the following steps of construction preparation, measuring, guide wall manufacturing, wall protection slurry manufacturing, grooving construction, bottom-clearing replacement, connector cleaning through wall brushing and unit slot section inspection, wherein a grabbing-milling integrated grooving method is used in the grooving construction. The method is high in grooving efficiency, short in construction time and short in groove wall soaking time, the grabbing-milling integrated grooving method is used in the grooving construction, technologies can be changed timely according to different stratum hardness situations, the characteristics that a grab bucket is high in digging speed at the soft soil layer and milling wheel can achieve rapid milling and digging footage at a hard soil layer or bed rod with standard penetration test blow count exceeding 45 are fully used, and therefore rapid and efficient grooving of the whole wall can be achieved.

Owner:ZHONGDING INT ENG

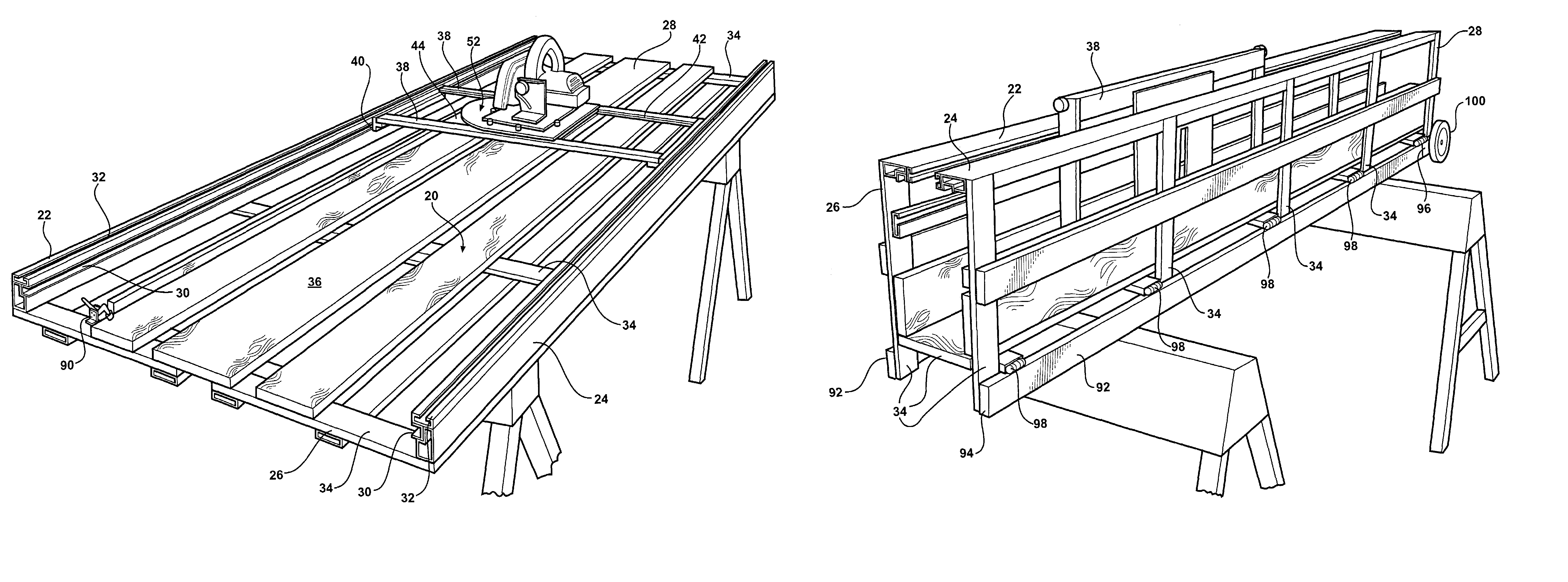

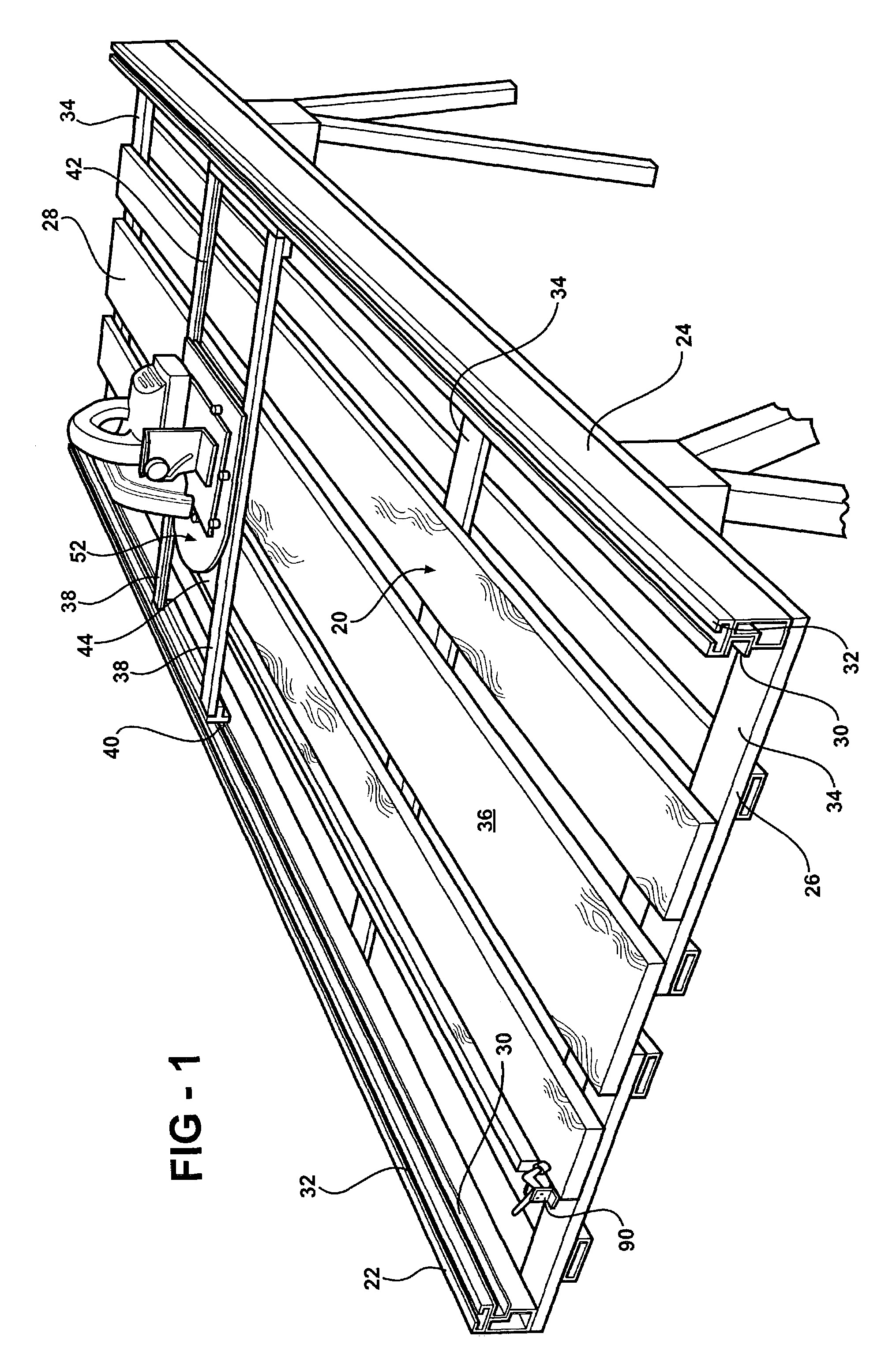

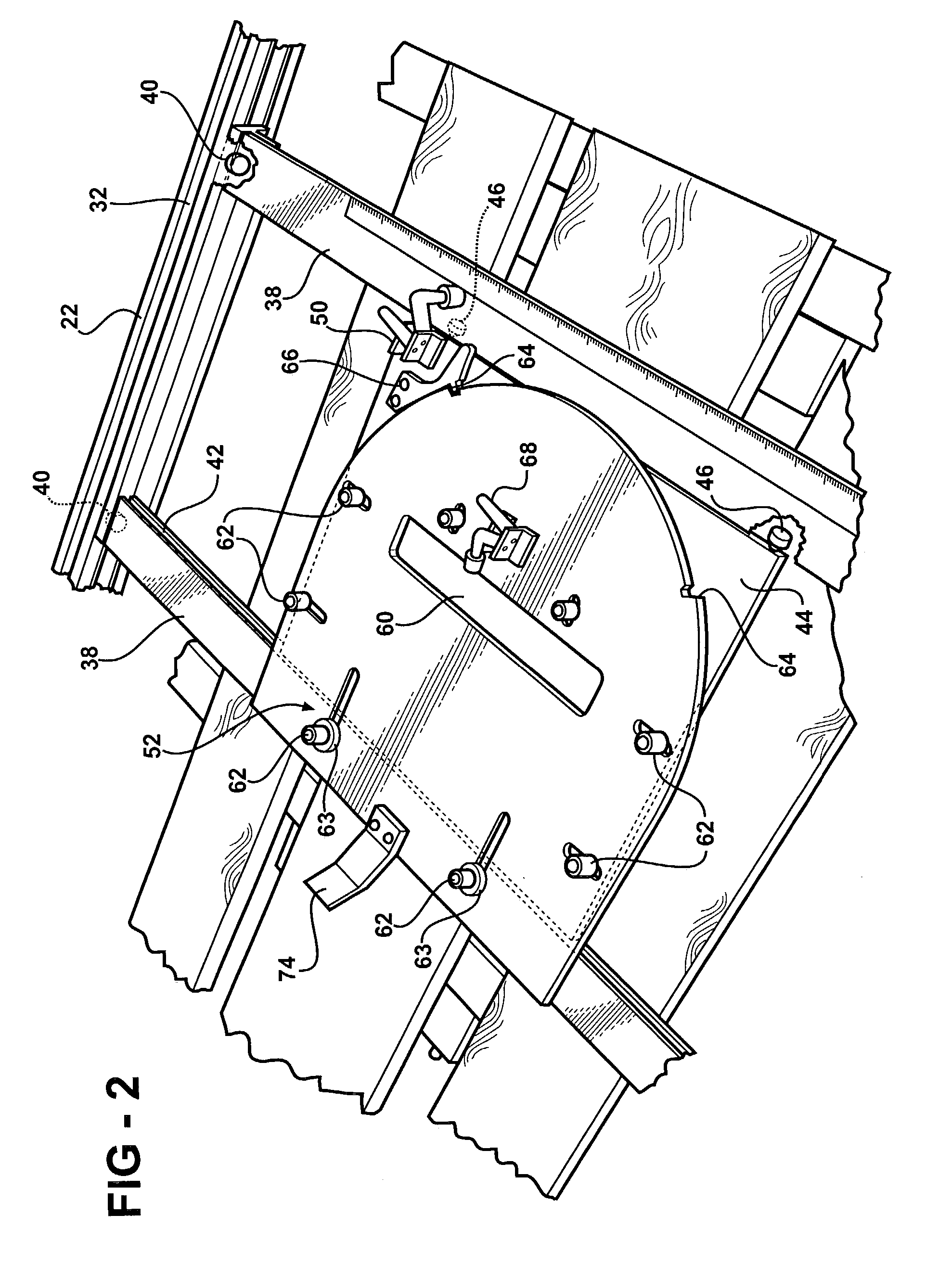

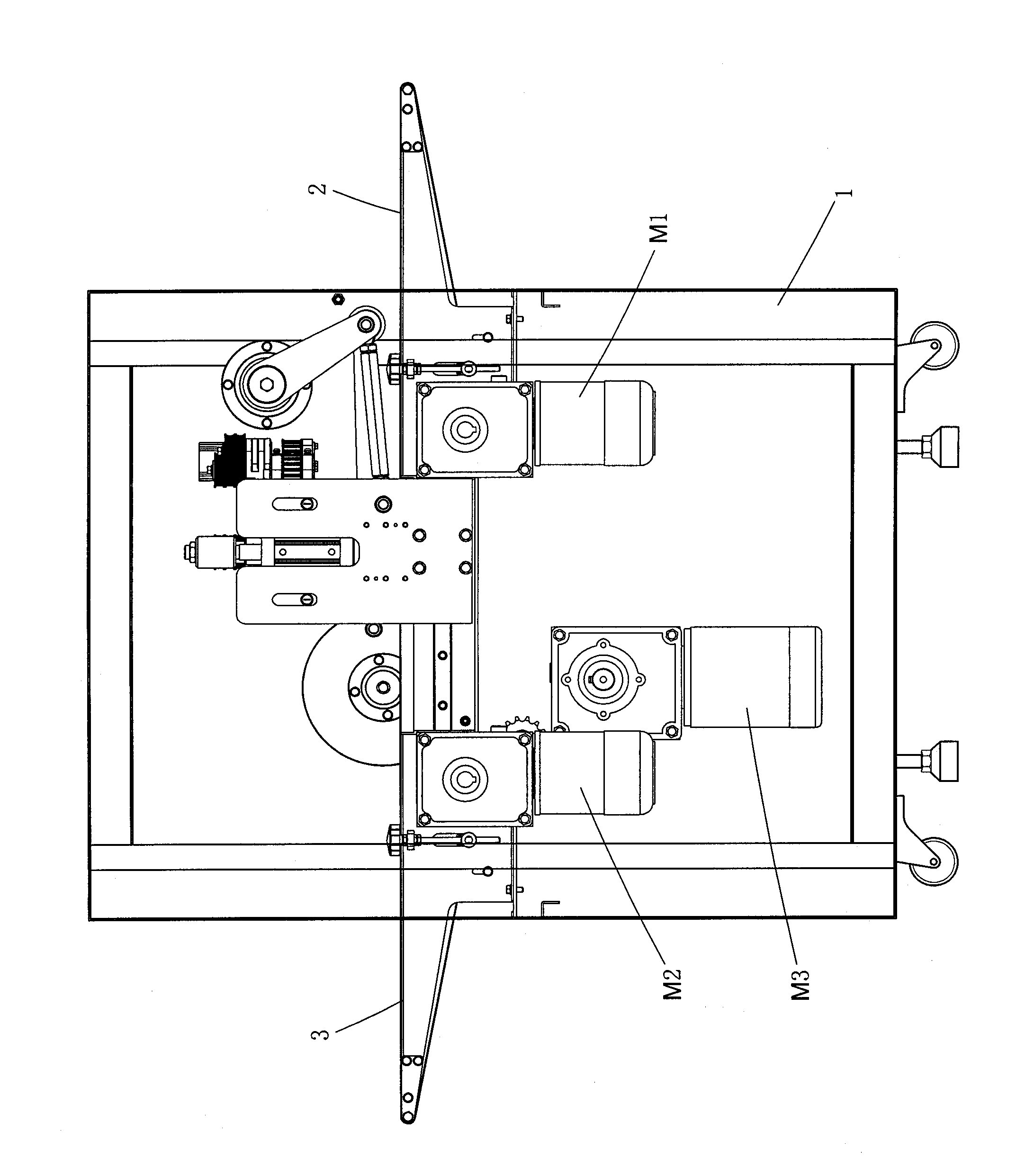

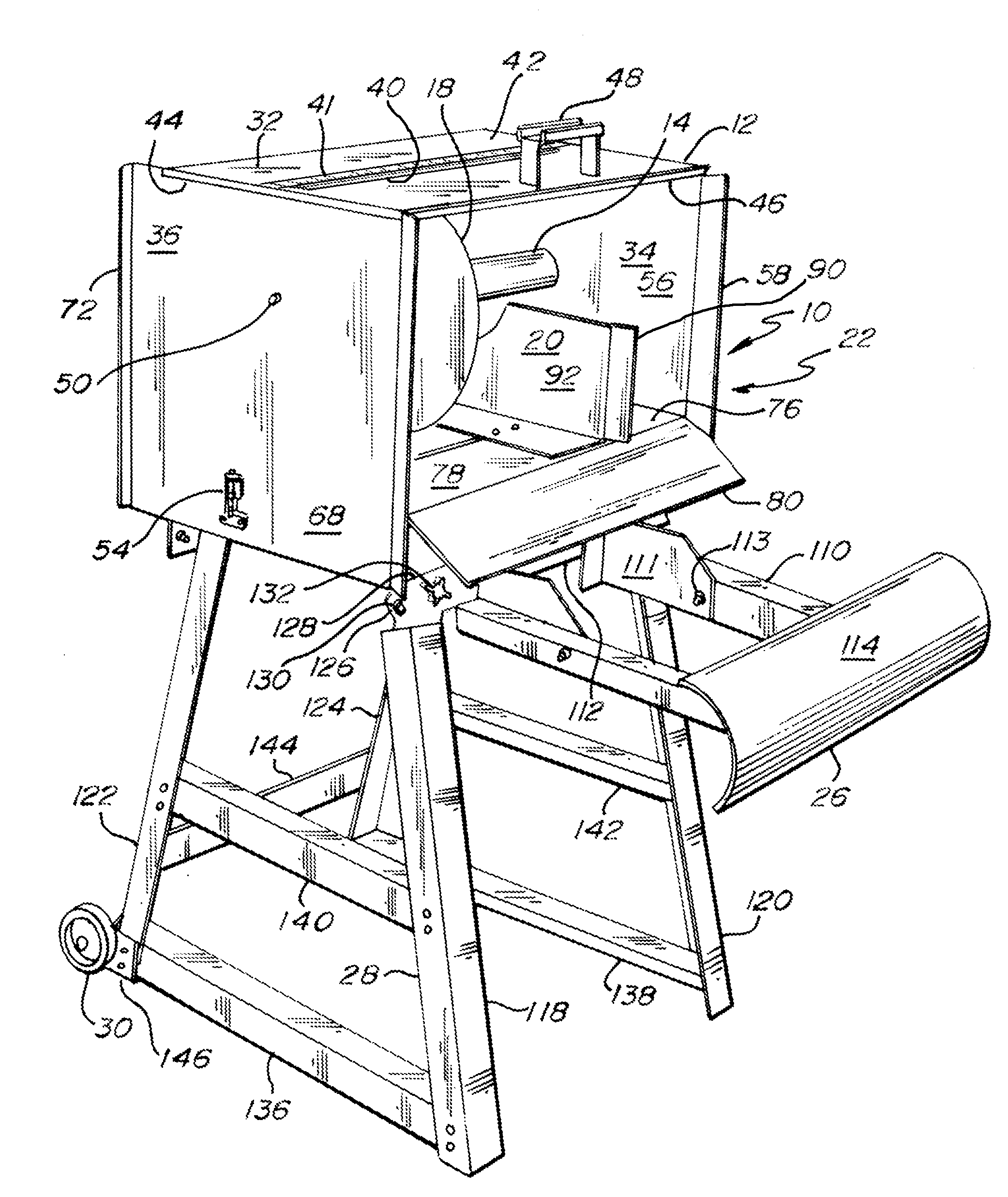

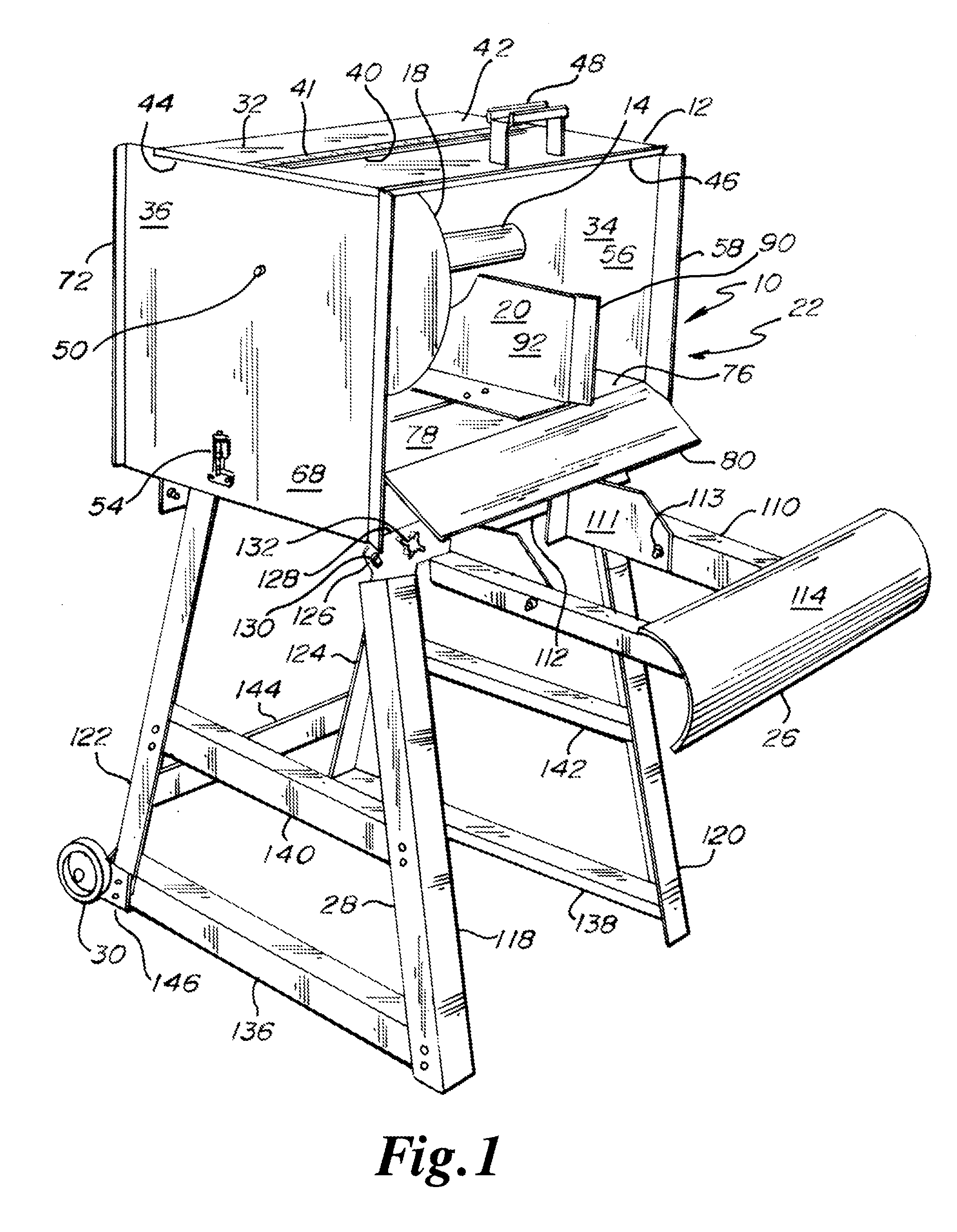

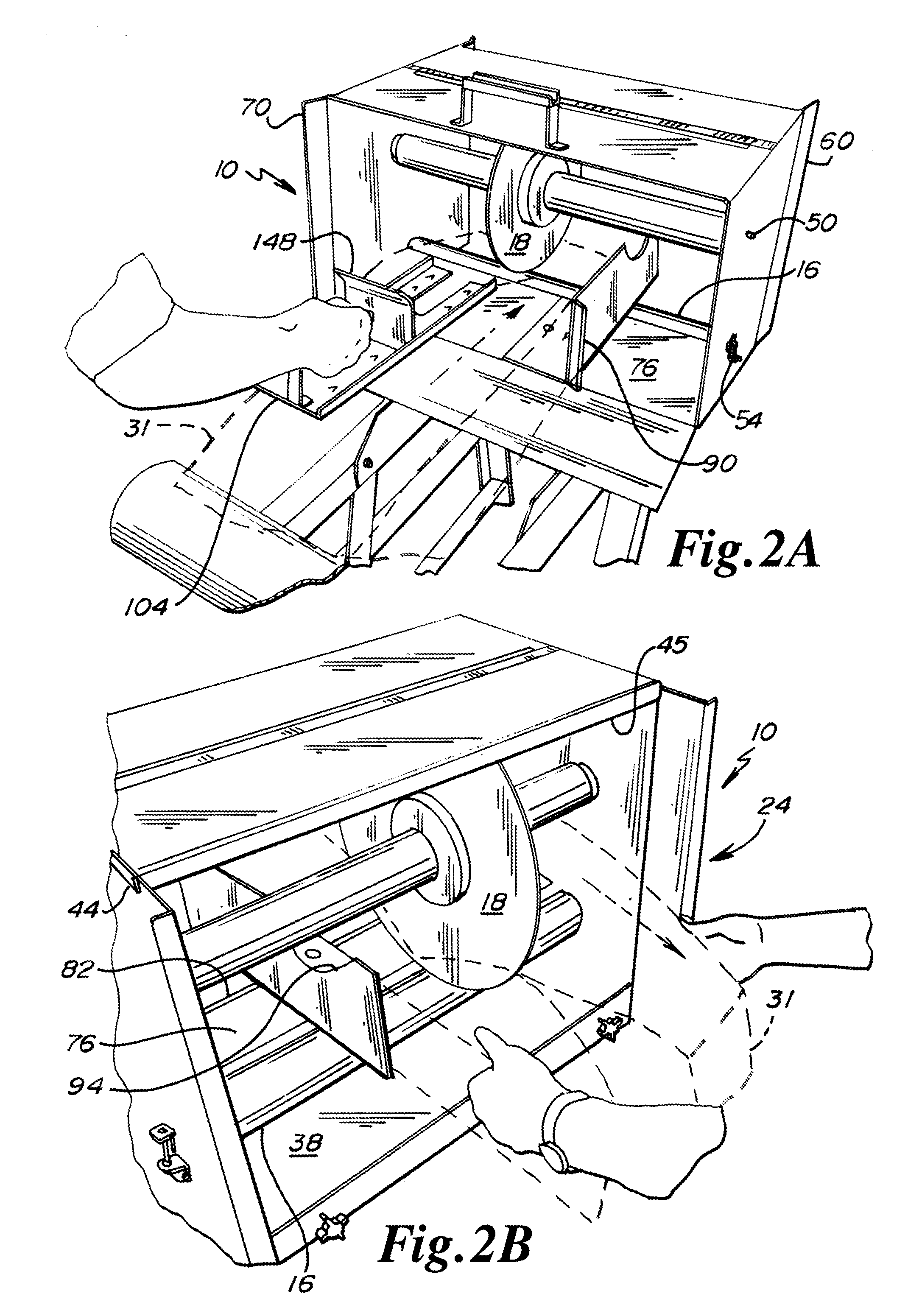

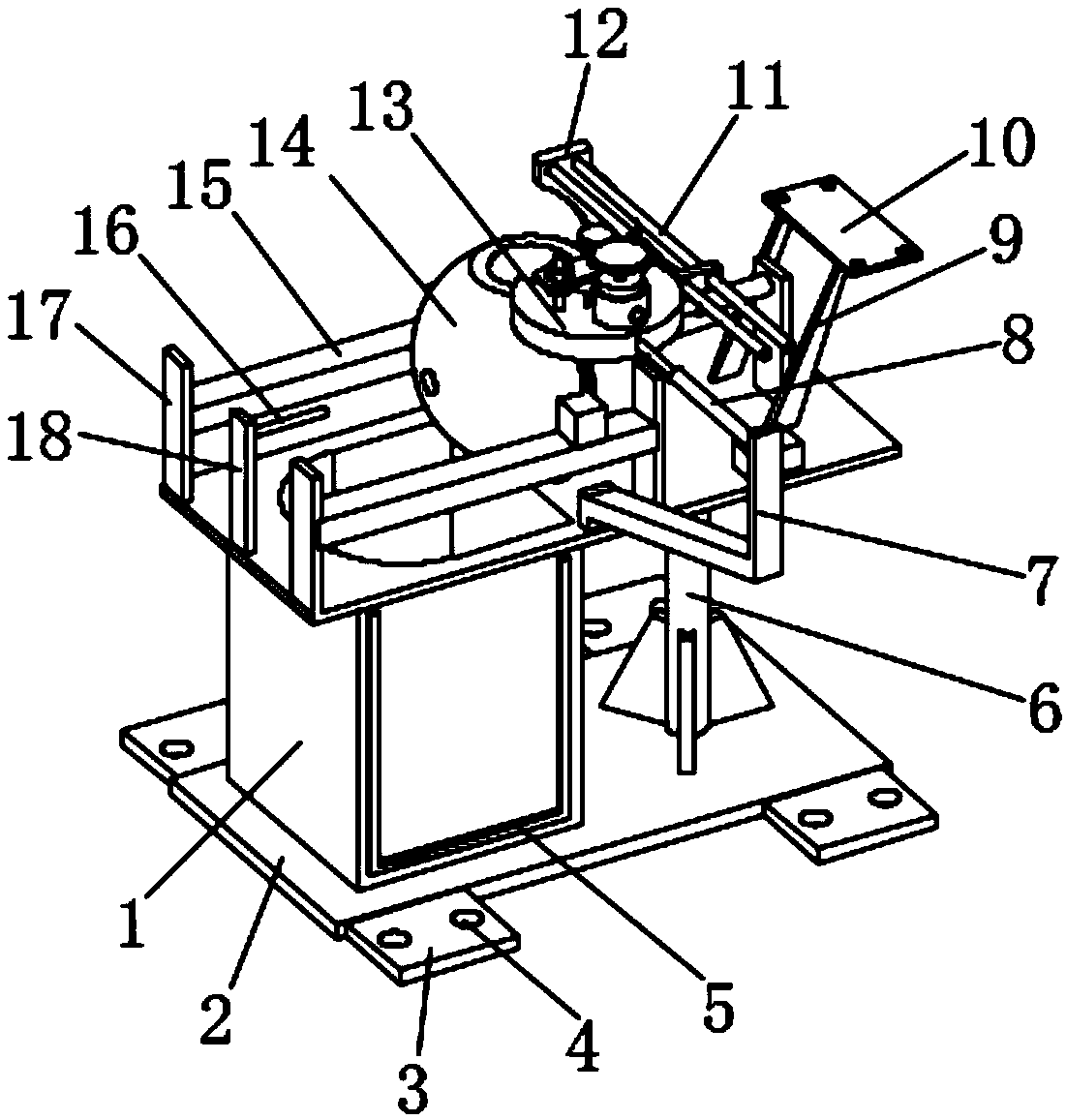

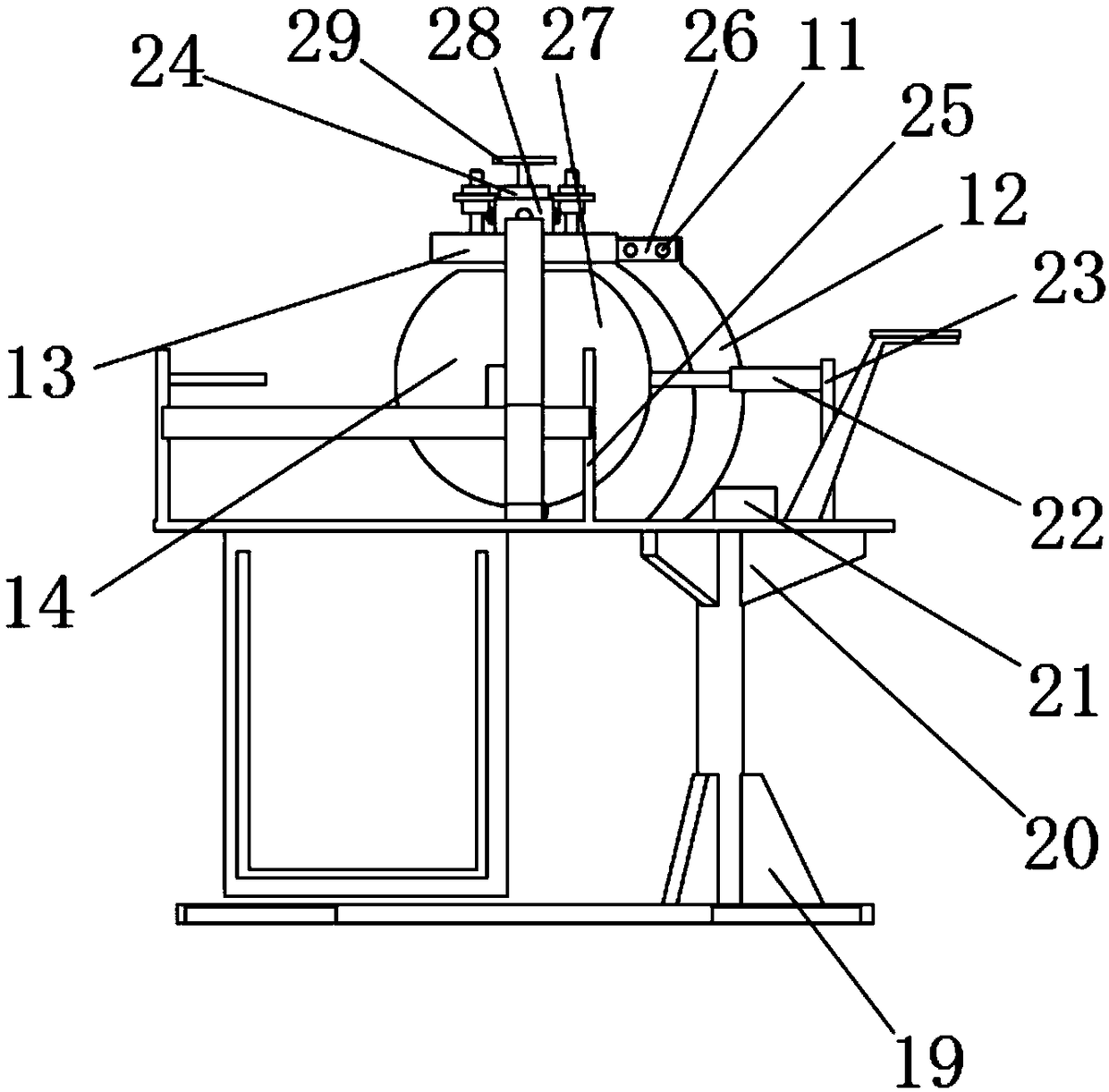

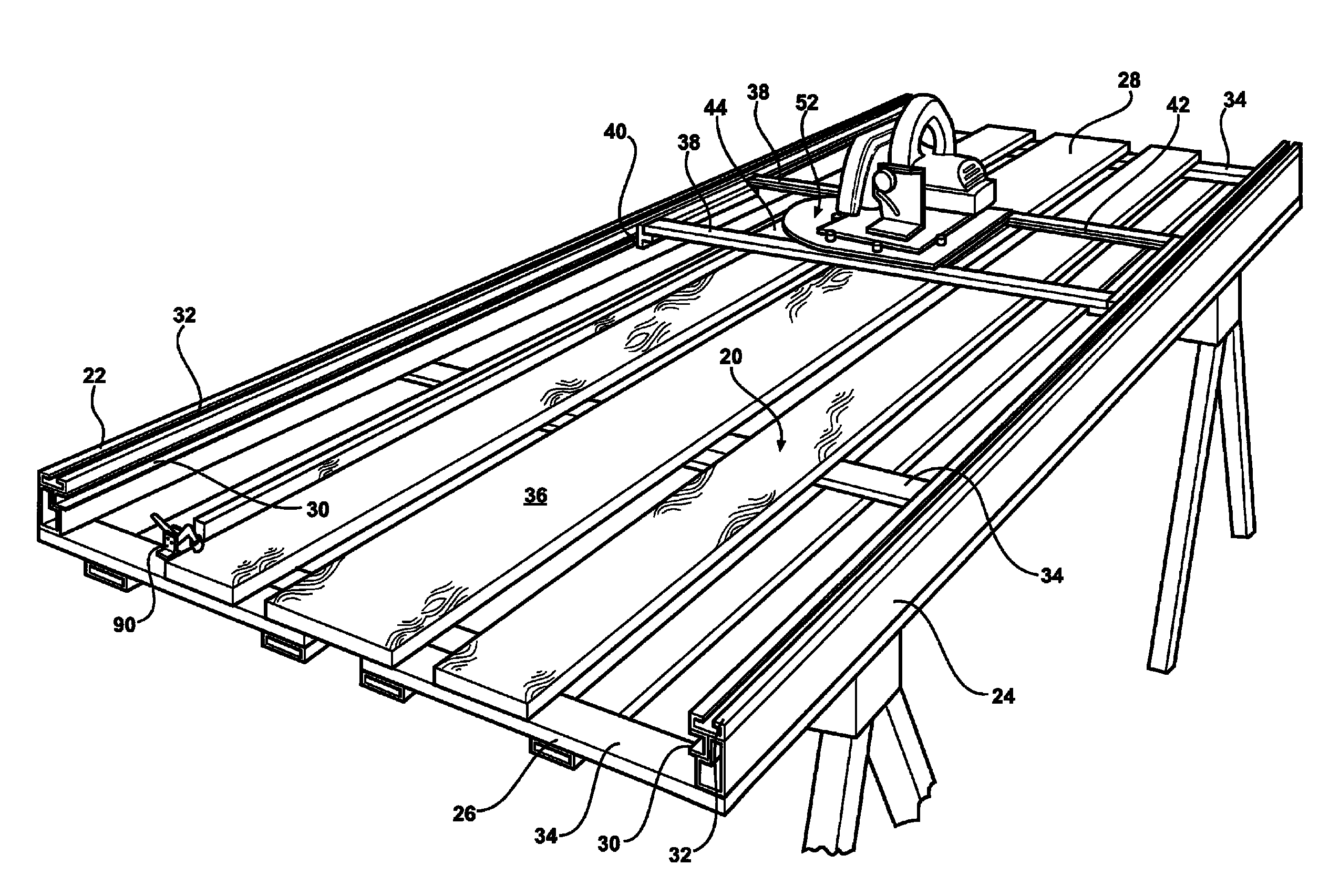

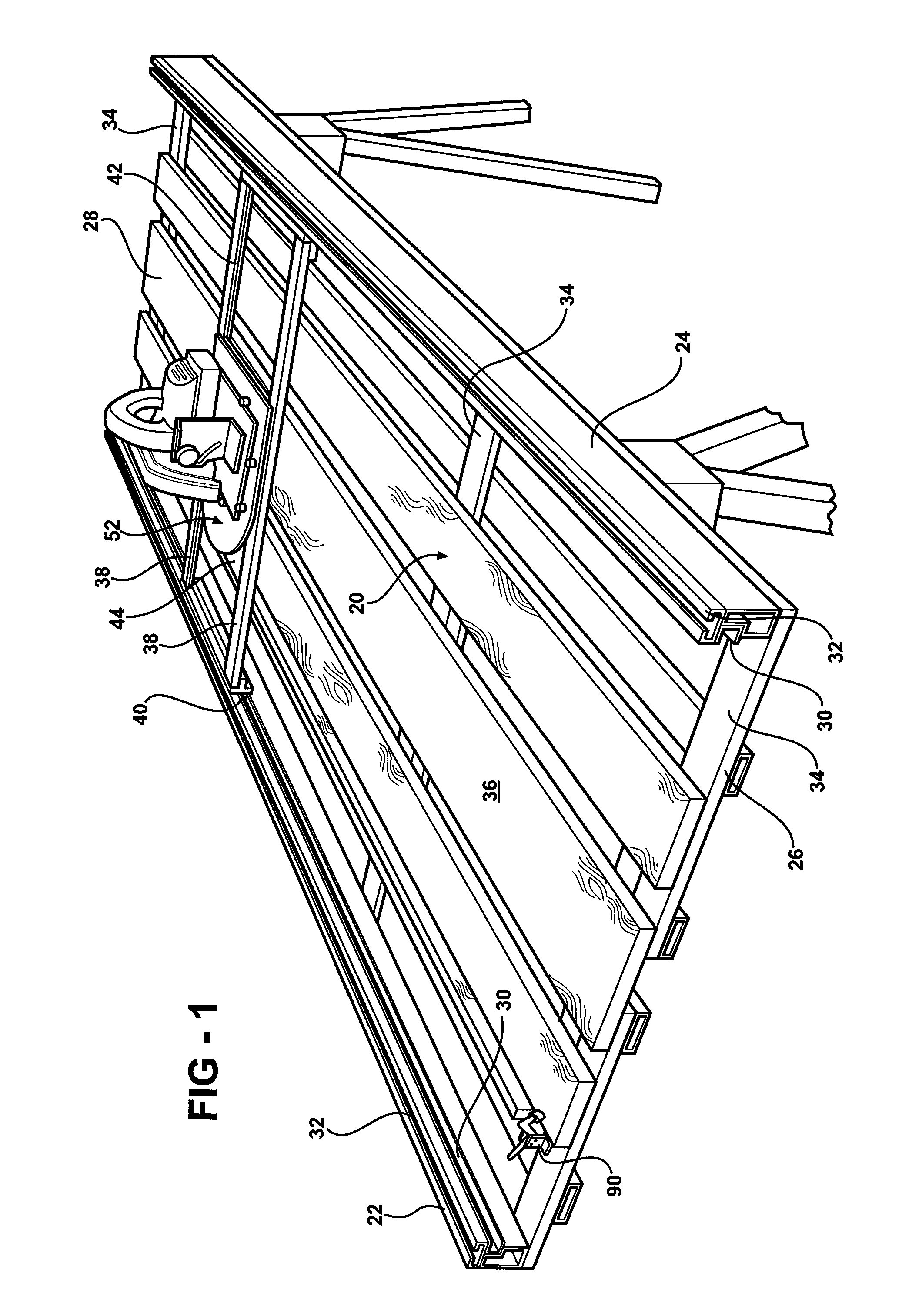

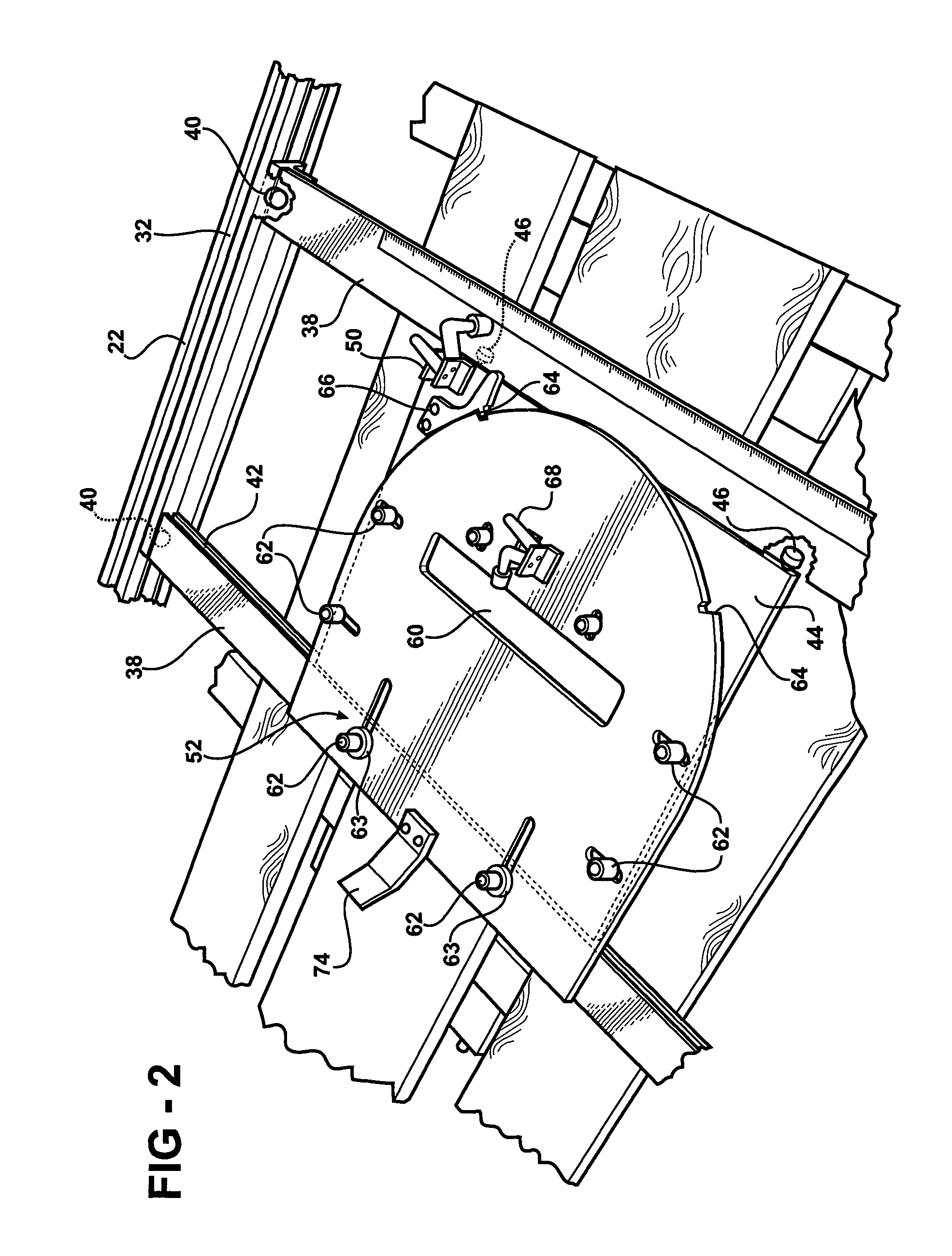

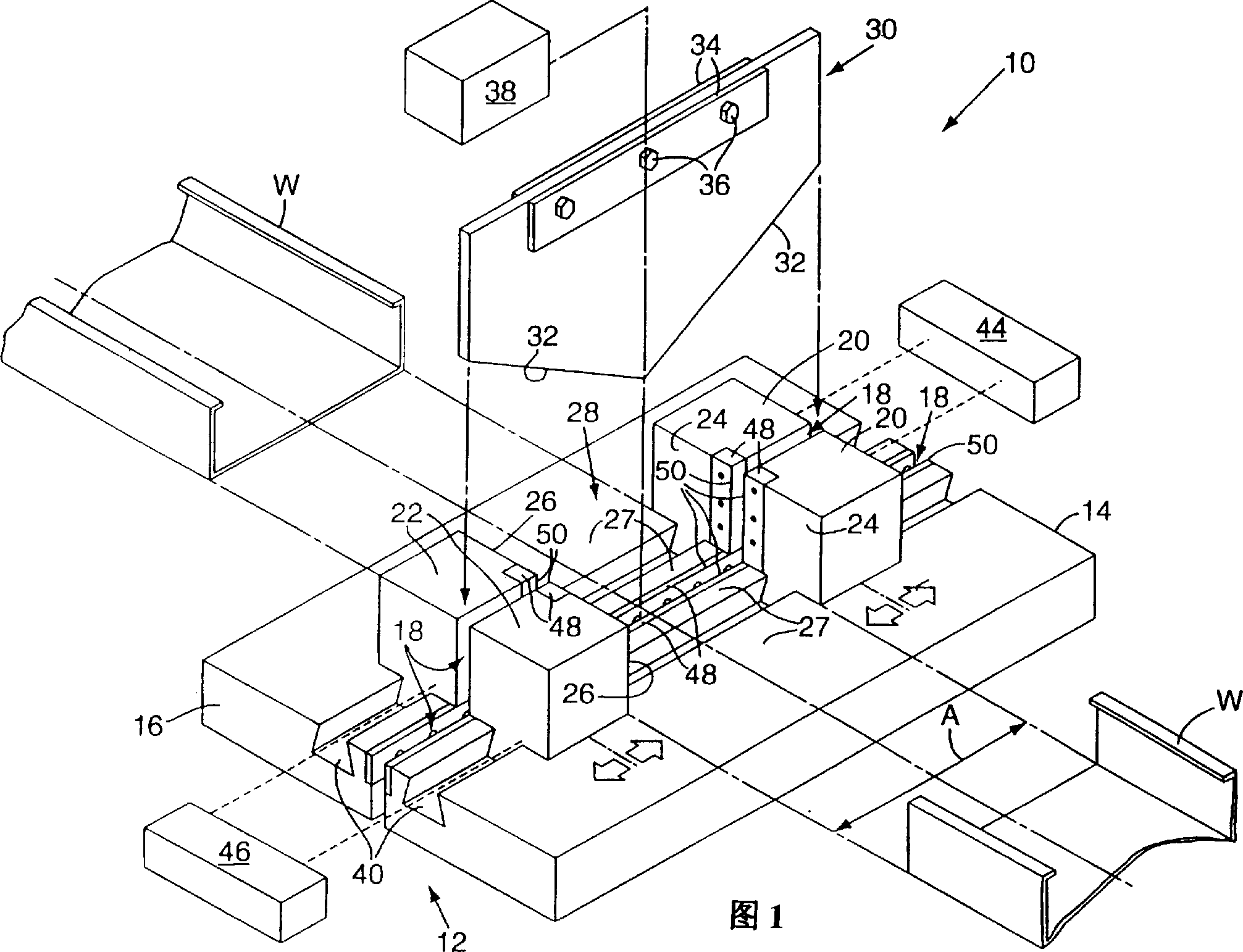

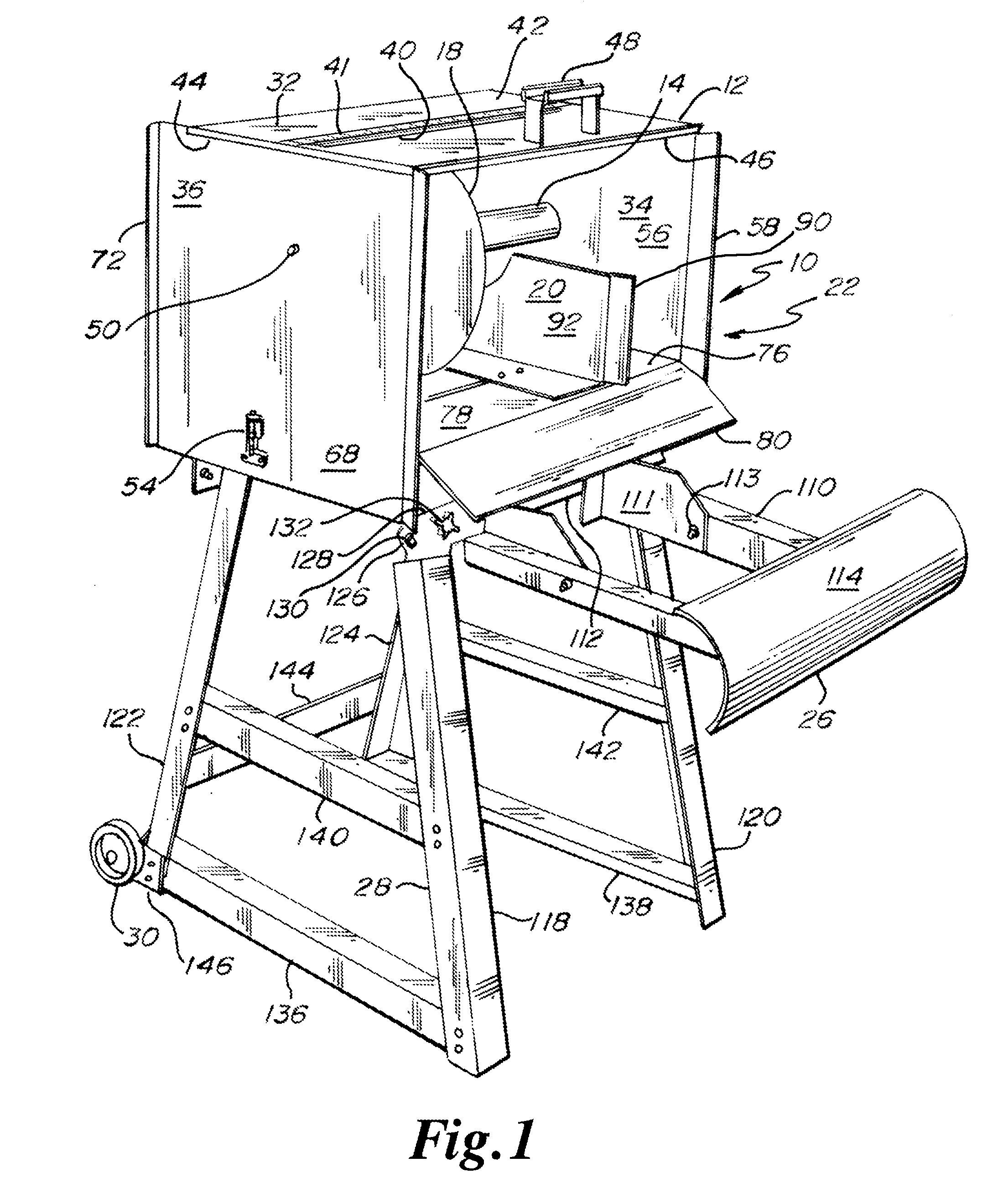

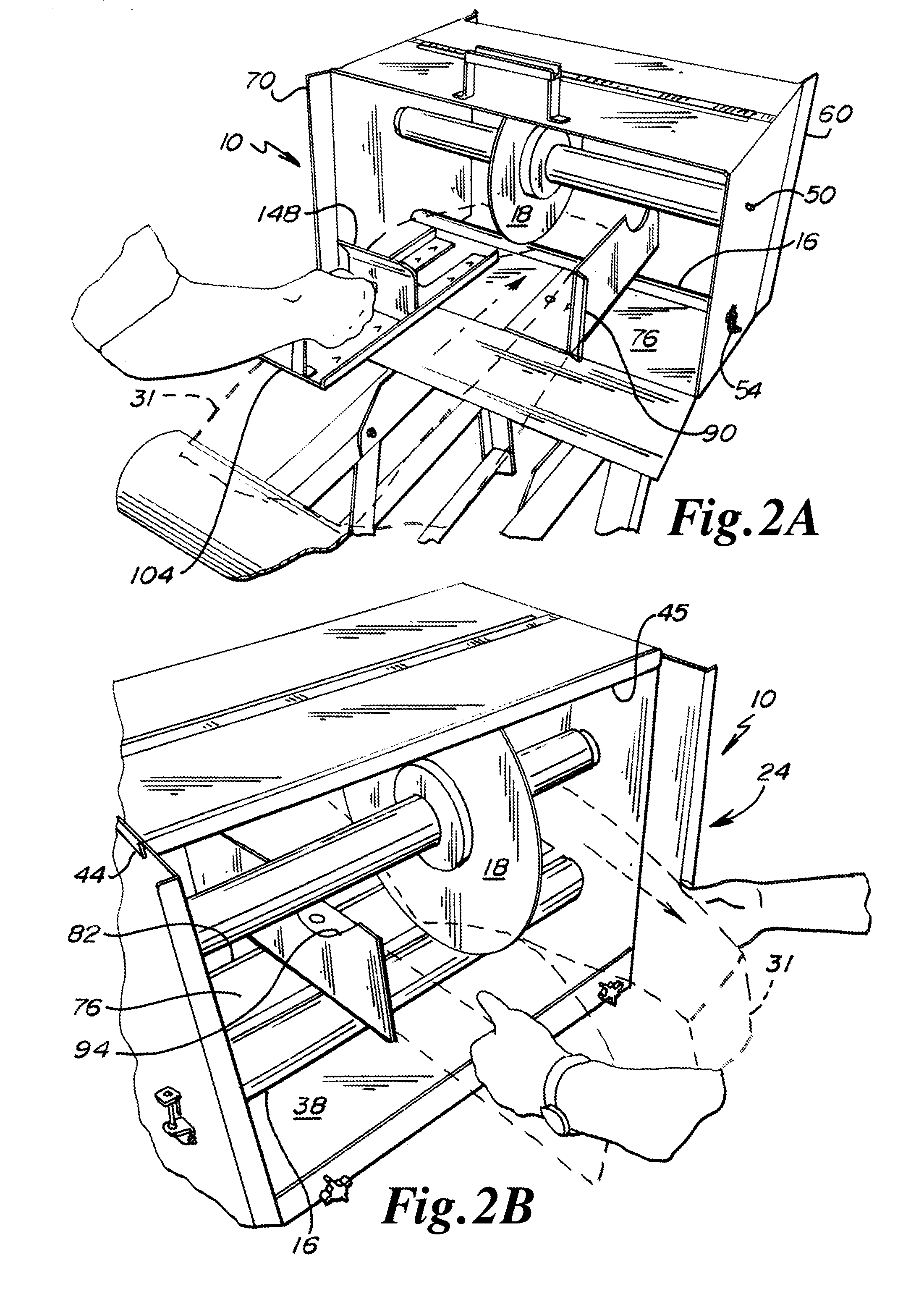

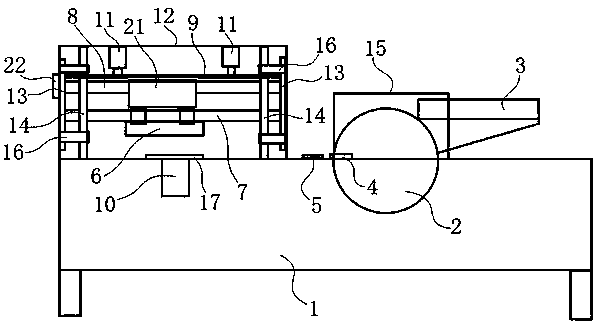

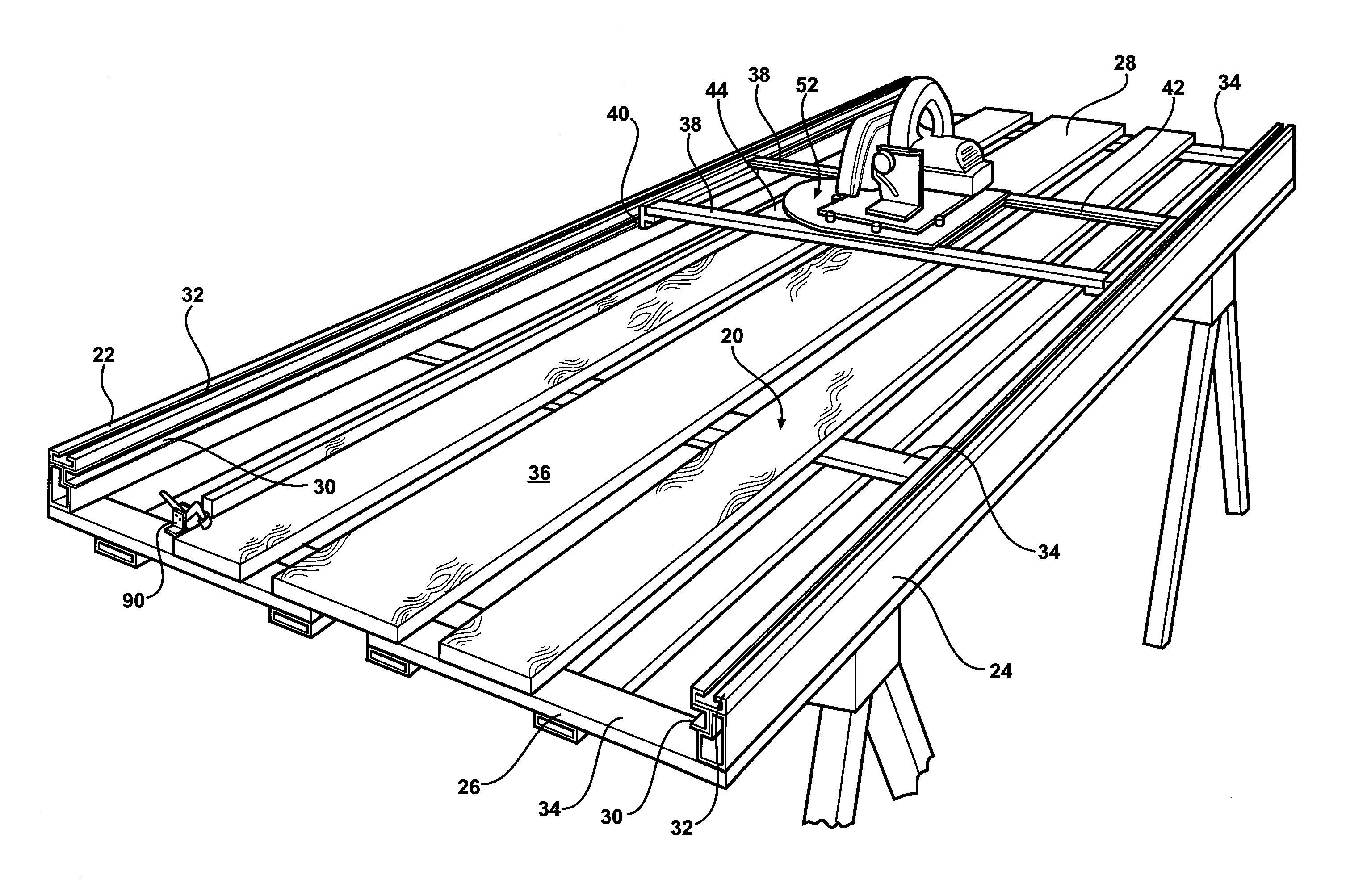

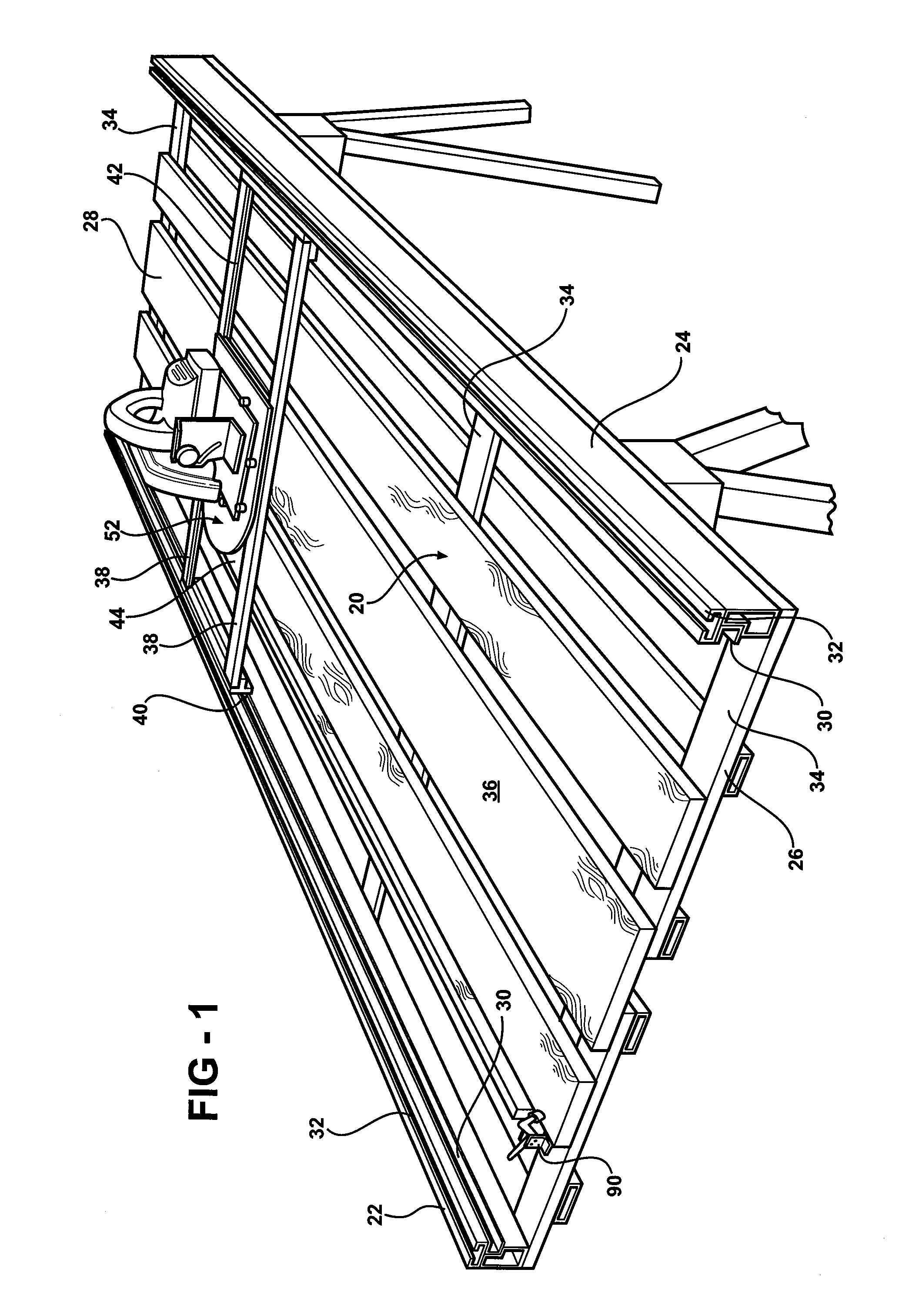

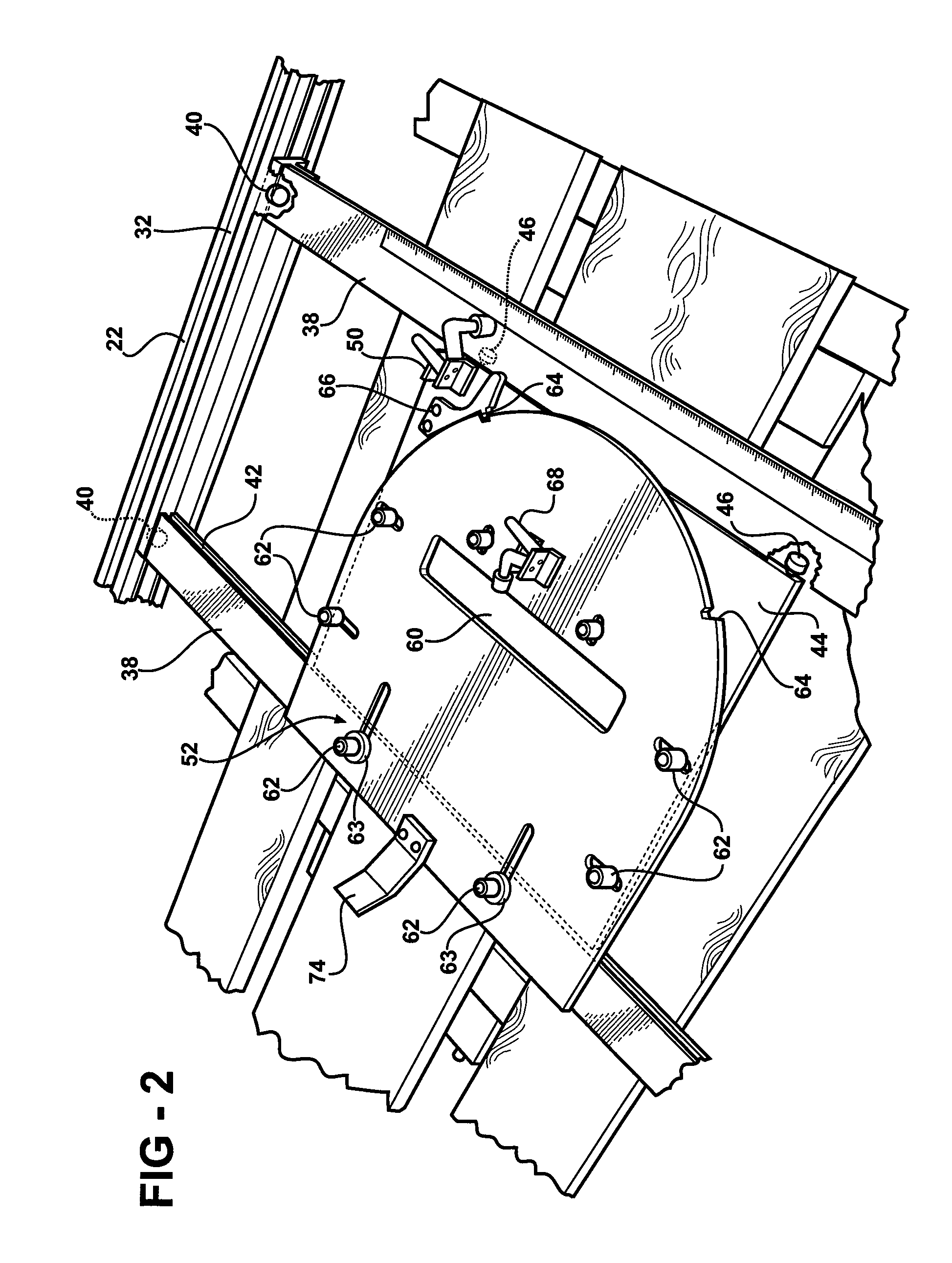

Portable saw table assembly

InactiveUS7555976B2Accurately cutConvenient to useMetal sawing devicesGuide fencesEngineeringMechanical engineering

The subject invention provides a portable saw table assembly for cutting a material longitudinally, laterally, and at various angles thereto. The assembly includes a first and a second table rail being parallel and spaced from each other and each extending between a proximal end and a distal end. A saw rail is moveably supported by the first and the second table rails for moving longitudinally along the table rails between the proximal and the distal ends and a mounting plate is moveably supported by the saw rails to allow movement of the mounting plate laterally along the saw rail between the first table rail and the second table rail. A saw plate is rotateably supported by the mounting plate for carrying a saw to cut the material. A guide bar is disposed diagonally relative to the first and the second table rails and engages the saw plate to guide the saw plate diagonally in response to simultaneous movement of the saw rail longitudinally and the mounting plate laterally.

Owner:TAPCO INTERNATIONAL CORPORATON

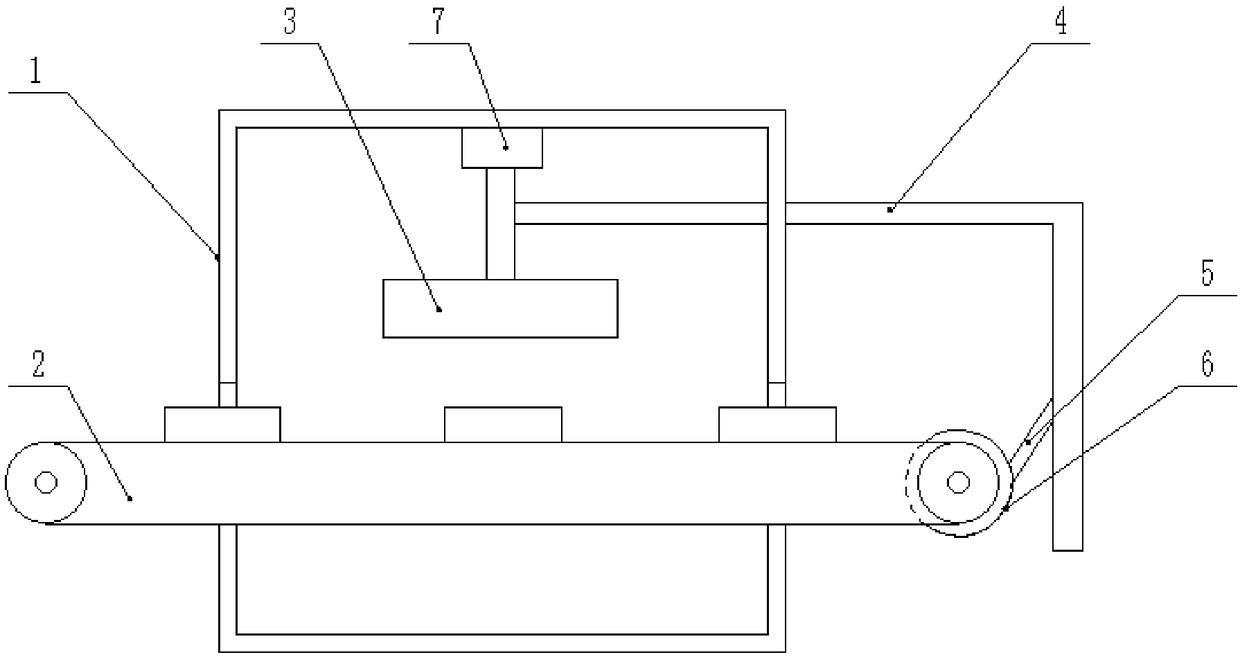

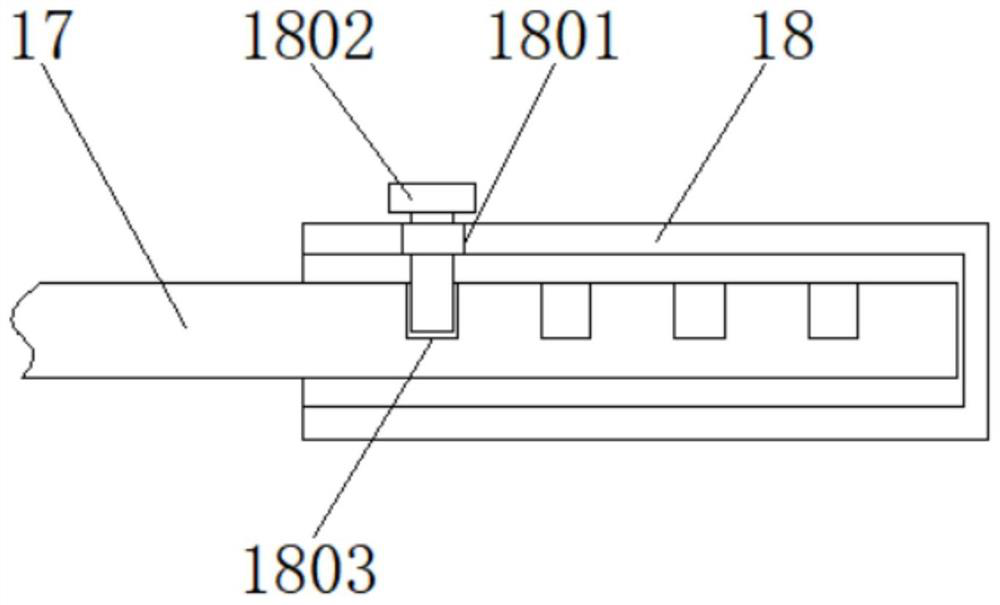

Book edge-cutting device

ActiveCN108356869ARealize automatic trimmingRealize transportationMetal working apparatusMechanical engineering

The invention relates to the technical field of paper cutting, and discloses a book edge-cutting device. The book edge-cutting device comprises a machine frame, the machine frame is rotatably connected with a belt transport mechanism, the machine frame is slidably connected with a cutter and a first connecting rod, and the cutter is located above the belt transport mechanism. The first connectingrod is fixedly provided with a first ratchet claw, the belt transport mechanism is coaxially connected with a first ratchet wheel which meshes with the first ratchet claw, and the machine frame is provided with a fixing mechanism used for fixing a book. The book edge-cutting device can automatically fix the book with the edge to be cut while cutting the edge, the book is prevented from deviation,and the efficiency of cutting edge and the qualified rate of the product are improved.

Owner:普天印务(重庆)股份有限公司

Croissant conical wrapper automatic cutting and turning method and device

InactiveCN103004911AAvoid collisionFast and efficient cuttingDough dividingDough processingEngineeringMechanical engineering

The invention provides an automatic cutting and turning method and device special for coiling a conical wrapper of croissant. The automatic cutting and turning method is characterized in that during parallel moving, strip-type wrappers are cut and are transversely cut into a plurality of conical wrappers by a cutter die; a plurality of transverse wrappers are turned to be straight wrappers; and therefore, stuffing is subsequently added into the wrappers or no stuffing is added into the wrappers to form the croissant.

Owner:黄正达

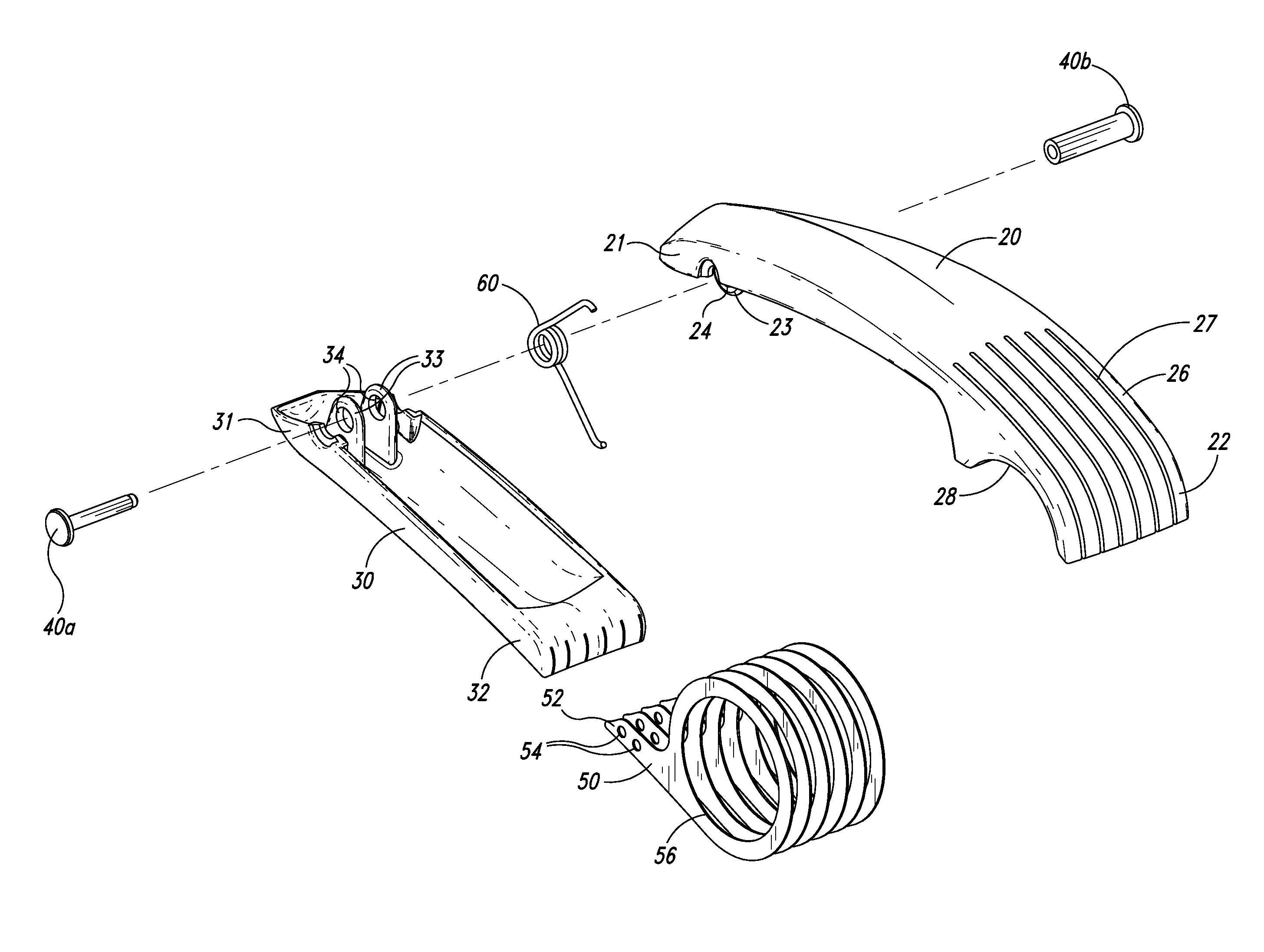

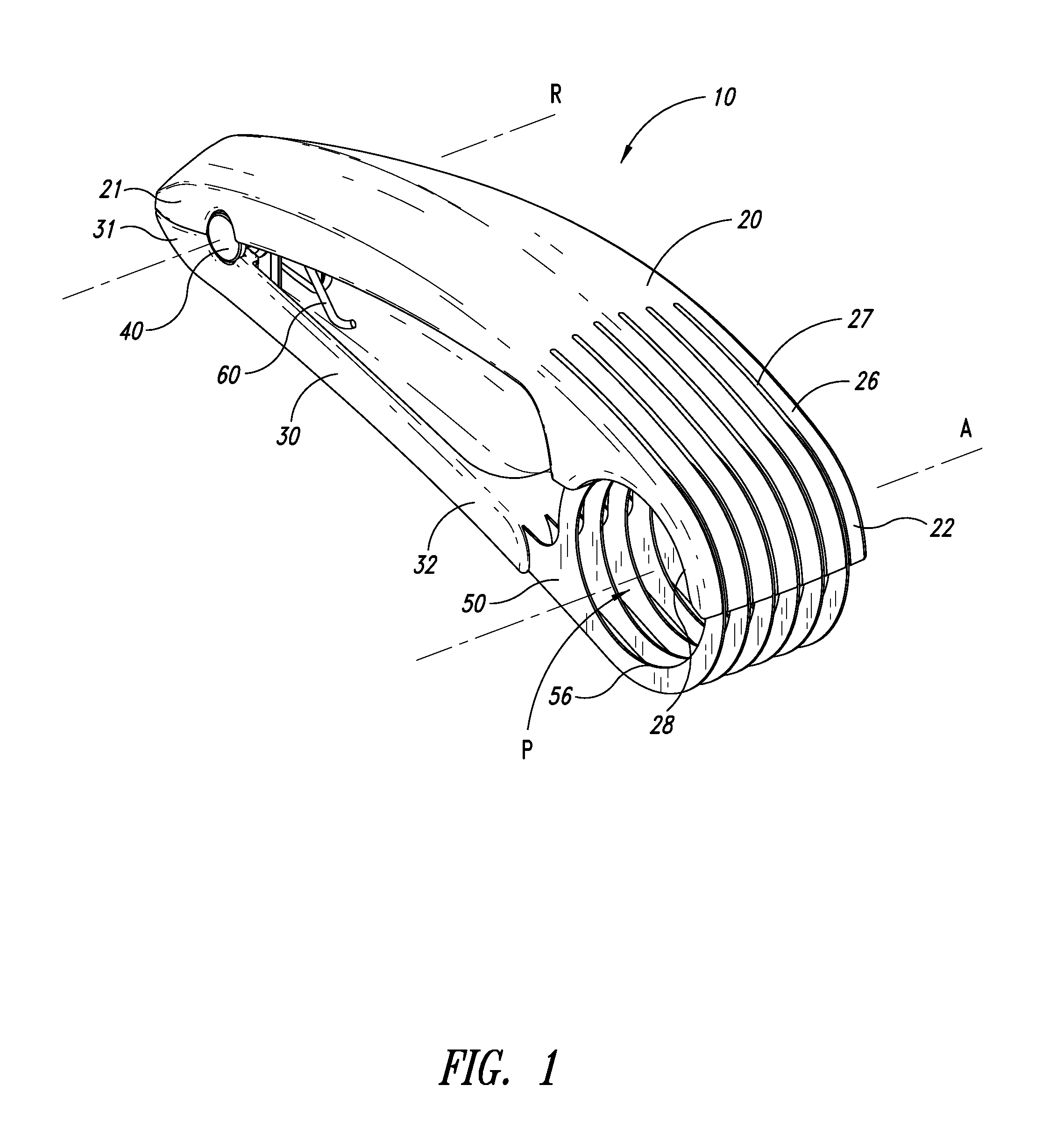

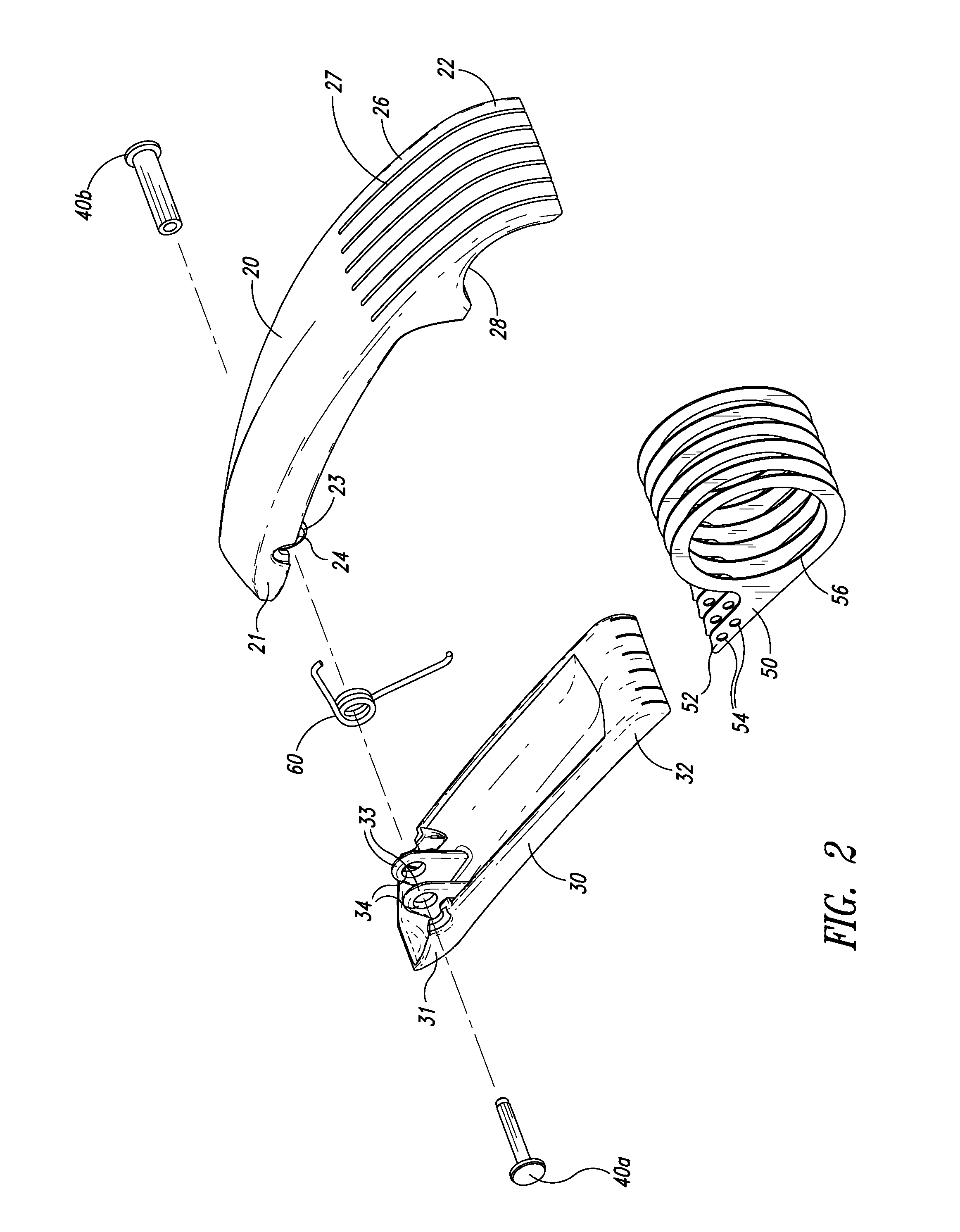

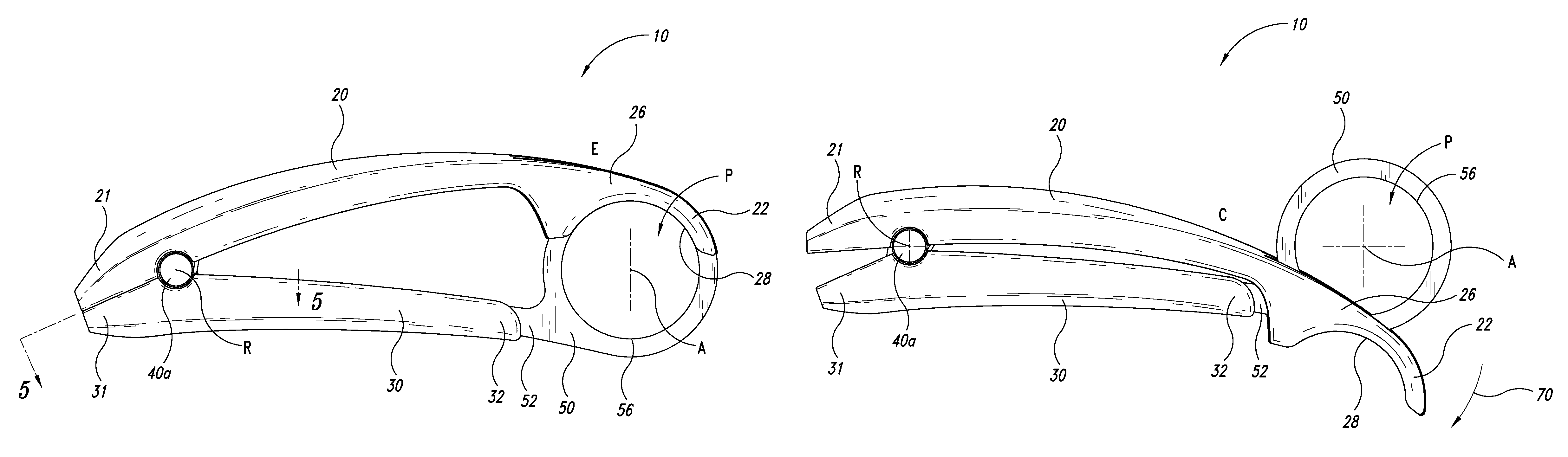

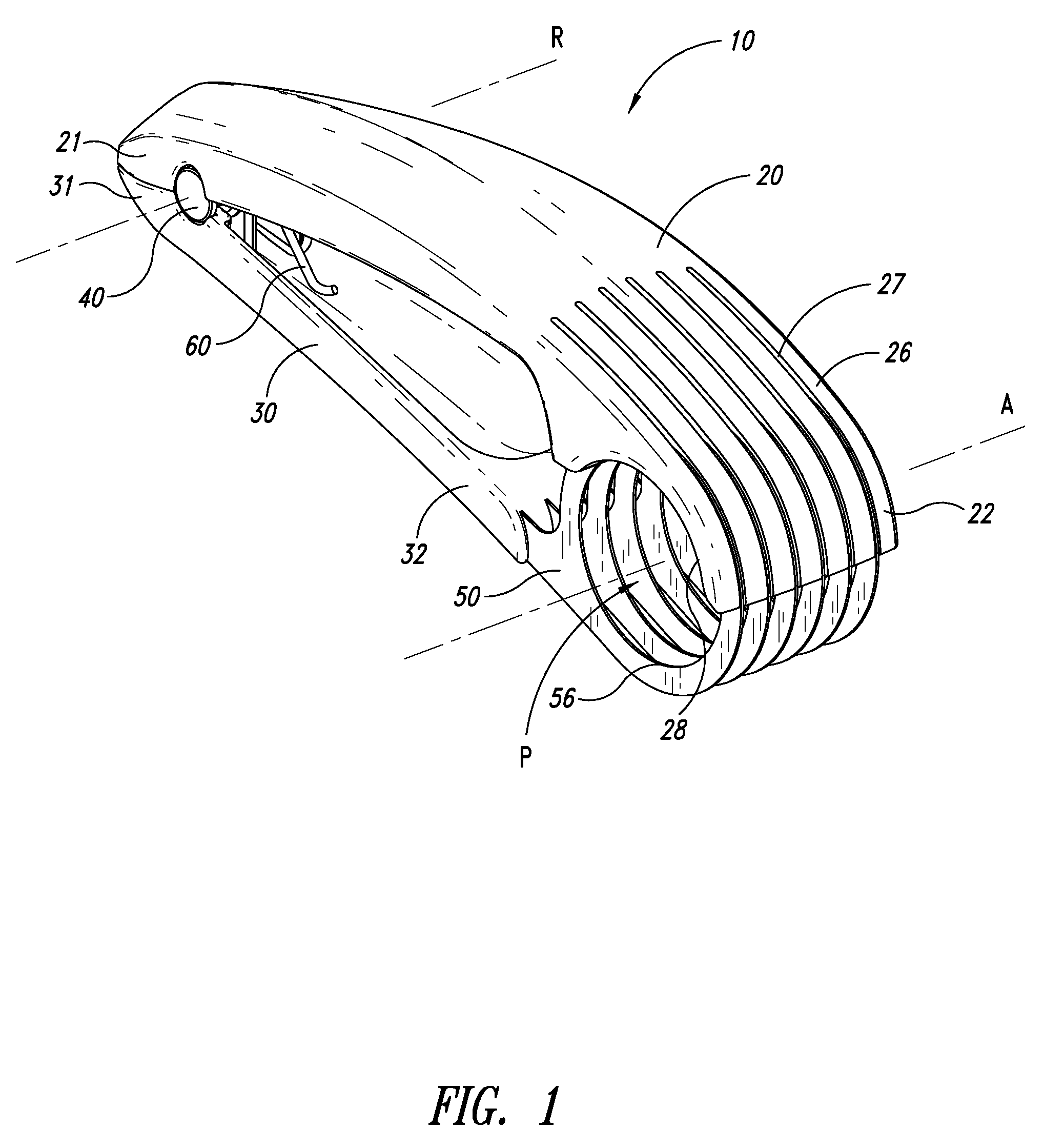

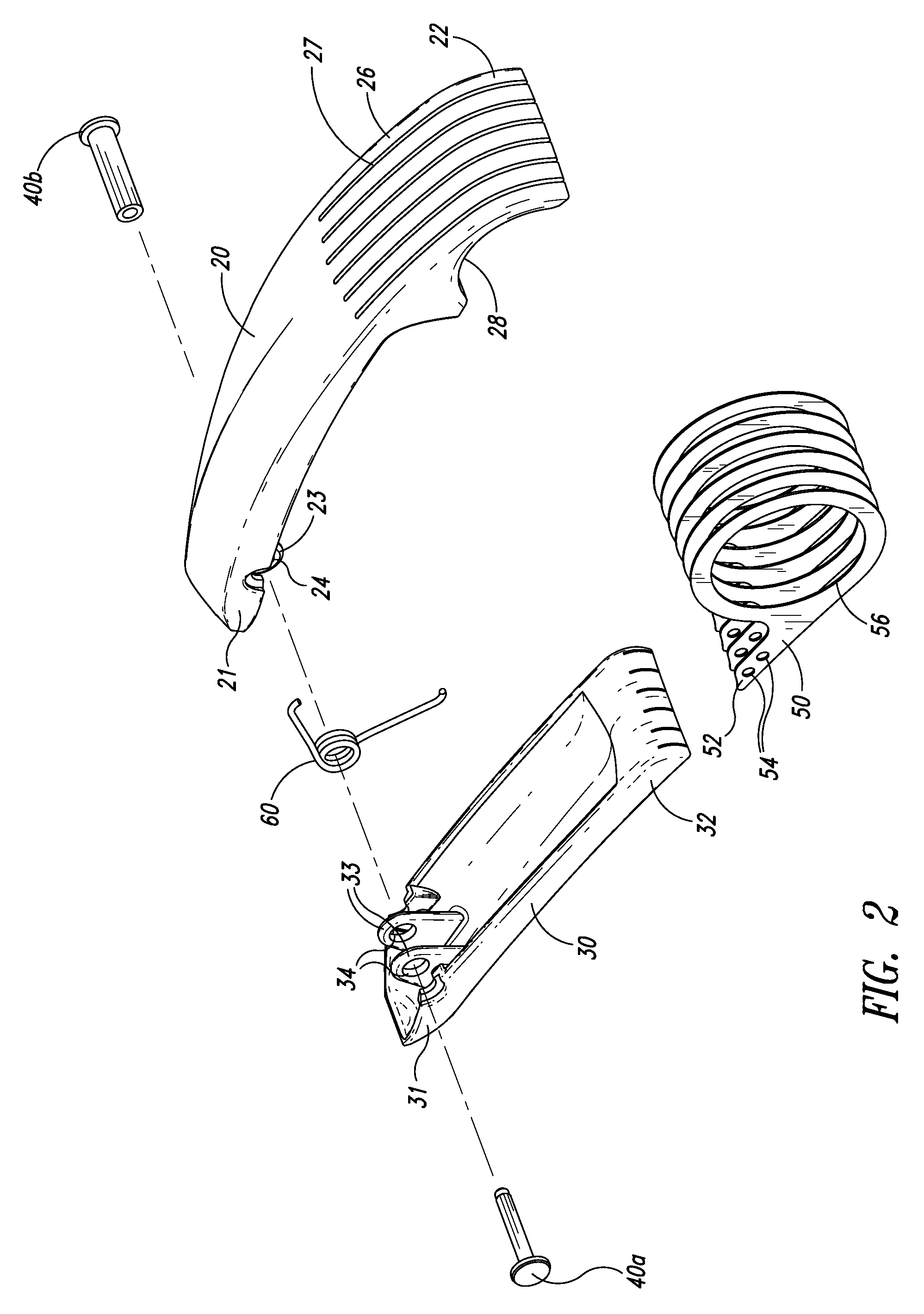

Handheld food slicer

ActiveUS20110192036A1Quick and efficient cuttingFast and efficient cuttingHand equipmentsMetal working apparatusBiomedical engineeringMicrotome

A handheld food slicer including a first handle having a plurality of elongated fingers, each finger separated from an adjacent finger by a blade receiving slot, a second handle movably coupled to the first handle and a plurality of blade members spaced to align with the blade receiving slots to mate with the fingers to collectively define a food receiving passageway when the first and the second handles are in an expanded configuration in which a distal end of the first handle is at least partially spaced apart from a distal end of the second handle, the fingers of the first handle configured to pass through the food receiving passageway adjacent the blade members as the first and the second handles move from the expanded configuration towards a compressed configuration in which the distal end of each of the first and the second handles is relatively closer to the other.

Owner:CHEFN

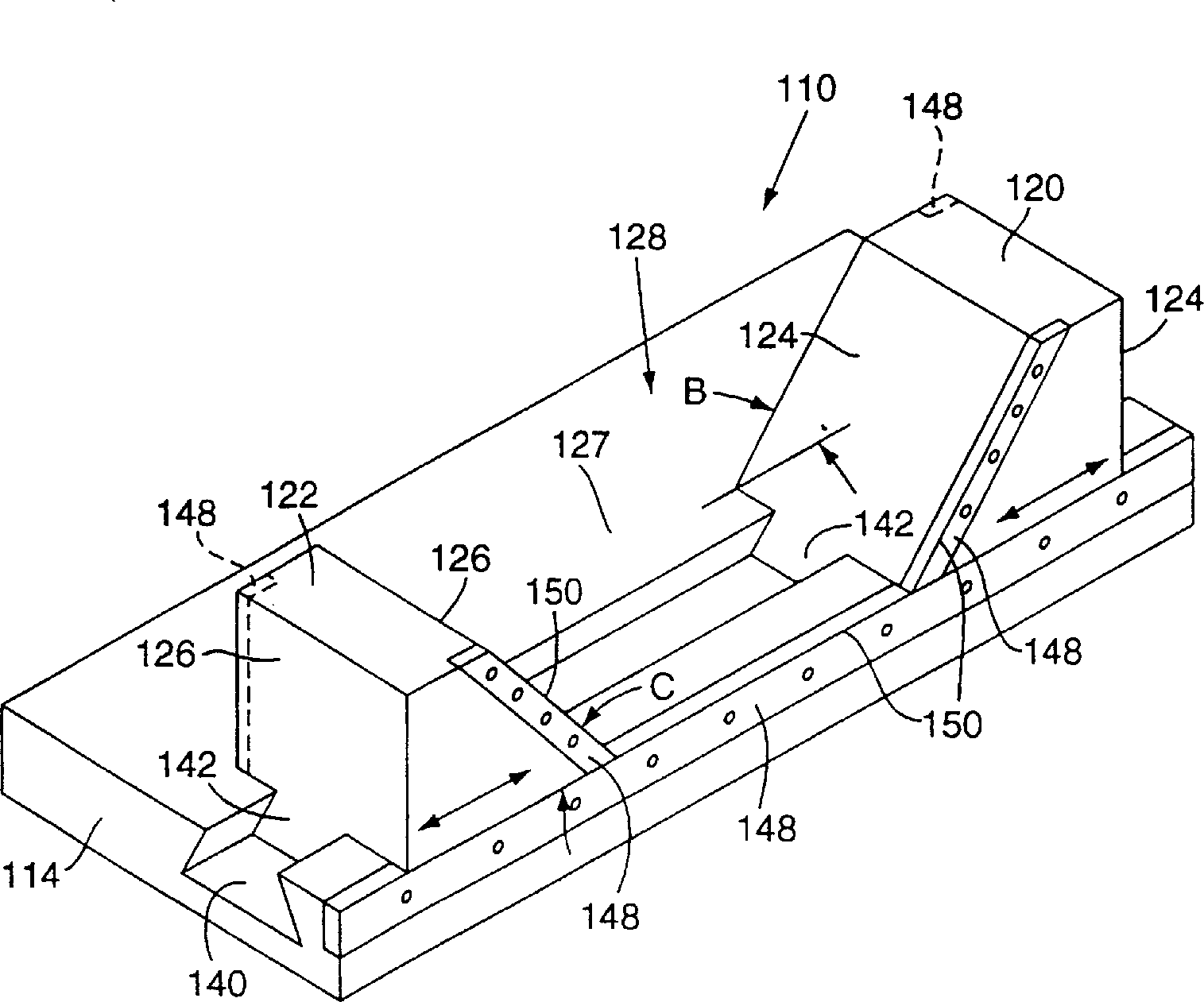

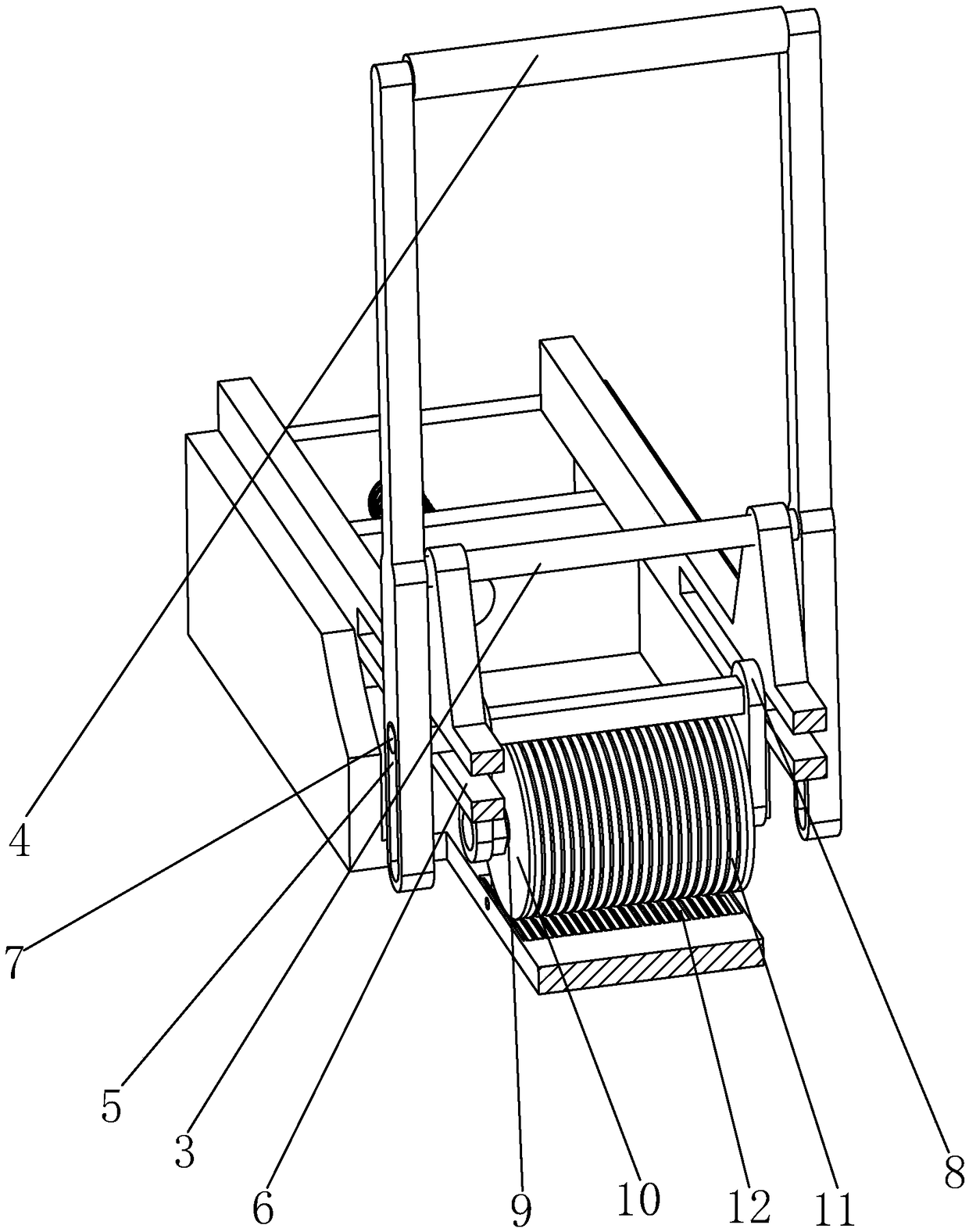

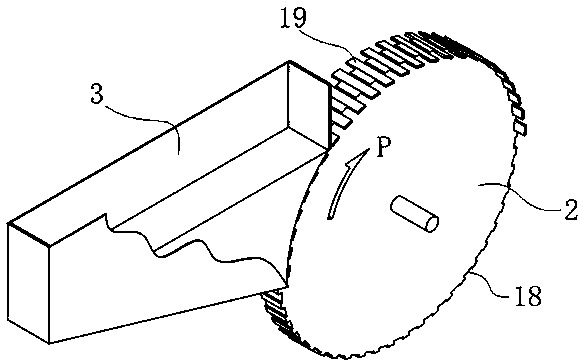

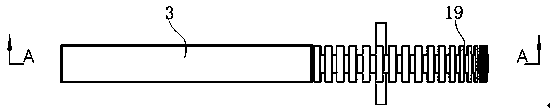

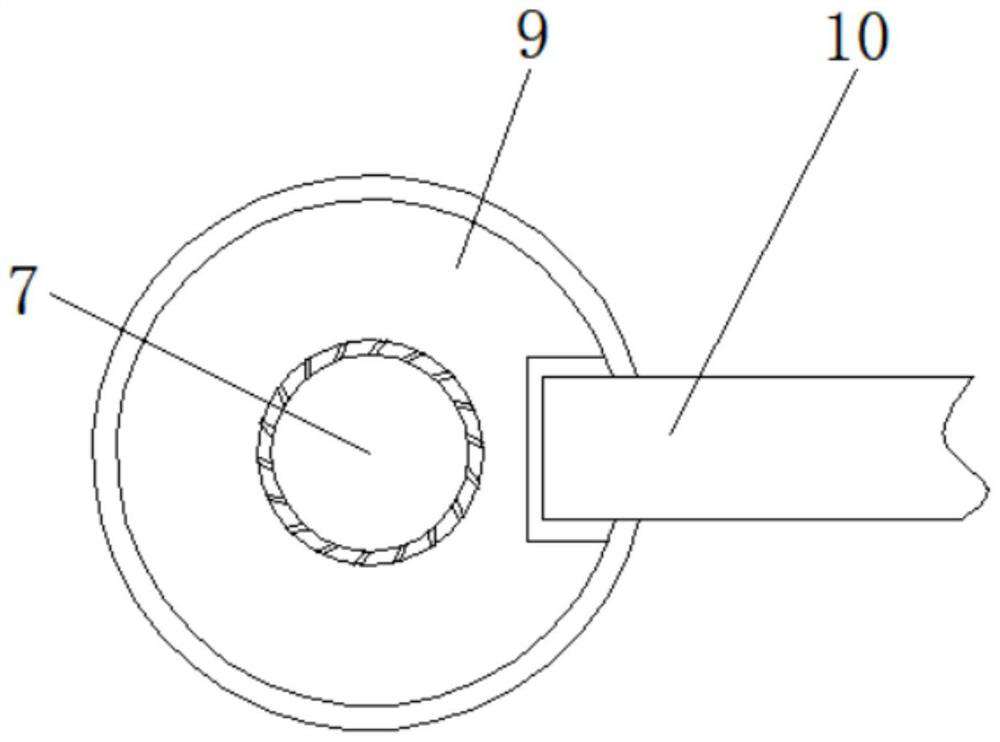

Push/Pull Rotary Cutting Apparatus Driven By Substrate

An apparatus for cutting fiberglass insulation batting with a rotary blade where an elongate section of fiberglass insulation batting is manually pushed into an inlet of the apparatus whereupon the blade bites into the fiberglass insulation batting and whereupon the elongate now split section of fiberglass insulation batting begins to protrude from the outlet of the apparatus, whereupon the protruding sections of fiberglass insulation batting are manually grabbed and pulled through the apparatus further driving the rotary blade and further cutting the fiberglass insulation batting.

Owner:BUSS RICHARD S

Handheld food slicer

ActiveUS9186806B2Fast and efficient cuttingHand equipmentsMetal working apparatusBiomedical engineeringMicrotome

A handheld food slicer including a first handle having a plurality of elongated fingers, each finger separated from an adjacent finger by a blade receiving slot, a second handle movably coupled to the first handle and a plurality of blade members spaced to align with the blade receiving slots to mate with the fingers to collectively define a food receiving passageway when the first and the second handles are in an expanded configuration in which a distal end of the first handle is at least partially spaced apart from a distal end of the second handle, the fingers of the first handle configured to pass through the food receiving passageway adjacent the blade members as the first and the second handles move from the expanded configuration towards a compressed configuration in which the distal end of each of the first and the second handles is relatively closer to the other.

Owner:CHEFN

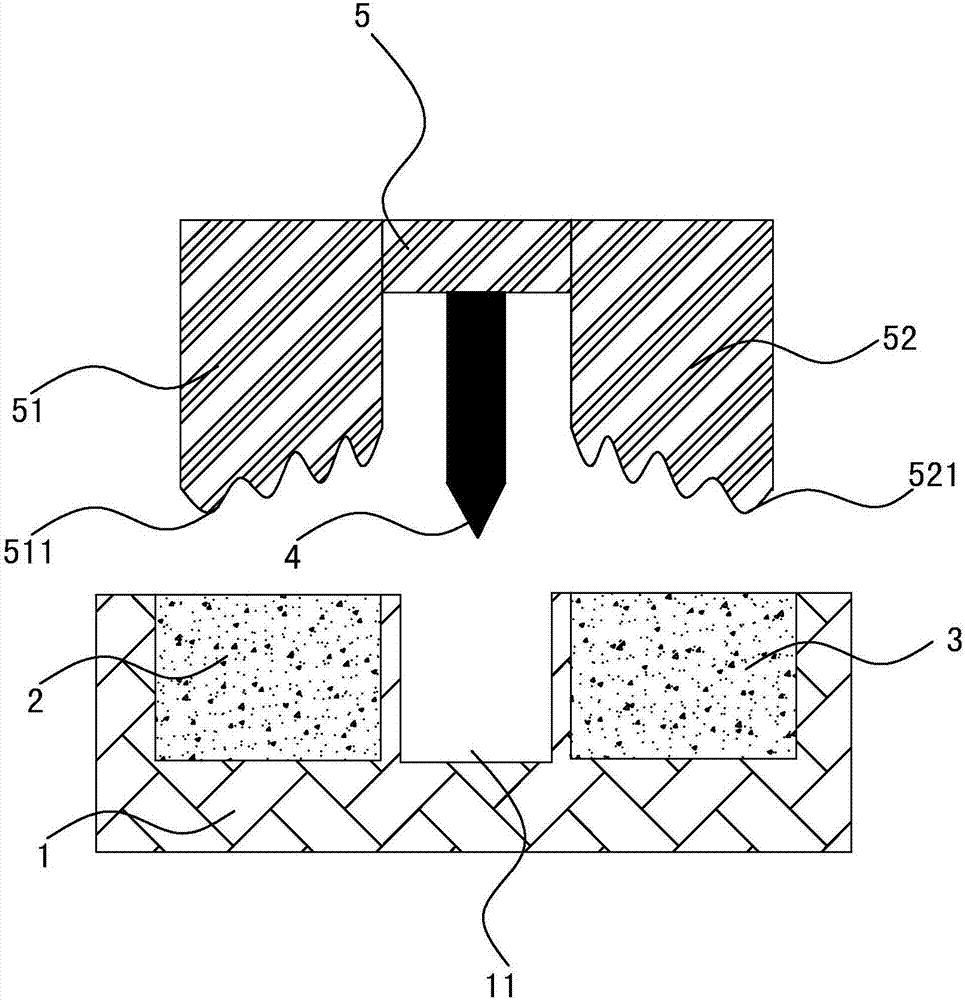

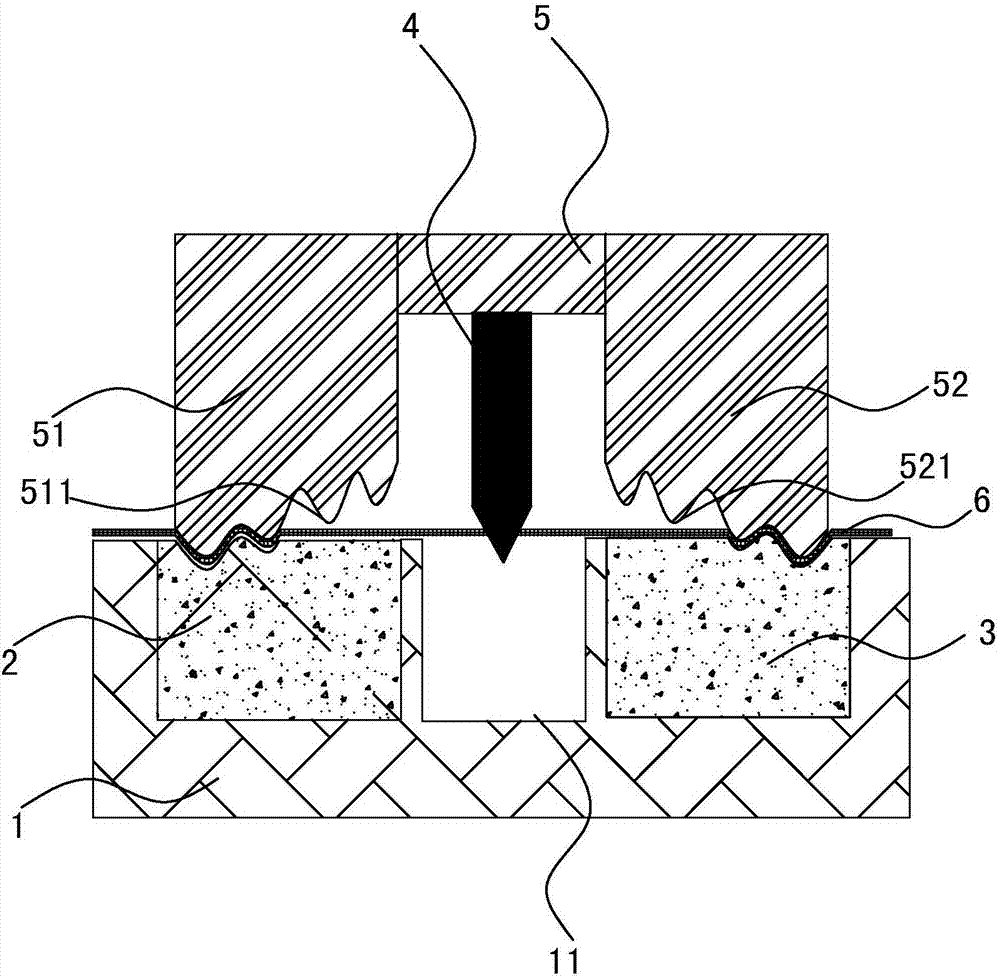

Flexible material cutting device

InactiveCN106956304AIncrease contact areaReduce manufacturing costMetal working apparatusMechanical engineering

The invention relates to the technical field of material cutting, and provides a flexible material cutting device. The flexible material cutting device comprises a base, a first elastic mat, a second elastic mat, a cutter and an upper pressing base; the upper pressing base is located at the corresponding position above the first elastic mat and the second elastic mat and is provided with a first compression part and a second compression part used for pressing a flexible material, at least two protruding parts facing the base are arranged on the face, facing the base, of the first compression part, and the top ends of the protruding parts are gradually and upwards distributed in a heightening manner in the slantly-upward direction from the side edge of the side, far away from the second compression part, of the upper pressing base to the middle portion; and at least two protruding parts facing the base are arranged on the face, facing the base, of the second compression part, and the top ends of the protruding parts are gradually and upwards distributed in a heightening manner in the slantly-upward direction from the side edge of the side, far away from the first compression part, of the upper pressing base to the middle portion. The flexible material cutting device solves the problem that after an existing flexible material cutting device is used for cutting the flexible material, the flexible material is low in quality, and the efficiency is not high.

Owner:王俊敏

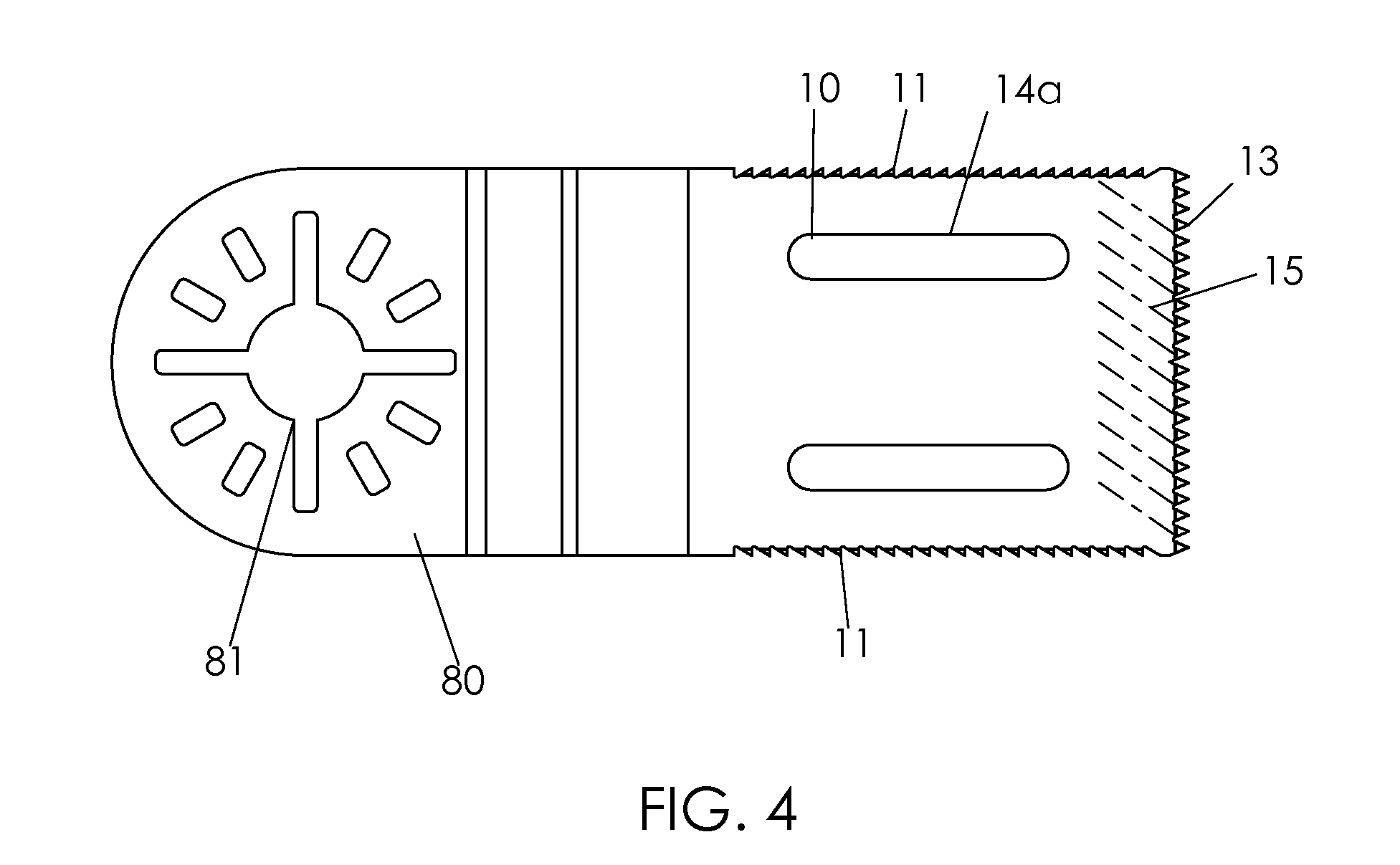

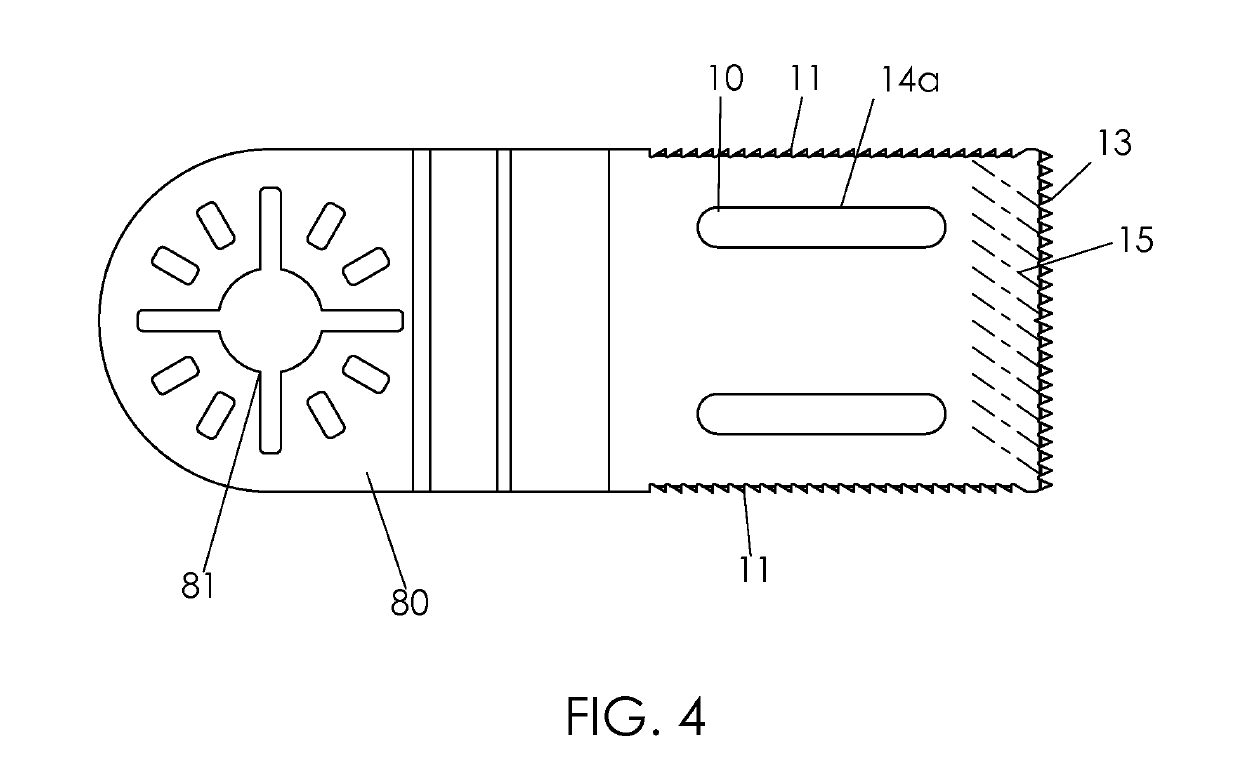

Cutting blade for oscillating tool

ActiveUS10307917B2Fast and efficient cuttingLess side guidancePower driven reciprocating sawsMetal working apparatusEngineeringPower tool

An improved blade for use with an oscillating power tool is disclosed. A rectangular style blade includes side teeth to eject debris and allow rapid but well controlled blind plunge cuts. The side teeth are preferably asymmetric with a forward orientation to bias debris out and the blade inward. Preferably one or more openings or slots allow for additional debris removal. The side teeth also allow for controlled side cutting.

Owner:WORKTOOLS

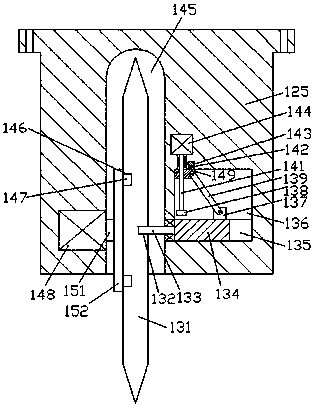

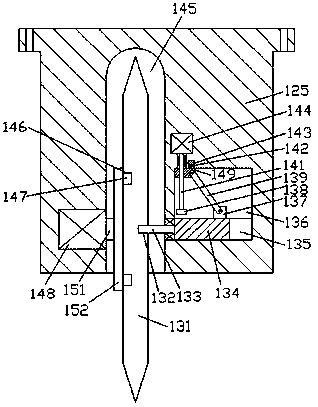

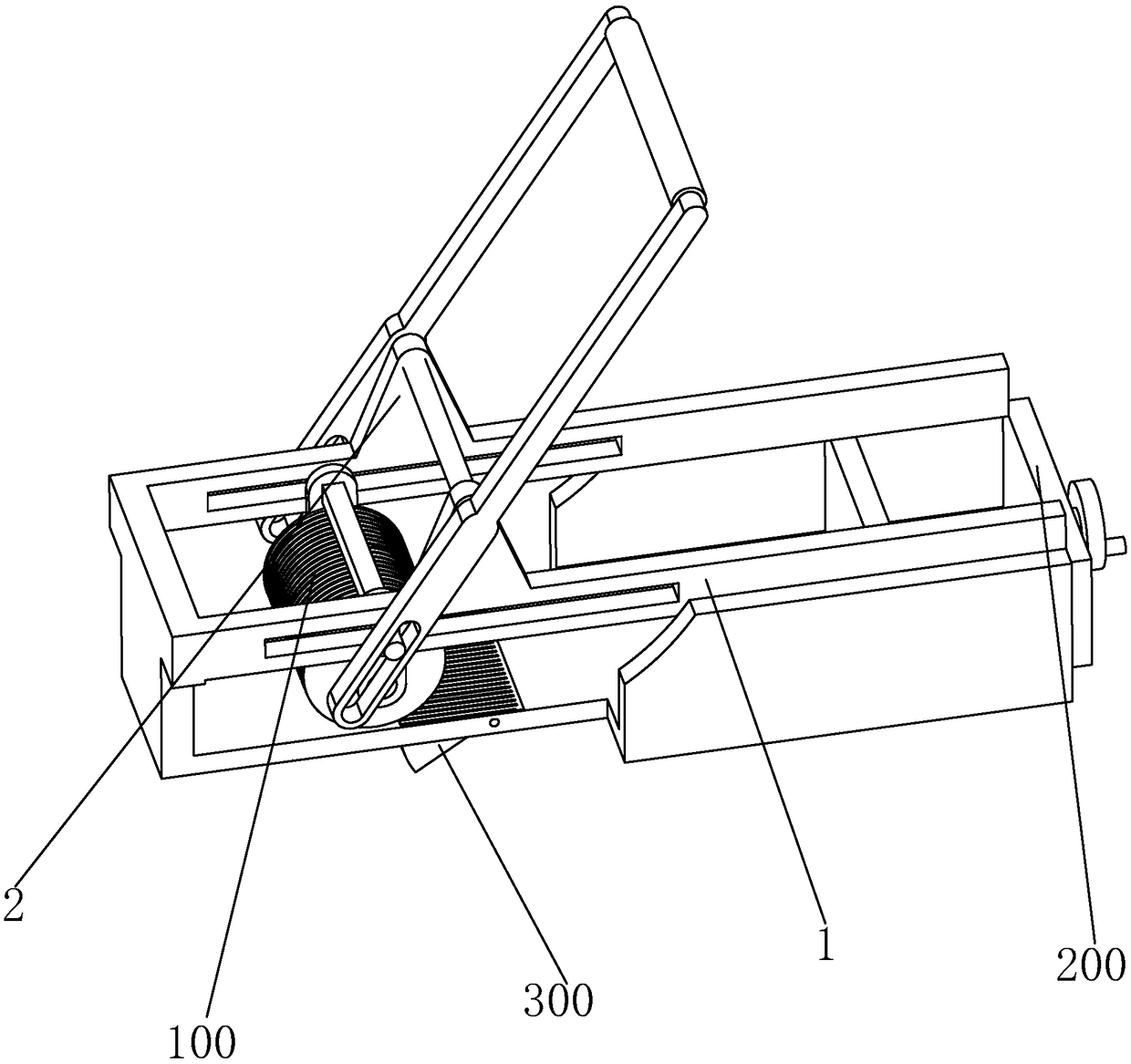

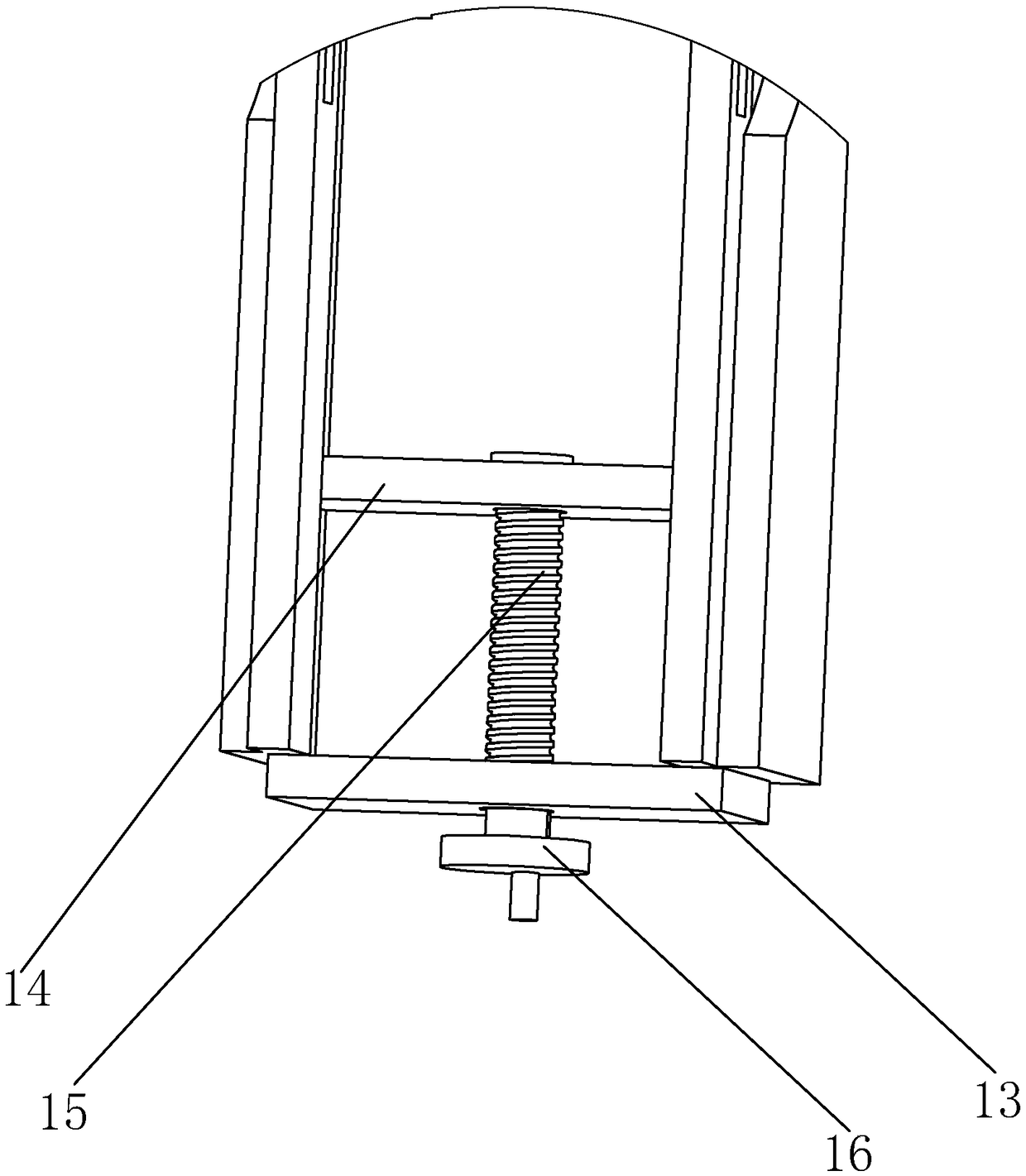

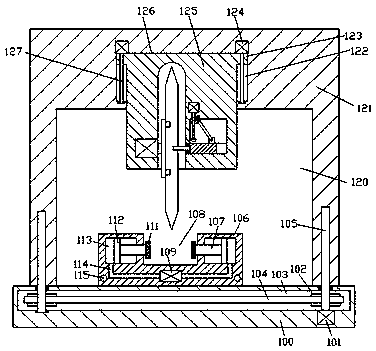

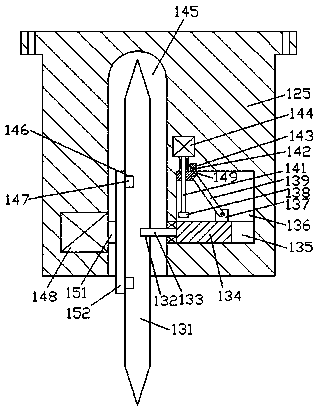

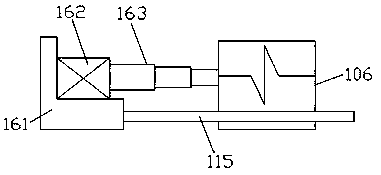

A cutting device of a fruit and vegetable picking manipulator

InactiveCN108886964AFast and efficient cuttingImprove protectionPicking devicesAgricultural engineeringLinear motor

The invention discloses a cutting device of a fruit and vegetable picking manipulator, including the base, A support column is arranged in the middle of the right end of the upper surface of the base,An upper end surface of the support column is provided with a support plate, the left end of the upper surface of the support plate is provided with an operation port, two front and rear symmetricalfirst vertical plates are arranged on the front and rear sides of the left end of the upper surface of the support plate, two front and rear symmetrical fourth vertical plates are arranged on the front and rear sides of the middle part of the upper surface of the support plate, a linear motor is arranged between the left side surface of the fourth vertical plate and the right side surface of the first vertical plate, the cutting device of the fruit and vegetable picking manipulator compact structure, The invention has the advantages of convenient operation, quick and efficient complete cuttingof fruit and vegetable from branches, convenient installation and positioning of the positioning plate combined with the positioning hole, good protection of the fruit and vegetable by the arrangement of the first hollow hemisphere cover combined with the second hollow hemisphere cover, and convenient positioning of the positioning rod for fixing the hollow annular protective cover.

Owner:傅文尾

Croissant conical wrapper automatic cutting and turning method and device

InactiveCN103004911BAvoid collisionFast and efficient cuttingDough dividingDough processingMechanical engineering

The invention provides an automatic cutting and turning method and device special for coiling a conical wrapper of croissant. The automatic cutting and turning method is characterized in that during parallel moving, strip-type wrappers are cut and are transversely cut into a plurality of conical wrappers by a cutter die; a plurality of transverse wrappers are turned to be straight wrappers; and therefore, stuffing is subsequently added into the wrappers or no stuffing is added into the wrappers to form the croissant.

Owner:黄正达

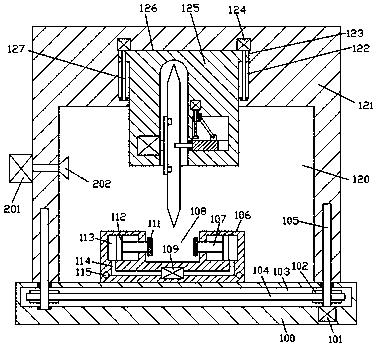

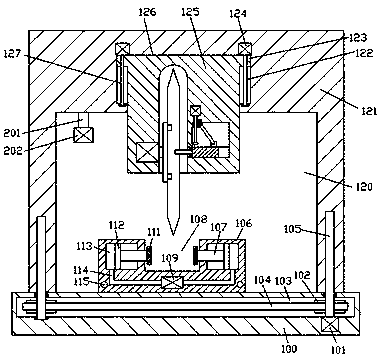

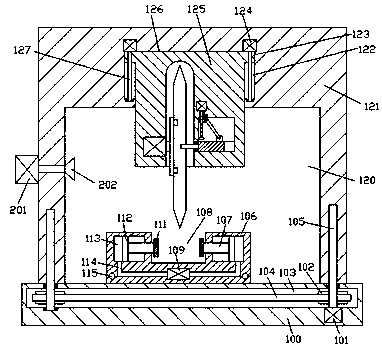

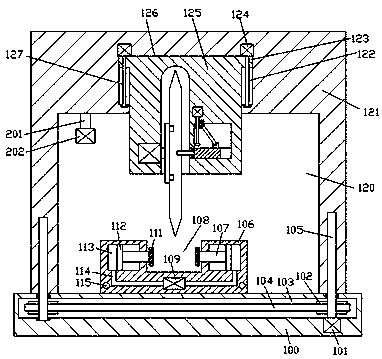

A PCB device

InactiveCN109005643AFast and efficient cuttingAvoid flyingInsulating layers/substrates workingMechanical engineeringFirst insertion

A PCB device includes a base frame and a main seat body mounted on an upper side of the base frame, A manufacture cavity is arranged in the end surface of the bottom of the main seat body, A first sliding cavity is arranged in the top wall of the manufacturing cavity, A manufacture frame is arranged in sliding fit in the first sliding joint cavity, A lif mechanism is symmetrically arranged on theleft and right side of the production frame, At the bottom end face of the manufacture frame, an embedding cavity is arranged, A cut blade is rotatably arranged in the embedding cavity, A first insertion groove is symmetrically arranged in the left end face of the cutting blade, A second insertion groove is arranged in the center of the right end face of the cutting blade, a first electric rotating machine is fixedly arranged in the left inner wall of the embedding cavity, an output shaft of the right end of the first electric rotating machine is fixedly provided with an attachment plate, andthe attachment plate on the right end face of the attachment plate is vertically symmetrically fixedly provided with a plugging plate which is inserted in and matched with the first insertion groove.

Owner:广州雅松商贸有限公司

Lateral type double-drum opencast machine

InactiveCN105201512ASmall, moderate and uniform particle sizeEliminate perforation blastingOpen-pit miningCutting machinesAgricultural engineeringCoal

The invention relates to a lateral type double-drum opencast machine. The lateral type double-drum opencast machine comprises a crawler walking mechanism, a main frame, operating chambers, a hydraulic system, an electrical system, spiral drum cutting mechanisms, scraper conveyers and a belt reversed loader, wherein the crawler walking mechanism is mounted on the lower side of the main frame; the operating chambers, the hydraulic system and the electrical system are mounted on the upper side of the main frame; the spiral drum cutting mechanisms are mounted on the left side of the main frame; the belt reversed loader is mounted on the right side of the main frame; a front spiral drum cutting mechanism is mounted at the front end of the left side of the main frame, and a rear spiral drum cutting mechanism is mounted at the rear end of the left side of the main frame; a front scraper conveyer is mounted at the front end of the left side of the main frame, a rear scraper conveyer is mounted at the rear end of the left side of the main frame, and a middle scraper conveyer is transversely arranged, so that materials are conveniently conveyed to the belt reversed loader on the right side of the main frame. The lateral type double-drum opencast machine can mine coal seams of opencast coal mines continuously and efficiently, can avoid intermediate links such as explosion, crushing and the like and is a safe and efficient open pit coal mine continuous miner.

Owner:XINJIANG YIZHONG HEAVY MACHINERY EQUIP MFG

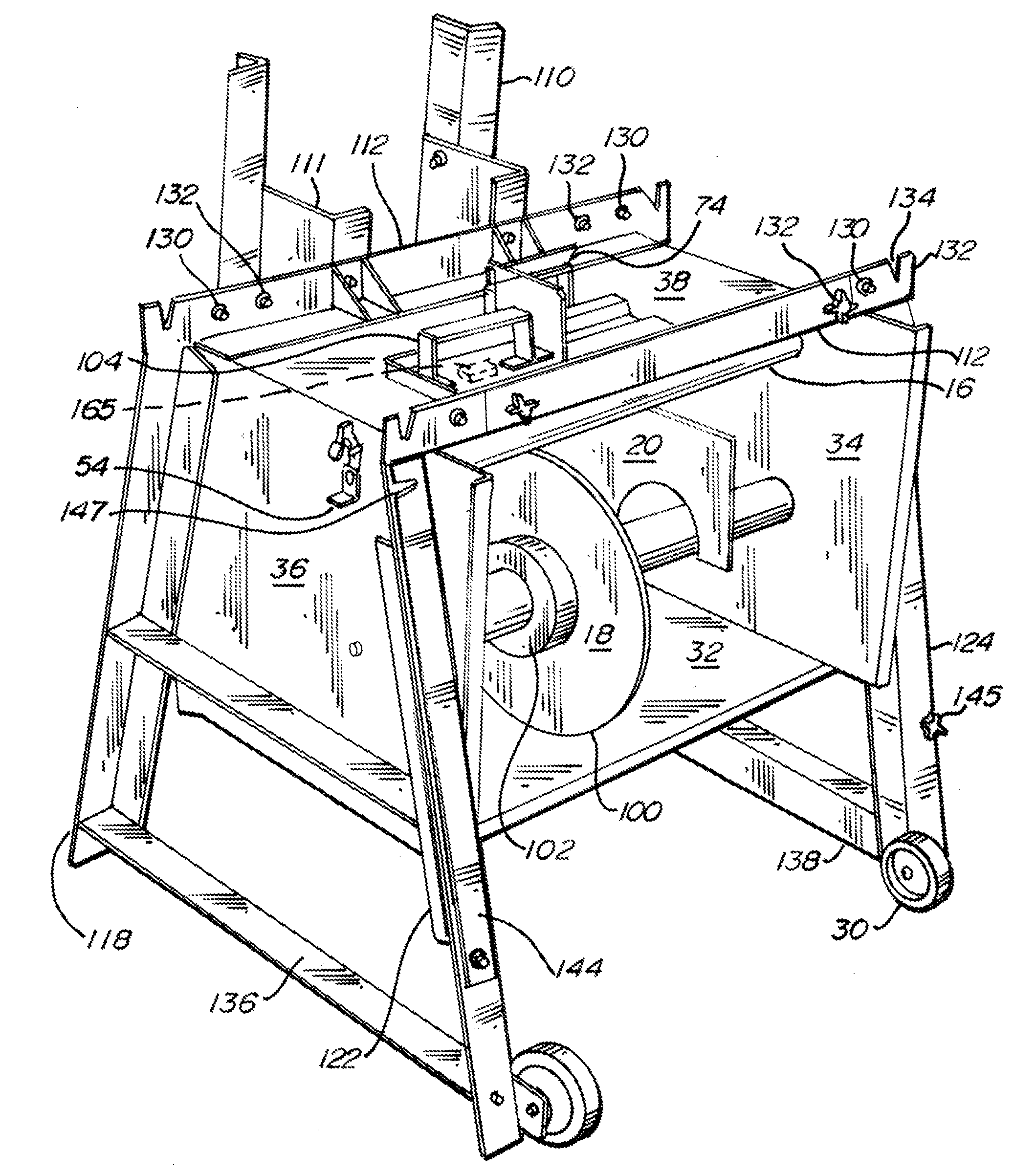

Portable saw table assembly

InactiveUS7926397B2Easy to useFast and efficient cuttingMetal sawing devicesGuide fencesMechanical engineering

The subject invention provides a portable saw table assembly for cutting a material longitudinally, laterally, and at various angles thereto. The assembly includes a first and a second table rail being parallel and spaced from each other and each extending between a proximal end and a distal end. A saw rail is moveably supported by the first and the second table rails for moving longitudinally along the table rails between the proximal and the distal ends and a mounting plate is moveably supported by the saw rails to allow movement of the mounting plate laterally along the saw rail between the first table rail and the second table rail. A saw plate is rotateably supported by the mounting plate for carrying a saw to cut the material. A guide bar is disposed diagonally relative to the first and the second table rails and engages the saw plate to guide the saw plate diagonally in response to simultaneous movement of the saw rail longitudinally and the mounting plate laterally.

Owner:TAPCO INTERNATIONAL CORPORATON

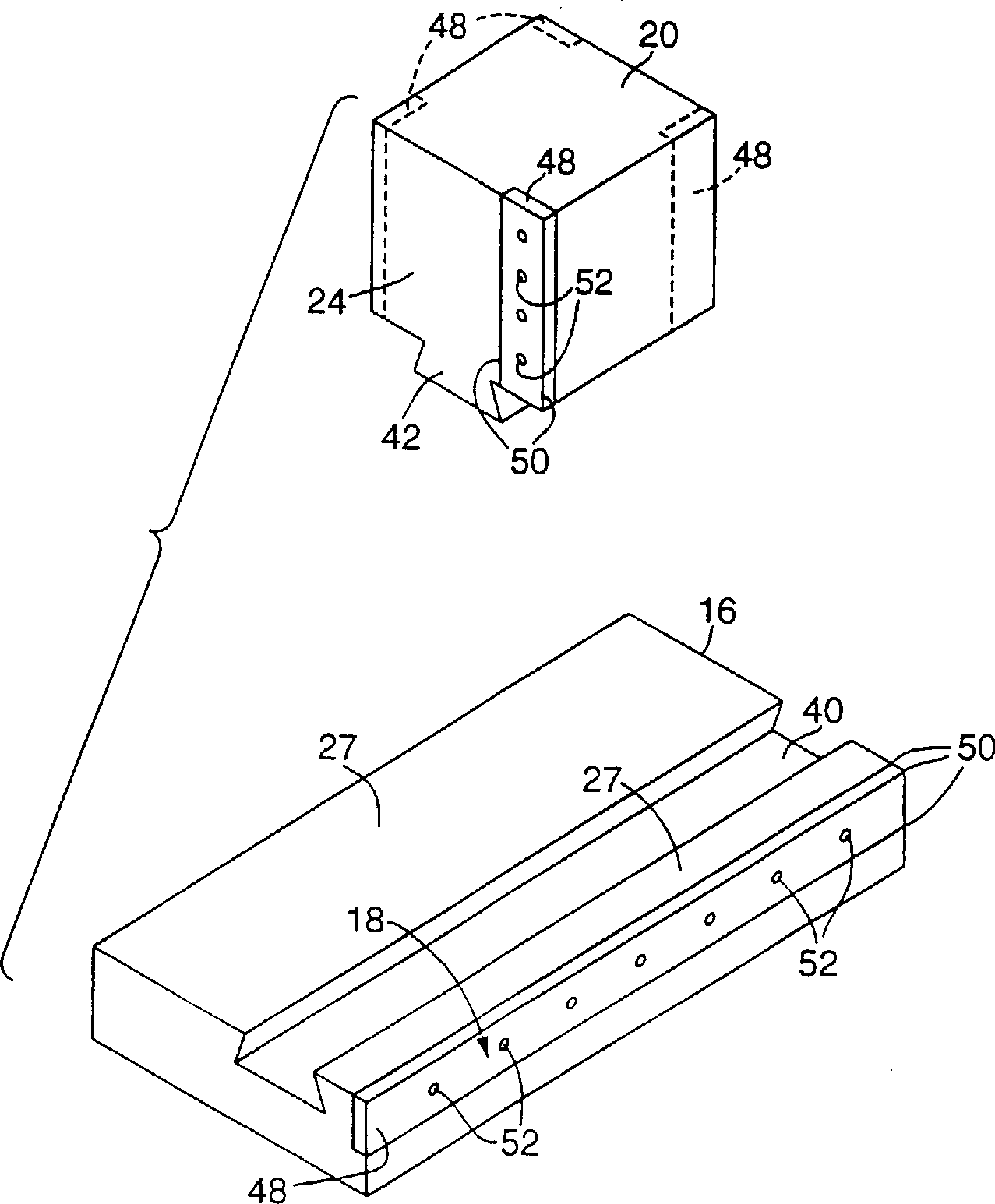

Apparatus for shearing multi-walled workpieces

In an apparatus for shearing multi-walled workpieces, such as metal framing studs, a base support (16) defines a blade gap therebetween, and a guillotine-like blade is slidably received within the gap for shearing the workpieces. A pair of first supports (20) are each slidably mounted on a respective base support (16, 18). A pair of second supports (22) are also each slidably mounted on the base support, and are spaced apart from and face the first supports to thereby define an adjustable-width channel (28) therebetween. Each of the supports defines a blade-like edge for engaging an elongated, multi-walled workpiece and the first and second support surfaces are each moved into contact with a respective wall of the workpiece. The supports can be oriented relative to one another such that the axis of the channel, and a longitudinal axis of the workpiece received within the channel can be oriented at a desired angle relative to the blade. The guillotine-like blade is then driven downwardly into engagement with the workpiece to shear the workpiece along a line of contact.

Owner:韦恩 C 法斯克

Novel aluminum alloy workpiece machining technology

InactiveCN108994390AFast and efficient cuttingAvoid flyingWork clamping meansPositioning apparatusMetallurgyMachining

The invention discloses a novel aluminum alloy workpiece machining technology. The machining technology comprises a bottom plate and a main frame body installed on the upper side of the bottom plate.A manufacturing cavity is formed in the end face of the bottom of the main frame body, a first sliding cavity is formed in the top wall of the manufacturing cavity, a manufacturing frame is installedin the first sliding cavity in a sliding fit mode, lifting mechanisms are symmetrically arranged on the left side and the right side of the manufacturing frame, an embedded cavity is formed in the endface of the bottom of the manufacturing frame, a cutting blade is rotationally arranged in the embedded cavity, first slots are formed in the end face of the left side of the cutting blade in an up-down symmetrical mode, a second slot is formed in the center of the end face of the right side of the cutting blade, a first motor is fixedly arranged in the inner wall of the left side of the embeddedcavity, an installation fixing plate is fixedly arranged on an output shaft of the right side end of the first motor, and inserting plates in inserted fit connection with the first slots are fixedlyarranged on the end face of the right side of the installation fixing plate in an up-down symmetrical mode.

Owner:广州宝升新型材料有限公司

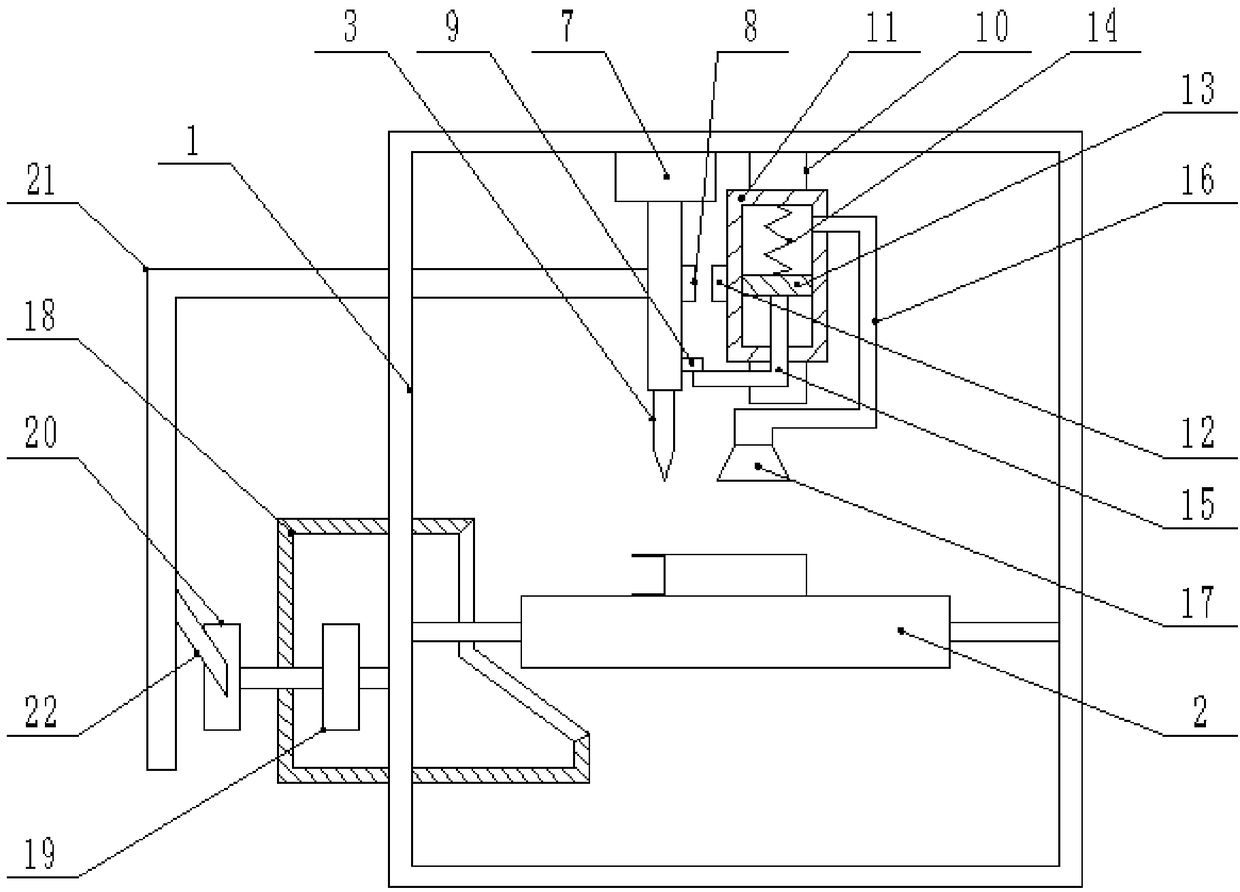

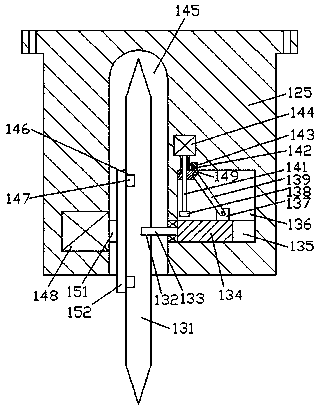

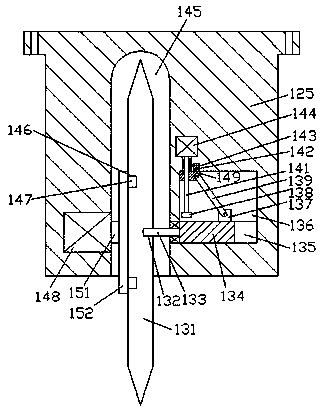

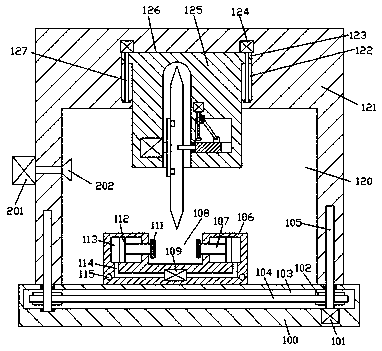

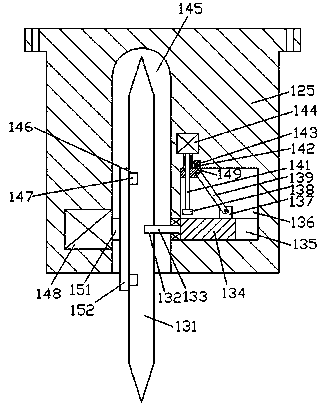

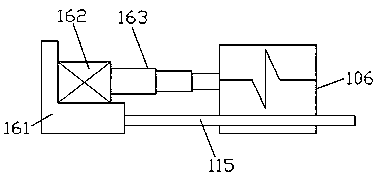

Building material board production device

InactiveCN108971607AFast and efficient cuttingAvoid flyingShearing machinesMaintainance and safety accessoriesBuilding materialArchitectural engineering

The invention discloses a building material board production device. The building material board production device comprises a base and an outer box body arranged on the upper side of the base, a machining cavity is formed in the end surface of the bottom of the outer box body, a first sliding cavity is formed in the top wall of the machining cavity, a machining frame is arranged in the first sliding cavity in a sliding fit mode, lifting mechanisms are symmetrically arranged on the left side and the right side of the machining frame, a sunken groove is formed in the end surface of the bottom of the machining frame, a cutting blade is rotationally arranged in the sunken groove, first inserting grooves are formed in the left end face of the cutting blade in an up-down symmetry mode, a secondinserting groove is formed in the center of the right end face of the cutting blade, a first driving machine is fixedly arranged in the inner wall of the left side of the sunken groove, the output shaft of the right end of the first driving machine is fixedly provided with an assembling plate, and inserting plates which are connected with the first inserting grooves in an inserting fit mode are fixedly arranged on the right end surface of the assembling plate in an up-down symmetry mode.

Owner:惠安县正和机械设备有限公司

Push/Pull Rotary Cutting Apparatus Driven By Substrate

InactiveUS20130220094A1Simple designLow costShearing machinesMetal working apparatusGlass fiberCutting glass

An apparatus for cutting fiberglass insulation batting with a rotary blade where an elongate section of fiberglass insulation batting is manually pushed into an inlet of the apparatus whereupon the blade bites into the fiberglass insulation batting and whereupon the elongate now split section of fiberglass insulation batting begins to protrude from the outlet of the apparatus, whereupon the protruding sections of fiberglass insulation batting are manually grabbed and pulled through the apparatus further driving the rotary blade and further cutting the fiberglass insulation batting.

Owner:BUSS RICHARD S

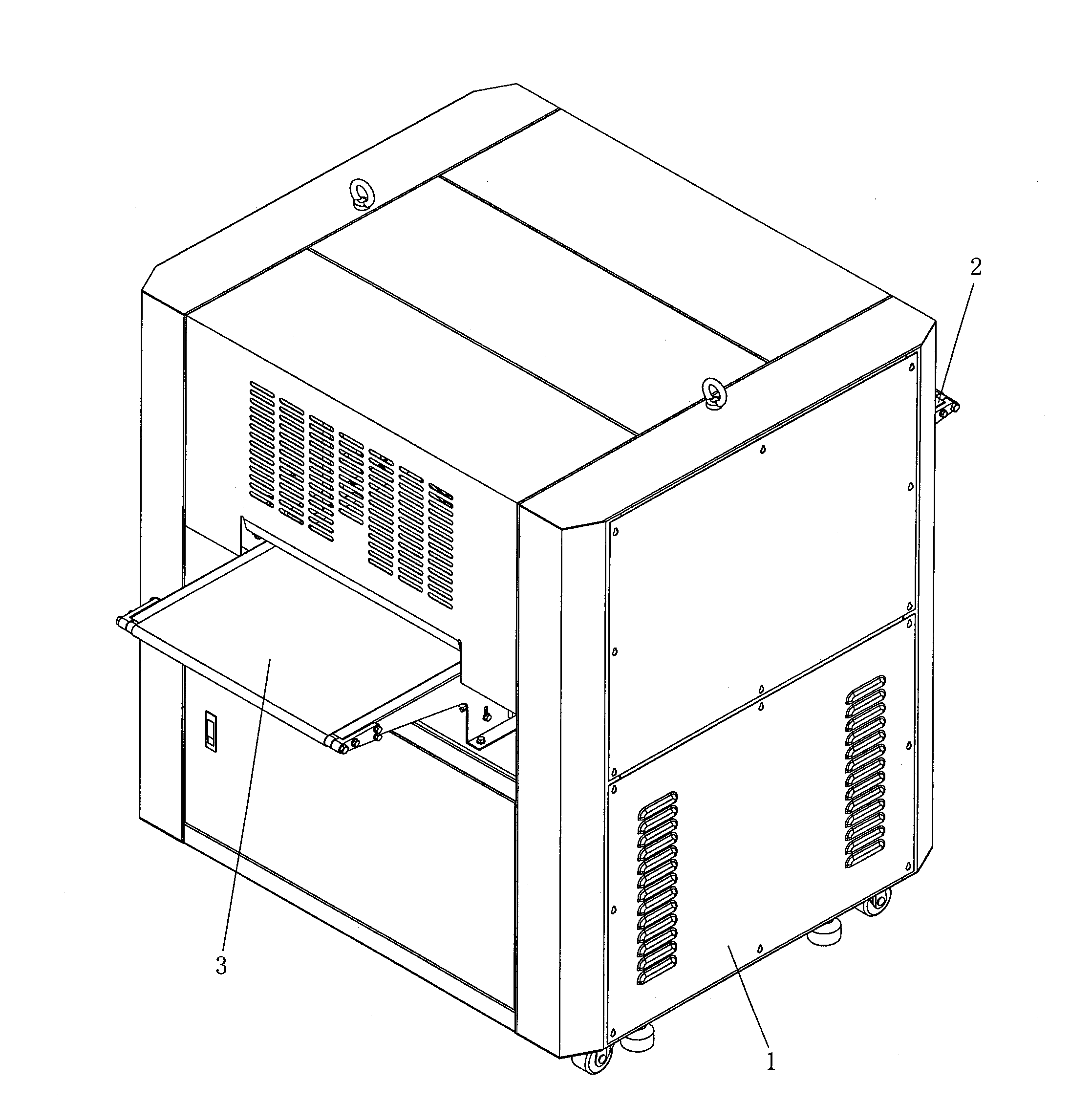

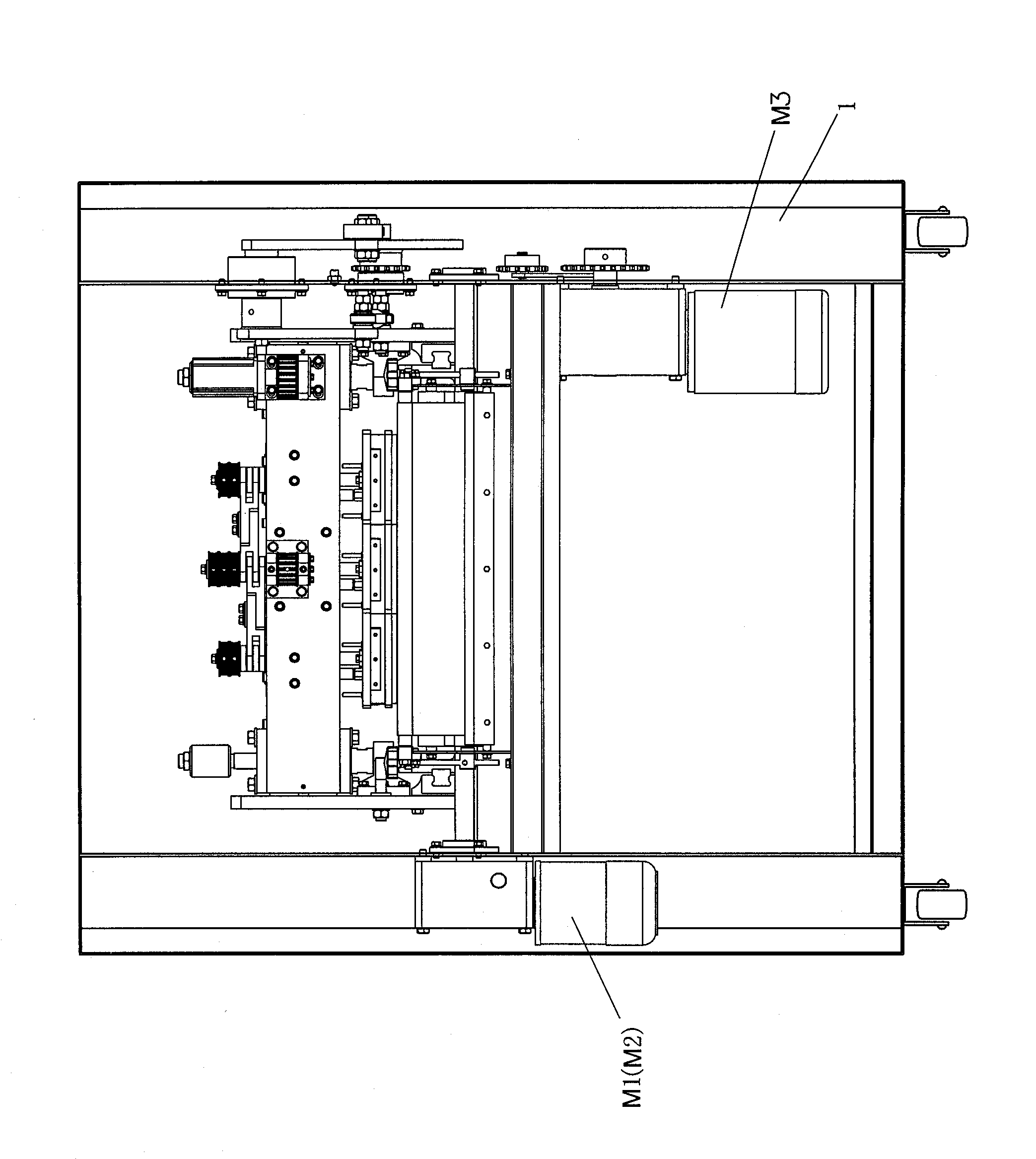

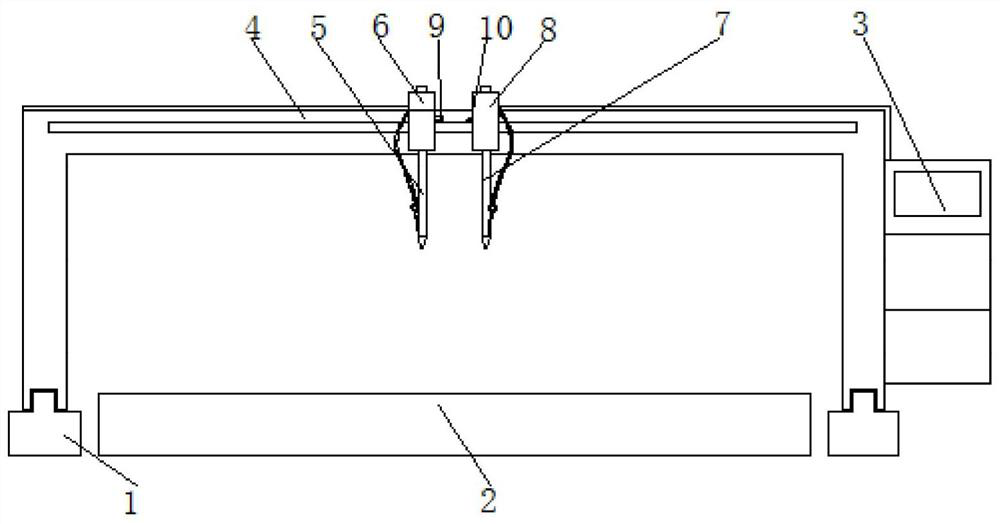

Clad steel plate processing method and plasma cutting machine

PendingCN112518089AImprove production qualityImprove work efficiencyPlasma welding apparatusSteel platesElectric machinery

The invention discloses a clad steel plate processing method and a plasma cutting machine. The clad steel plate processing method comprises checking, rust removal, feeding, cutting and packaging. Theplasma cutting machine comprises a main control device, a cross beam, a first spray gun and a second spray gun; the lower end of the cross beam is provided with guide rails, and the cross beam and theguide rails are of a sliding structure; a cutting bed is arranged below the cross beam; the right end of the cross beam is provided with the main control device; a fastener is arranged at the right side of a first motor; and the left side of a second motor is provided with a clamping groove. The clad steel plate processing method can effectively and rapidly cut clad steel plates, and processes and produces the clad steel plates accurately and orderly, so that the production quality of the clad steel plates is greatly improved; meanwhile, the cross beam of the plasma cutting machine is lengthened, the two plasma spray guns are arranged, so that two clad steel plates can be cut simultaneously, and the two plasma spray guns can be separated and combined, and can work simultaneously or separately, so that the working efficiency is greatly improved.

Owner:扬州明弘机械有限公司

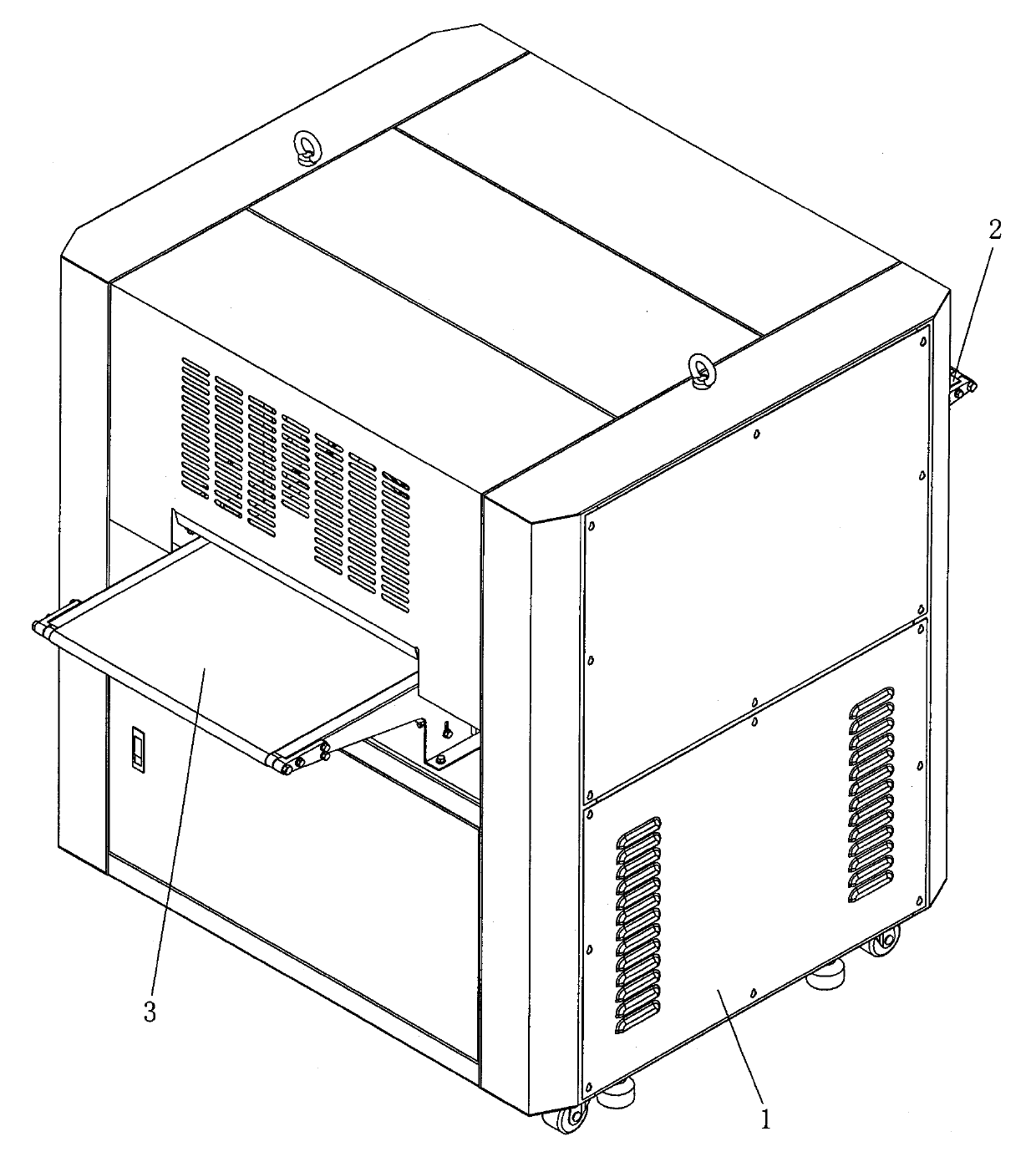

Rapid slicing machine

InactiveCN108638156AEasy to cleanFast and efficient cuttingMetal working apparatusEngineeringWork time

The invention discloses a rapid slicing machine. The rapid slicing machine comprises a shell, and is characterized in that supporting frames symmetrically arranged on one side of the shell are provided with a cutting mechanism capable of cutting fruits, one side of the shell is provided with a pushing mechanism for pushing the fruits into the cutting mechanism, and the surface of the shell is provided with a residue removal mechanism capable of removing residues in gaps in the cutting mechanism; through the arrangement of the residue removal mechanism, the pushing mechanism and the cutting mechanism, the slicing machine can rapidly and effectively conduct slicing, the cutting mechanism can be rapidly and conveniently cleaned after cutting is finished, the work time is greatly saved, the requirements of people are met, and practicability is high.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

Environment-friendly low-smoke flame retardant PVC material and preparation equipment thereof

InactiveCN109109050AFast and efficient cuttingAvoid flyingMetal working apparatusEngineeringKnife blades

The invention discloses an environment-friendly low-smoke flame retardant PVC material and preparation equipment of the environment-friendly low-smoke flame retardant PVC material. The equipment comprises a bottom frame and an outer frame installed on the upper side of the bottom frame, a preparation cavity is arranged in the end face of the bottom of the outer frame, a first sliding cavity is formed in the top wall of the preparation cavity, a preparation frame body is installed in the first sliding cavity through sliding fit, lifting mechanisms are symmetrically arranged on the left side andthe right side of the preparation frame body, an embedded cavity is arranged in the end face of the bottom of the preparation frame body, a cutting blade is rotationally arranged in the embedded cavity, first inserting cavities are arranged in the end face of the left side of the cutting blade in an up-down symmetrical mode, a second inserting cavity is arranged in the center of the end face of the right side of the cutting blade, a first motor is fixedly arranged in the inner wall of the left side of the embedded cavity, an installation plate is fixedly arranged on an output shaft of the right side end of the first motor, and inserting blocks in inserted fit connection with the first inserting cavities are fixedly arranged on the end face of the right side of the installation plate in anup-down symmetrical mode.

Owner:FOSHAN CHENFAN ENVIRONMENTAL TECH CO LTD

An ultra-deep underground diaphragm wall and its construction method

The invention relates to a super-deep underground continuous wall which comprises an underground continuous wall body. Guide walls are symmetrically arranged on the two sides of the wall body, the cross sections of the guide walls are in the shape of an L, the lower ends of the guide walls are located on underground rock-soil, and the lug edges of the guide walls are connected with a concrete pavement. The invention further discloses a construction method of the super-deep underground continuous wall. The method includes the following steps of construction preparation, measuring, guide wall manufacturing, wall protection slurry manufacturing, grooving construction, bottom-clearing replacement, connector cleaning through wall brushing and unit slot section inspection, wherein a grabbing-milling integrated grooving method is used in the grooving construction. The method is high in grooving efficiency, short in construction time and short in groove wall soaking time, the grabbing-milling integrated grooving method is used in the grooving construction, technologies can be changed timely according to different stratum hardness situations, the characteristics that a grab bucket is high in digging speed at the soft soil layer and milling wheel can achieve rapid milling and digging footage at a hard soil layer or bed rod with standard penetration test blow count exceeding 45 are fully used, and therefore rapid and efficient grooving of the whole wall can be achieved.

Owner:ZHONGDING INT ENG

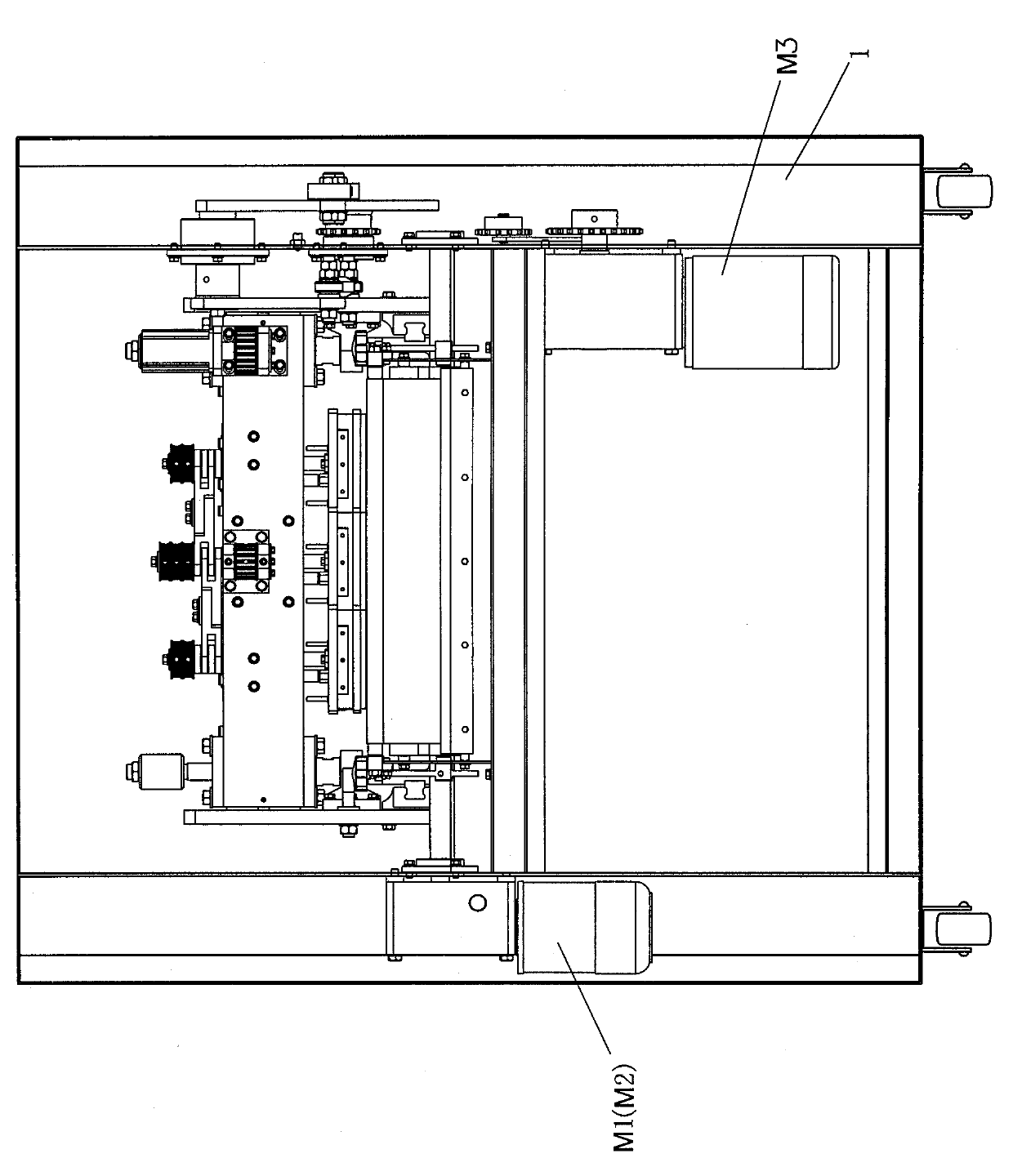

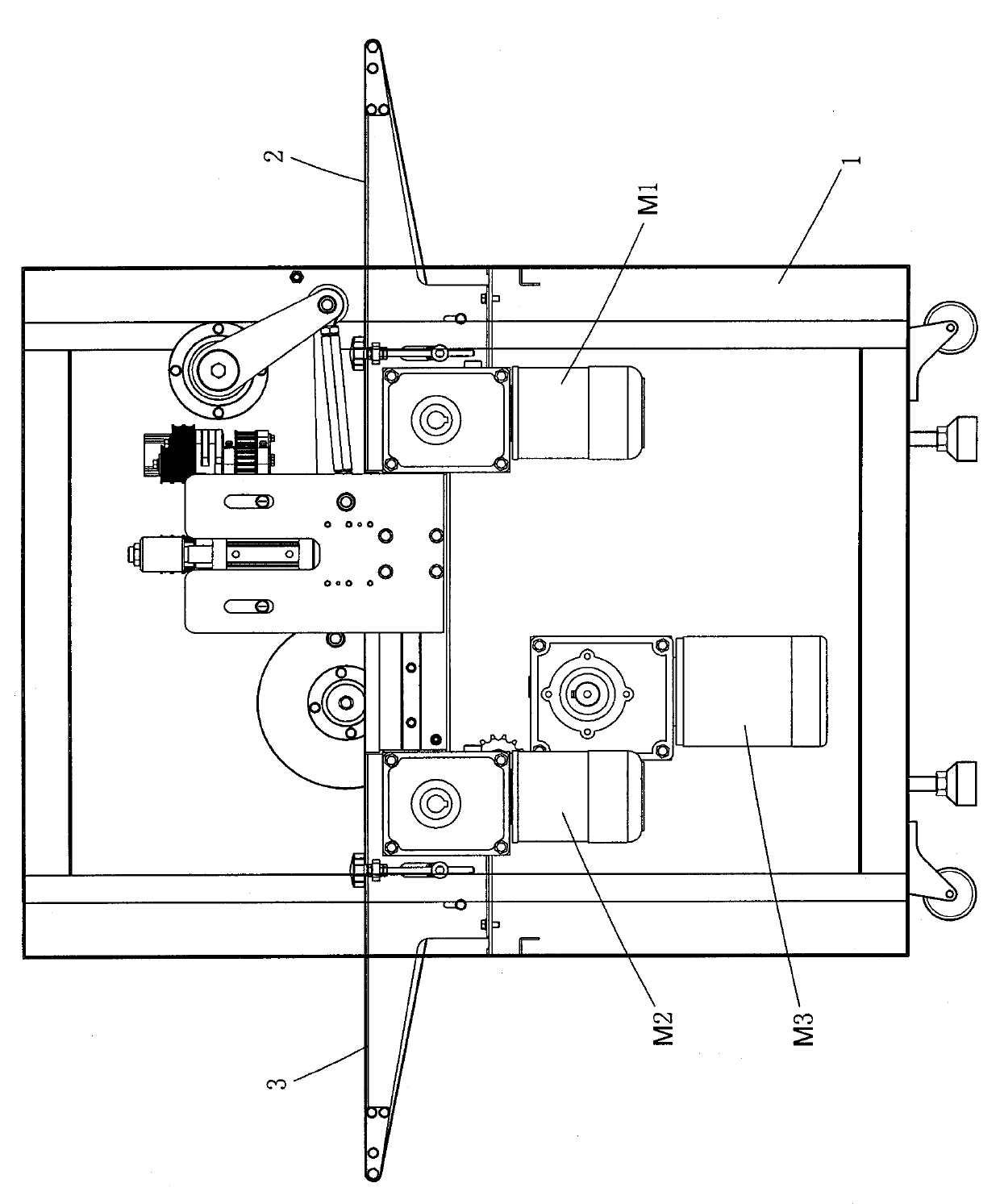

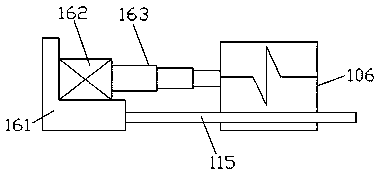

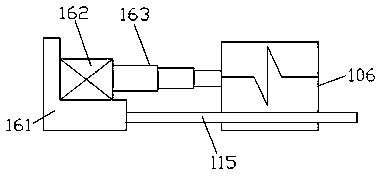

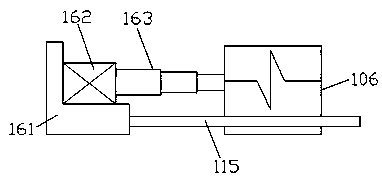

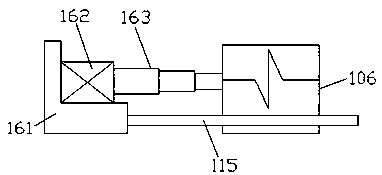

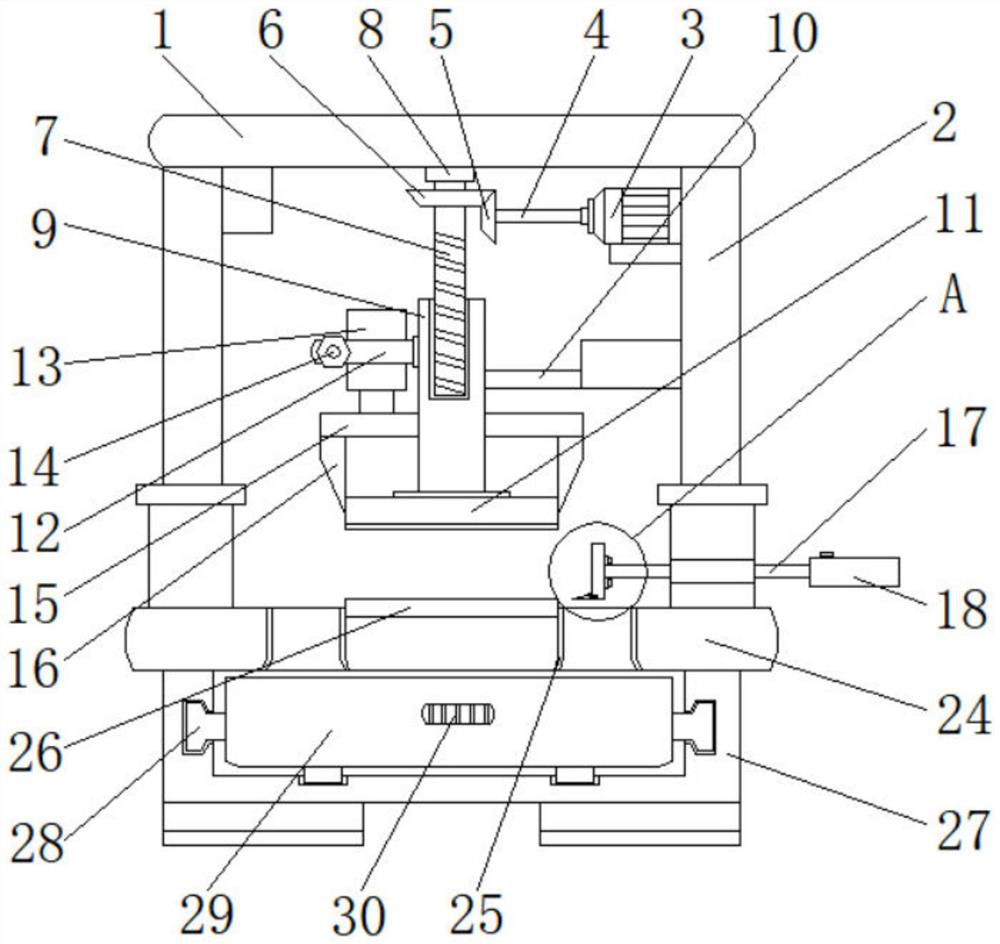

Flat workpiece cutting device

PendingCN111590141AEfficient feedingOrganize quickly and efficientlyMetal working apparatusEngineeringProcessing cost

The invention provides a flat workpiece cutting device. The flat workpiece cutting device comprises a main tool, a feeding assembly, a finishing assembly and a clamp cutting assembly. The feeding assembly is arranged on the table facet of the main tool, located at one end of the table facet and is used for providing flat workpieces for the finishing assembly; the finishing assembly is arranged onthe table facet of the main tool and is located at the side edge of the feeding assembly; the finishing assembly is used for finishing the flat workpieces transferred by the feeding assembly to enablethe flat workpieces to form an array arrangement; the clamp cutting assembly is arranged on the table facet of the main tool and is located at the other end of the table facet; and the clamp cuttingassembly is used for clamping the flat workpieces on the finishing assembly for cutting. According to the flat workpiece cutting device, feeding, finishing and cutting of the workpieces are quickly and efficiently, so that accurate processing and transportation of the workpieces are realized. The flat workpiece cutting device is simple in structure, the cutting and processing efficiency of the workpieces can be effectively improved, the labor intensity of workers is reduced, and thus the processing cost of parts is reduced.

Owner:安吉安盛竹木机械有限公司

Portable saw table assembly

InactiveUS20090266215A1Easy to useFast and efficient cuttingMetal sawing devicesGuide fencesEngineeringMechanical engineering

Owner:TAPCO INTERNATIONAL CORPORATON

Processing technology of aluminum alloy workpiece

InactiveCN108714718AFast and efficient cuttingAvoid flyingWork clamping meansPositioning apparatusMaterials scienceAluminium alloy

The invention discloses a processing technology of an aluminum alloy workpiece. The processing technology refers to a bottom plate and a main frame mounted on the upper side of the bottom plate. A manufacturing cavity is formed in the bottom end face of the main frame; a first sliding cavity is formed in the top wall of the manufacturing cavity; a manufacturing frame is mounted in the first sliding cavity in a sliding fit mode; lifting mechanisms are symmetrically arranged on the left and right sides of the manufacturing frame; an embedded cavity is formed in the bottom end face of the manufacturing frame; a cutting blade is rotatably arranged in the embedded cavity; first inserting grooves are formed in the end face of the left side of the cutting blade in a vertical symmetry mode; a second inserting groove is formed in the center of the end face of the right side of the cutting blade; a first motor is fixedly arranged in the inner wall of the left side of the embedded cavity; a mounting and fixing plate is fixedly arranged at an output shaft of the right side end of the first motor; and inserting plates connected with the first inserting grooves in an inserting-fit mode are fixedly arranged on the end face of the right side of the mounting and fixing plate in a vertical symmetry mode.

Owner:广州宝升新型材料有限公司

Polyvinyl chloride material equipment

InactiveCN109129628AFast and efficient cuttingAvoid flyingMetal working apparatusPolyvinyl chlorideEmbedded system

The invention discloses polyvinyl chloride material equipment comprising a bottom frame and an outer frame installed on the upper side of the bottom frame. A preparation cavity is formed in the bottomend face of the outer frame. A first sliding cavity is formed in the top wall of the preparation cavity. A preparation frame is installed in the first sliding cavity in a sliding fit mode. Lifting mechanisms are arranged on the left and right sides of the preparation frame symmetrically. An embedded cavity is formed in the bottom end face of the preparation frame. A cutting blade is rotationallyarranged in the embedded cavity. First inserting cavities are formed in the left side end face of the cutting blade symmetrically up and down. A second inserting cavity is formed in the dead center ofthe right side end face of the cutting blade. A first motor is fixedly arranged in the left side end wall of the embedded cavity. An installing plate is fixedly arranged on an output shaft at the right side end of the first motor. Inserting blocks are arranged on the right side end face of the installing plate fixedly and symmetrically up and down and are connected with the first inserting cavities in an inserted fit mode.

Owner:FOSHAN CHENFAN ENVIRONMENTAL TECH CO LTD

A plastic recovery device for processing plastic shells with a compression structure

The invention relates to a plastic recycling device with a compression structure for processing plastic shells, which includes a top plate, an annular sleeve, a workbench and a base. A pillar is fixed on the bottom of the top plate, and a servo motor is installed on the left side of the right pillar. The left side of the servo motor is provided with a connecting shaft, and the left side of the connecting shaft is provided with a first gear, the left side of the first gear is provided with a second gear, and the inner side of the second gear is provided with a screw, the The top of the screw rod is equipped with a bearing, and the top end of the bearing is provided with a top plate, and the bottom end of the screw rod is provided with a lifting column. The beneficial effect of the present invention is that: the hydraulic telescopic rod can make the movable rod inserted inside the lifting column descend downward, and the cutting piece can also cut downward to cut the remaining material exposed on the edge of the placement plate. The hopper drains into the hopper, cutting and collecting the waste quickly and efficiently, which can save the manual treatment of the waste, and the treatment method has high economic benefits.

Owner:深圳市佳鑫一帆科技有限公司

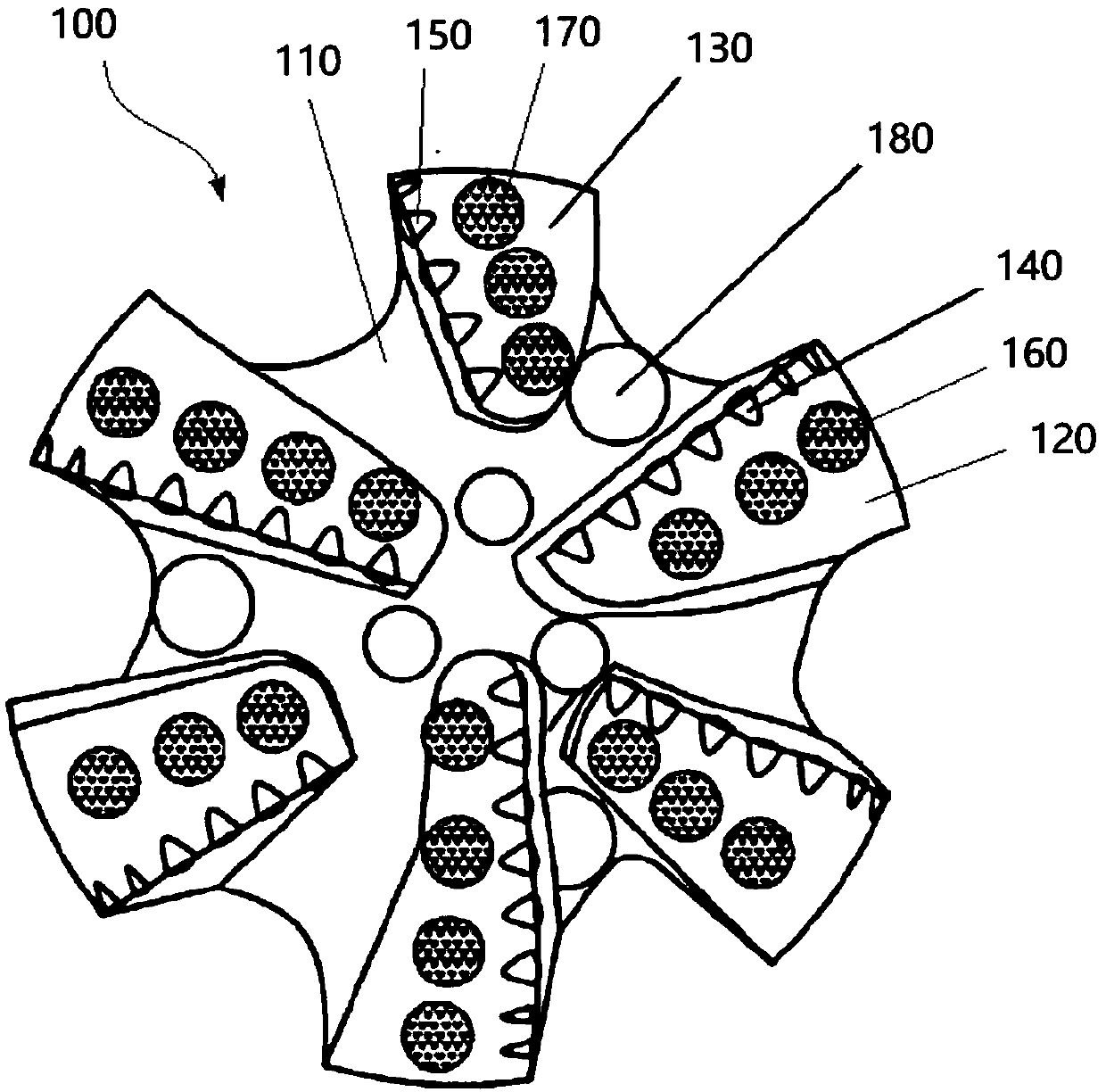

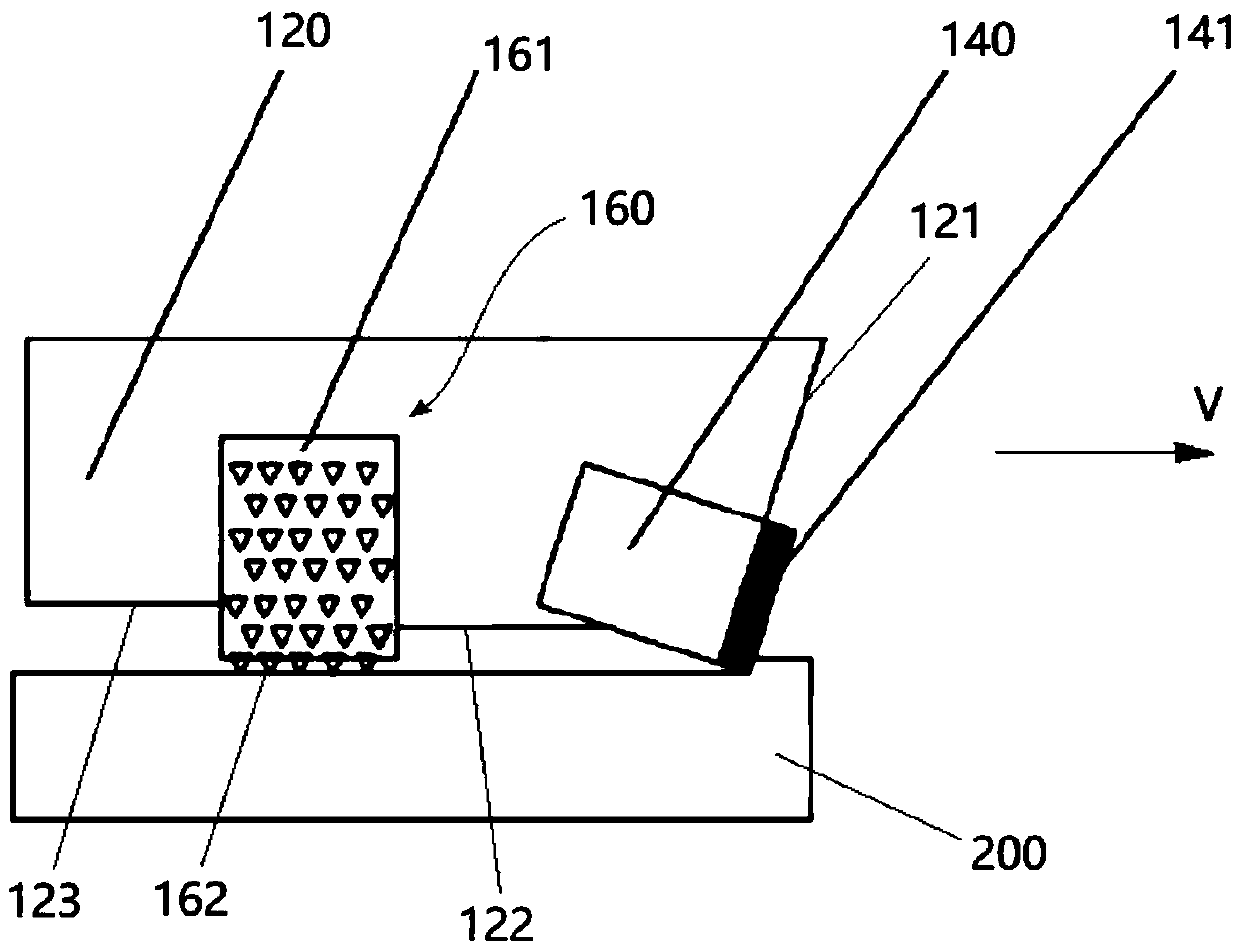

Impregnated diamond and polycrystalline diamond composite drill bit

InactiveCN111425143ADrilling effect is goodExtended service lifeDrill bitsPolycrystalline diamondDrill bit

The invention relates to a drill bit. The drill bit comprises a rotation main body. Polycrystalline diamond compacts and impregnated diamond columns are installed at the lower end of the rotation mainbody. Each impregnated diamond column comprises a basic body fixed to the rotation main body, and diamond particles embedded in the basic body. One part of each of at least part of the diamond particles protrudes out from the lower end face of the corresponding basic body. In the drilling process, the polycrystalline diamond compacts and the diamond particles make contact with a stratum and rotate together with the rotation main body. The drill bit is suitable for hard strata and abrasive strata, a drilling effect is good, and the service life is long.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com