Lateral type double-drum opencast machine

A double-drum and shearer technology, which is applied in open-pit mining, cutting machinery, earth drilling and mining, etc., can solve the problem of insufficient collection of star-wheel loading mechanism and unsatisfactory use effect of rolling-cutting continuous excavator , Land splashes and other problems, to achieve the effect of continuous coal mining production operations, reduce the cost per ton of coal, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned technical content and structural features of the present invention more easily understood by those skilled in the art, the present application will be further described below in conjunction with the accompanying drawings and technical points.

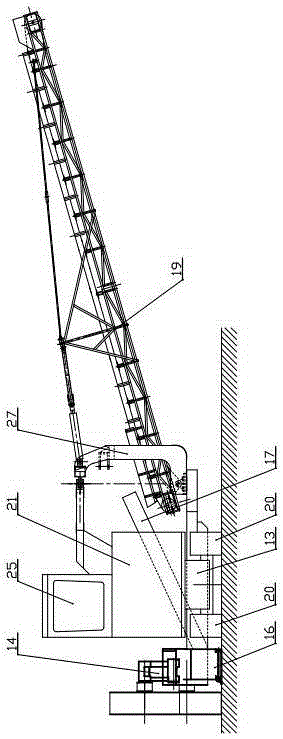

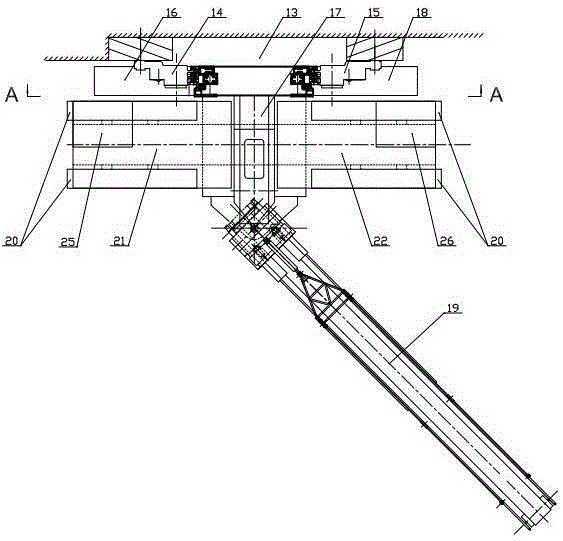

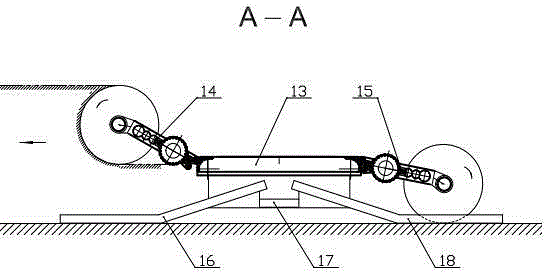

[0029] Such as Figure 1 to Figure 5 As shown, the side-mounted double-drum surface coal mining machine of the present invention includes a crawler-type traveling mechanism 20, a main frame 13, an operating room, a hydraulic system 21, an electrical system 22, a spiral drum cutting mechanism, a scraper conveyor and a belt conveyor machine19.

[0030] Such as Figure 1 to Figure 3 As shown, the crawler-type traveling mechanism 20 is installed on the main frame 13 lower side. The main frame 13 is installed on the connecting beam 24 of the crawler-type traveling mechanism 20, and is detachably connected.

[0031] The crawler type traveling mechanism of the present invention is made up of crawl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com