Apparatus for shearing multi-walled workpieces

A technology for workpieces and components, which is applied in the field of devices for cutting board materials, can solve the problems of inability to cut, not accommodate, and cannot accommodate workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

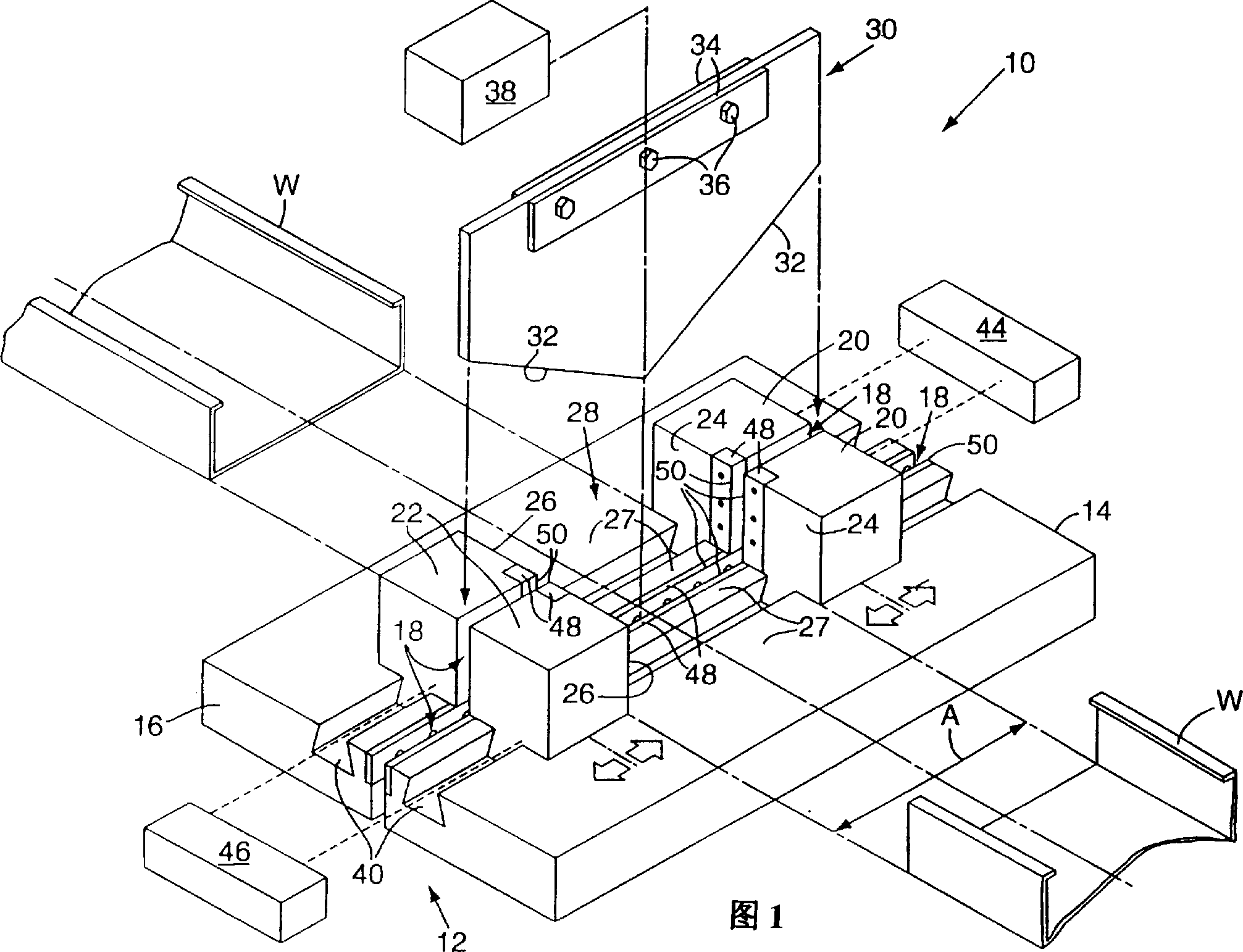

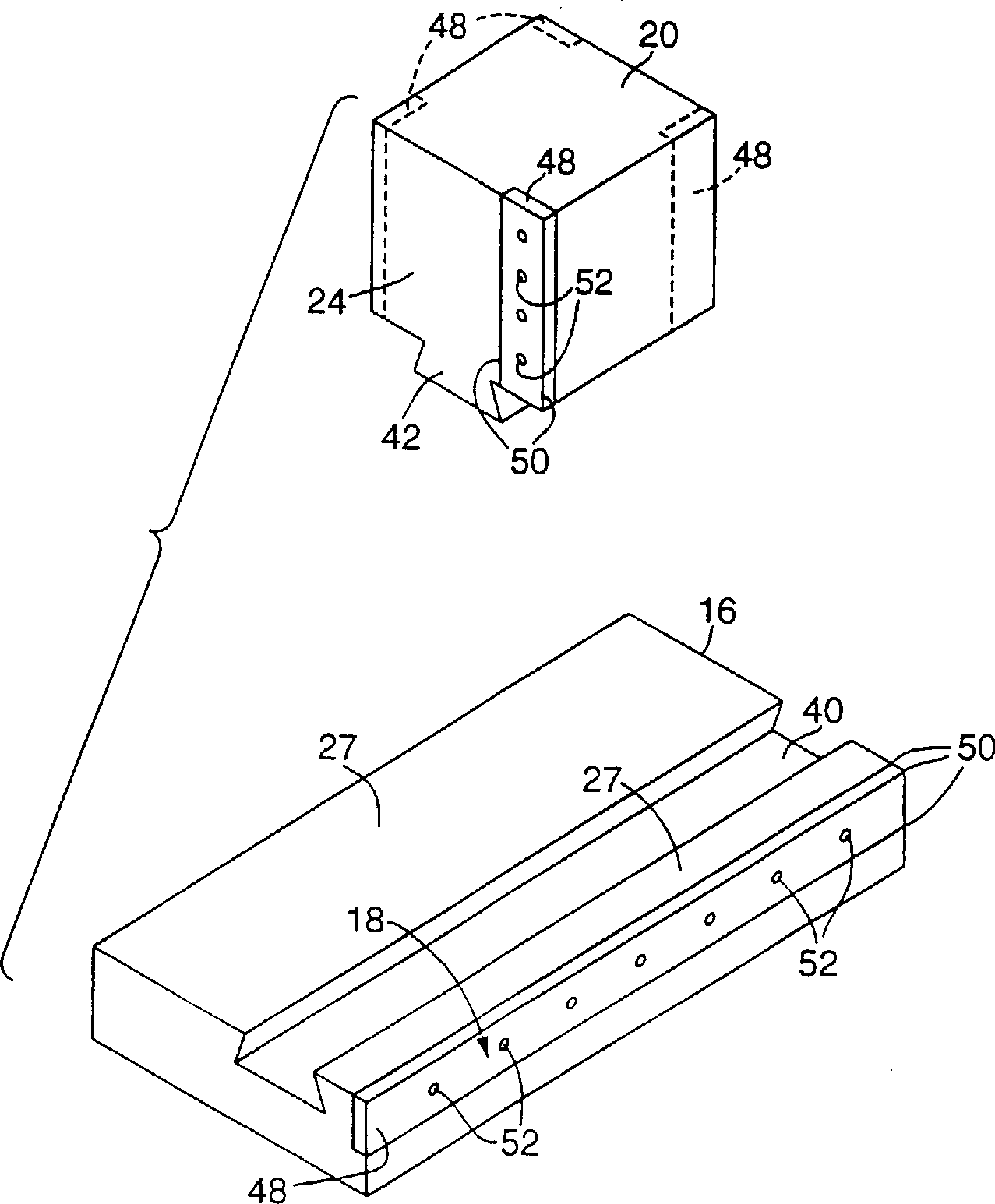

[0023] In FIG. 1, an apparatus embodying the invention is indicated by reference numeral 10 . Apparatus 10 comprises: a base assembly 12, and it contains a first base support body 14 and the second base support body 16 that is spaced apart from the first base support body, and forms blade gap 18 between them; Each of the bodies 20 is movably mounted on one side of the first and second base supports 14, 16, and each of the pair of second support bodies 22 is movably mounted on the first , On the opposite side of the second support body. Each first support 20 forms at least one first support surface 24 for engaging a first side of the workpiece 'W', and each second support 22 forms at least one second support surface 26 for engaging a second side of the workpiece W. The base supports 14, 16 similarly form a third support surface 27 extending between the first and second support surfaces 24 and 26, supporting the workpiece and cooperating with a third side thereof. In FIG. 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com