Clad steel plate processing method and plasma cutting machine

A technology of plasma cutting machine and composite steel plate, applied in the field of composite steel plate processing, can solve the problems of poor cutting effect, low efficiency of plasma cutting machine, unstable cutting of composite steel plate, etc., and achieve the effect of improving production quality and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

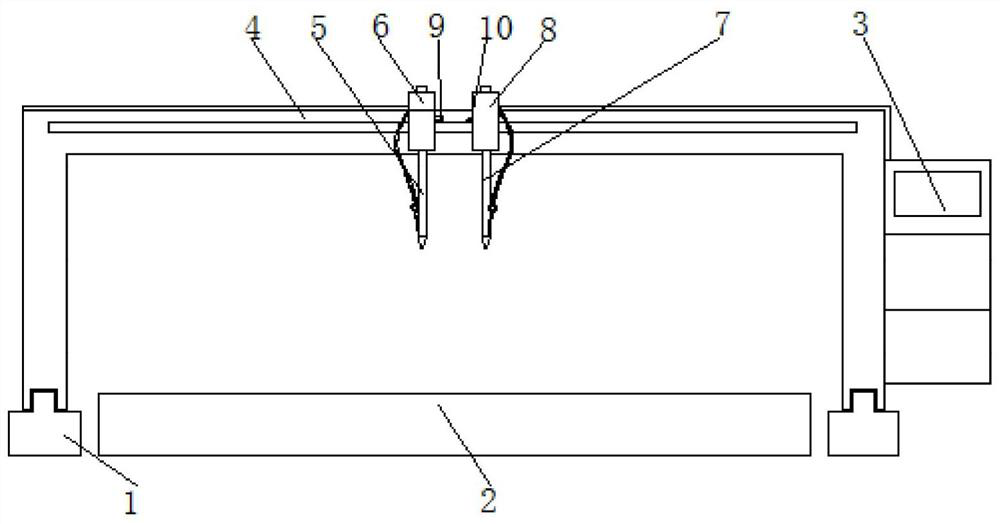

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] In the composite steel plate processing method and plasma cutting machine of the present application, the upper layer of the composite steel plate is made of carbon steel, and the lower layer is made of stainless steel.

[0024] The first step: inspection: check the grade, price and surface quality of the composite steel plate. The composite steel plate used for cutting and blanking should be inspected and accepted by the quality department. Parts where the depth of corrosion pits exceed the negative deviation of the national standard steel plate are not allowed to be used in products. Small area of pitting can be repaired and polished until qualified without reducing the design thickness;

[0025] The second step: derusting: derusting and decontaminating the composite steel plate, which can be derusted and decontaminated by high-pressure water abrasives;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com