Croissant conical wrapper automatic cutting and turning method and device

A technology of croissant, steering device, applied in the direction of dough processing, dough cutting machinery, baking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

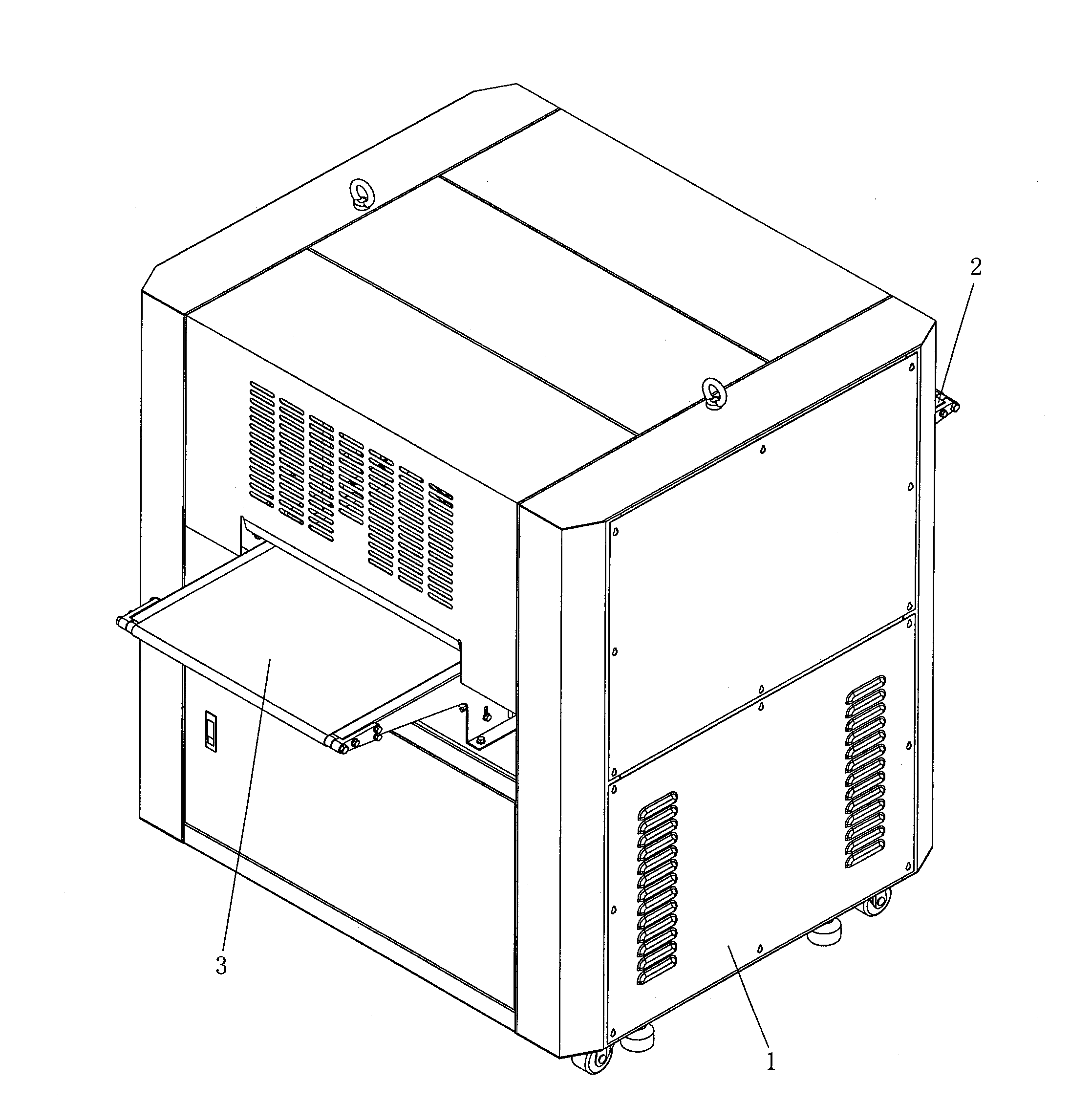

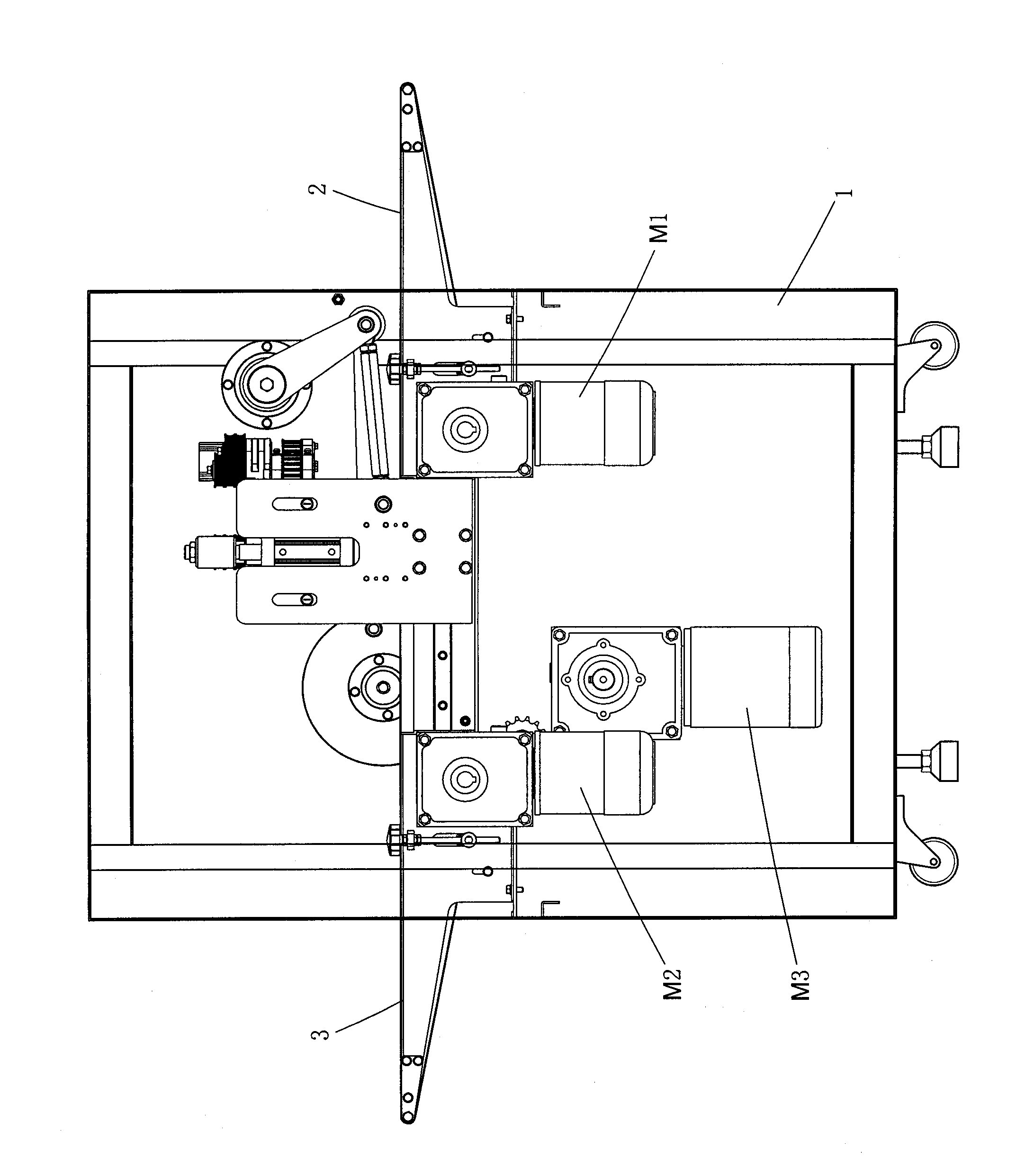

[0039] ginseng figure 1 and Figure 10 As shown, the automatic cutting and steering method and device for croissant conical dough of the present invention mainly include a machine 1, a front conveyor belt 2, a rear conveyor belt 3, a cutting and bogie 4 and a dough conveying and dividing auxiliary frame 5.

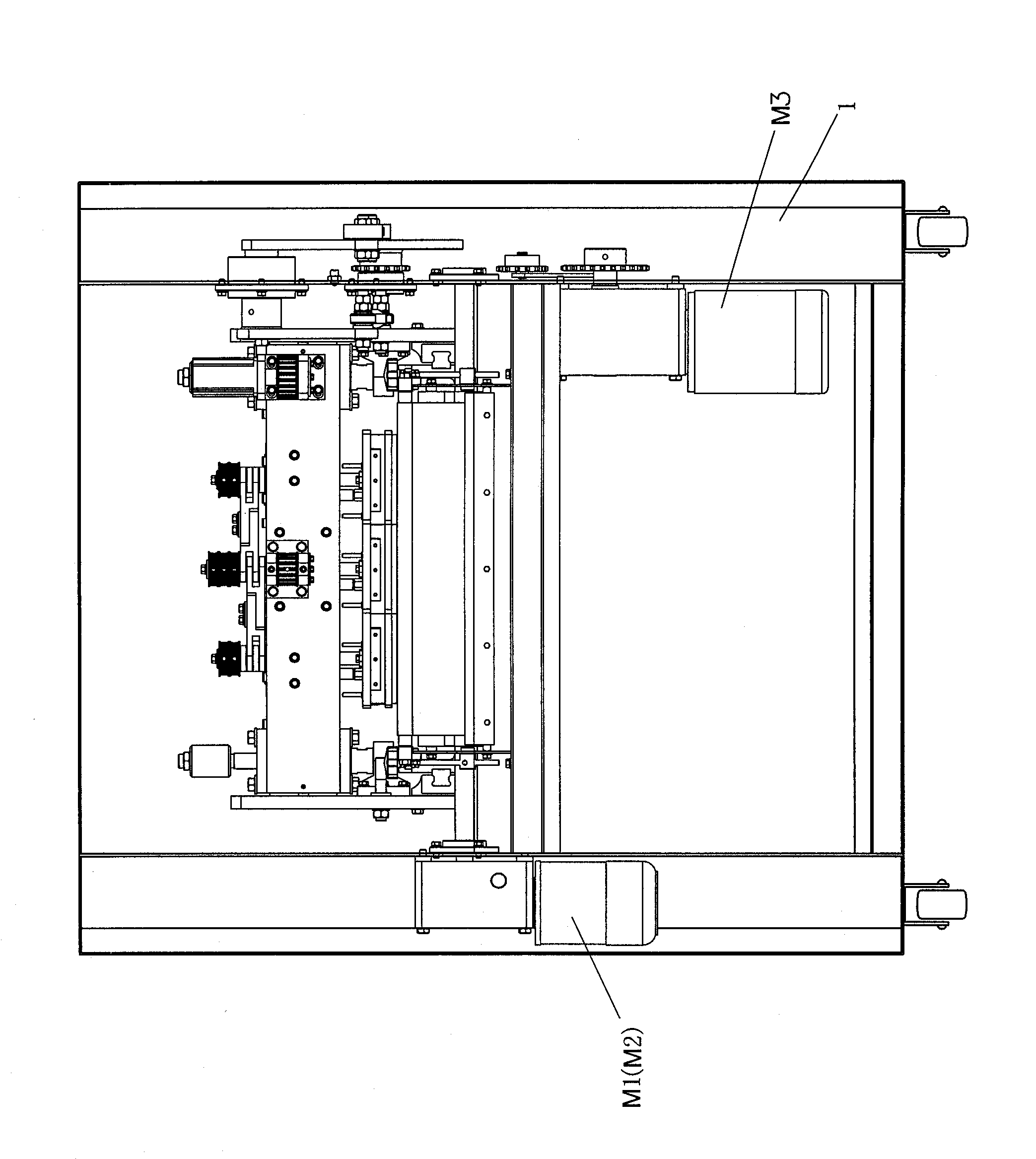

[0040] Such as Figure 2 to Figure 6 As shown, a platform 11 is fixed on the machine platform 1, and a front conveyor belt 2 and a rear conveyor belt 3 are respectively arranged on the platform 11, and the front conveyor belt 2 and the rear conveyor belt 2 are driven by servo motors M1 and M2 fixed on the machine platform 1. The front conveyor belt 3 continues to move backwards, and the platform 11 is located on both sides of the connection between the front conveyor belt 2 and the rear and front conveyor belt 3, and a group of symmetrical slide rails 12 are provided.

[0041] A cutting and bogie 4 straddling the slide rail 12 is combined with the above slide rail 12 by vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com