Method for manufacturing micro nth skipping-thread measuring gear

A manufacturing method and technology of jumping teeth, applied in the direction of components with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of low production efficiency, poor product quality, low measurement accuracy of tooth surfaces, etc. The effect of high precision, simple manufacturing process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

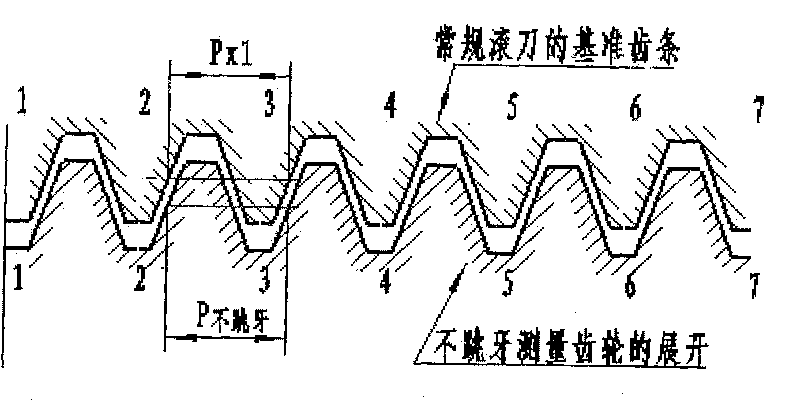

[0027] The manufacturing method of the present invention is to use a multi-lead hob (or worm grinding wheel) with a thicker tooth thickness value to process conventional, tiny (usually gear modulus less than 0.4mm), non-skipping measuring gears into tiny Jump tooth measurement gear.

[0028] Manufacturing of tiny non-skipping measuring gears

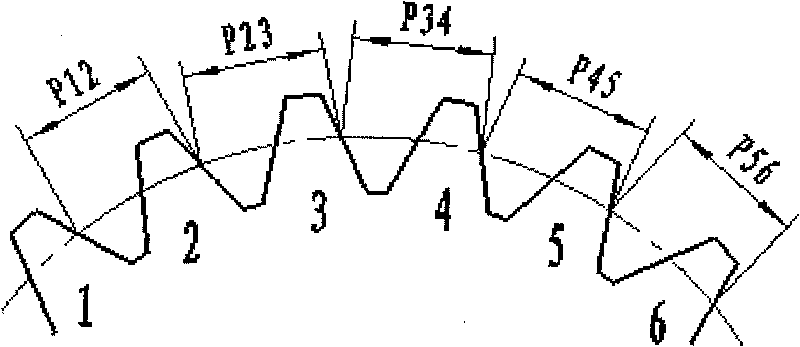

[0029] Measuring gears without jumping teeth, which is commonly referred to as measuring gears. The dimensions of each individual pitch are equal, and the width dimensions of each tooth groove are also equal, such as figure 1 . In the figure, if the inter-tooth pitch between No. 1 tooth and No. 2 tooth is P12, and so on, there are:

[0030] P12=P23=P34=P45=P56

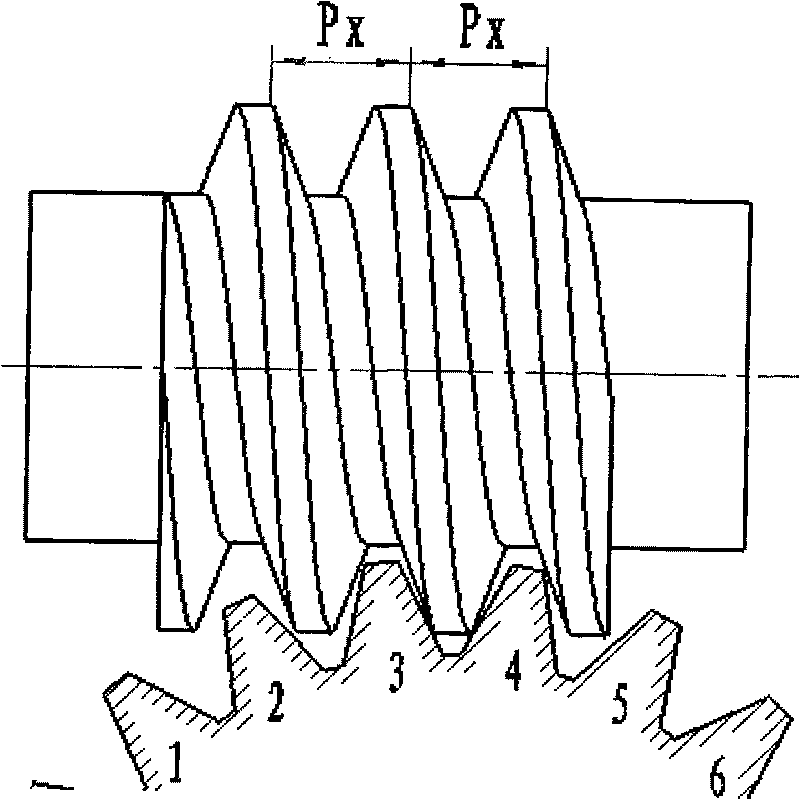

[0031] Its manufacturing method is to process with a high-precision hob (or grinding wheel) of conventional geometry, such as figure 2 . At this time, the tooth shape of the non-skipping measuring gear and the tooth shape of the hob are consistent with the tooth shape of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

| Pressure angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com