Four-drive two-face chip polishing machine

A technology for polishing machines and wafers, which is applied in the direction of grinding racks, grinding machine parts, grinding/polishing equipment, etc., and can solve problems such as imperfect design of wafer grinding machines and insufficient production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

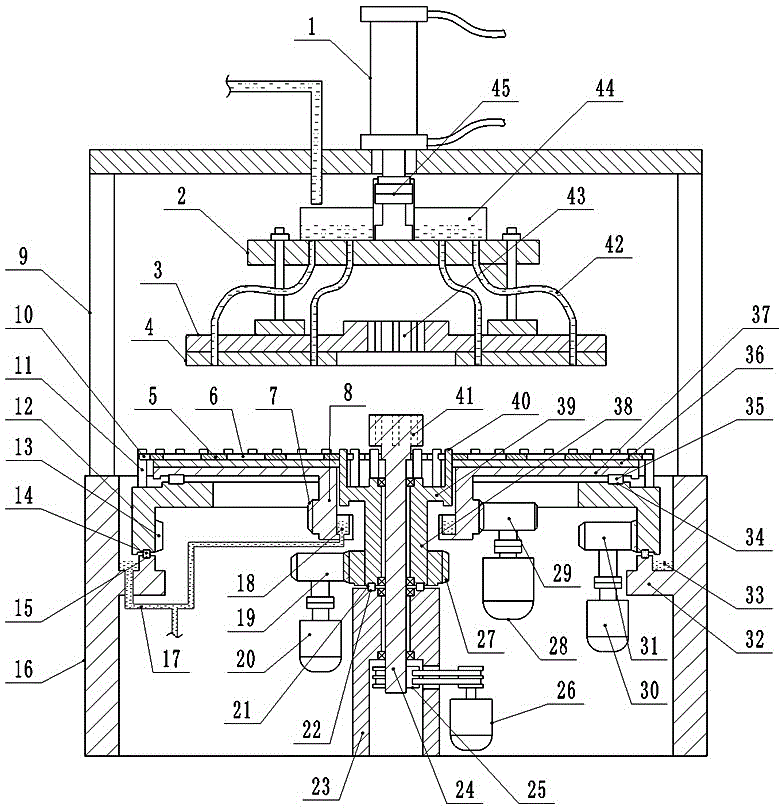

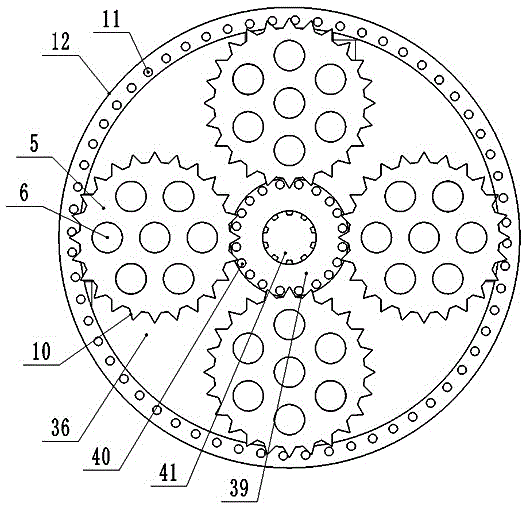

[0009] Examples such as figure 1 and figure 2 Shown: a four-wheel-drive double-sided wafer grinder, the double-sided grinder is composed of a lower grinding device and an upper grinding device, the lower grinding device is installed in the chassis, the upper grinding device is installed on the frame 9, and the frame 9 Installed on the chassis 16, the cylinder 1 of the upper grinding device is vertically installed on the crossbeam of the frame 9, the end of the piston rod of the cylinder 1 is equipped with a connecting plate 2, and a pressure plate 3 is installed below the connecting plate 2, and the pressure plate 3 is lowered. An upper grinding disc 4 is installed, a grinding liquid tank 44 is installed on the connecting plate 2, and a grinding liquid delivery pipe 42 is installed on the pressure plate 3; a linkage hole 43 is processed in the middle of the pressure plate 3, and a rack is processed in the linkage hole 43 , the piston rod end of the cylinder 1 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com