Stamping equipment for grid plates of lead-acid storage battery

A lead-acid battery, stamping equipment technology, applied in metal processing equipment, storage devices, punching tools and other directions, can solve the problems of insufficient position accuracy, low efficiency, complex structure, etc., to achieve stable operation, improve quality and service life, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

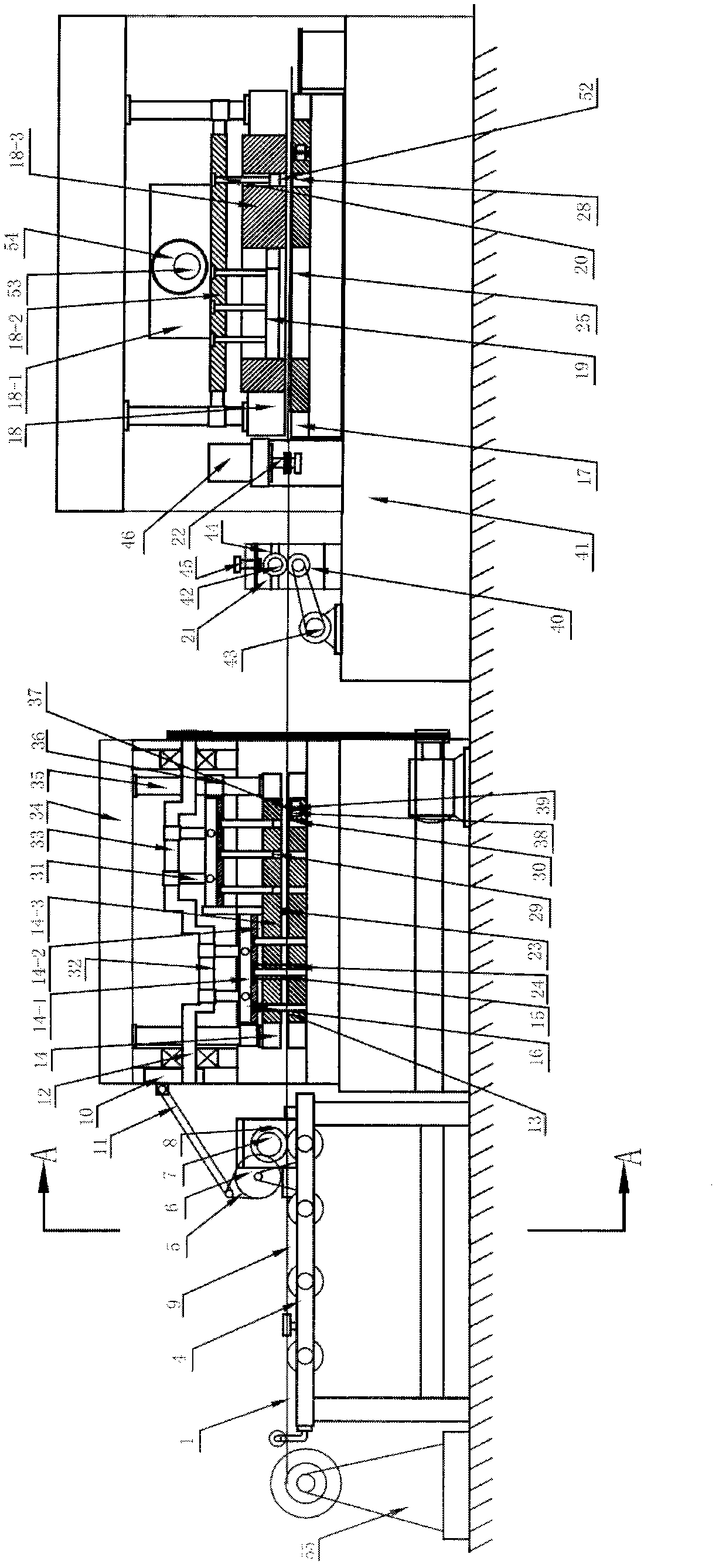

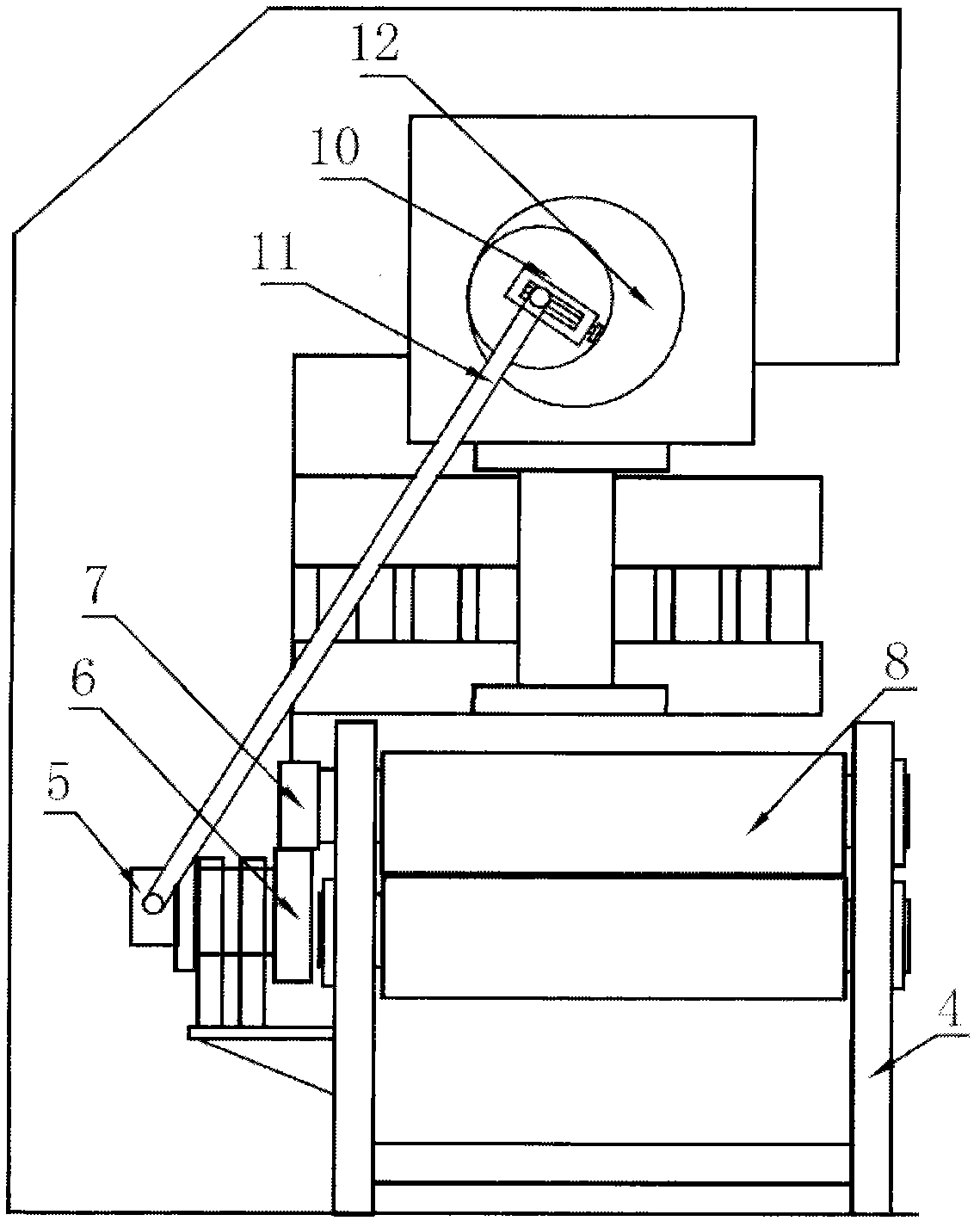

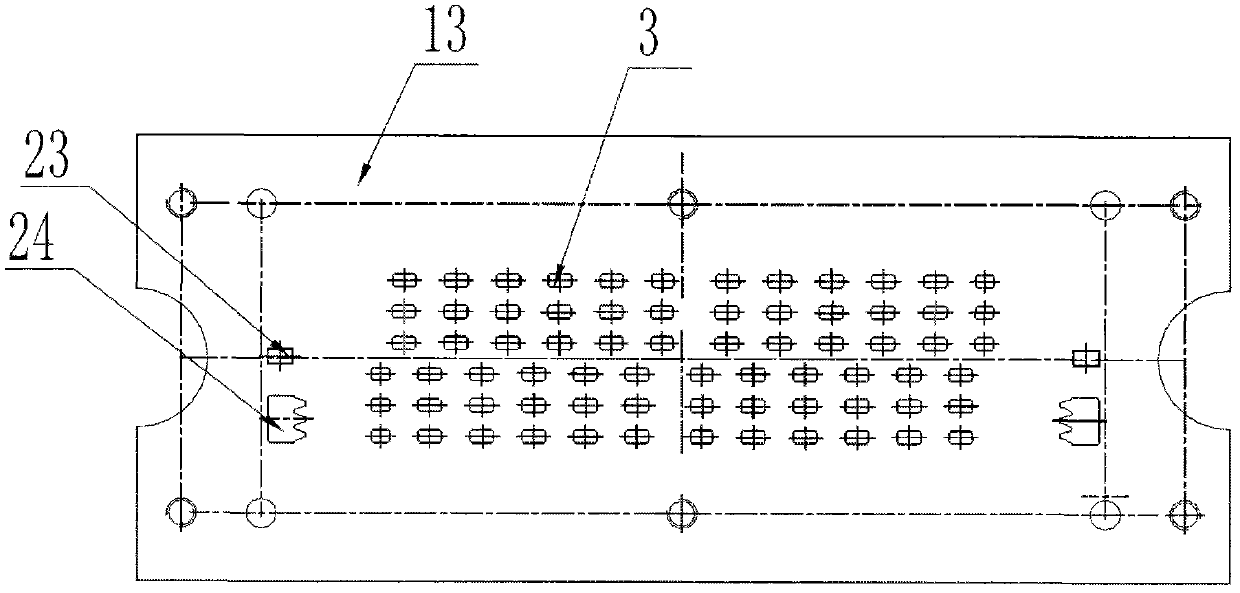

[0030] Such as Figure 1 to Figure 7 As shown, the present invention is a stamping equipment for a lead-acid battery grid, the stamping equipment includes a first feeding mechanism that automatically sends the rolled lead plate 1 into a punch press, and is used for stamping a cold-rolled plate or a hot-rolled plate The punch press of the edge teeth 2 and the mesh 3 is used to cut the continuous whole grid into the cutting punch of the acid battery grid; the first feeding mechanism includes a feeding platform 4, and the feeding platform One side of 4 is provided with a second cam 5, the second cam 6 is coaxially connected with the second gear 6, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com