Gear shift mechanism of engine speed changer

A shift mechanism and transmission technology, applied in the field of motor vehicle shift devices, can solve problems such as shift failure, burden, user trouble, etc., and achieve the effect of ensuring reliability and prolonging return time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

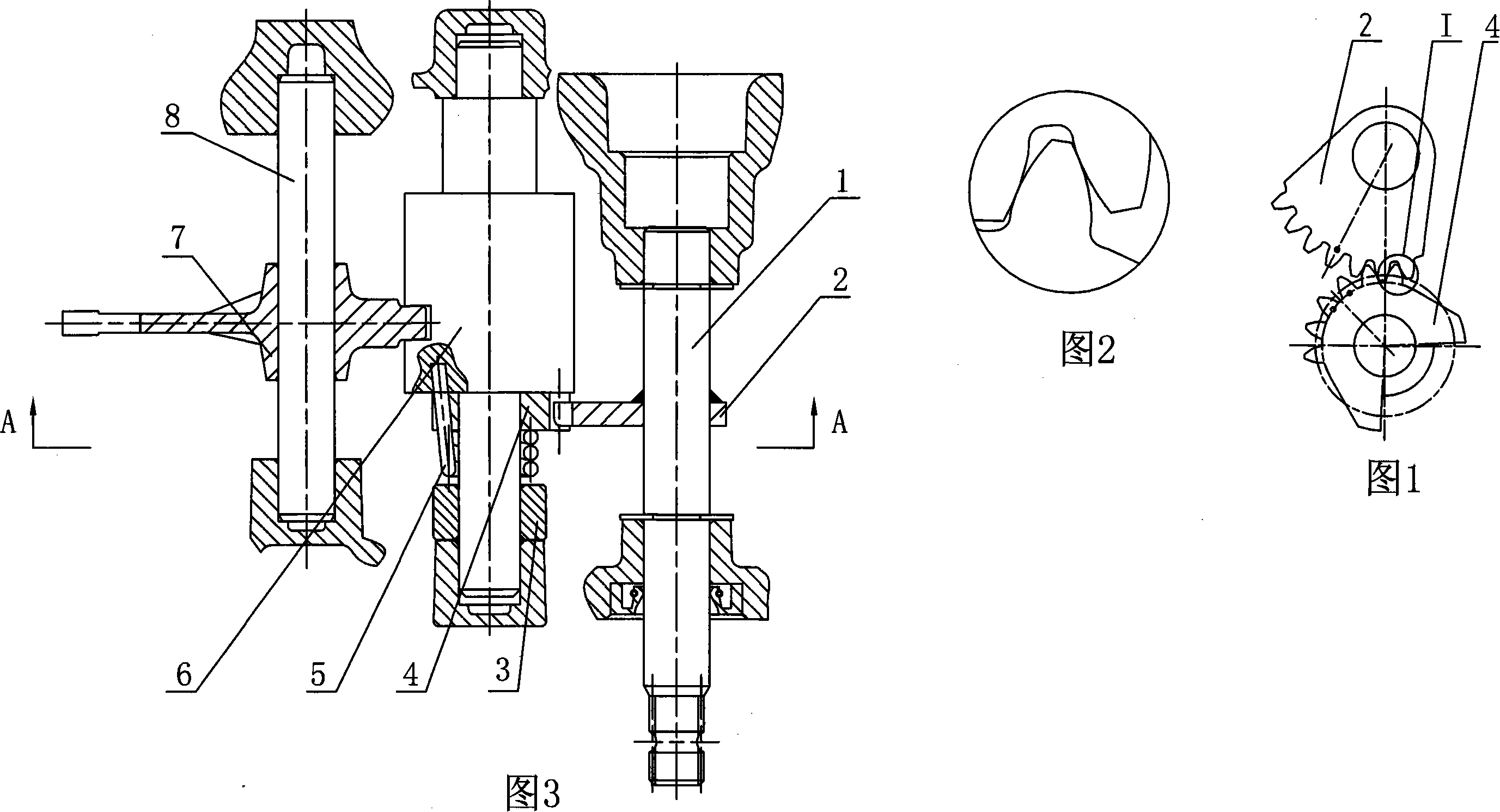

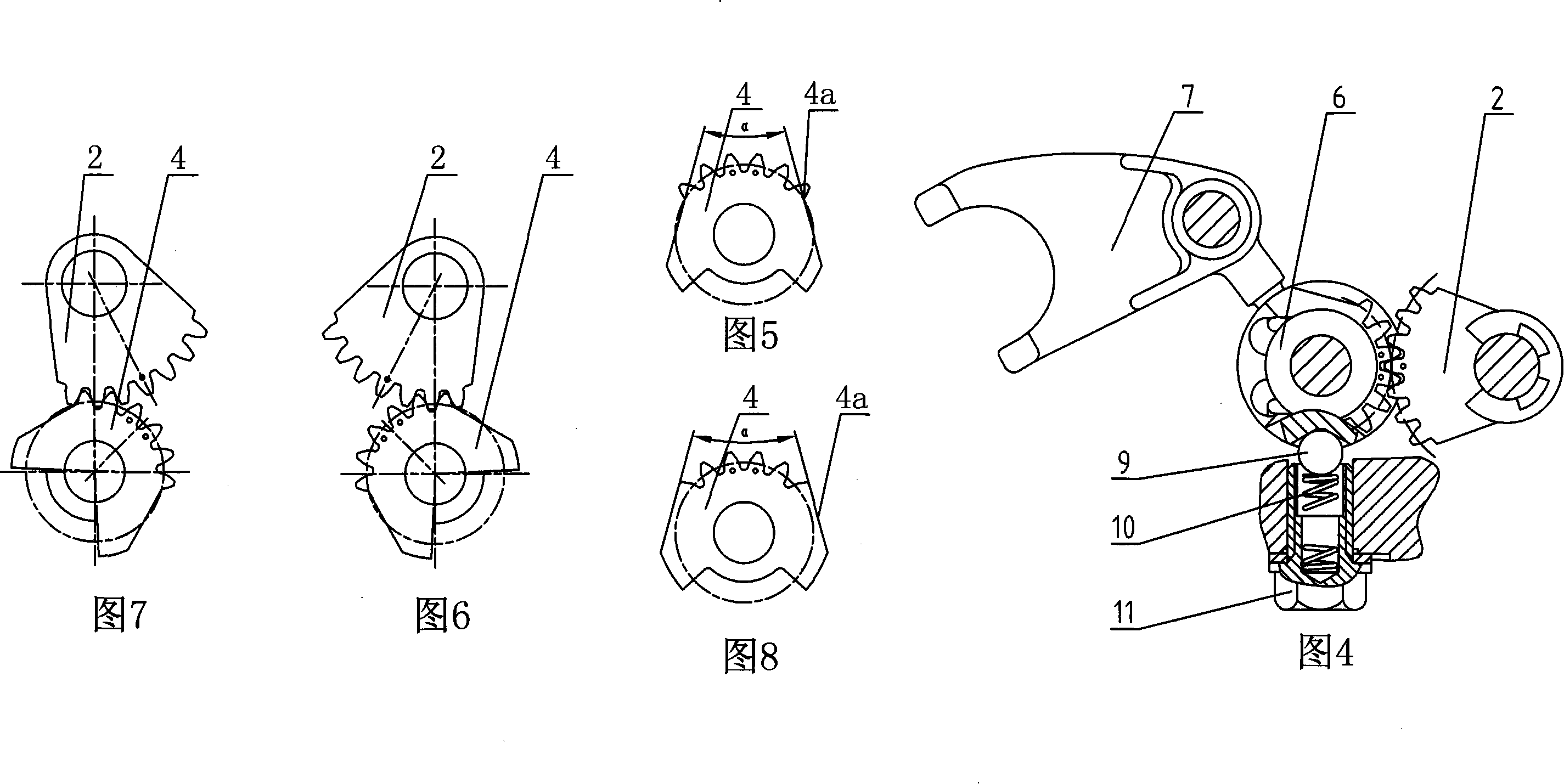

[0019] 3 to 5, the shift mechanism of the engine transmission of the present invention includes a shift shaft, a driving sector gear, a transmission hub, a driven sector gear, a fork shaft, and a shift fork. One end of the gearshift shaft 1 is installed in the crankcase, and the other end is used to connect with the gearshift pedal. The driving sector gear 2 is fixed on the shift shaft, and the driving sector gear 2 is welded and fixed on the shift shaft. The driven sector gear is fit on the shaft of the transmission hub with clearance, and forms a flexible connection with the transmission hub through the torsion spring. One end is connected, and the other end of the torsion spring 5 is inserted into the hole provided on the end face of the transmission hub 6 . The torsion spring 5 is in contact with the bushing 3 mounted on the transmission hub shaft, and the bushing 3 is in interference fit with the transmission hub 6, and the bushing is used to ensure the axial position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com