Planetary harmonic gear reducer

A gear reducer, planetary harmonic technology, applied in belt/chain/gear, mechanical equipment, transmission and other directions, can solve the problems of reducing service life, fatigue damage, complex process, etc., to improve working life, improve performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

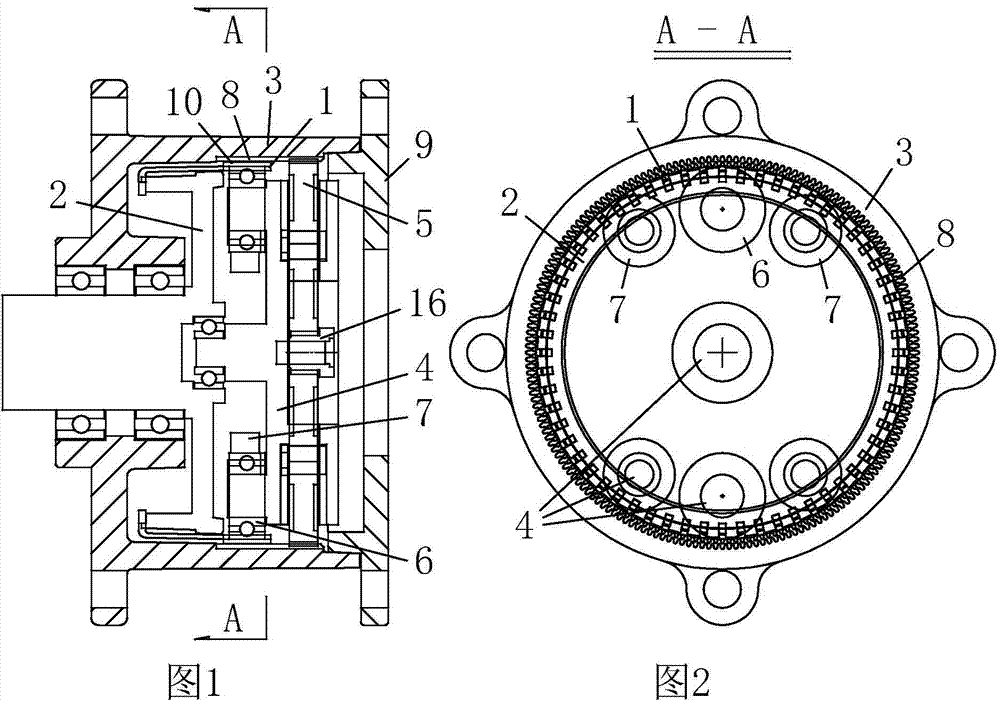

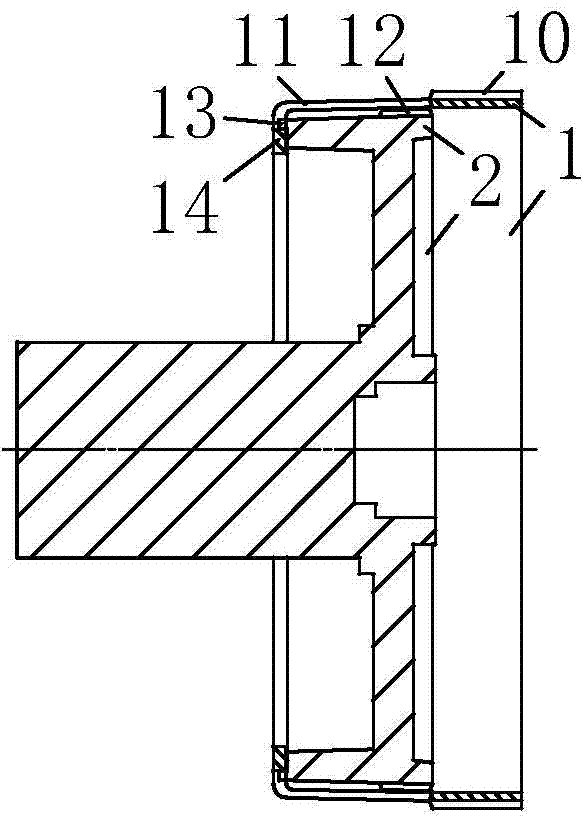

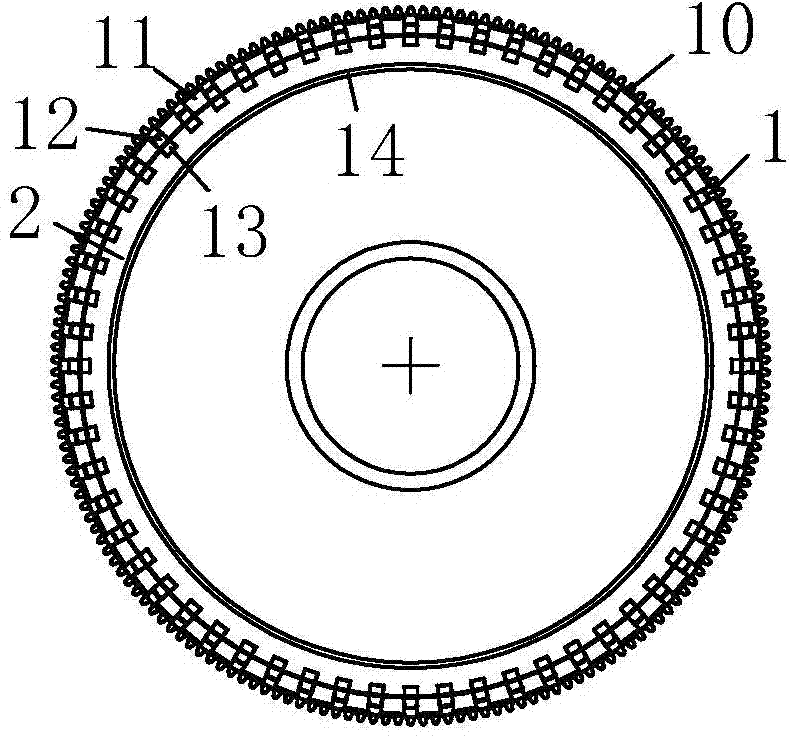

[0030] Please refer to Figure 1 to Figure 11 , the present invention provides a planetary harmonic gear reducer, including: a planetary harmonic ring gear 3 with rigid internal teeth 8; a drive frame 4 with a harmonic coupling part on one side; a flexible ring gear 1 set on In the planetary harmonic inner ring gear 3, the harmonic coupling part is set at the position corresponding to the flexible outer tooth part 10 of the flexible ring gear 1; the output shaft 2 has an outer ring gear 12, and the outer ring gear 12 and The flexible ring gear 1 is meshed after being deformed by the flexible side teeth 11 or the flexible inner teeth 15, and the number of mating teeth of the outer ring gear 12 of the output shaft 2 and the flexible side teeth 11 or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com